Patents

Literature

66results about How to "High production process efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-side wet permeability polyester knitted fabric processing method

InactiveCN106498765AStrong water absorptionImprove waterproof performanceHeating/cooling textile fabricsDyeing processPolyesterMoisture absorption

The invention discloses a single-side wet permeability polyester knitted fabric processing method which includes the steps: 1) dyeing; 2) setting and drying; 3) one-sided coating; 4) setting and baking; 5) performing moisture absorption and perspiration. A polyester knitted fabric is obvious in water absorption and waterproof effect and has the advantages of wearing comfort, moderate cost, high production process efficiency, water conservation and environmental protection.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

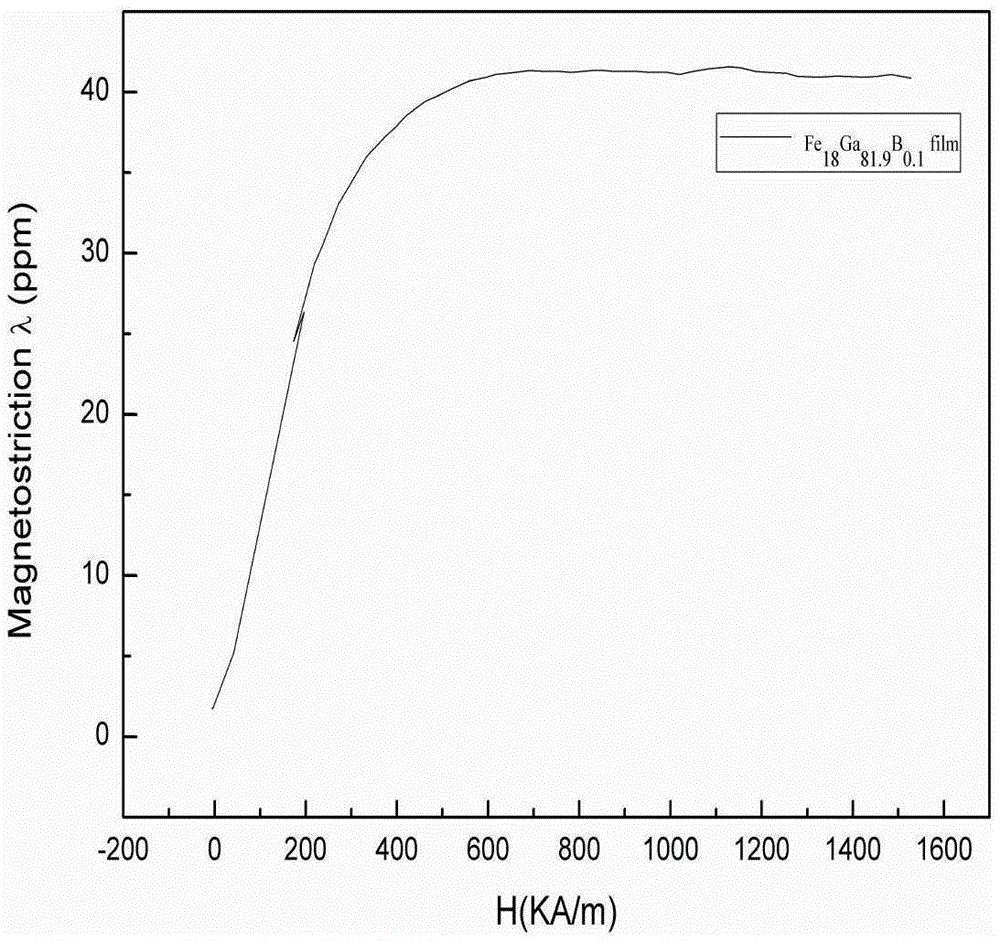

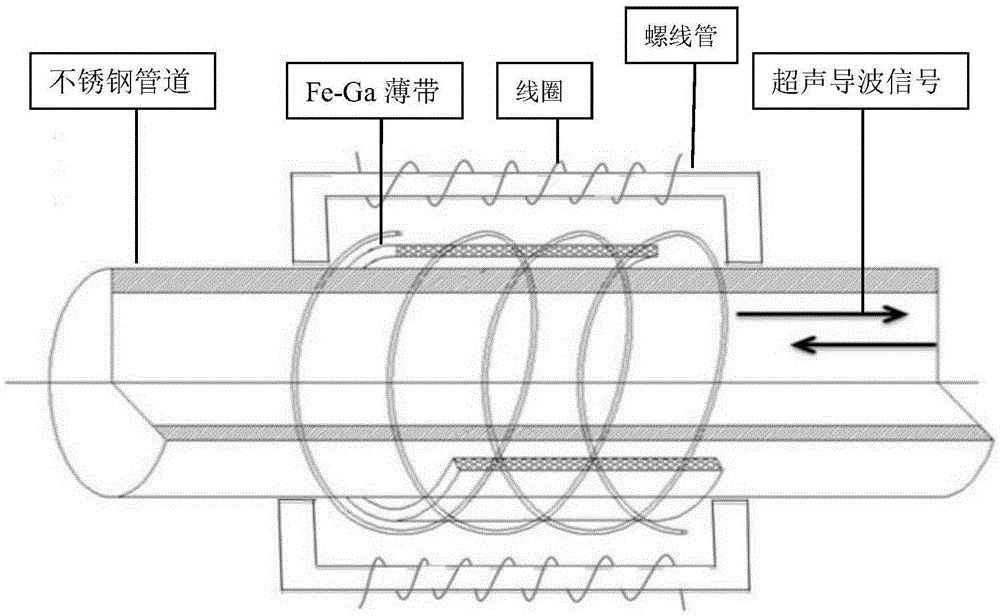

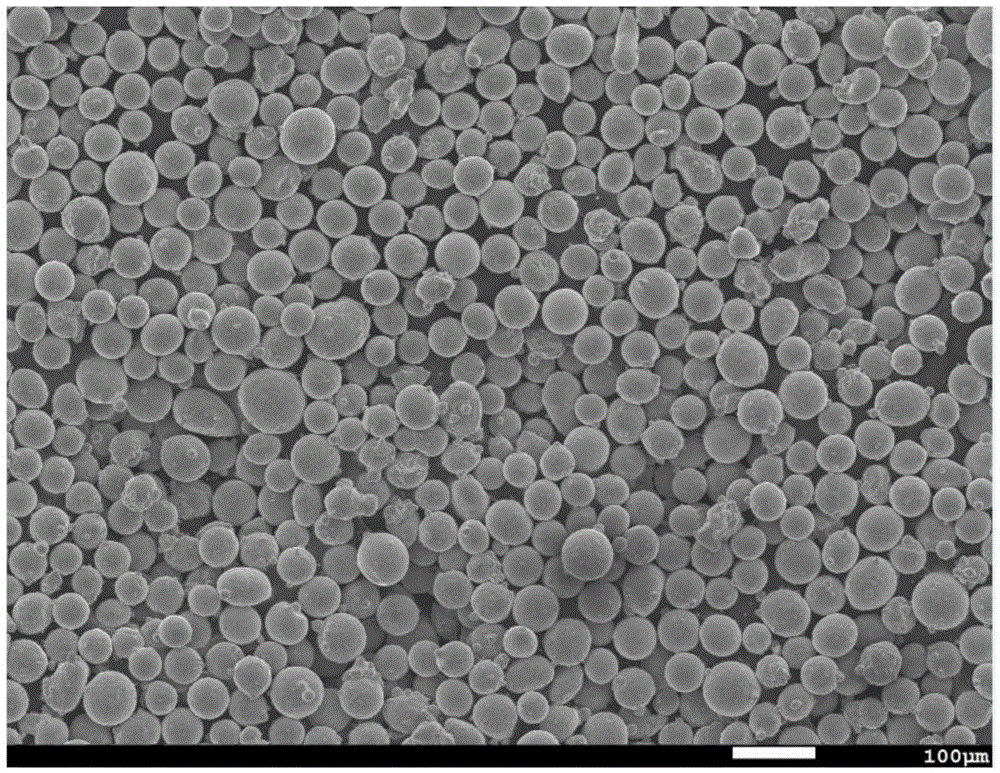

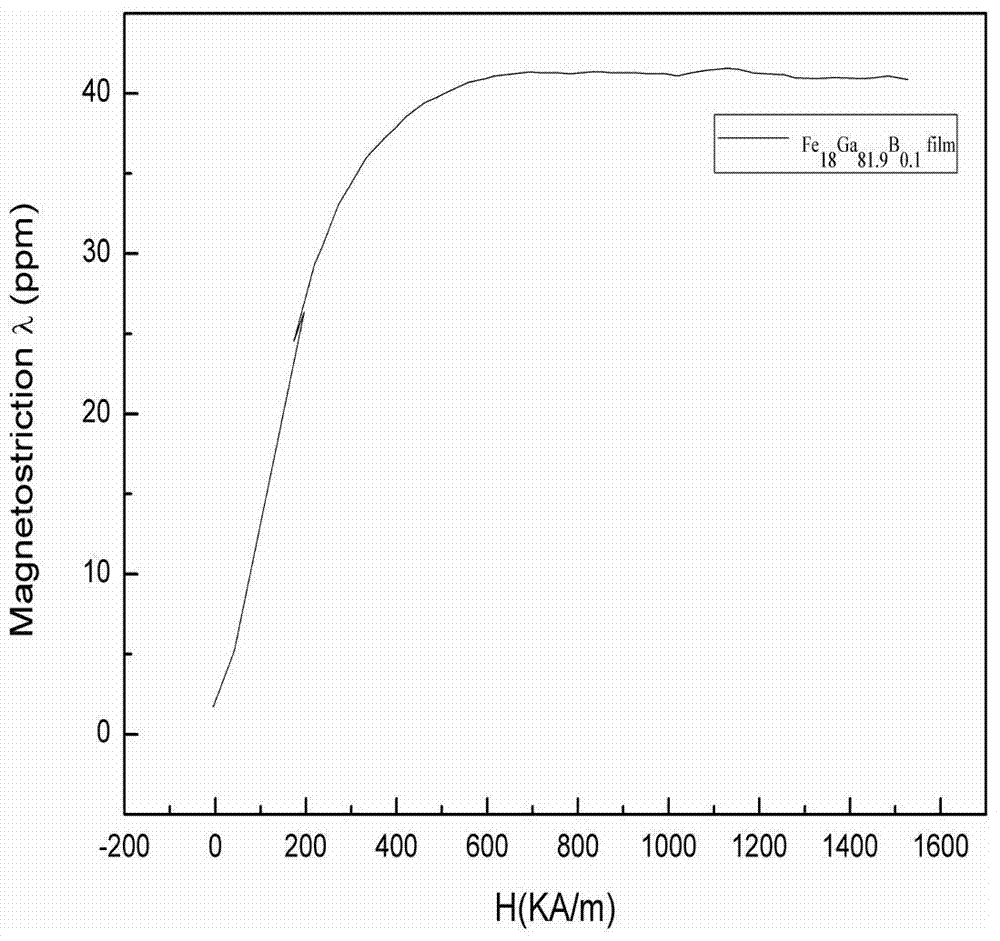

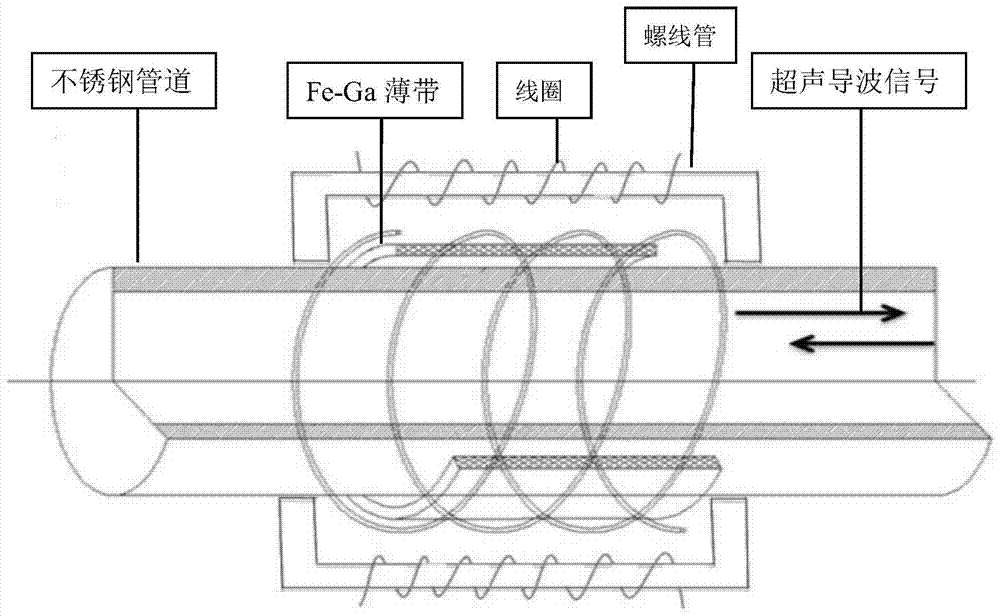

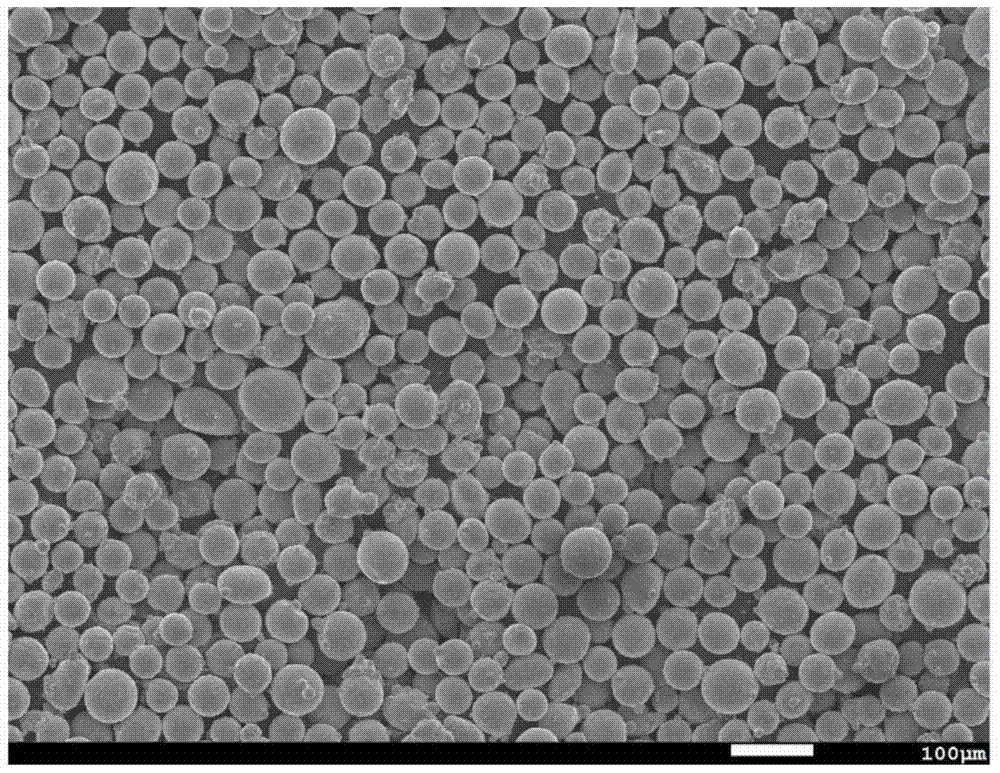

Method for manufacturing iron-based magnetostrictive coating through thermal spraying technology

ActiveCN105252011AHigh magnetostriction coefficientNot easily oxidizedMolten spray coatingPorosityThermal spraying

The invention provides a method for manufacturing an iron-based magnetostrictive coating through the thermal spraying technology and belongs to the field of magnetic materials. An iron-based magnetostrictive material is manufactured into spherical gasified and atomized powder, a metal material serves as a substrate, the spherical gasified and atomized powder is sprayed to the metal substrate in a plasma spraying manner, and the iron-based magnetostrictive coating is manufactured. The method includes the specific steps that the iron-based magnetostrictive material is smelted into a cast ingot in a vacuum smelting furnace, oxide skin on the surface is removed in a machining manner, the cast ingot is then conveyed to a high-pressure atomization powder making device, and molten alloy flow is crushed into small drops through high-speed argon flow and then condensed into powder. Plasma spraying is adopted in the thermal spraying technology, plasma gas is mainly nitrogen, hydrogen is auxiliary gas, the iron-based magnetostrictive gasified and atomized powder is conveyed into a plasma chamber, and through heating, smelting, flight, base body impact, cooling and solidification, the coating is formed. The method has the beneficial effects that the coating combination strength is high, the structure is dense, the porosity is low, and included oxide slag is reduced due to the addition of alloy elements.

