Glass processing equipment

A technology for processing equipment and glass, which is applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc. It can solve problems such as easy scratches on workers, uneven corners, and broken glass to achieve better processing results. Good, not easy to drop, easy to take effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

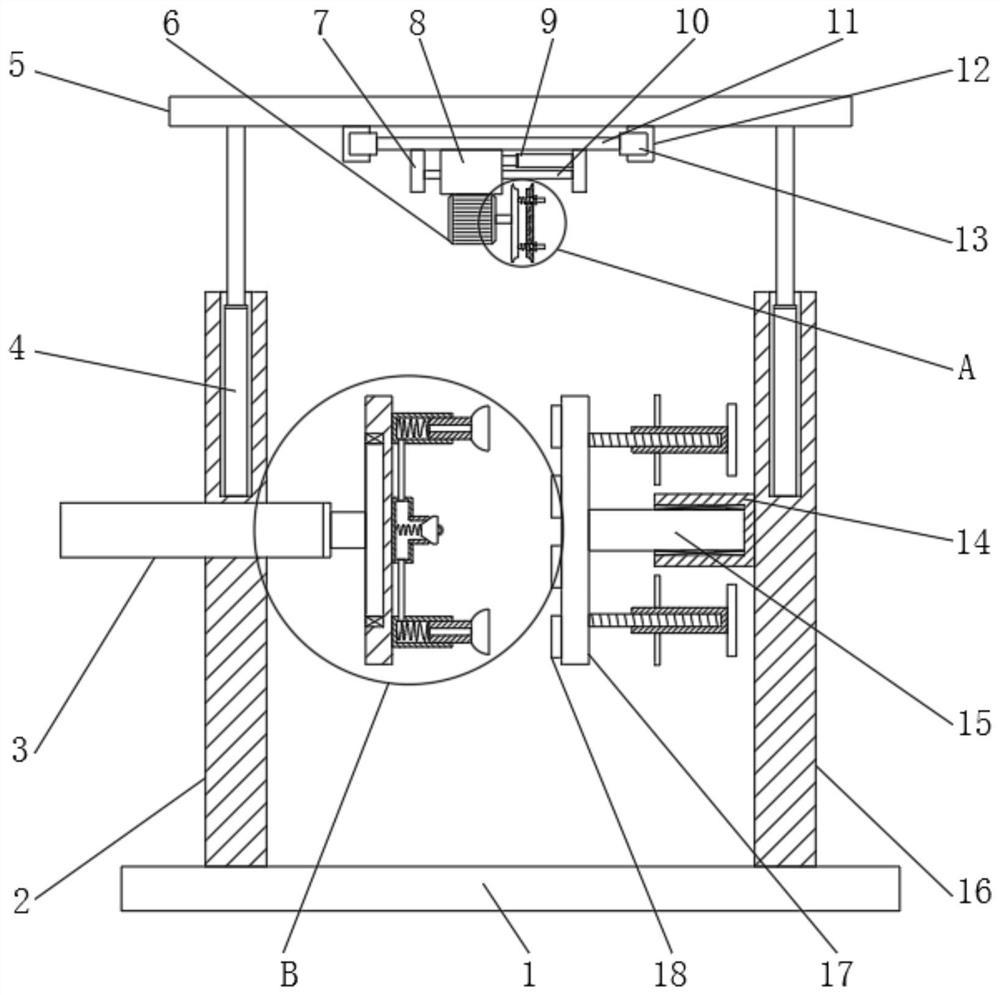

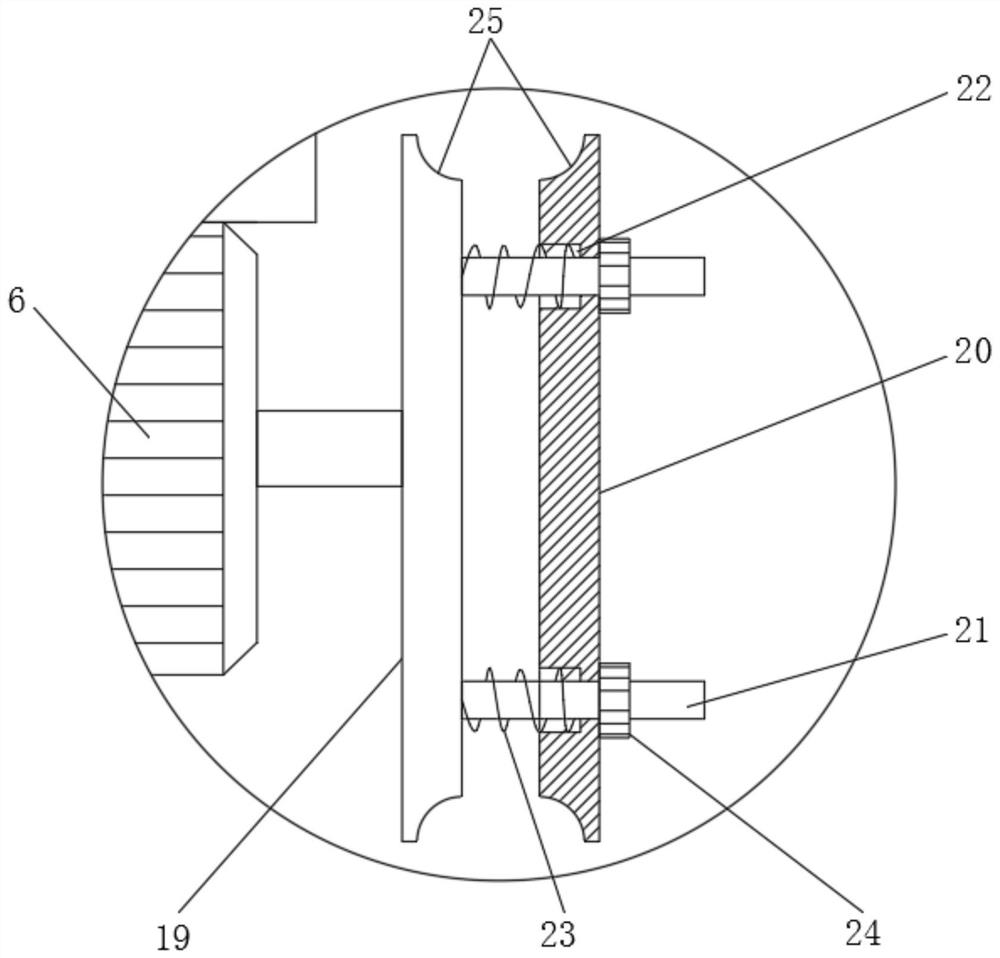

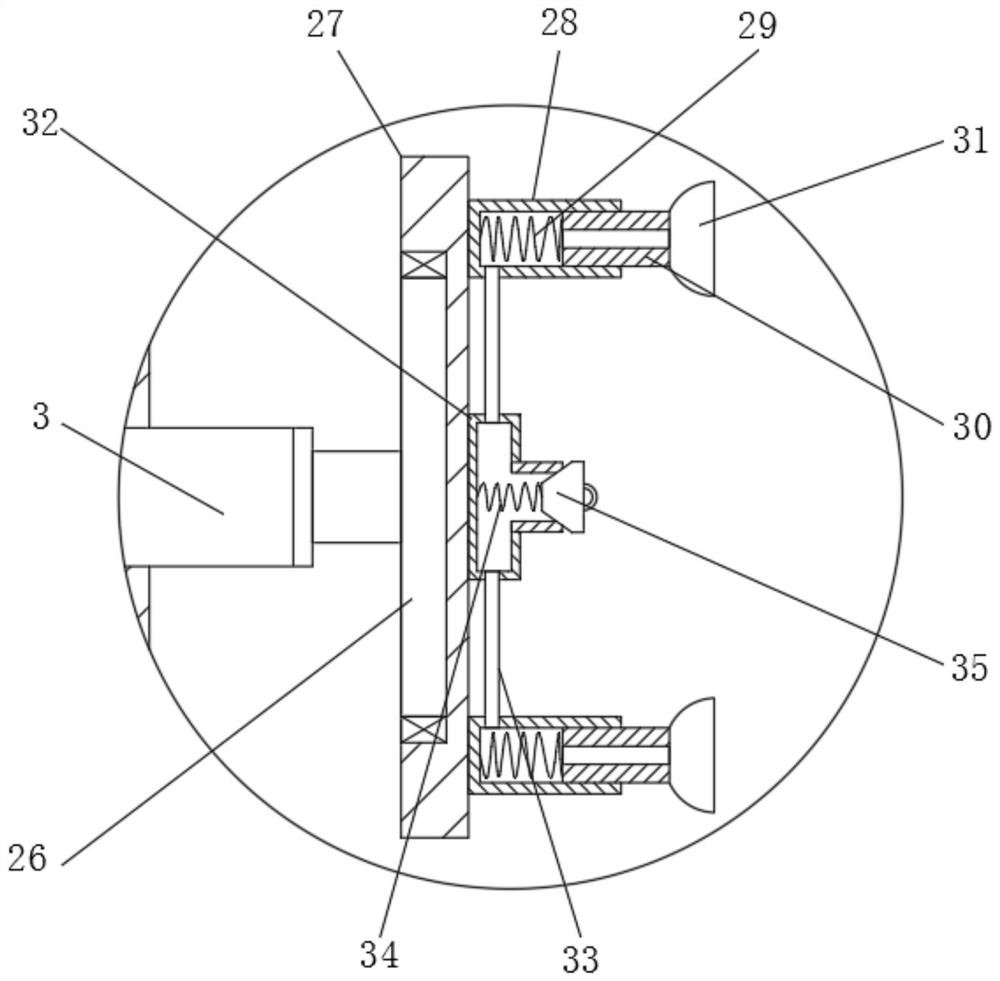

[0031] refer to Figure 1-4 , a glass processing equipment, comprising a bottom plate 1, a left vertical plate 2 is fixedly connected to the top outer wall of the bottom plate 1, and a mounting opening is opened on one side of the left vertical plate 2, and a first hydraulic cylinder 3 is arranged on the inner wall of the mounting port, And one