High-moisture tobacco material drying method and drying tower

A technology of tobacco material and drying tower, which is applied in the fields of tobacco, tobacco preparation, food science, etc., can solve the problems of unresolved shredding problem, inability to effectively dry tobacco material, etc., to meet the requirements of processing strength and drying uniformity, The effect of lowering the temperature and lowering the drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

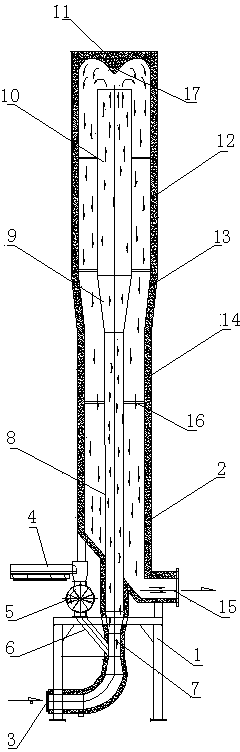

[0023] Such as figure 1 As shown, the novel tobacco material drying tower of the present invention includes a support 1, which is the support of the drying tower, and the whole drying cylinder has a thermal insulation layer 2, and the dry hot air inlet pipe 3 is at the bottom of the drying tower, and the air inlet pipe is connected to the drying tower. Venturi tube 7 is connected, feed air lock 5 is installed on the upper part of support 1, a vibrating conveyor 4 is installed in front of its entrance, the outlet of air lock 5 is connected with feed pipe 6, the throat part of venturi tube 7 It is connected with the feed pipe 6, the venturi tube 7 is connected with the lower inner cylinder 8, the transition inner cylinder 9 and the upper inner cylinder 10 as a whole, and the outlet of the upper inner cylinder 10 faces the conical deflector 11 arranged on the top of the outer cylinder , the upper outer cylinder 12 is integrated with the transition outer cylinder 13 and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com