Owner:UNIV OF SCI & TECH BEIJING

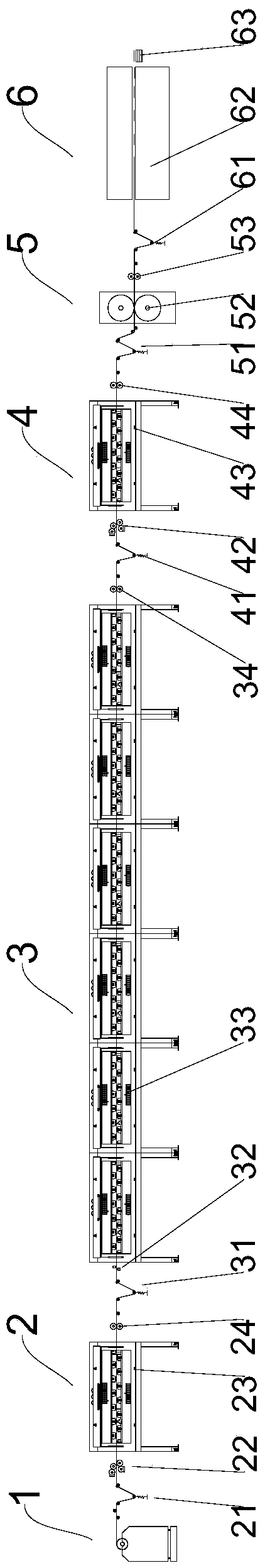

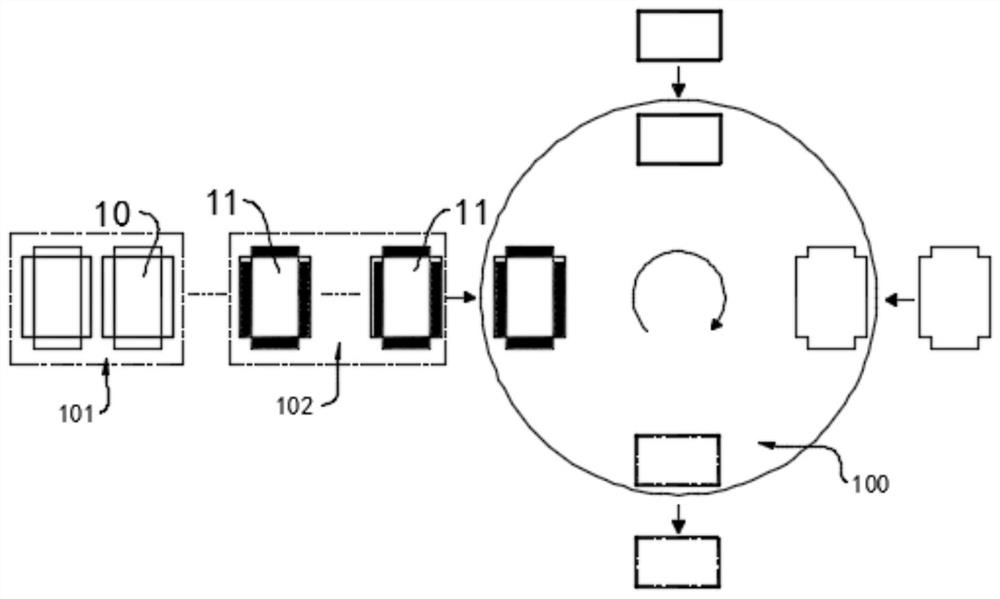

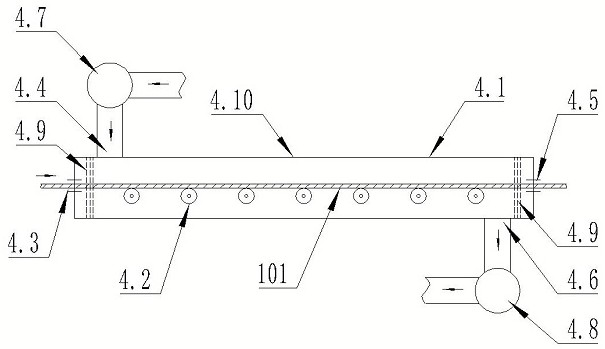

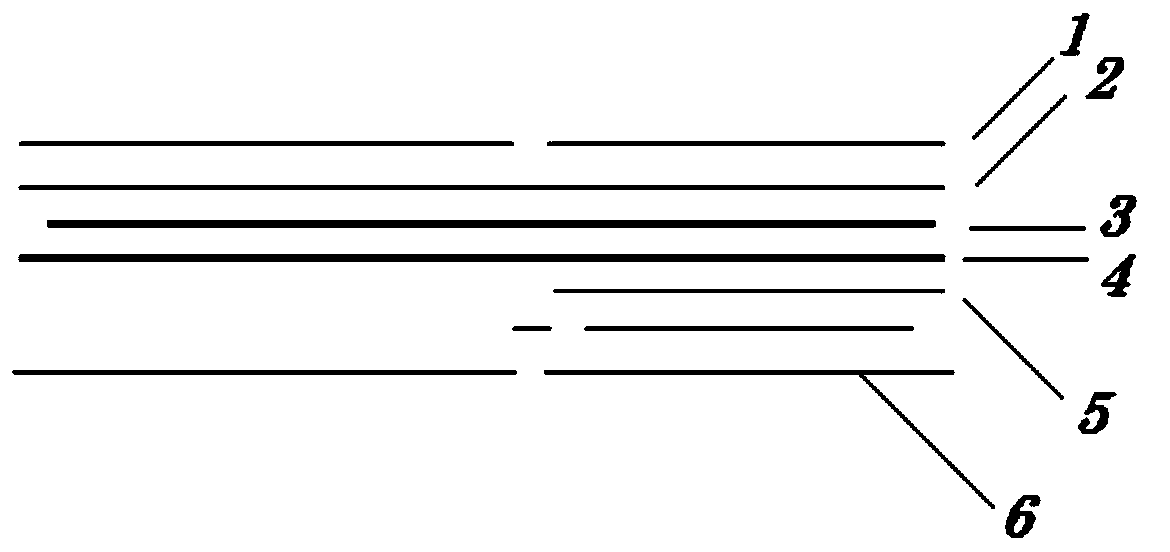

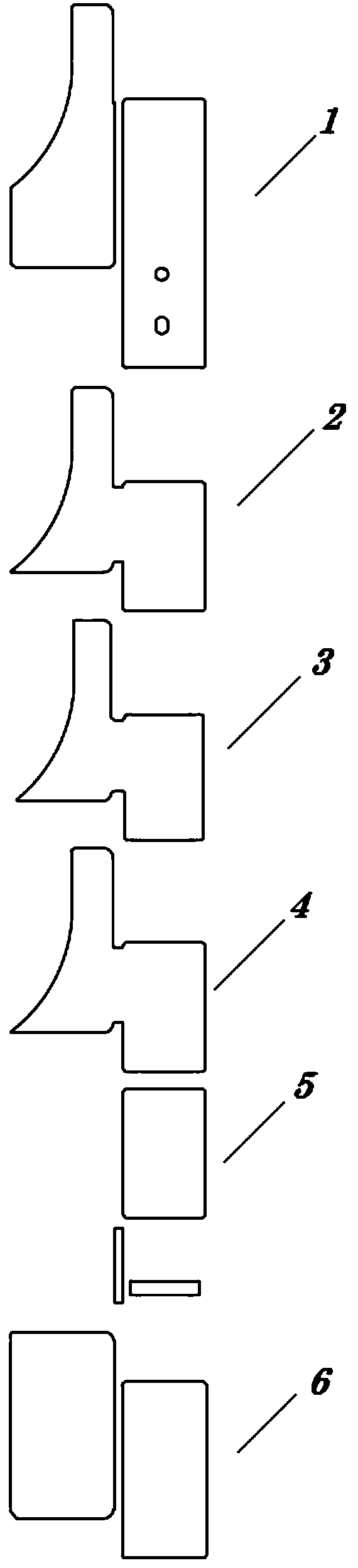

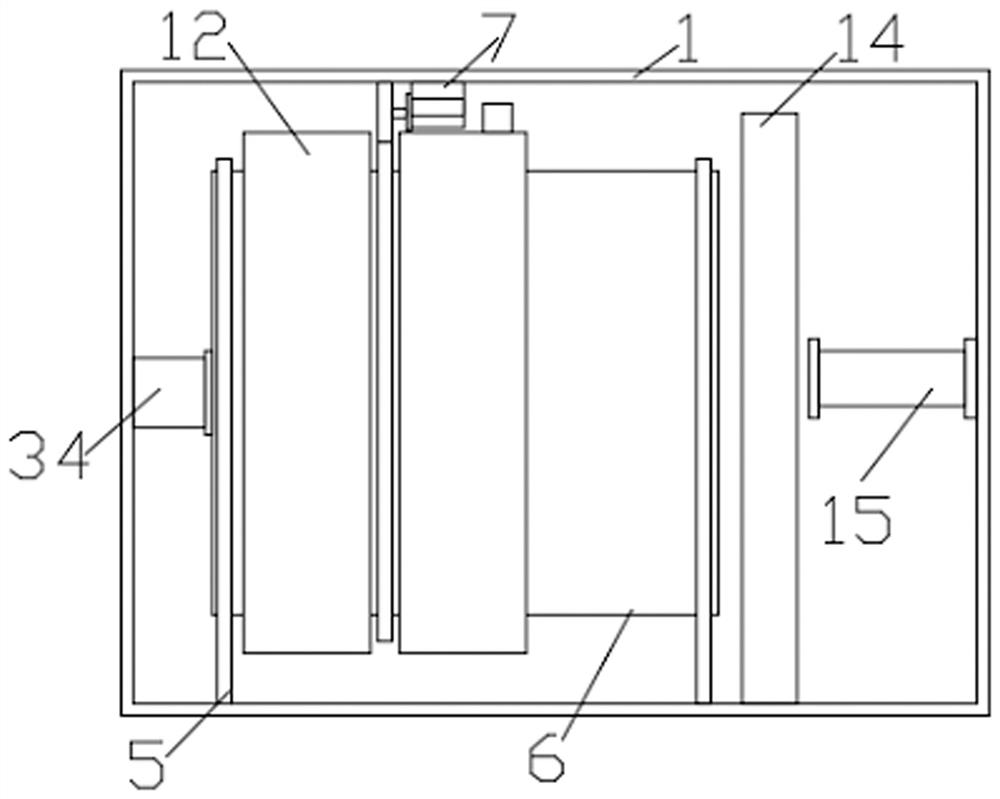

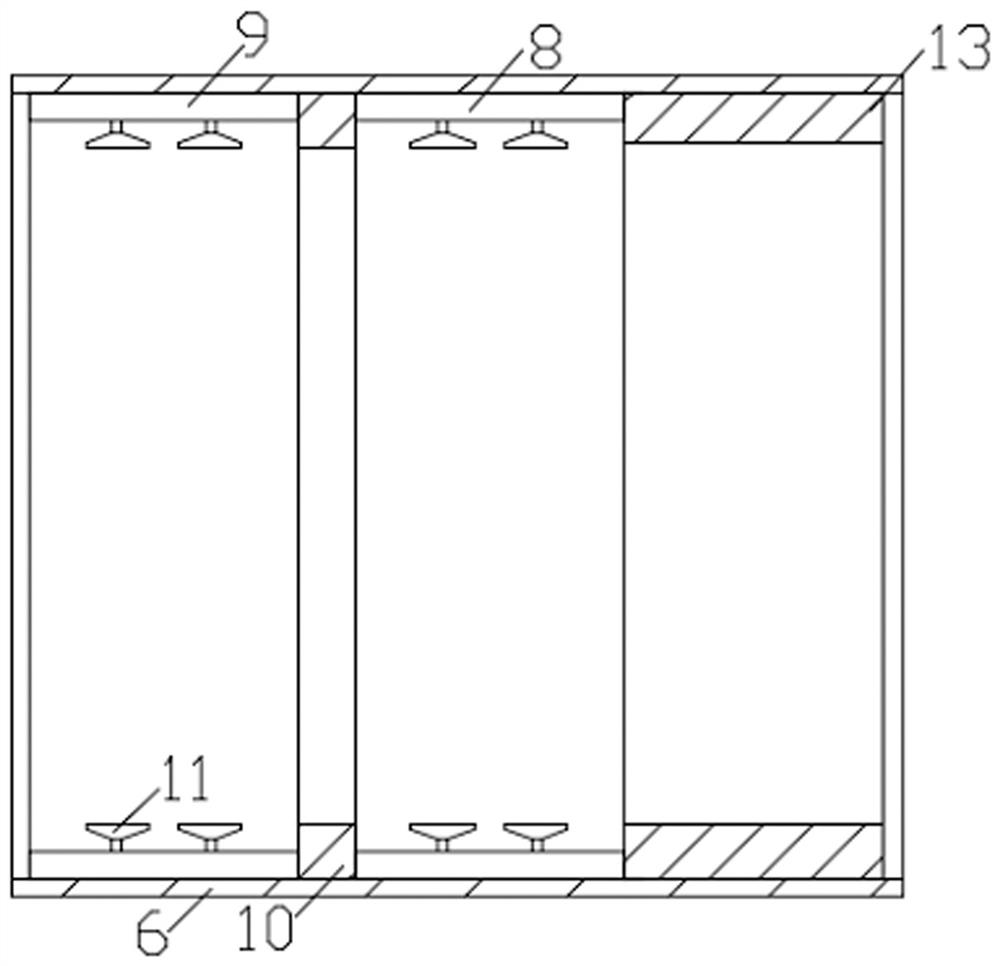

Coating and drying method for pole belts, pole piece preparation method and pole piece preparation system

InactiveCN105499093AImprove efficiencyHigh production process efficiencyCell electrodesPretreated surfacesConduction bandPulp and paper industry

The invention relates to the electrode field, in particular to a coating and drying method for pole belts, a pole piece preparation method and a pole piece preparation system. The coating and drying method comprises the steps that the pole belts are conveyed in a tension-controllable mode, the two surfaces of the pole belts are coated with slurry simultaneously in the conveying process and then are dried simultaneously in a suspension type drying oven, and the tension of the pole belts and the wind force in the suspension type drying oven are controlled together so that the pole belts can penetrate through the suspension type drying oven in a suspension mode. The coating and drying step in the pole piece preparation method adopts the coating and drying method. The pole piece preparation system comprises a coating and drying device, and the coating and drying device comprises a tension control correction module, a double-surface coating module, the suspension type drying oven and a roll-in type tension conduction band module, wherein the tension control correction module, the roll-in type tension conduction band module and the suspension type drying oven jointly control the pole belts to penetrate through the suspension type drying oven in a suspension mode. The production efficiency of the coating and drying method, the pole piece preparation method and the pole piece preparation system is high.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

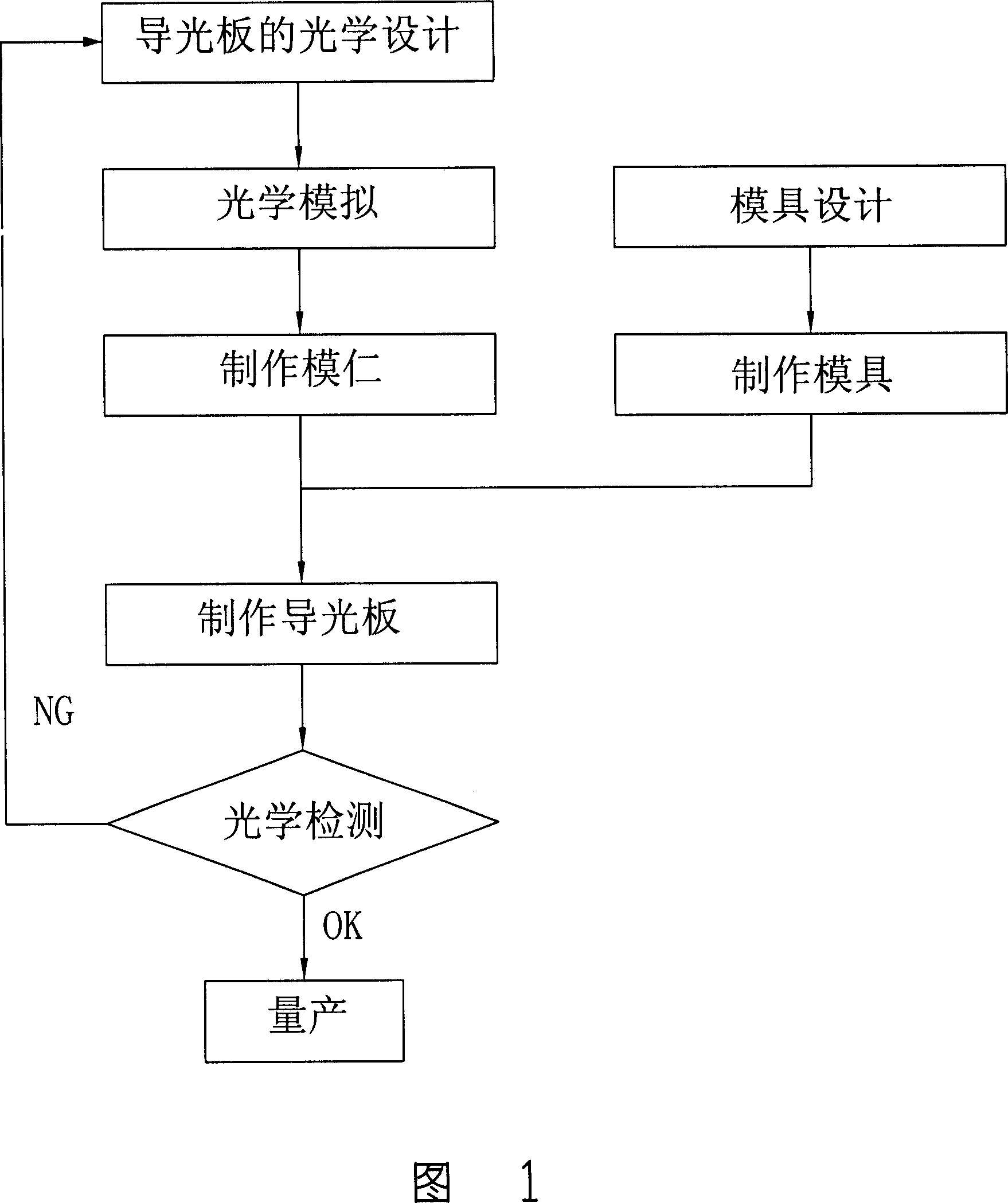

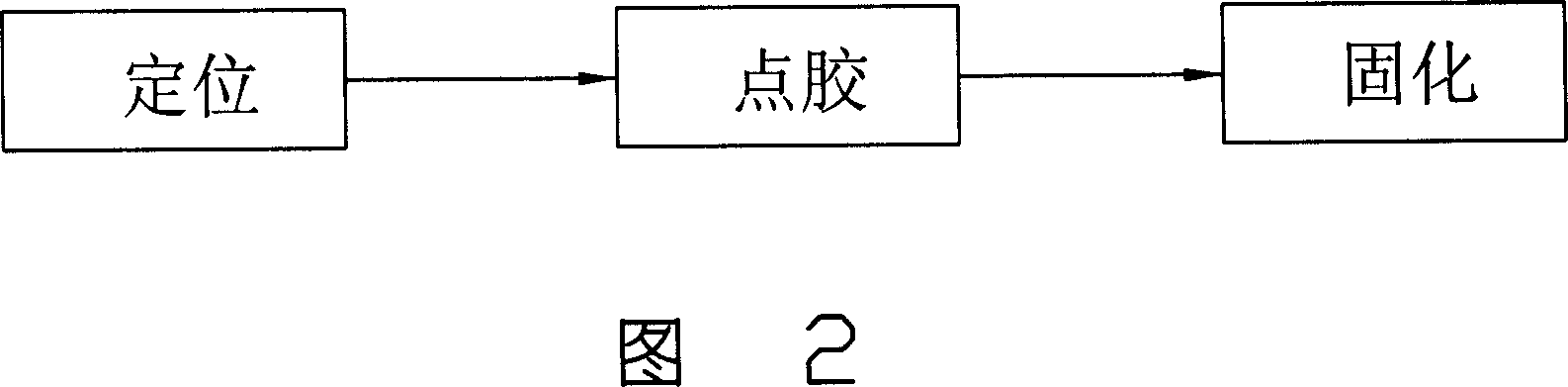

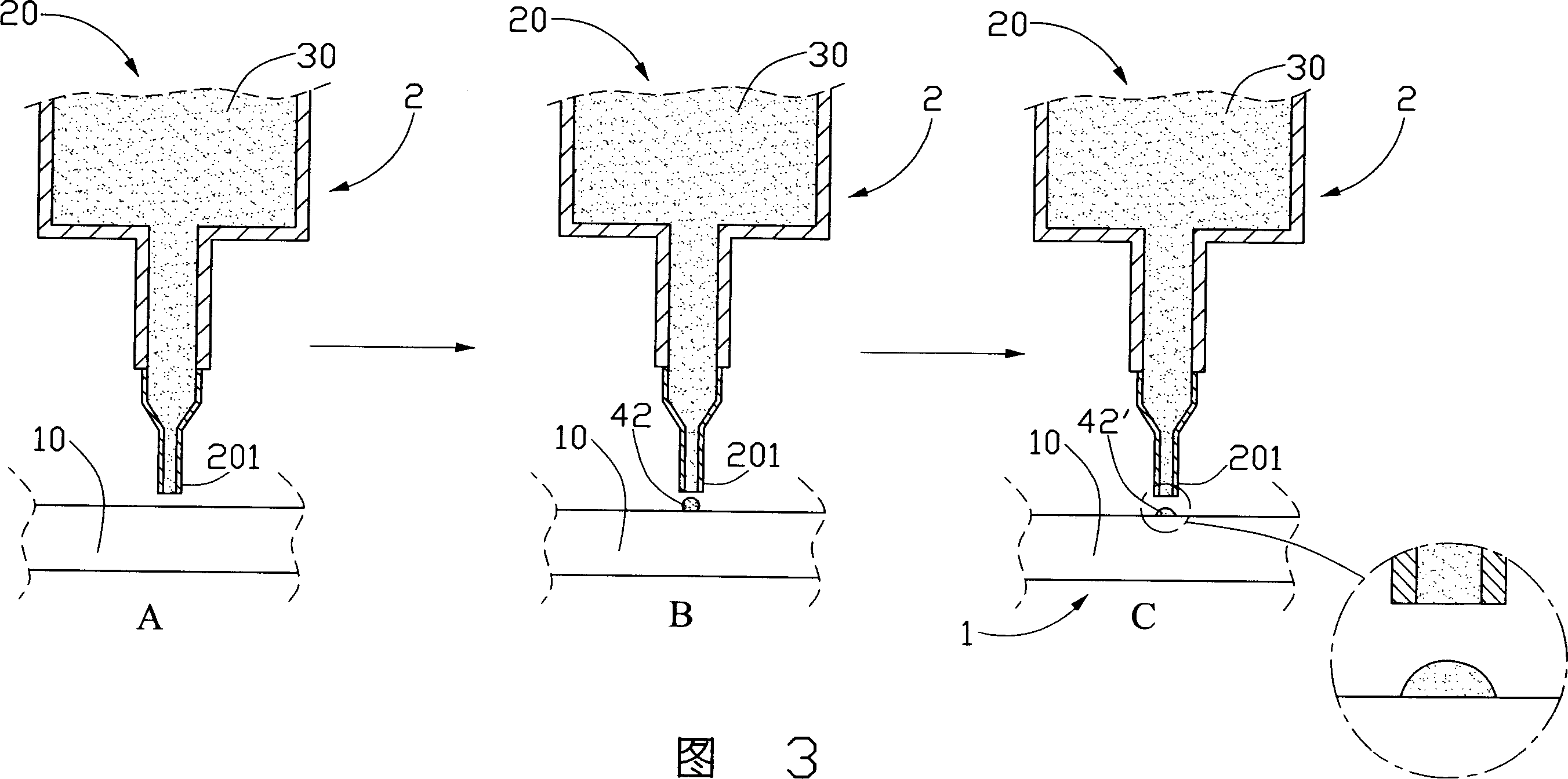

Manufacturing method of light conducting board and light conducting board stamper and manufacturing processing of light conducting board

The invention discloses an illuminator manufacturing method, an illuminator-scale manufacturing methods and illuminator manufacturing processes. The illuminator manufacturing method includes the following steps: (1) providing a substrate; (2) providing a point gum machine. The point gum machine includes a capacity and a syringe cavity, the cavity with Yung-curing adhesive solution, syringes positioning of the substrate prepared by the design of the site to form networks; (3) throw a certain amount of solution-curing adhesive from syringes to the prepared positioning of the site to form networks, substrate bonding with it; (4) under certain conditions in curing adhesive substrate solution-curing adhesive; (5) repeat steps (3), (4), until completion of all substrates outlets, which have illuminator.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

