Ultrasonic vibration magneto-rheological brush polishing machine for non-magnetic screws

A technology of ultrasonic vibration and magnetorheological brush, which is applied in the field of non-magnetic screw ultrasonic vibration magnetorheological brush polishing machine, can solve the problem of high surface roughness and achieve the effect of high surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

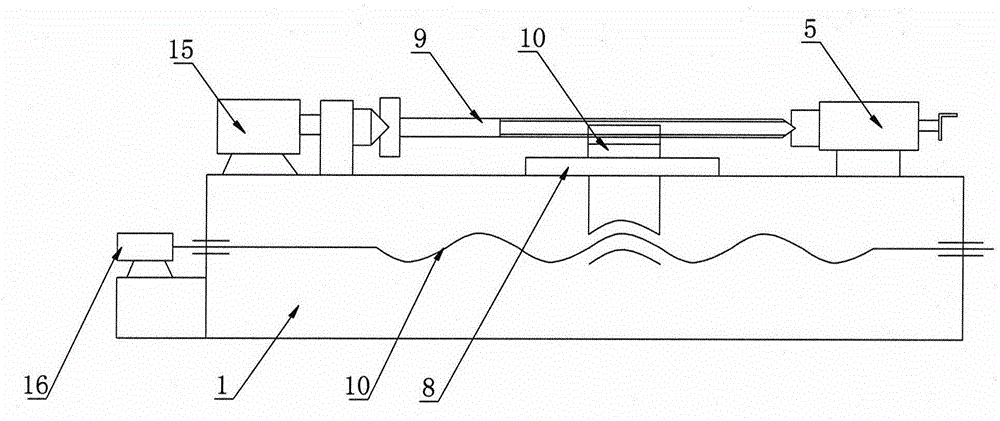

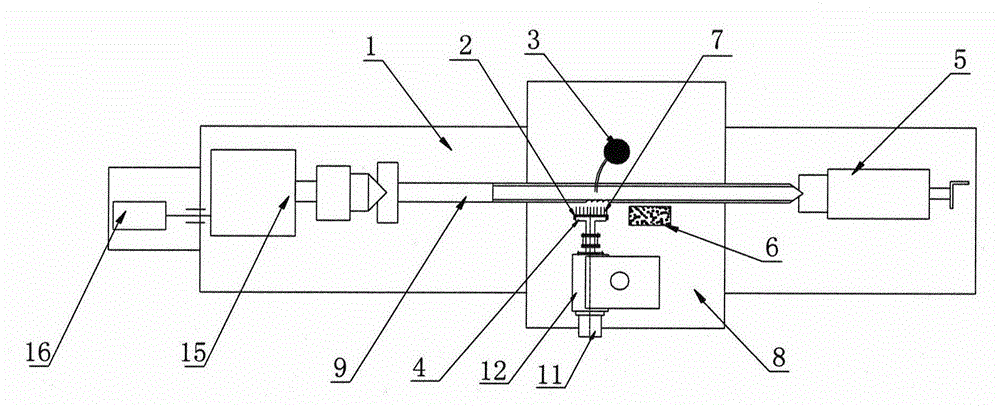

[0017] refer to figure 1 , figure 2 It is an embodiment of the non-magnetic screw ultrasonic vibration magnetorheological brush polishing machine of the present invention. The non-magnetic screw ultrasonic vibration magnetorheological brush polishing machine includes a lathe body 1, a polishing liquid 13 containing magnetorheological fluid, and is fixed on the lathe The ultrasonic magnetic polishing assembly on the carriage 8 and the pump body 3 that sprays the polishing liquid 13 on the ultrasonic magnetic polishing assembly;

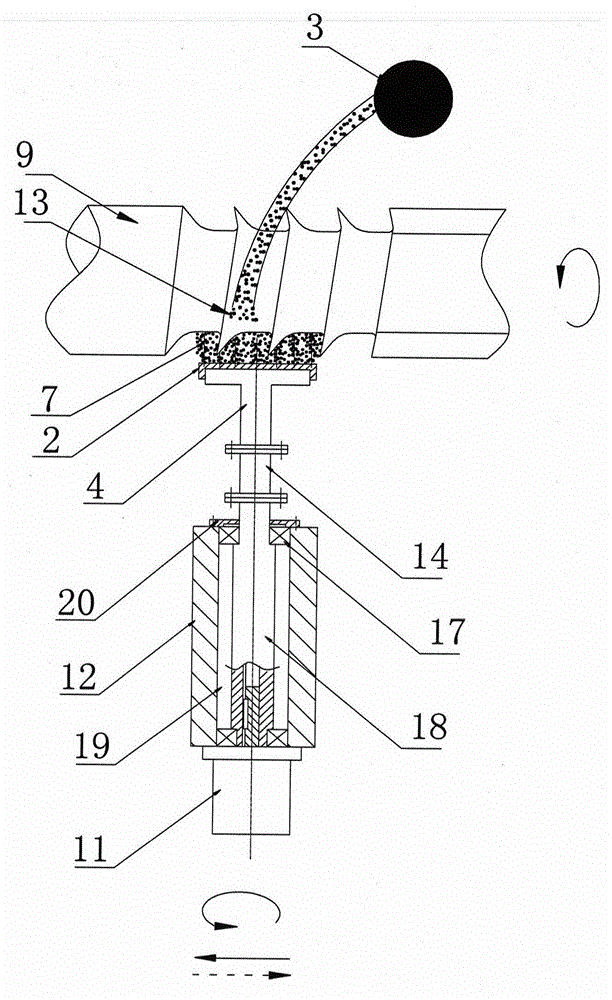

[0018] Such as image 3 As shown, the ultrasonic magnetic polishing assembly includes a clamping handle 12 fixed on the lathe carriage 8, a first connecting shaft 18 arranged in the clamping handle 12 for rotation, and a device for driving the first connecting shaft 18 to rotate on the lathe carriage 8. The rotation motor, the ultrasonic vibrator 14 fixedly connected to the front end of the first connecting shaft 18, and the brush plate 2 fixedly co...

Embodiment 2

[0024] refer to Figure 4 , the difference from Embodiment 1 is that the structure of the ultrasonic magnetic polishing assembly is different, and the ultrasonic magnetic polishing assembly includes a clamp handle 12 fixed on the lathe carriage 8, an ultrasonic vibrator 14 fixed on the clamp handle 12, and an ultrasonic vibrator 14 The connected wheel brush holder 23, the second connection shaft 21 arranged on the wheel brush holder 23, the magnetic field generator sleeved on the second connection shaft 21, the brush plate 2 arranged on the outer wall of the magnetic field generator 4, the The magnetic conduction brush 7 is fixed on the brush plate 2 .

[0025] The wheel brush holder 23 includes a connecting portion 22 fixedly connected with the clamp handle 12 and a fixed portion 24 fixed at the front end of the connecting portion 22, the second connecting shaft 21 is erected on the fixing portion 24, and the magnetic field generator 4 is rotationally connected with the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com