end of the piston of the first hydraulic cylinder 3 is provided with a disc 26, the outer wall of the disc 26 is rotatably connected with a turntable 27 through a bearing, and one side outer wall of the turntable 27 is provided with a clamping mechanism, and the top outer wall of the bottom plate 1 is fixedly connected with a right Vertical plate 16, and one side outer wall of right vertical plate 16 is fixedly connected with fixed tube 14, and the inner wall of fixed tube 14 is connected with rotating shaft 15 through bearing rotation, and one end of rotating shaft 15 is fixedly connected with splint 17, and one side outer wall of splin...

Embodiment 2

[0040] refer to Figure 5 , a kind of glass processing equipment. Compared with Embodiment 1, this embodiment also includes that the top outer wall of the bottom plate 1 is fixedly connected with the limiting cylinder 40, and the bottom inner wall of the limiting cylinder 40 is provided with a fourth spring 41, and the fourth spring 41 The top end of the telescopic rod 42 is provided with a telescopic rod 42, and the top end of the telescopic rod 42 is fixedly connected with a tray 43.

[0041] The inner wall of the tray 43 is provided with a sponge pad 44 .

[0042] Working principle: When in use, when the glass falls due to an accident, it will fall on the tray 43 at the bottom. At this time, the telescopic rod 42 at the bottom of the tray 43 will compress the fourth spring 41 in the limit cylinder 40, which can play Effective cushioning effect, and the sponge pad 44 located in the tray 43 can prevent the glass from being damaged, and the use effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com