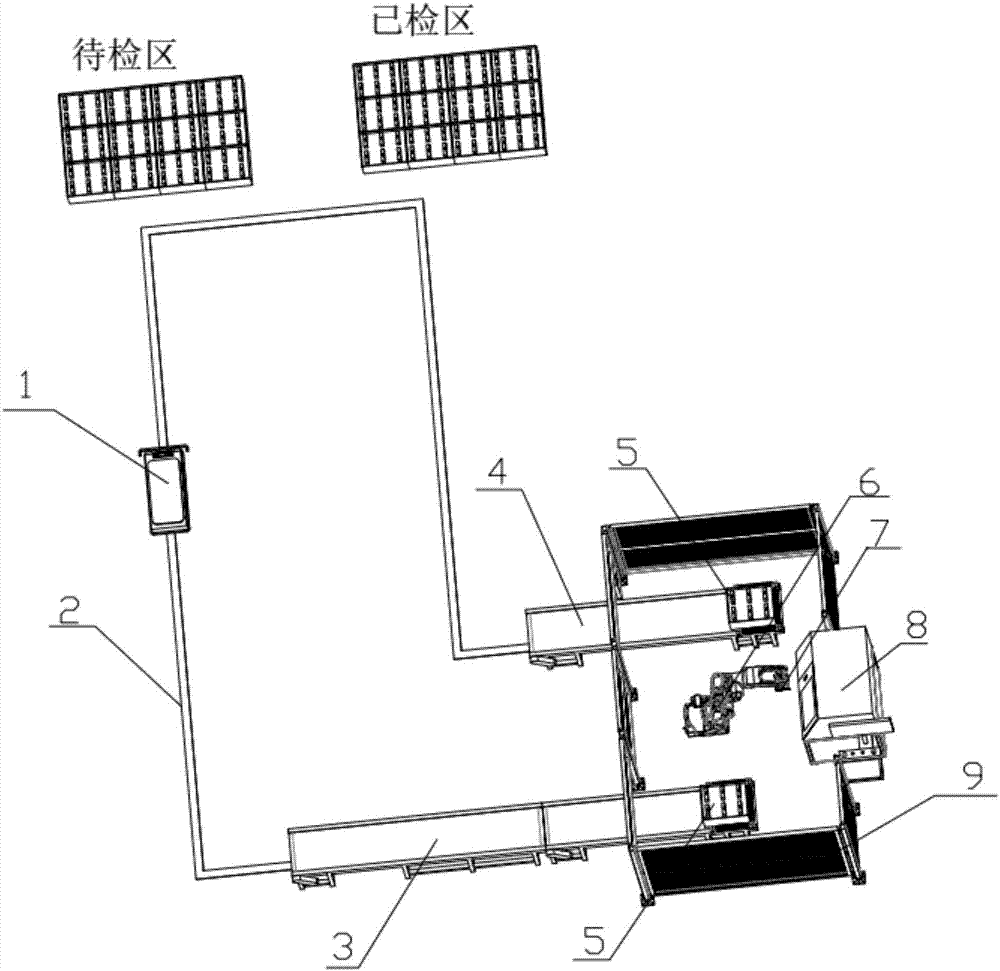

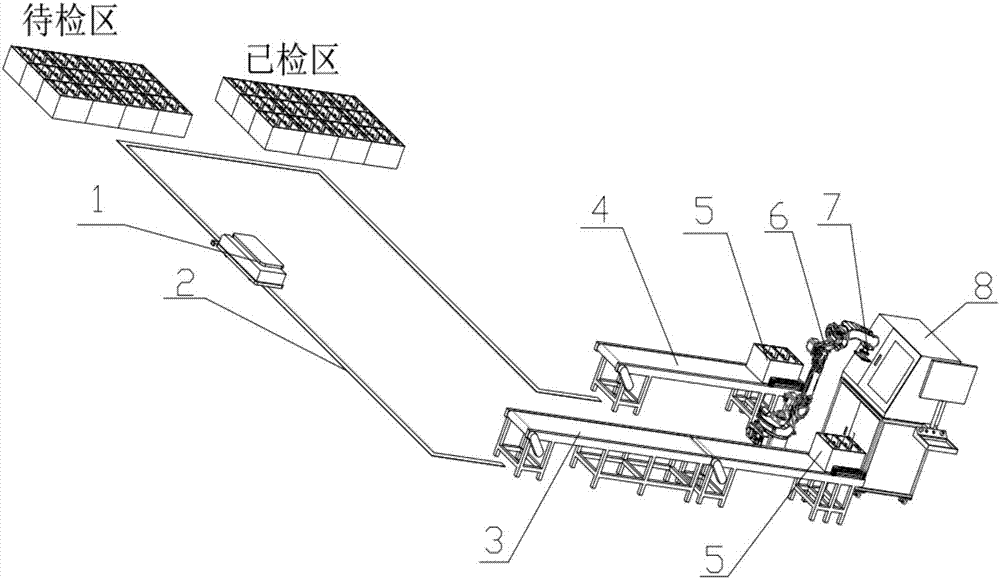

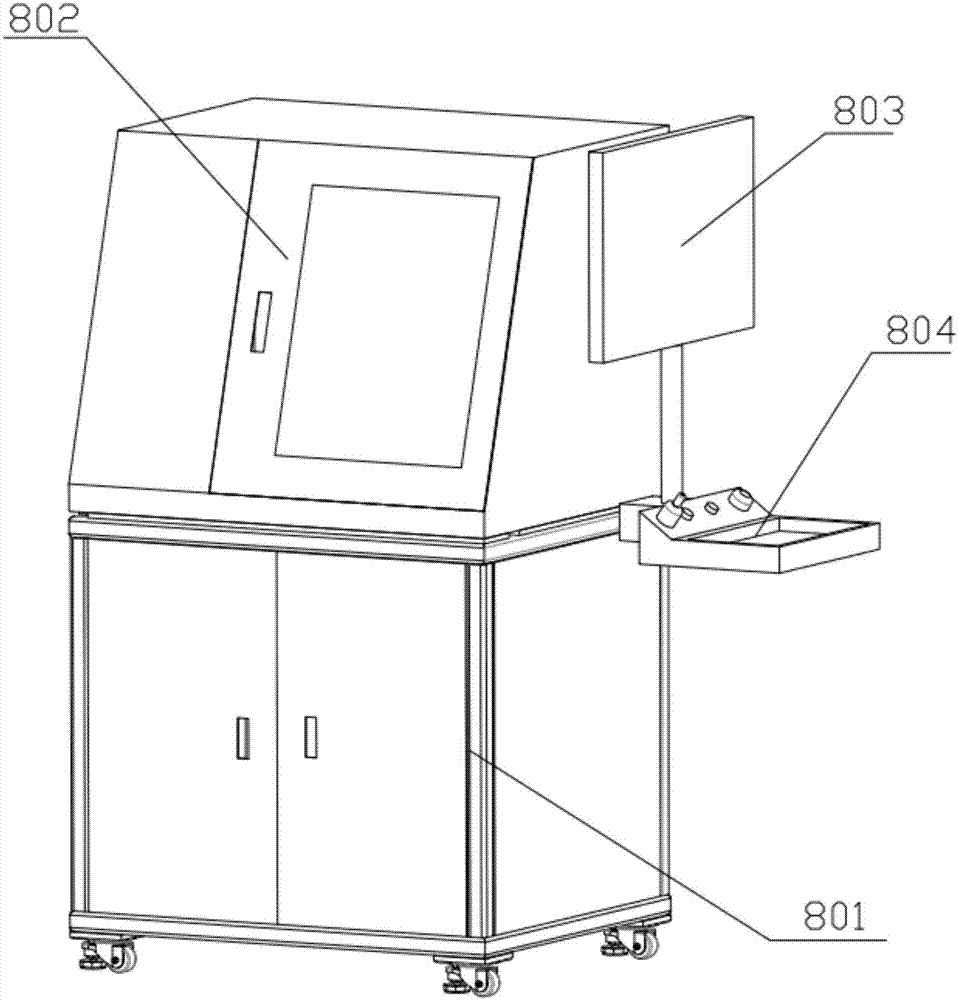

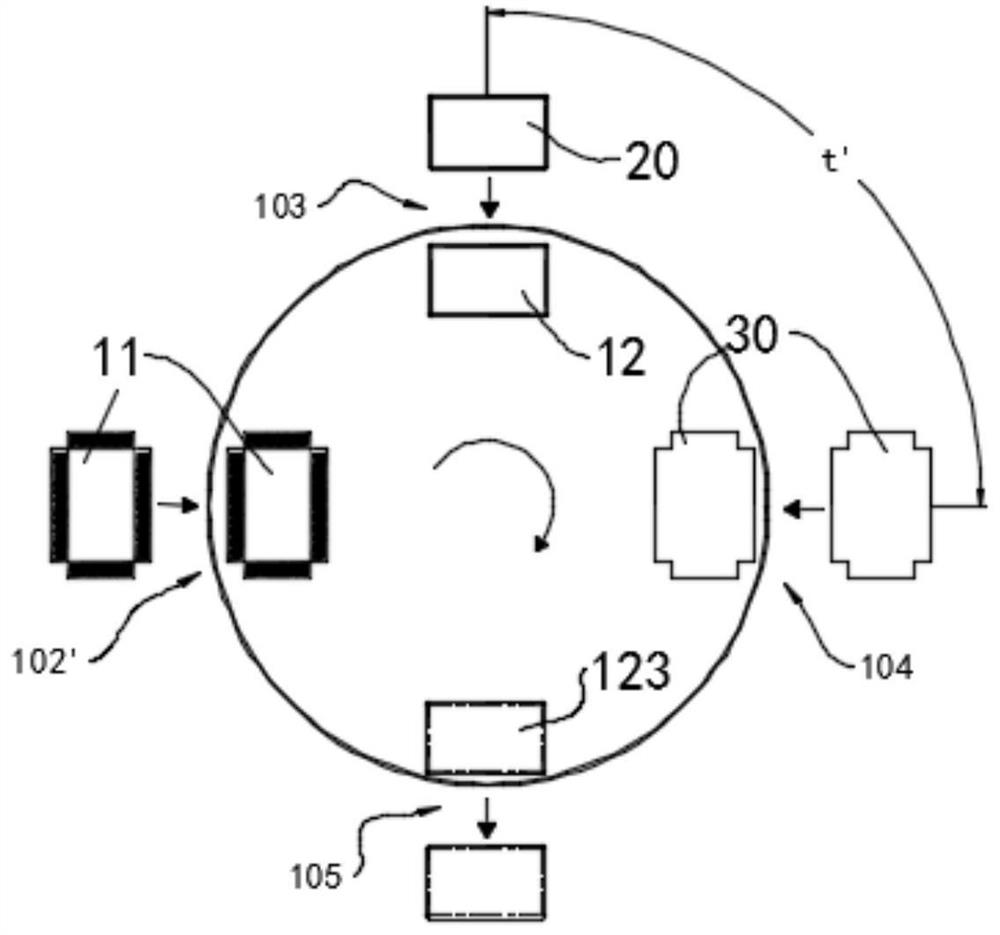

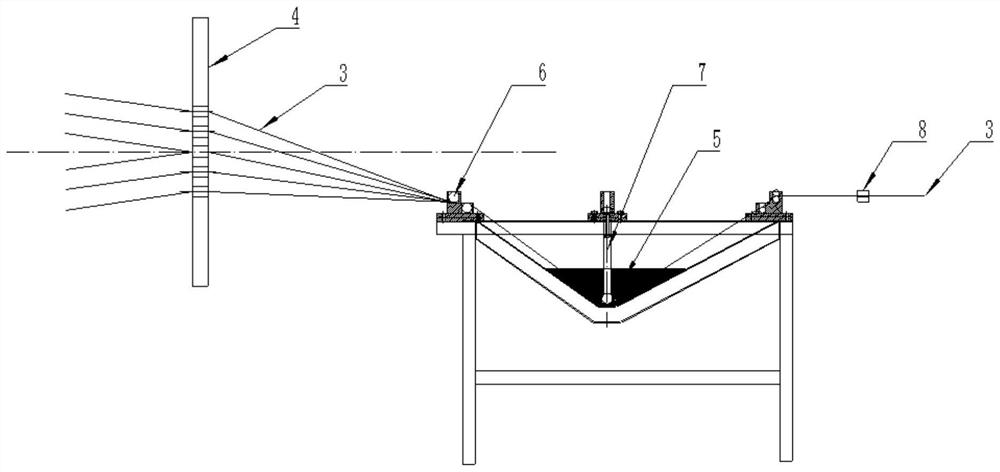

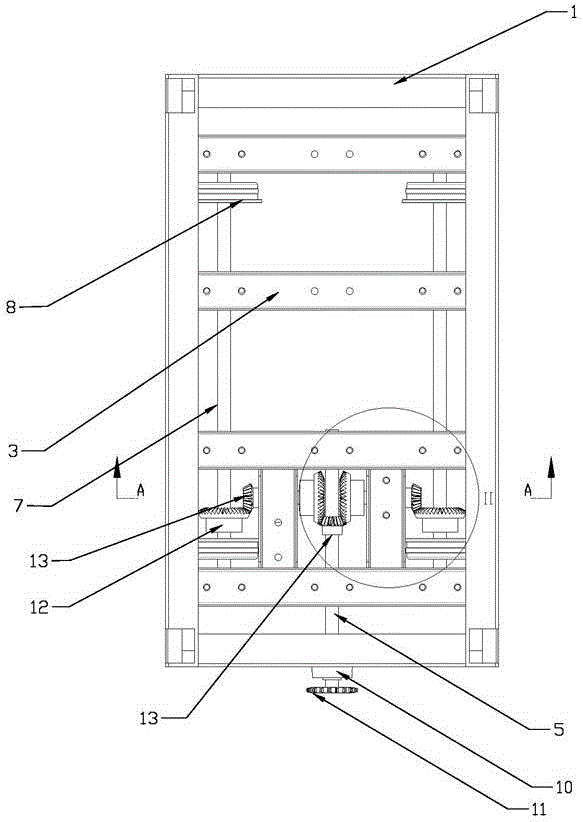

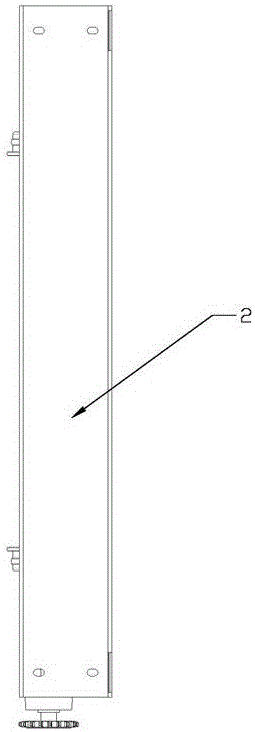

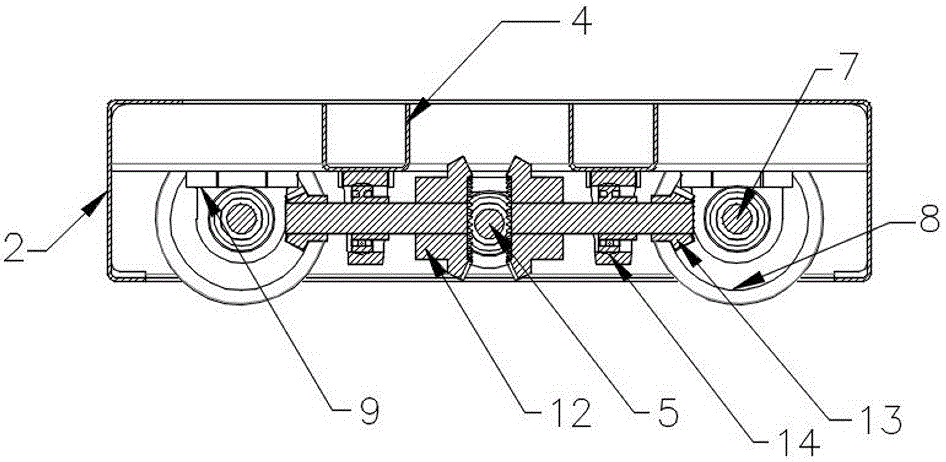

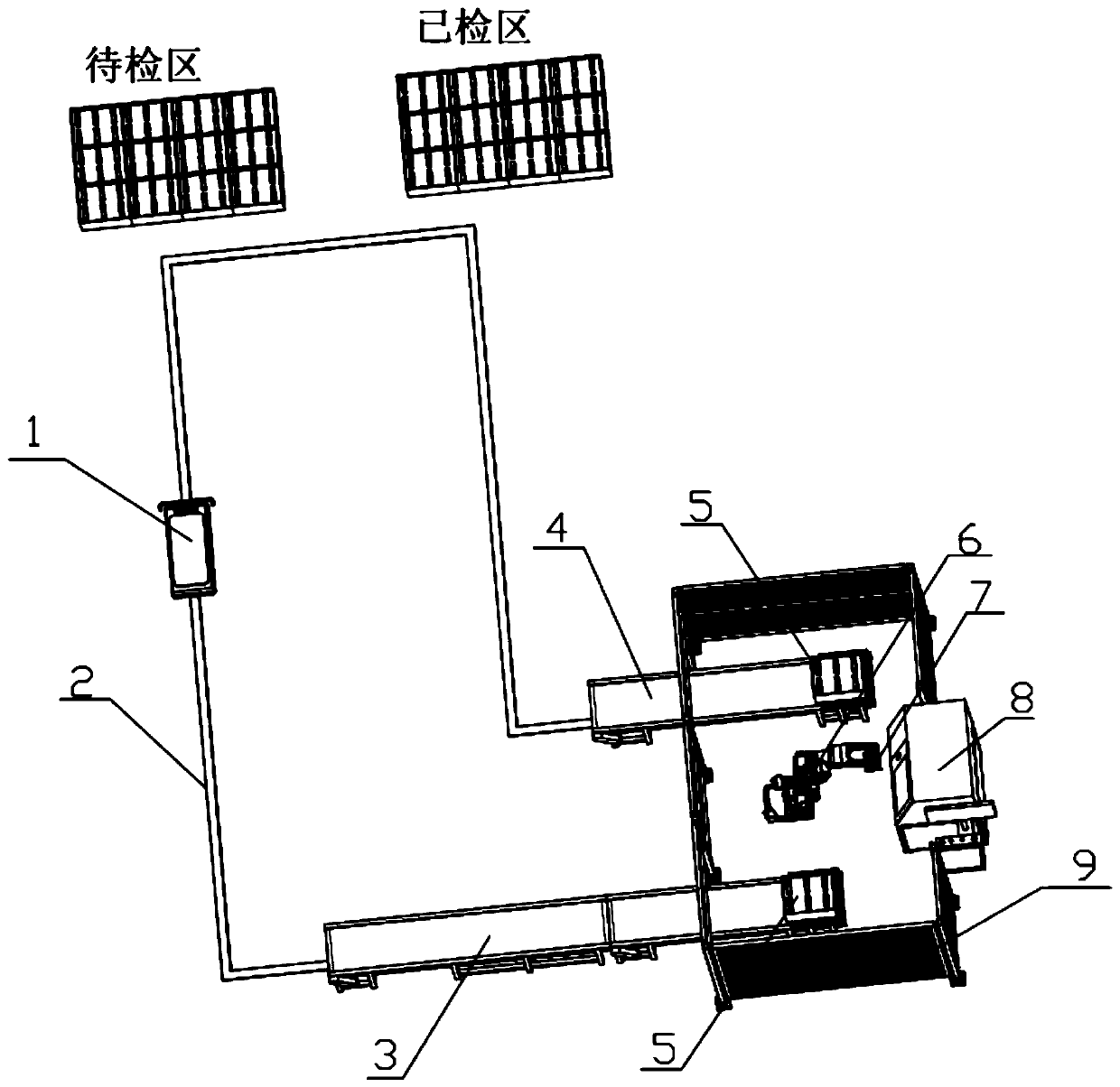

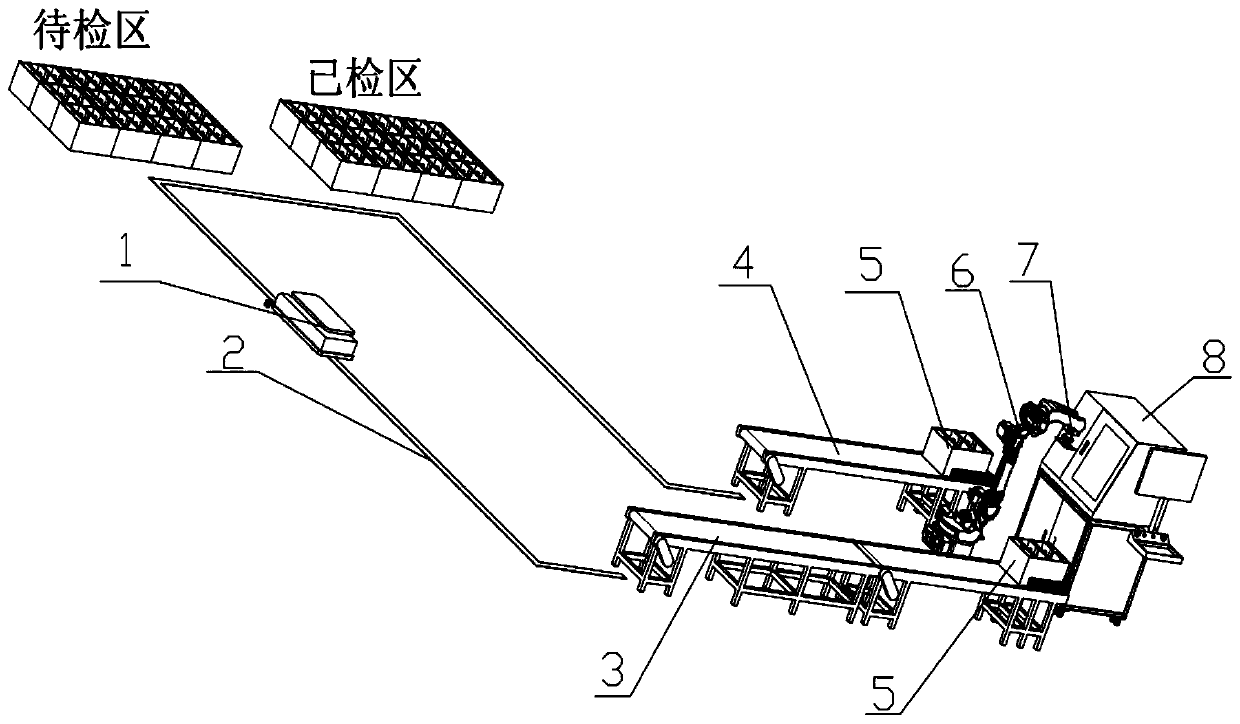

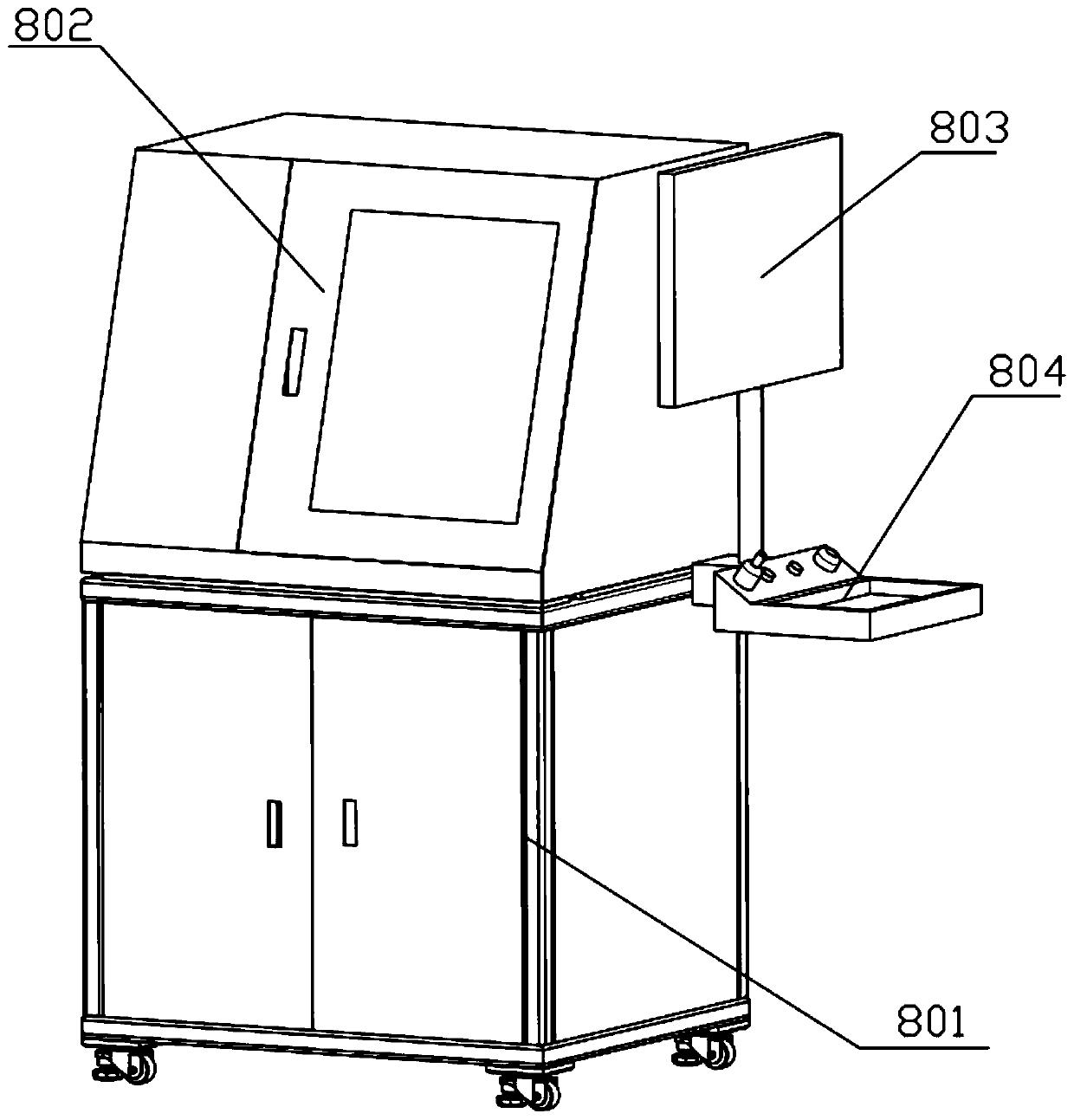

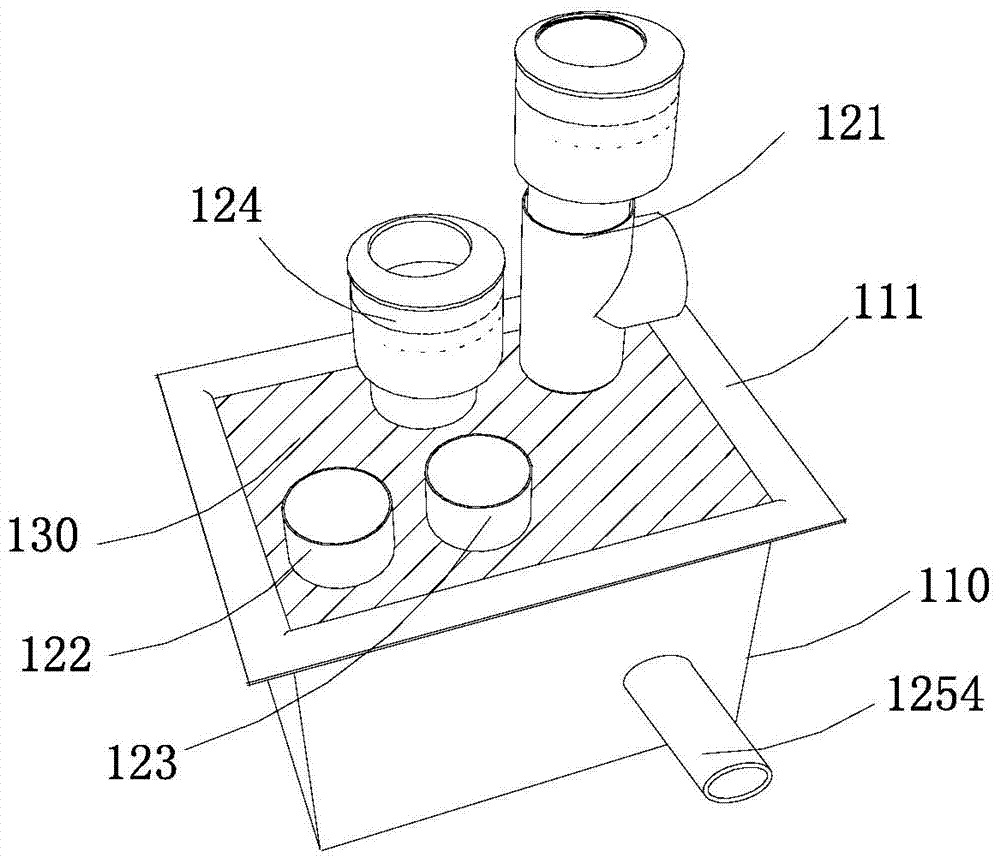

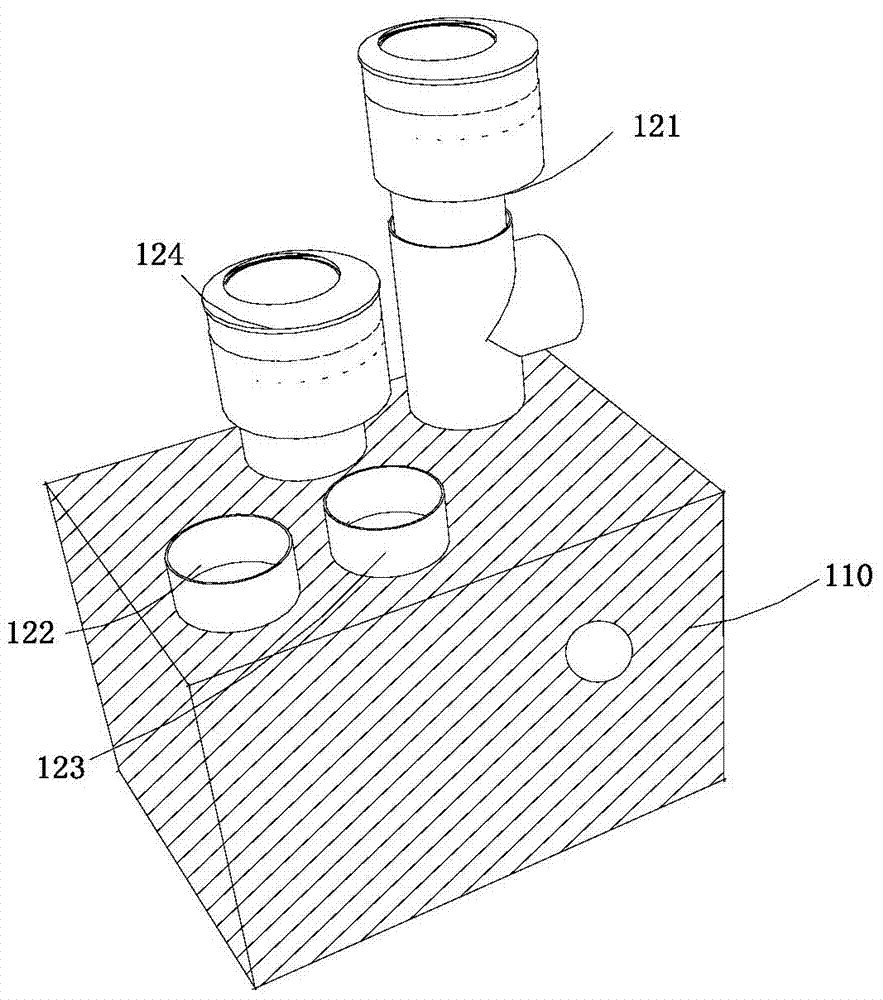

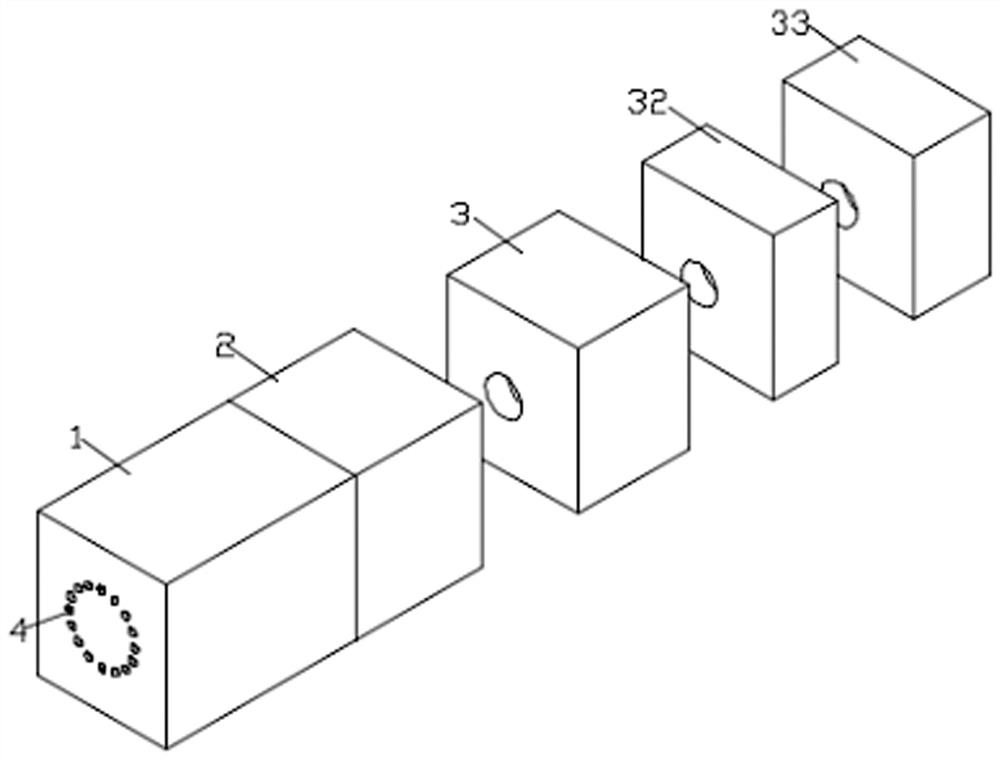

Lithium battery core cladding structure X-Ray detection system and detection method

ActiveCN106945890AImprove detection efficiencyImprove accuracyPackaging automatic controlMaterial analysis by transmitting radiationRadiationDisplay device

The invention discloses a lithium battery core cladding structure X-Ray detection system and a detection method. The lithium battery core cladding X-Ray detection system is characterized in that the lithium battery core cladding X-Ray detection system comprises a transmission device, a feeding and discharging device and an X-Ray detection device. A lithium battery core cladding is transferred and transported to the feeding and discharging device through a transmission device. The X-Ray detection device carries out the structure detection to the lithium battery core cladding transported from the feeding and discharging device. After detection the lithium battery core cladding is transported to a detected area. The X detection device comprises a frame, an automatic door, a display device, a operating table and a detection part. The display device and the operating table are arranged on the side of the frame. The automatic door is arranged on the front side of the frame. The detection part is arranged at the lower end of the frame. According to the lithium battery core cladding structure X-Ray detection system and the detection method, a series of automatic technological process of automatic transmission, automatic feeding and discharging and automatic detection of the lithium battery core cladding is realized. A protective net is adopted in the feeding and discharging device area, and the safety of the system and personnel is protected. In addition, the X-Ray detection device uses a fully enclosed protective cover, and the X Ray radiation is effectively isolated.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

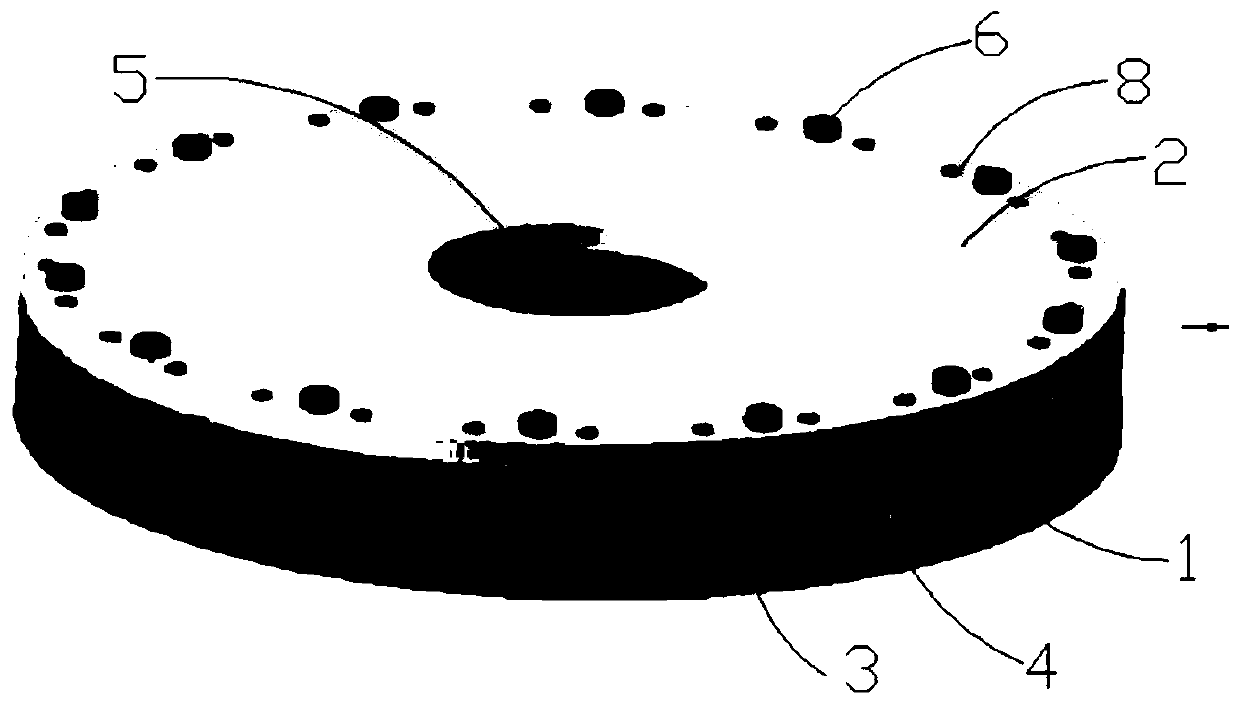

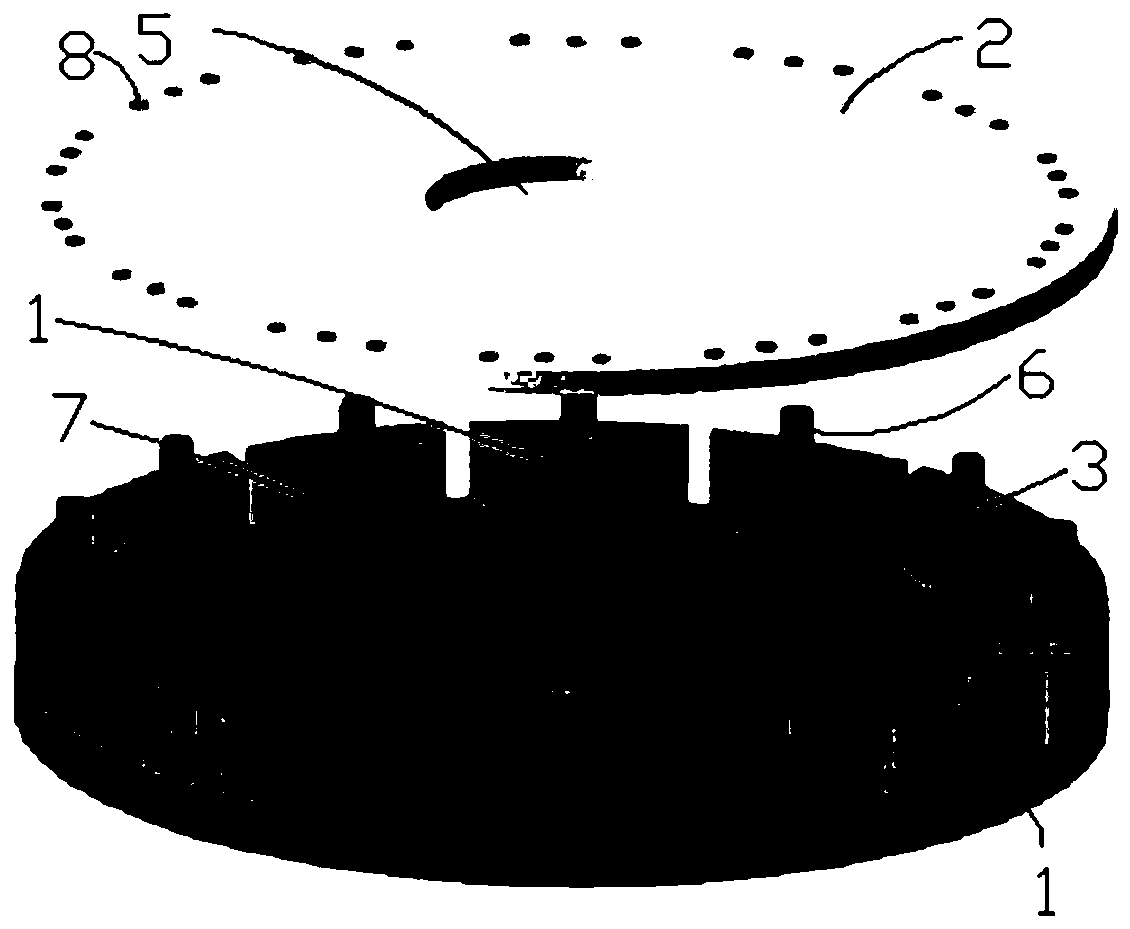

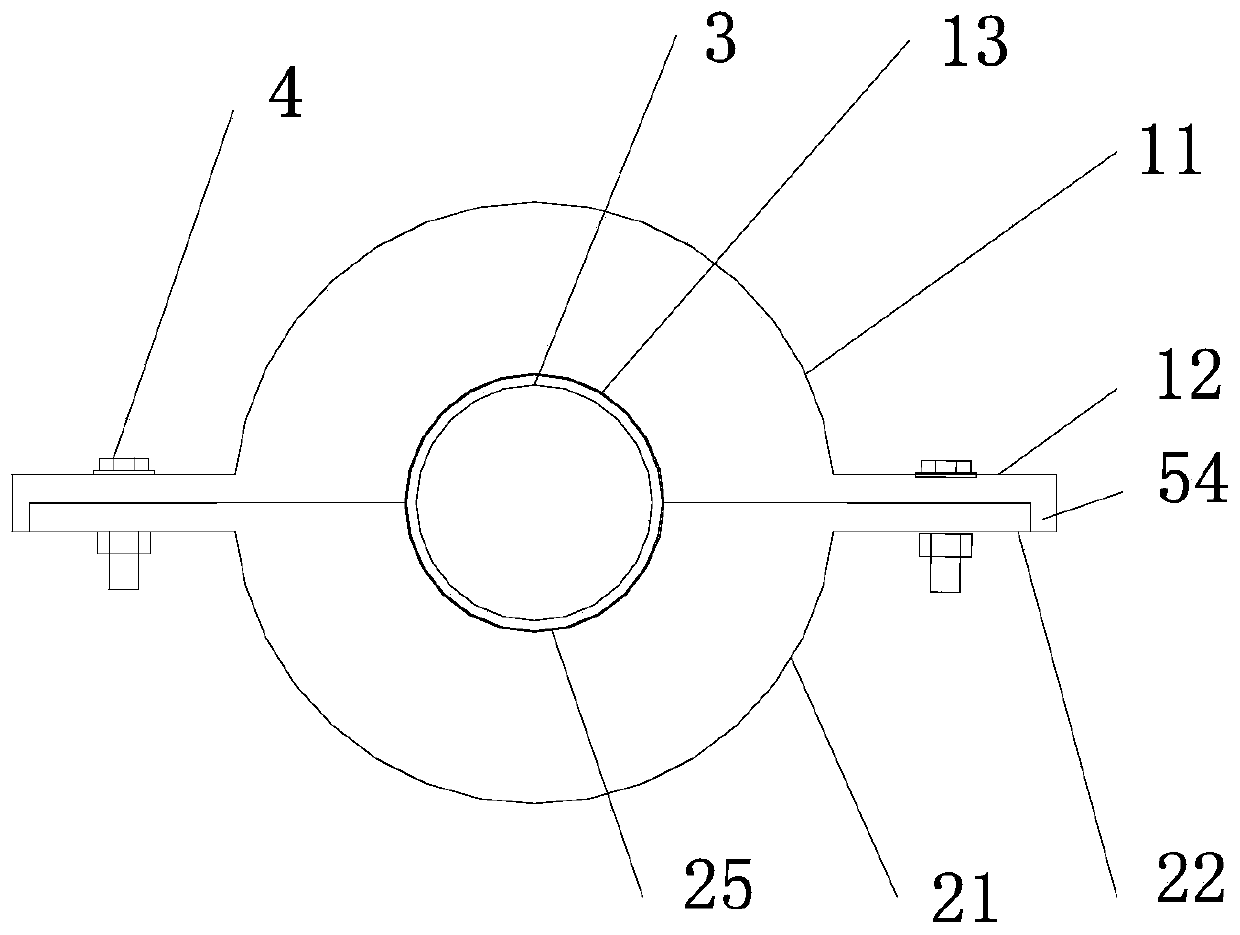

Atomizing rotary spray disc for fertilizer production and granulator

PendingCN110449089AReduce cloggingImprove the efficiency of the production processMovable spraying apparatusGranulation by liquid drop formationEngineeringDrive motor

The invention discloses an atomizing rotary spray disc for fertilizer production. The atomizing rotary spray disc comprises a lower end plate, a plurality of indexing blocks and an upper end plate which are arranged from bottom to top; the plurality of indexing blocks are uniformly distributed at intervals at the peripheral edge positions of the lower end plate; the lower end plate, the pluralityof indexing blocks and the upper end plate define an inner cavity of the spray disc; the center of the upper end plate is provided with a molten liquid inlet; and the center of the lower end plate isconnected with an output shaft of a driving motor. Each indexing block of the atomizing rotary spray disc is convex and is widened from center to two sides in turn, and a backflow structure is formed,so that the molten liquid can be sprayed more smoothly. Rectangular nozzles have a certain width and height and rotate at a high speed to generate huge centrifugal force, so that the probability thatthe rectangular nozzles are blocked by solid impurities is greatly reduced.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

Top and bottom cover assembling device for inner box

PendingCN112454986AHigh production process efficiencyRealize online gluingBox making operationsPaper-makingAdhesive glueStructural engineering

The invention relates to the technical field of packaging box processing machinery, and discloses a top and bottom cover assembling device for an inner box. The device comprises a carrier for bearingand moving materials and processing stations arranged at a carrier parking point, wherein the processing stations at least comprise a ground cover feeding station, a foxing assembly station, a top cover feeding station and a discharging station, the ground cover feeding station is used for transferring a ground cover incoming material to the carrier, and the ground cover incoming material is already glued and dried outside the carrier; the foxing assembly station is used for providing a first foxing inner mold combination body for shape preservation for the glued ground cover incoming materialand assembling the first foxing inner mold combination body with the ground cover incoming material moving to the station to form a second combination body; the top cover feeding station is used forproviding a top cover incoming material for the assembled second assembly; and the second assembly and the top cover incoming material are transferred to the discharging station to form a third assembly to be discharged. The carrier output efficiency can be prevented from being limited by the drying time of glue, and then the production efficiency of the inner box can be improved.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

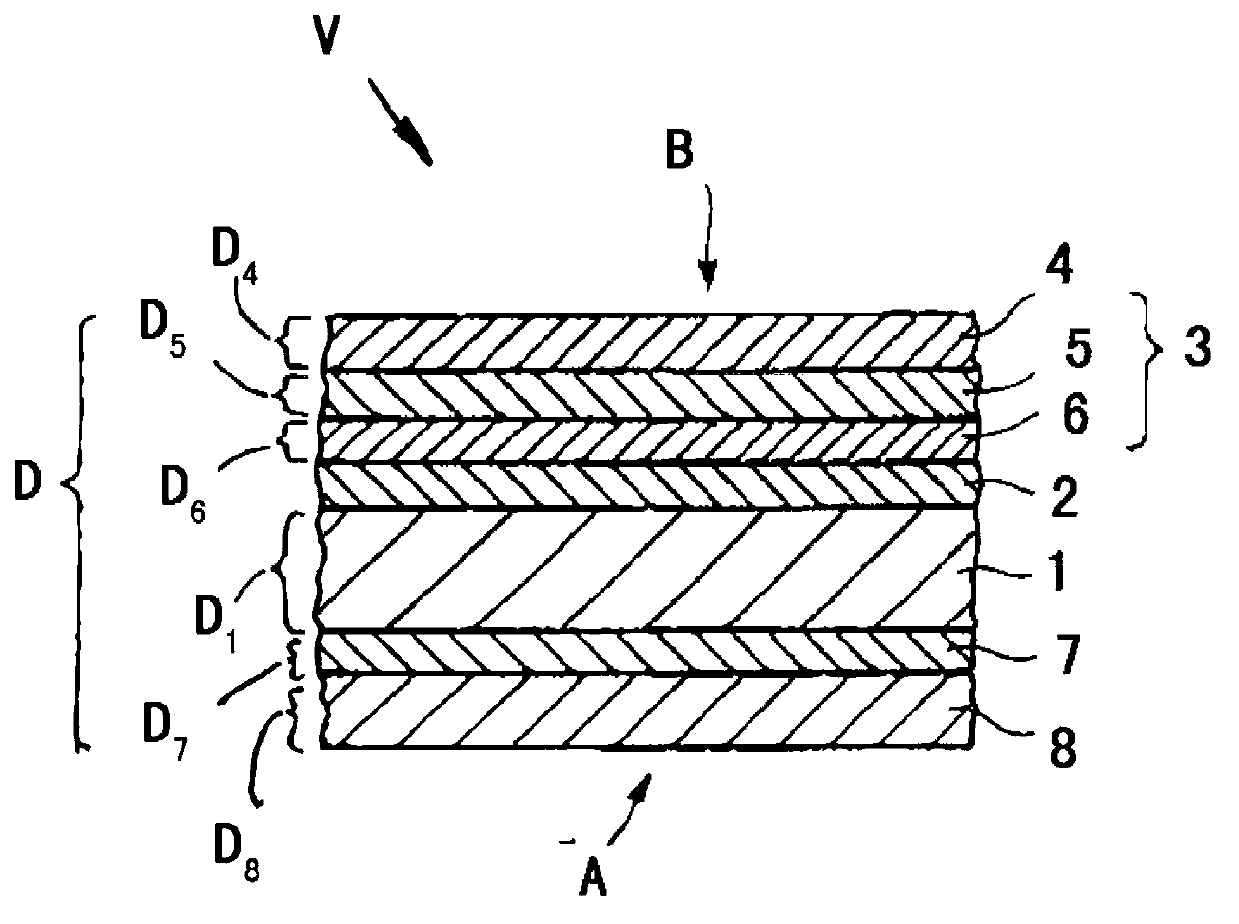

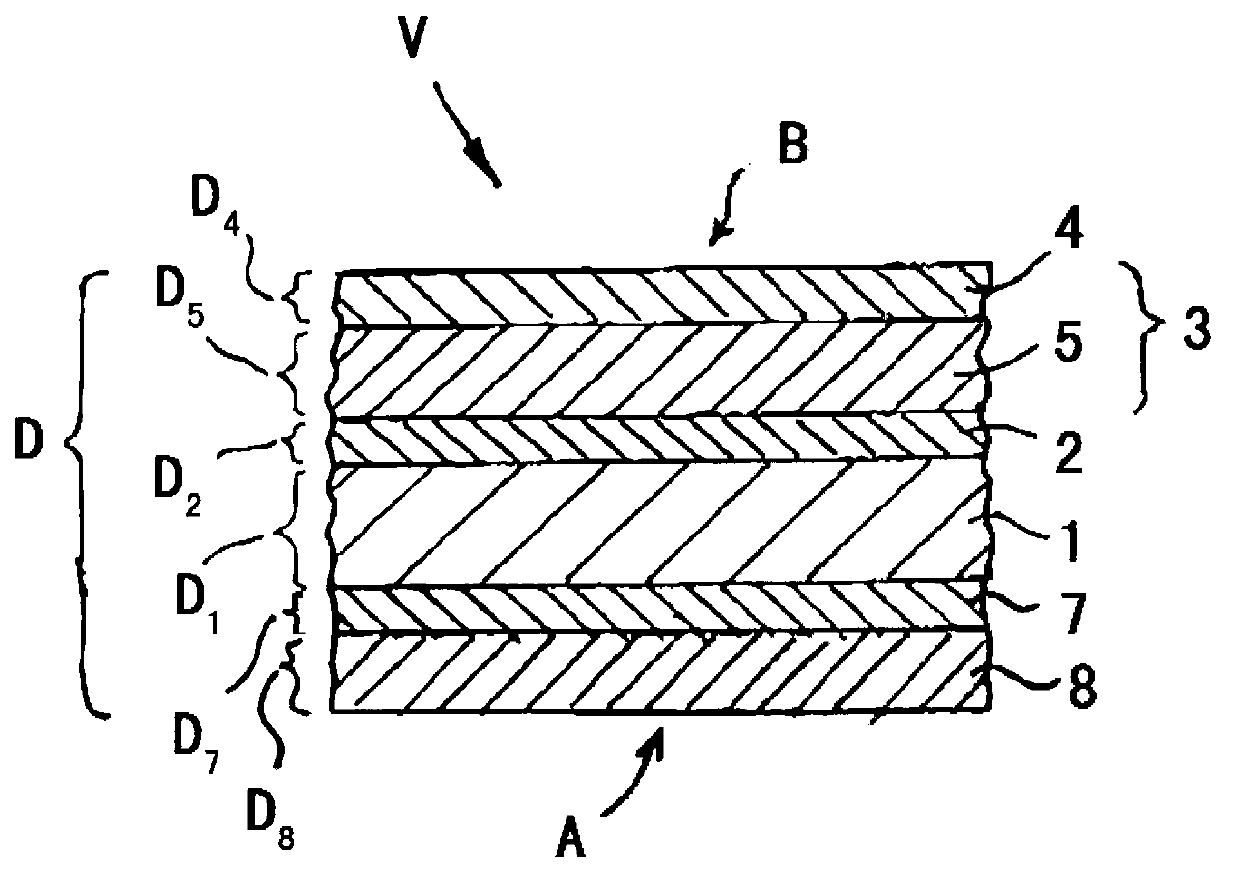

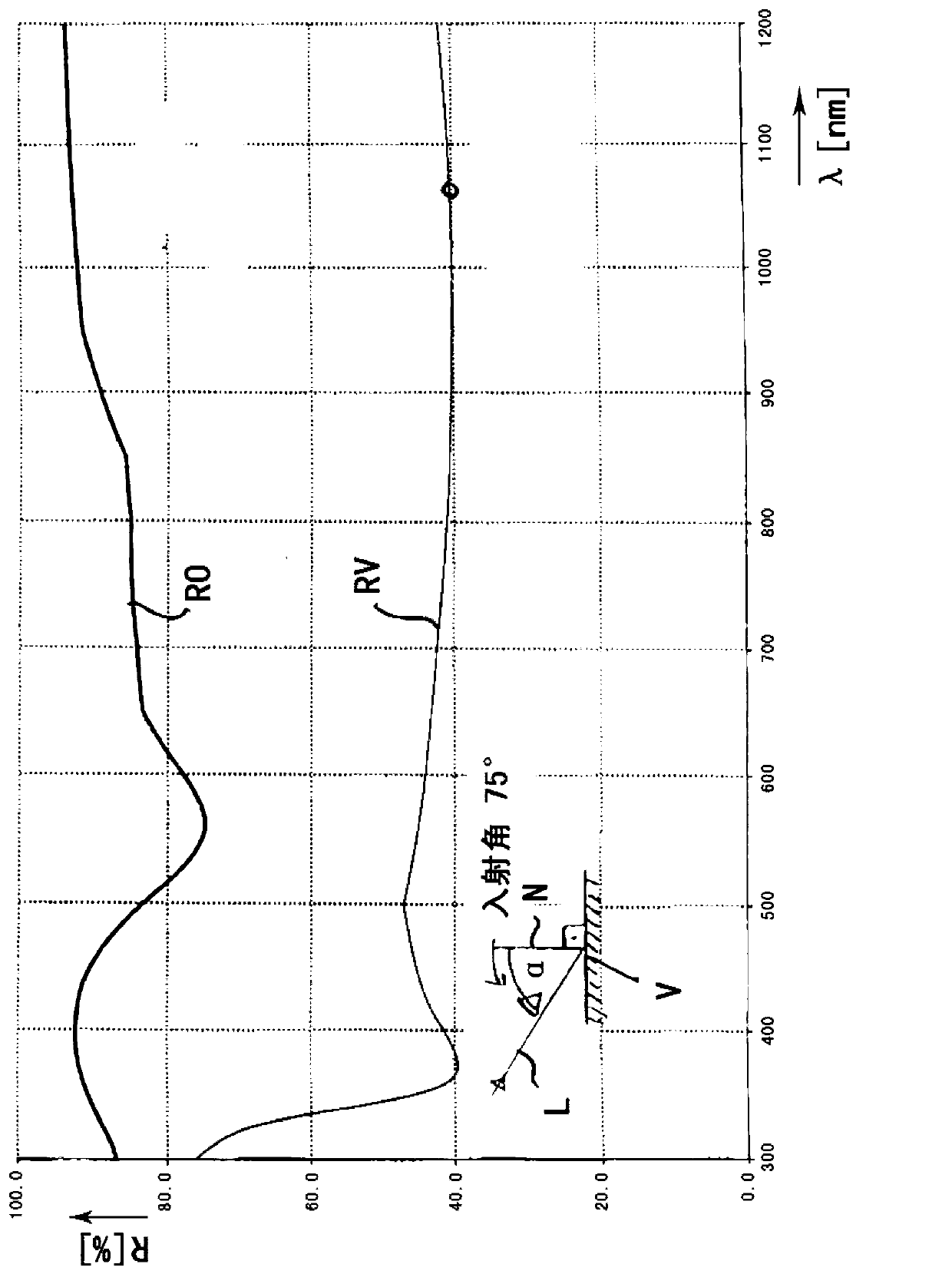

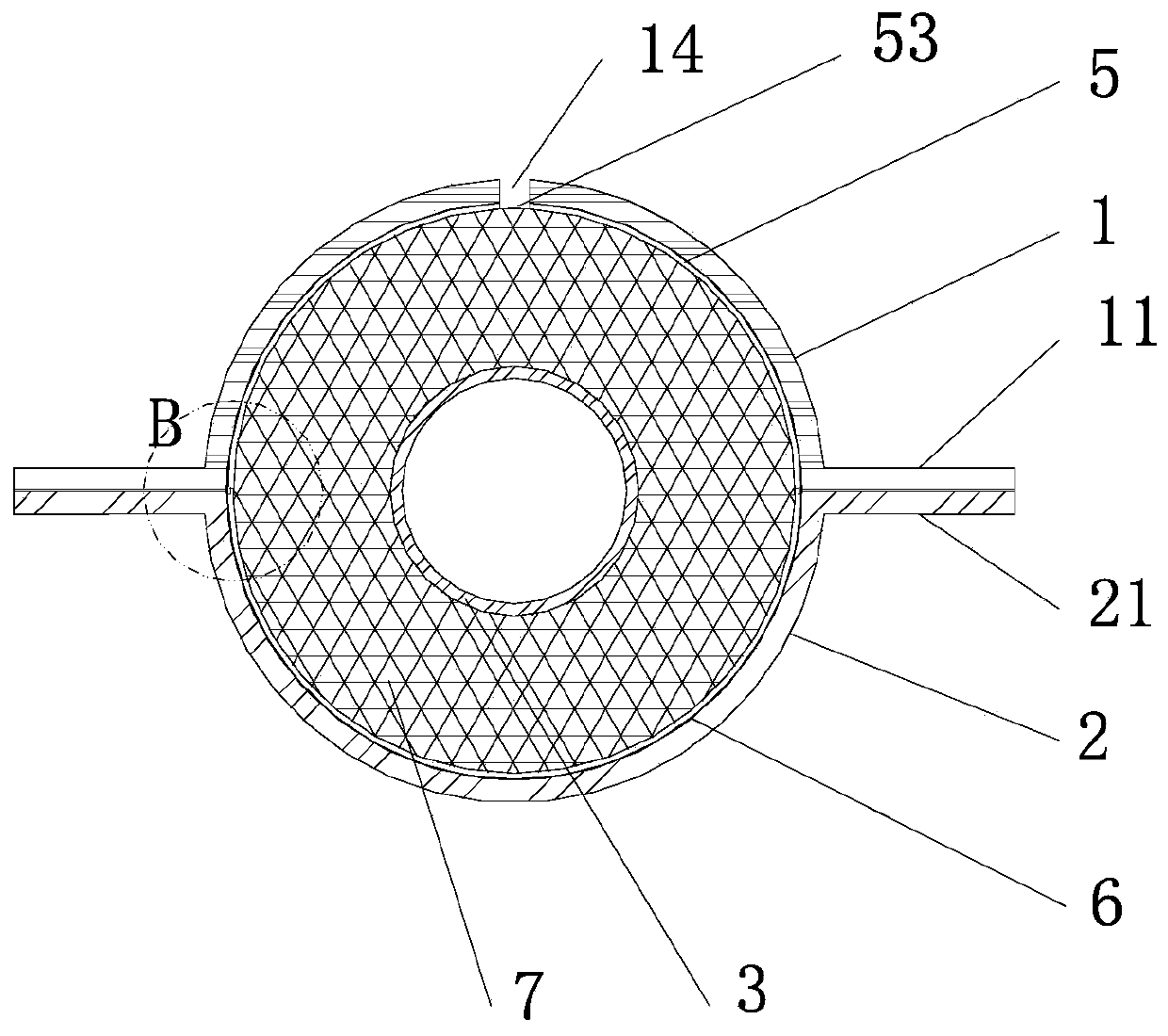

Laser welding composite material for solar collector

ActiveCN103101249AImprove functionalityReduce manufacturing costSolar heating energyAnodisationAngle of incidenceBand shape

The composite material (V) has a band-shaped metal (1) with high reflectivity for laser radiation beam having lower side (A) on which a ceramic coating (7) is formed. The metallic layer (8) is formed over the ceramic coating. The thickness (D7) of the ceramic coating and the thickness (D8) of metallic layer are dimensioned in accordance with DIN 5036, such that specific total reflectance at an angle of incidence ranges from 65-80[deg] of the incident laser light beam (L) with a wavelength of 1064 nm on lower side of metal, is lesser than 60%.

Owner:阿兰诺德股份有限两合公司

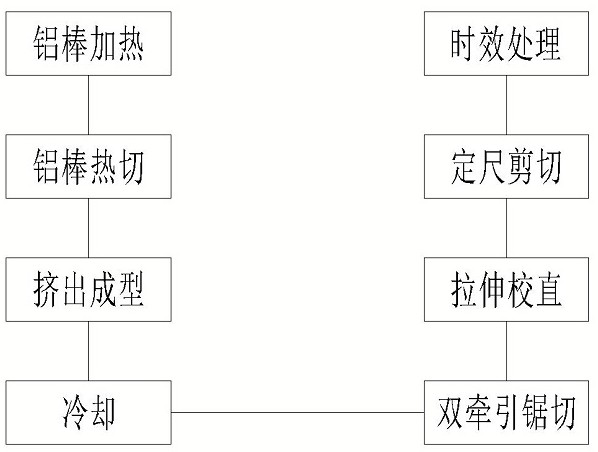

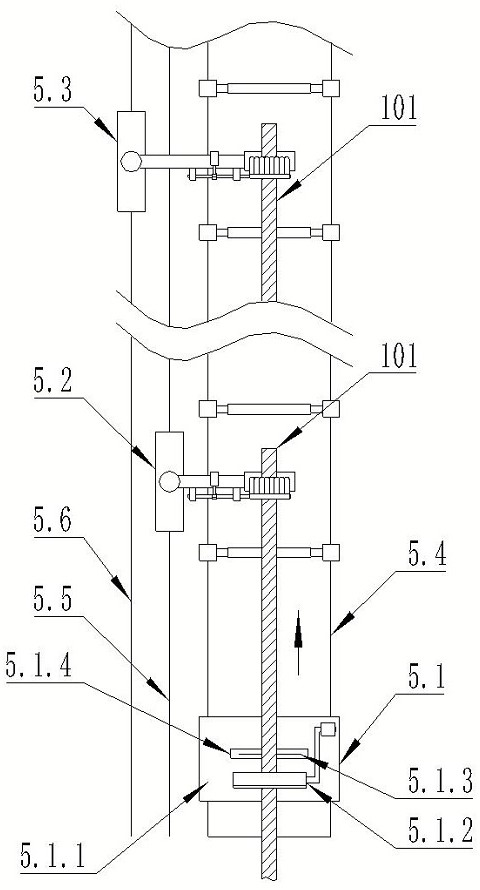

Efficient aluminum profile production line and production process thereof

PendingCN112025323ANo shakingReduce noiseOther manufacturing equipments/toolsCooling effectProcess engineering

The invention relates to an efficient aluminum profile production line and a production process thereof. The efficient aluminum profile production process comprises the following process steps of aluminum bar heating, aluminum bar hot cutting, extrusion forming, air cooling, double-traction saw cutting, stretching straightening, sizing shearing and aging treatment. According to the efficient aluminum profile production line and the production process thereof, air outside a workshop flows through the surface of an aluminum profile at a high speed to achieve a rapid cooling effect, meanwhile, hot air is exhausted out of the workshop, noise and high temperature of the production workshop are reduced, power consumption of a cooling fan is reduced, in a sawing process, the aluminum profile is pressed and does not shake, the sawing section size of the aluminum profile is accurate and does not deform, the production efficiency is high due to alternate replacement and traction of two tractionwheels, and the aluminum profile is automatically aligned, so that straightening and stretching are automatically operated, materials are automatically fed and discharged during the aging treatment, and the whole production process is high in production efficiency, environment-friendly and safe.

Owner:向阳精密工业有限公司

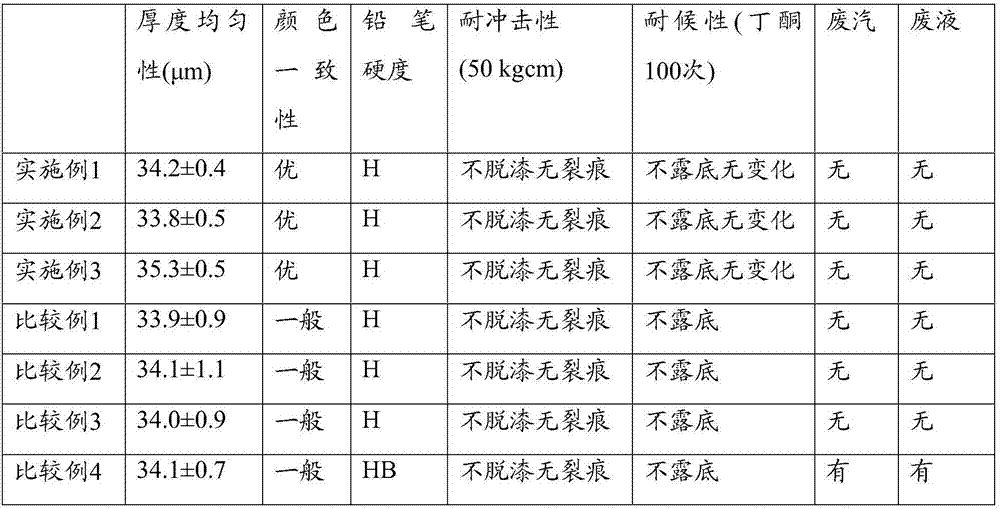

Color-varying and color-coated aluminum strip and production technology thereof

PendingCN107457166AReduce pollutionHigh production process efficiencyPretreated surfacesMetallic material coating processesWeather resistanceTime changes

The invention relates to a color-varying and color-coated aluminum strip and a production technology thereof. The color-varying and color-coated aluminum strip is uniform in thickness, good in color consistency, good in compactness and good in weather resistance; through time change, the color change of the aluminum strip can be clearly seen according to the illumination intensity, a visual impact is provided for people, so that the effect of pursuing the aesthetic feeling is achieved and good visual enjoyment is achieved; in addition, the production technology has no waste steam and waste liquid discharge, and environmental pollution is reduced; and the production technology is high in efficiency and can be applied to continuous high-speed production.

Owner:滨州永光工贸有限公司

Sticky note printing technology

PendingCN108128047AGorgeous and lastingAvoid processing errorsOther printing apparatusGraphicsEnvironmental resistance

The invention discloses a sticky note printing technology. The sticky note printing technology comprises the following specific manufacturing processing steps: a, selection and analysis of a manuscript: the manuscript is the original ground of a printed image copying process, selecting graphics and text information in a material object or a carrier; b, design and production and proofing: using a scanned picture or a picture document of a graph library for design and production; c, carrying out proofing when a film is printed to add colors during printing; d, selecting proper printing stock inkand carrying out printing by way of flexography; and e, later period processing technology: binding, folding, covering, commonly cutting and pasting the printed sticky note to finish processing. Thesticky note printing technology provided by the invention is energy-saving and environment-friendly in the whole production process course, the printing process is environment-friendly, and the pattern is clear and bright and lasting and can be transferred to products of any materials. The sticky note printing technology is particularly suitable for processing the sticky note, and the whole production process is relatively high in efficiency.

Owner:深圳市海印印刷包装有限公司

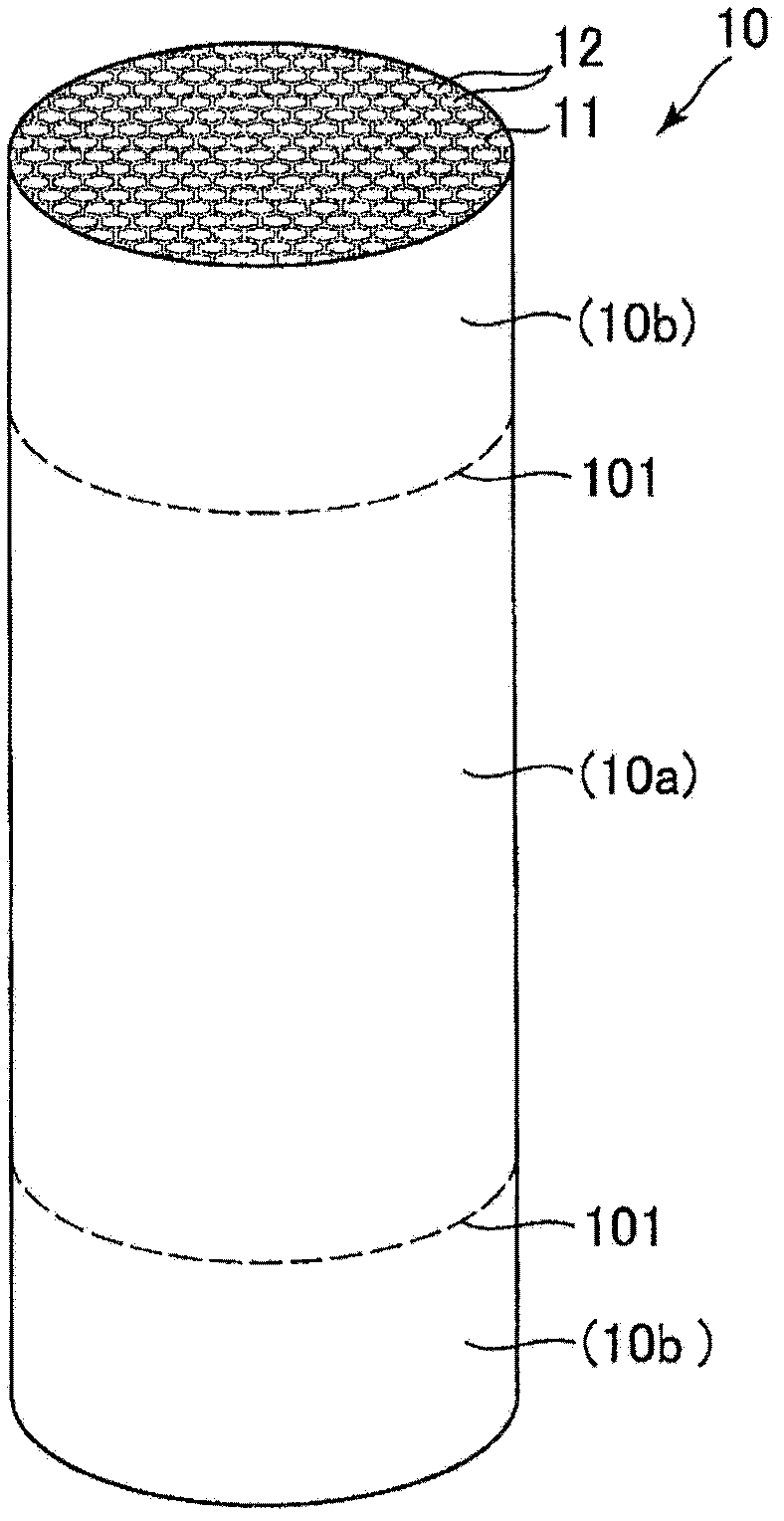

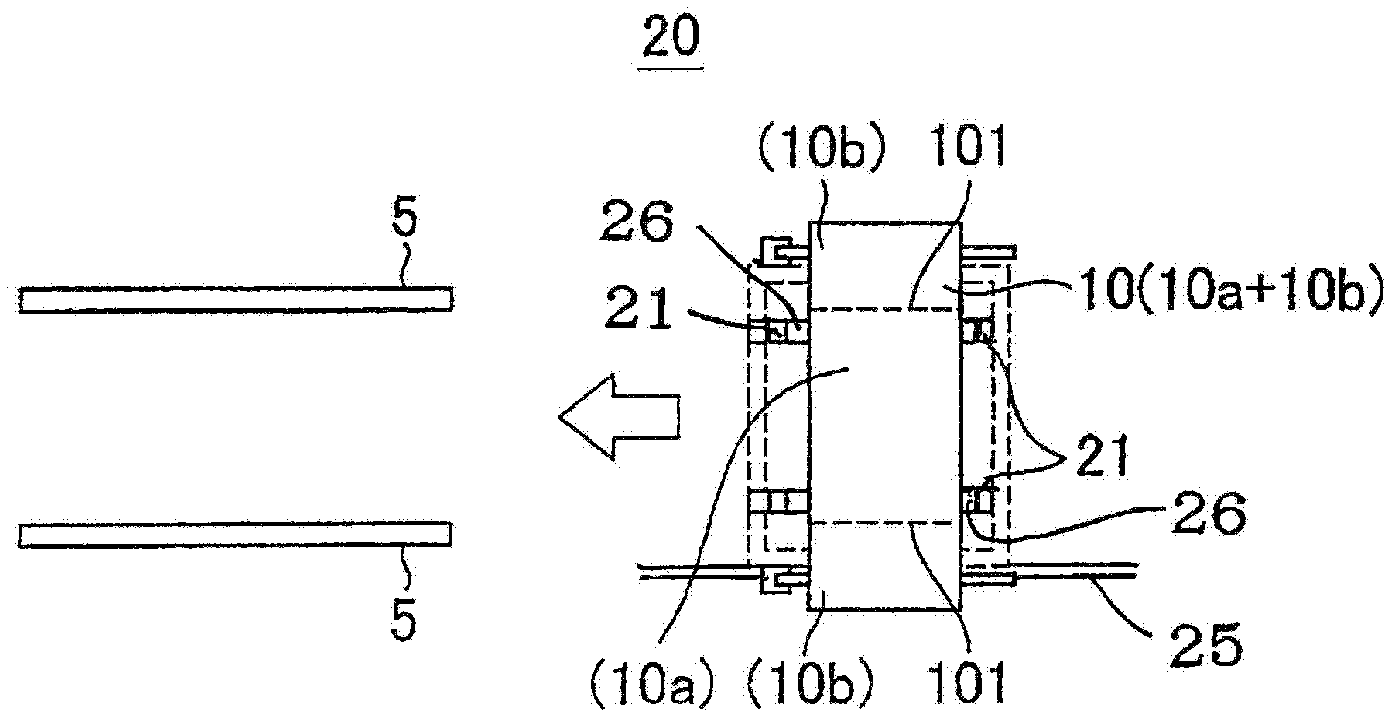

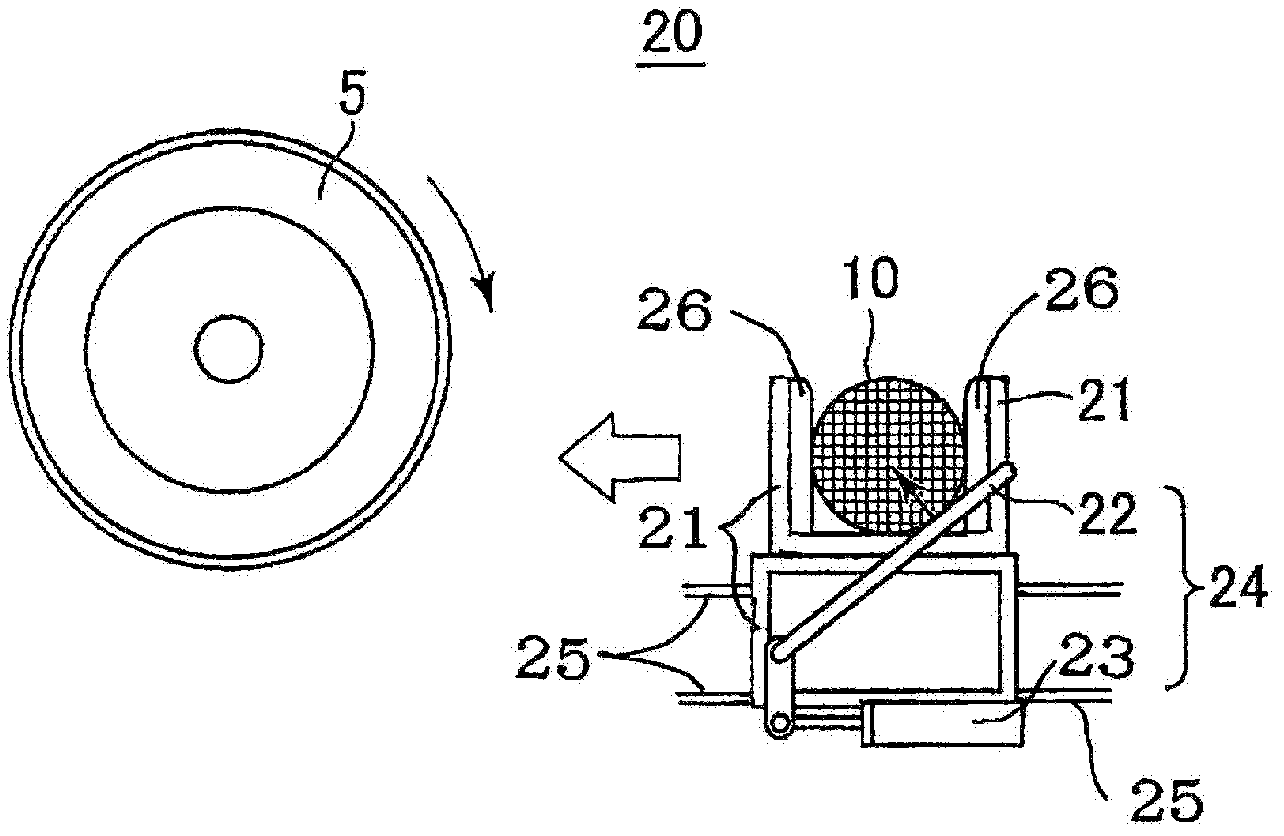

Cutting method of honeycomb dried body and honeycomb dried body cutting device

ActiveCN102729323AImprove efficiencyReduce gapCeramic shaping apparatusGrinding machinesGrindstoneHoneycomb

Owner:NGK INSULATORS LTD

Processing method of high-quality roxburgh rose powder

InactiveCN107836672AEffective preservationReduce loadFood membrane processNatural extract food ingredientsFreeze-dryingReverse osmosis

The invention discloses a processing method of high-quality roxburgh rose powder. The processing method comprises the following steps of putting selected roxburgh rose fruits in a roller cleaning machine, and after stabs on the outer peels of the roxburgh rose fruits fall down, taking out the treated roxburgh rose fruits for standby application; squeezing the cleaned roxburgh rose fruits to obtainjuice; adding a gelatine solution, and pouring clarified roxburgh rose juice into a filter drum; and performing reverse osmosis treatment on the treated roxburgh rose juice, pouring the roxburgh rosejuice after reverse osmosis treatment in a freeze drier, and performing freeze drying on the roxburgh rose juice to obtain powder namely the roxburgh rose powder. According to the processing method,in the process of producing the roxburgh rose powder, the roxburgh rose juice is in the normal-temperature or low-temperature state, components of vitamins and the like in the roxburgh rose cannot bedamaged by high temperature, nutrient components in the roxburgh rose are effectively preserved, and besides, before freeze drying, the roxburgh rose juice is subjected to primary reverse osmosis, sothat most of moisture in the roxburgh rose juice is removed, the energy is saved, the efficiency of the entire production flow is improved, the load of the freeze drier is low, and the production costis reduced.

Owner:贵州旺业农业科技有限公司

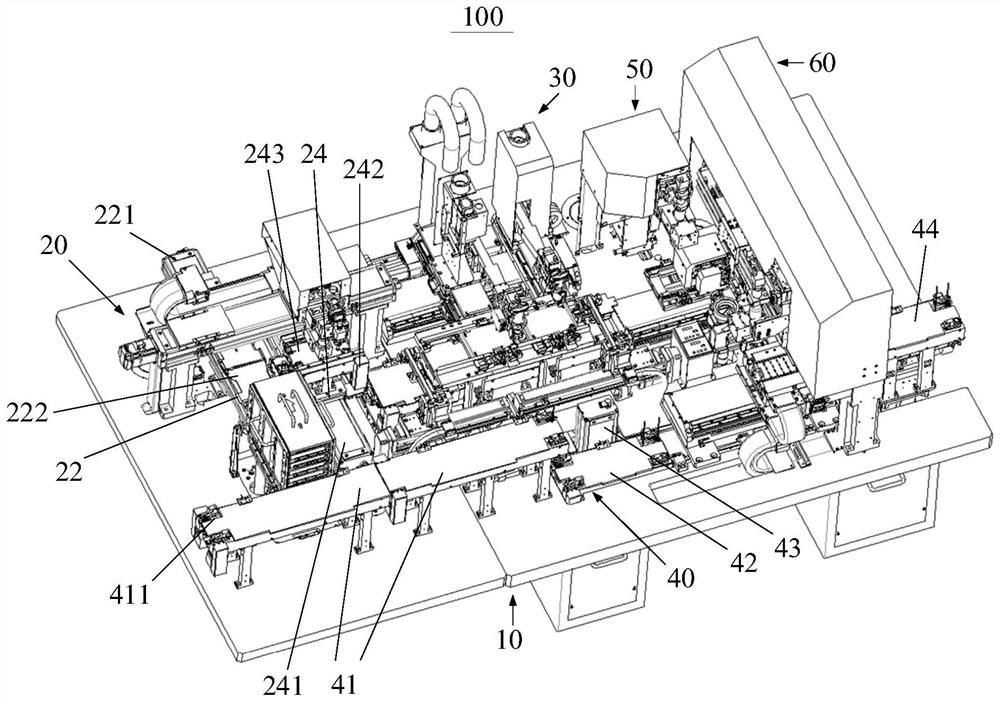

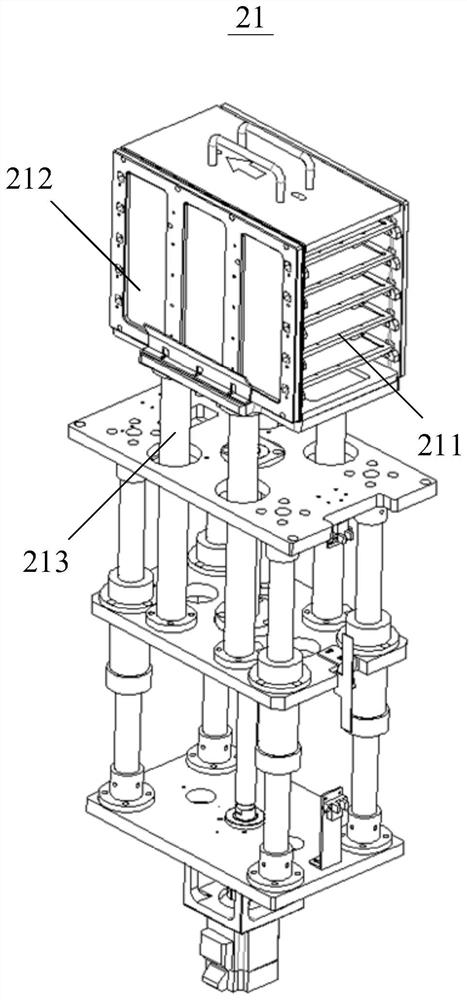

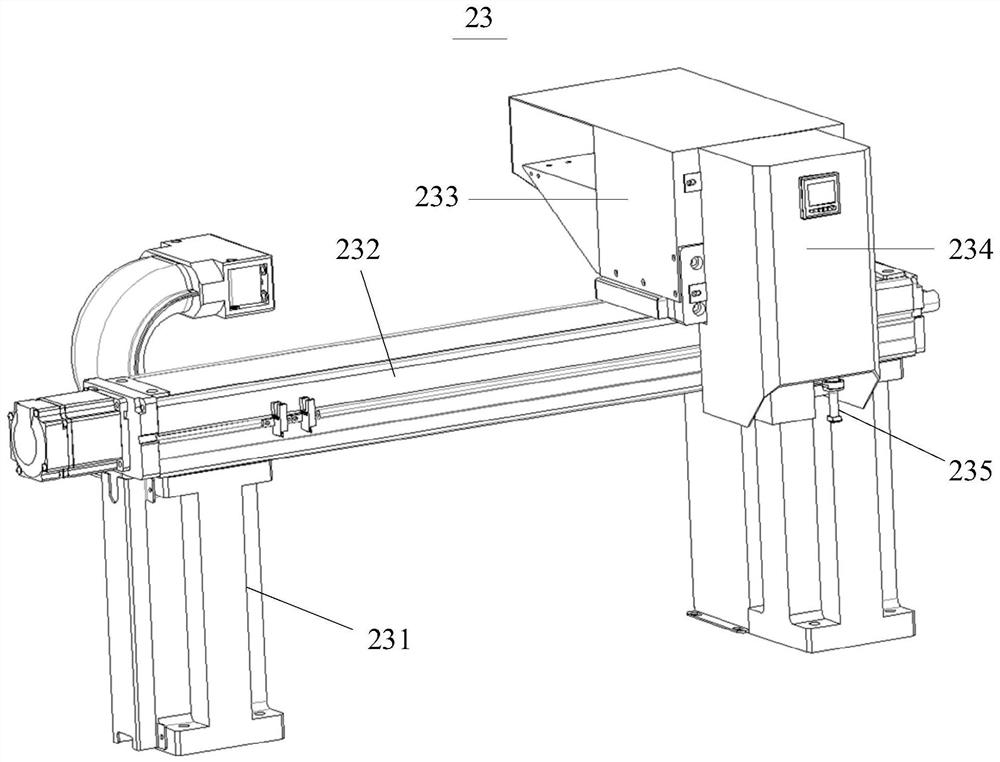

Chip laminating equipment

PendingCN114093799AImprove pass rateLow costLiquid surface applicatorsSemiconductor/solid-state device testing/measurementComputer hardwareMechanical engineering

The invention discloses chip laminating equipment, which is used for laminating a chip. The chip laminating equipment comprises a main worktable, and a feeding and tray placing module, a dispensing module, a carrier plate conveying module, an overturning module and an attaching module which are mounted on the main worktable, the feeding and tray placing module is used for placing a chip base at a preset feeding position, locating and detecting the chip base, and placing the located and detected chip base in a transfer tray, the dispensing module is used for locating and detecting the height of the placed chip base, performing dispensing operation on the chip base and conveying the dispensed chip base to the overturning module, the overturning module is used for overturning the chip base. The carrier plate conveying module is used for conveying a carrier plate on which a chip is mounted to the attaching module and conveying a carrier plate on which a chip base is not attached to a next attaching device, and the attaching module is used for attaching the overturned chip base to the chip of the carrier plate.

Owner:SHENZHEN EAGLE EYE ONLINE ELECTRONICS TECH

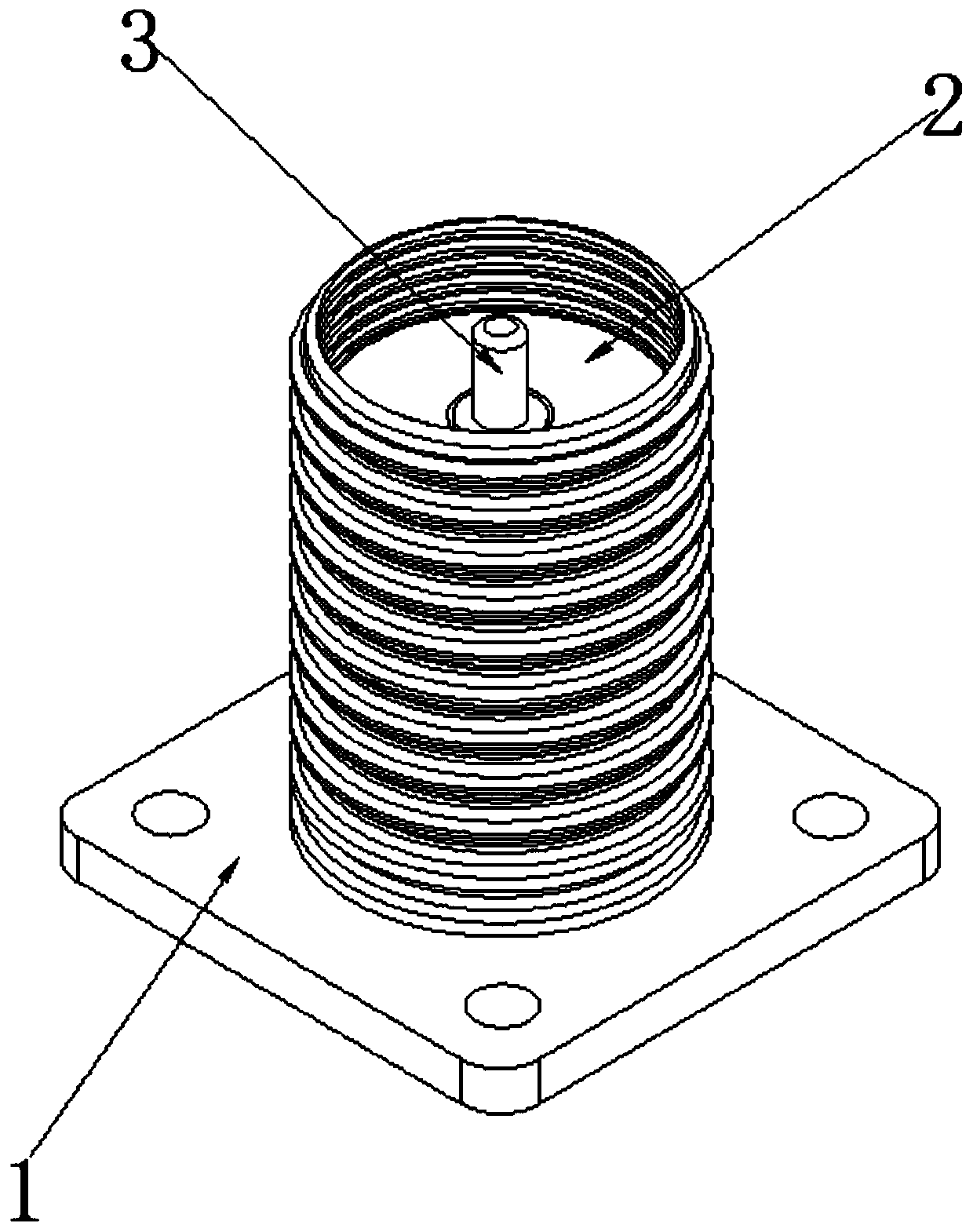

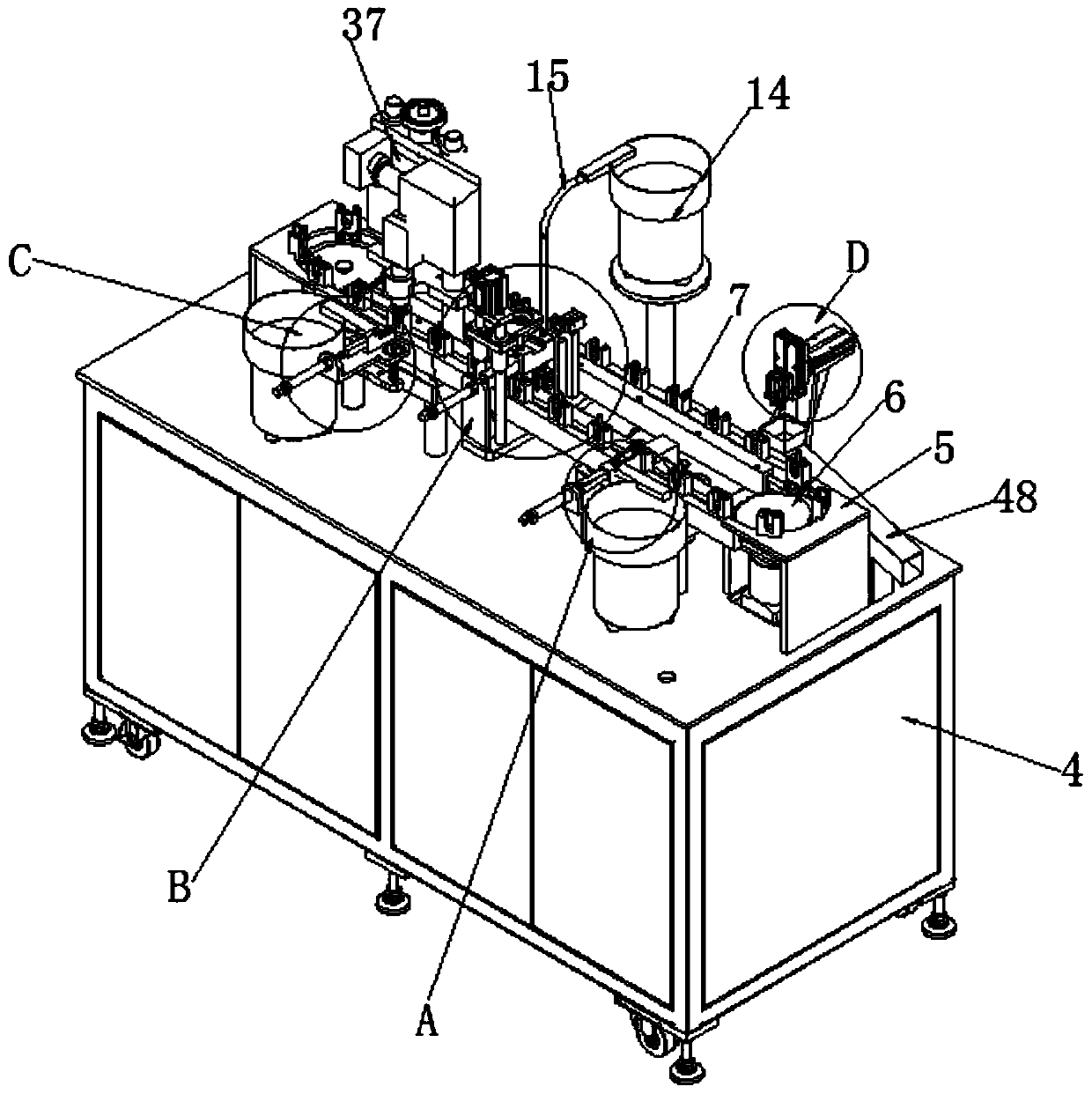

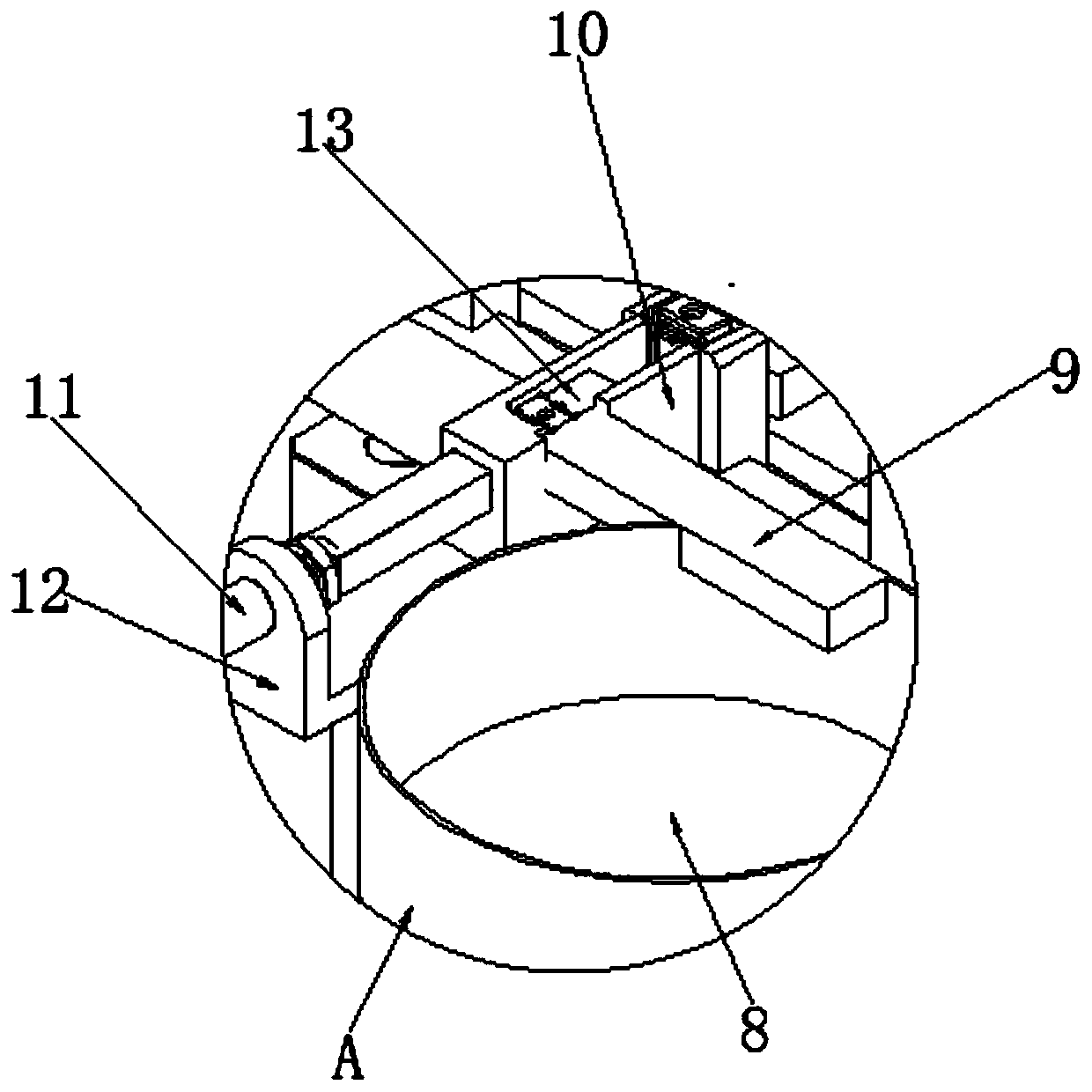

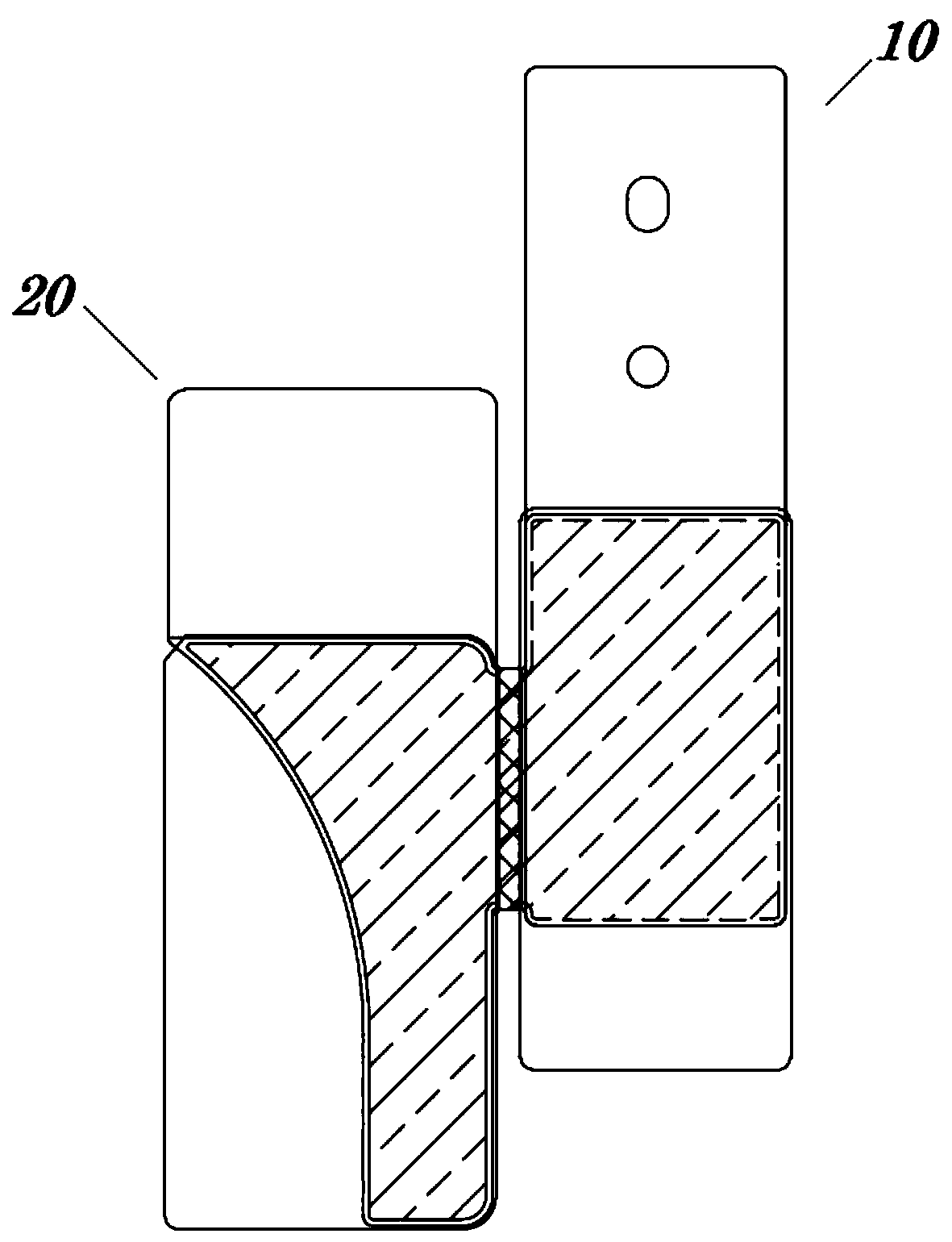

Production process of radio frequency coaxial connector for antenna connection

ActiveCN111029882AImprove the efficiency of the production processShorten production process timeContact member manufacturingContact member assembly/disassemblyRadio frequencyElectrical conductor

The invention discloses a production process of a radio frequency coaxial connector for antenna connection. The radio frequency coaxial connector comprises a shell, an inner insulator and an inner conductor, wherein the inner insulator is installed in the shell, and the inner conductor is installed in the inner insulator in a penetrating mode. The production process comprises the following specific operation steps of: sequentially producing the shell, the inner insulator and the inner conductor through a mold, and completing production on an assembling device for the shell, the inner insulatorand the inner conductor which are produced. Through work of the assembling device and a full-automatic operation mode, automatic feeding of the shell, the inner insulator and the inner conductor is completed, the shell, the inner insulator and the inner conductor are rapidly assembled on the device in sequence, the efficiency of the production process of a radio frequency coaxial connector is greatly improved, the time of the production process is shortened, and the percent of pass of radio frequency coaxial connector products is greatly improved.

Owner:扬州市精诚电子有限公司

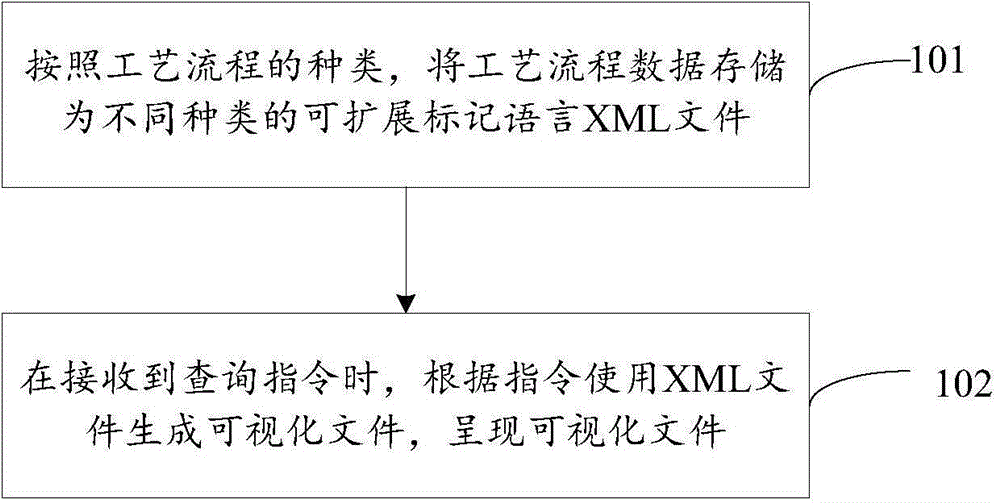

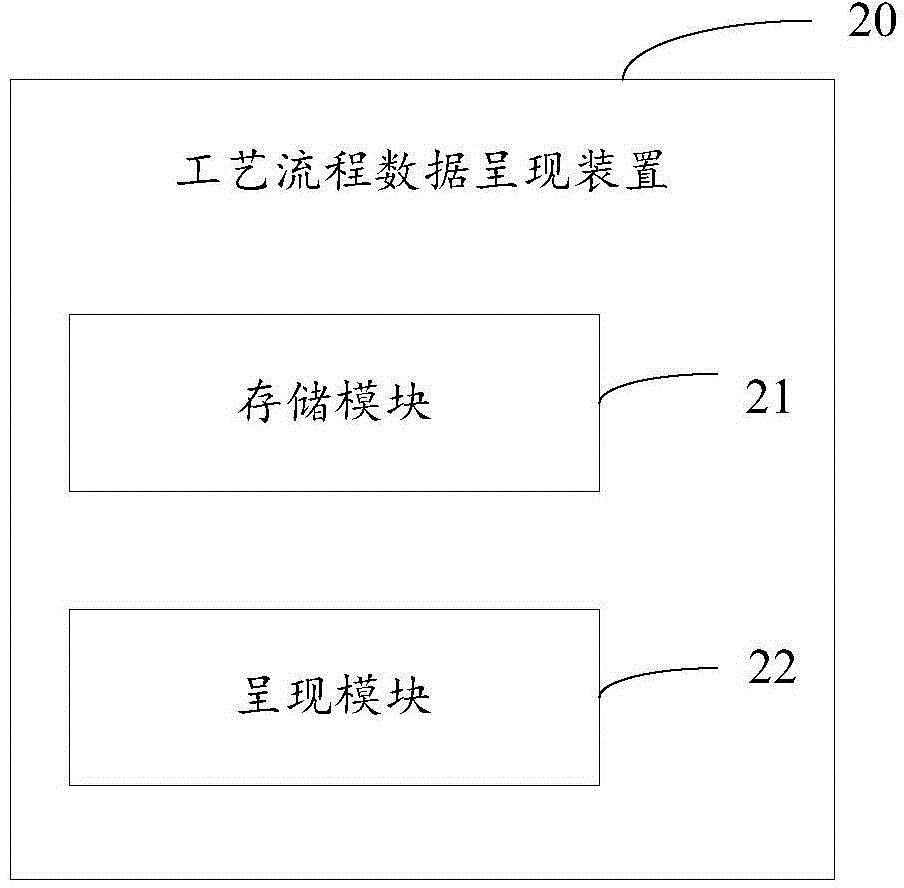

Technological process data presentation method and apparatus

InactiveCN105808597AConvenient queryEasy to modifySpecial data processing applicationsWeb pageData store

The invention provides a technological process data presentation method and apparatus, which are used for solving the problem of relatively low efficiency of executing a production process through a technological process guide book at present. The technological process data presentation method comprises the steps of storing technological process data as different types of XML files according to technological process types; and when a query instruction is received, generating visual technological files by using the XML files according to the instruction, presenting files such as interactive forms, charts, web pages and the like, and performing electronic and structured conversion on information of the visual files in an image characteristic identification and code identification way, thereby facilitating data feedback and analysis. The method improves the efficiency of the production process.

Owner:BEIJING AEROSPACE MEASUREMENT & CONTROL TECH

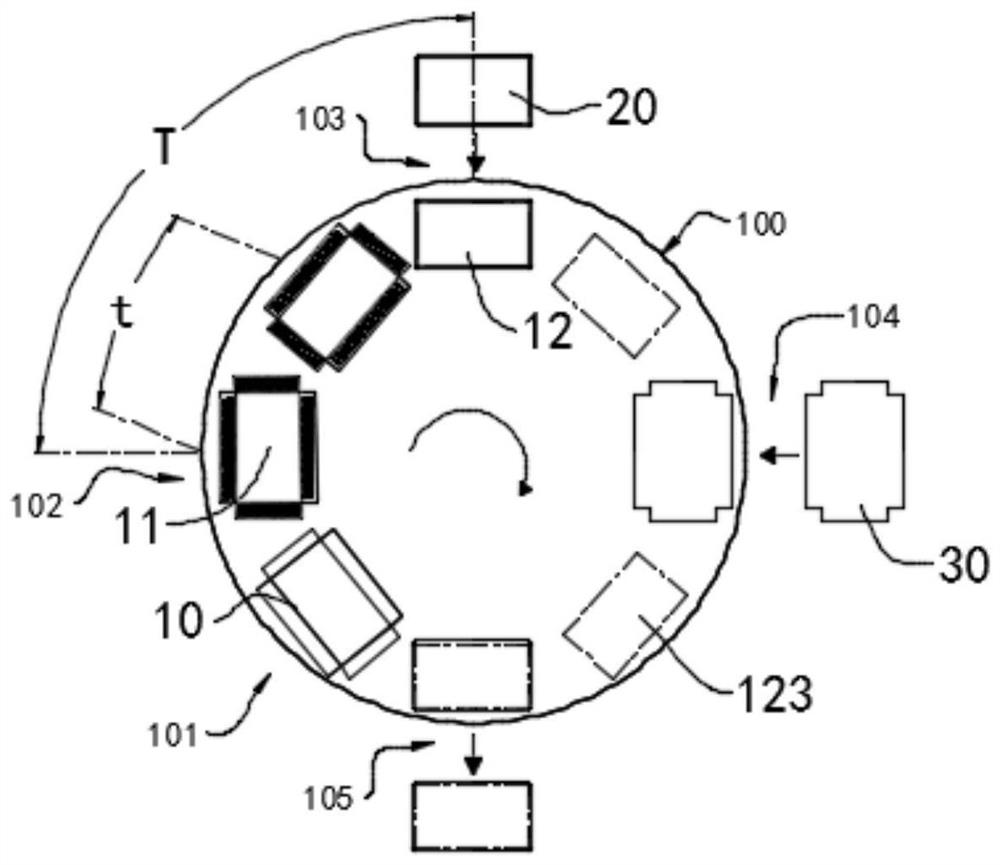

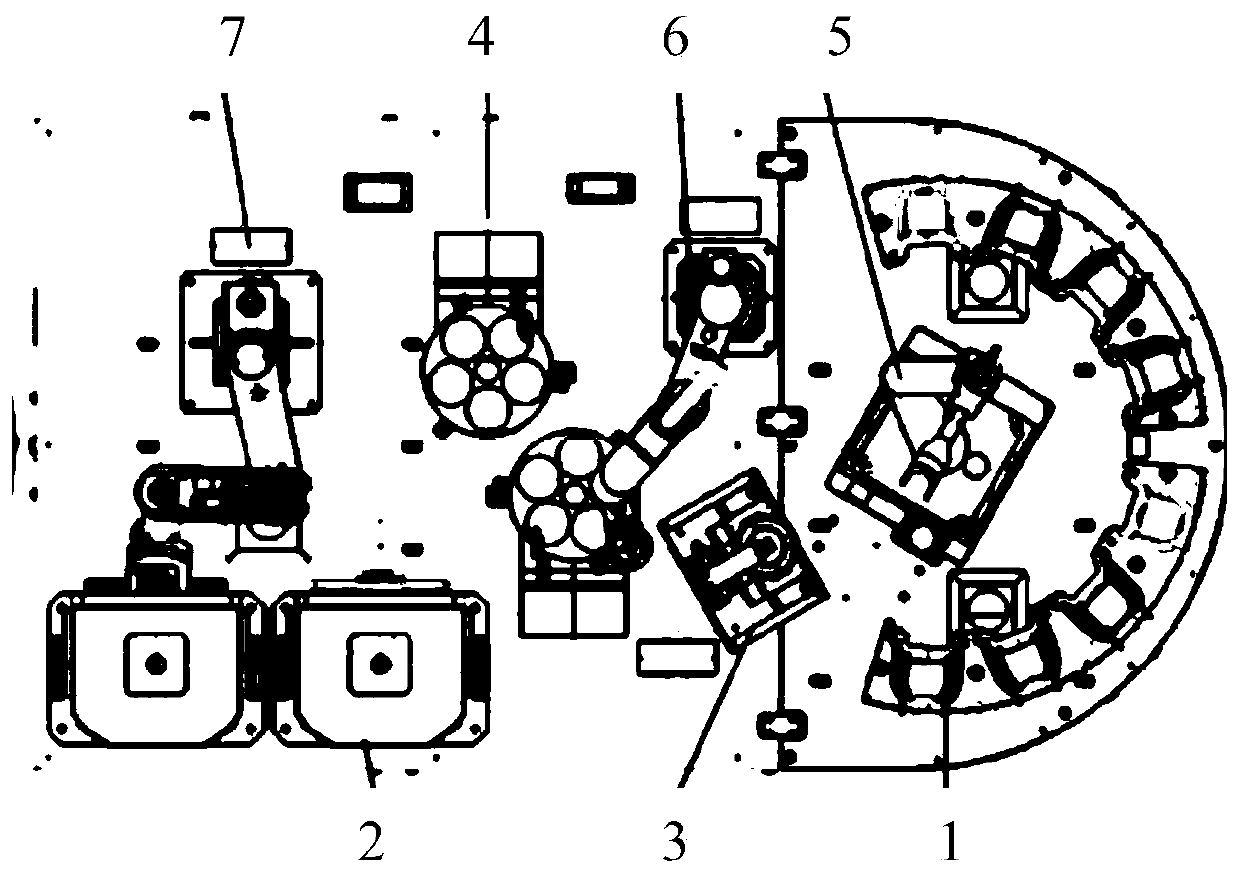

Wafer turnover device and wafer turnover method

ActiveCN109712923AImprove pass rateImprove the efficiency of the production processSemiconductor/solid-state device manufacturingConveyor partsWafer dicingEngineering

The invention discloses a wafer turnover device and a wafer turnover method. The wafer turnover device comprises a wafer box carrying table, a wafer disc carrying table, a first transfer table, a second transfer table, three carrying mechanisms and a control unit. The first transfer table comprises a wafer edge finder for identifying and adjusting the flat edge position of a wafer; and the secondtransfer table comprises a wafer disc edge finder for identifying and adjusting the flat edge position of a bearing part of a wafer disc. The control unit controls the three carrying mechanisms to transfer wafers between the wafer box carrying table and the wafer edge finder, between the wafer edge finder and the wafer disc edge finder and between the wafer disc edge finder and the wafer disc carrying table, so that the wafers can be efficiently carried from the wafer box carrying table to the wafer disc carrying table or from the wafer disc carrying table to the wafer box carrying table.

Owner:上海福赛特机器人股份有限公司

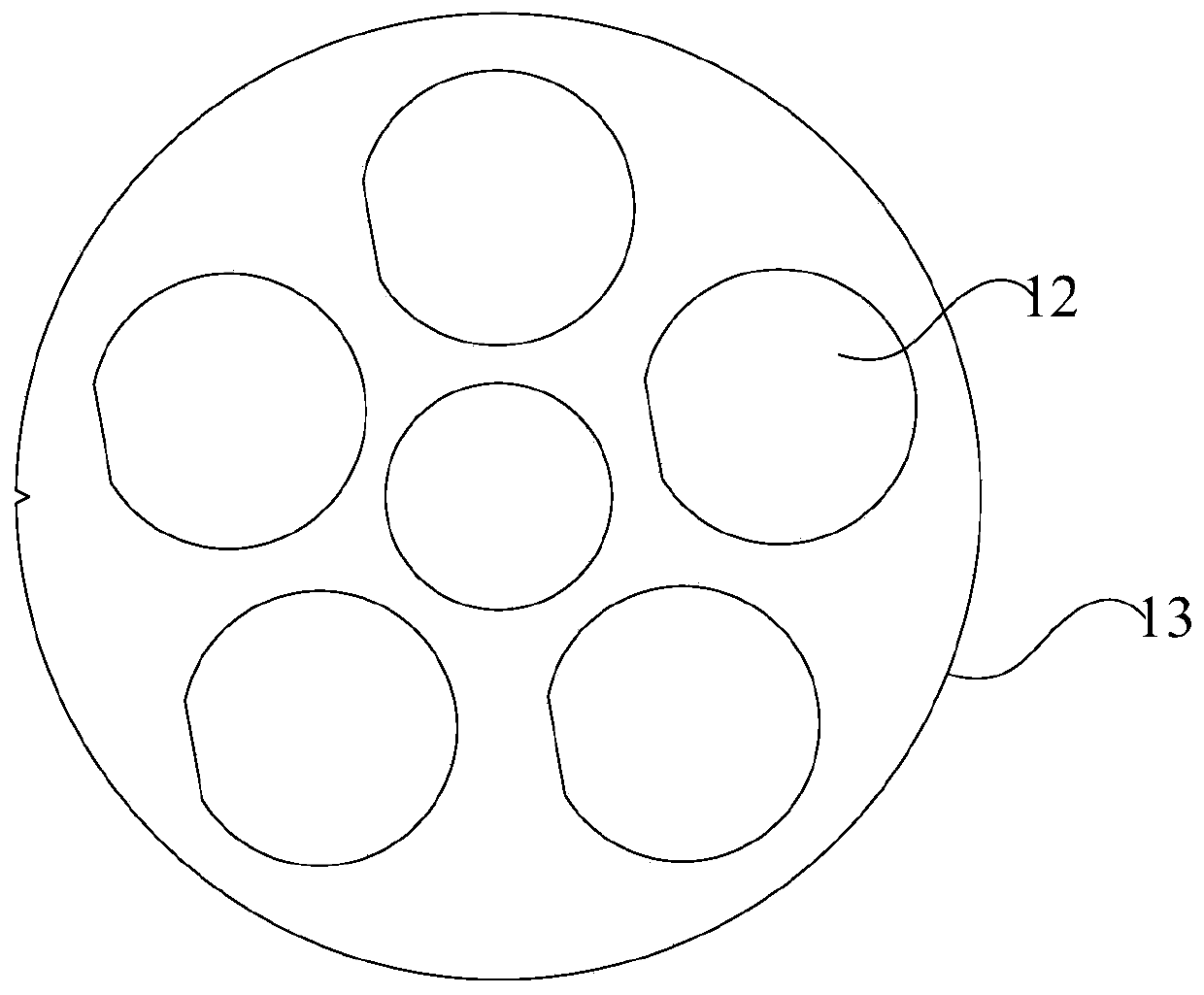

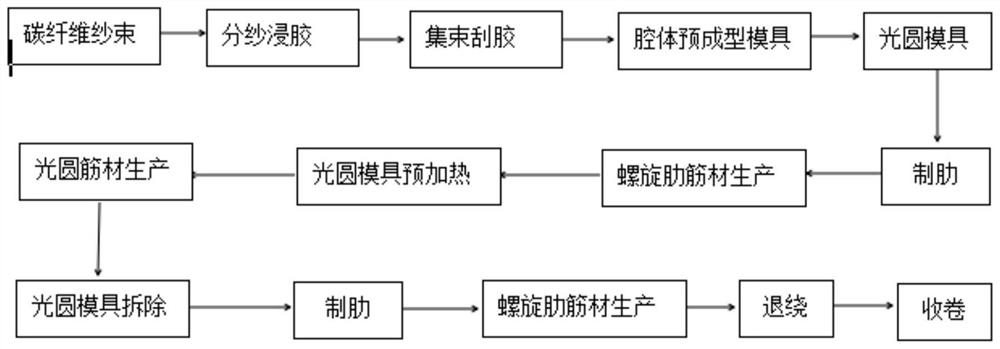

Carbon fiber composite material rib with spiral resin ribs at two ends and preparation method thereof

PendingCN111877158AImprove reliabilitySmall deviation in outer diameterBridge structural detailsDomestic articlesEpoxyFiber bundle

The invention relates to a carbon fiber composite material rib with spiral resin ribs at two ends and a preparation method thereof; wherein a core part is a unidirectional carbon fiber reinforced epoxy resin matrix composite material, the end part of the rib material is used as an anchoring section, the outer surface of the anchoring section is provided with a continuous spiral rib structure, andthe middle section of the rib material is the outer surface of a plain circle. The volume content of the carbon fiber bundles in the rib material is 65%-78%. The cured resin on the surface of the ribmaterial can form a spiral rib or keep a smooth round state according to the purposes of different areas and requirements. With a bridge inhaul cable as an example, the two ends of a rib material aremachined into spiral rib structures to serve as anchoring sections, anchoring reliability can be improved, resin spiral ribs are formed on the anchoring sections, the middle section between the two anchoring sections is kept smooth and round, and uniform distribution of tensile stress is facilitated.

Owner:FASTEN HONGSHENG GRP CO LTD +1

Movable frame base driven by bevel gears

InactiveCN106151783AEasy off chainReduce friction areaPortable framesToothed gearingsFrame basedGear wheel

The invention discloses a movable frame base driven by bevel gears. The base comprises straight beams, longitudinal beams, bearing fixing supports, bearing block fixing parts, intermediate driving shafts, straight driving shafts, edge driving shafts, cast iron travelling wheels, PA204 bearings, UELFLU204 bearings with rhombohedral seats, 21-tooth chain wheels, bevel gears 40, bevel gears 20 and bearing blocks. The movable frame base has the advantages that the driving cost is lower than that of a mechanical gear in the former application, the defect that the size of the frame body of the original mechanical gear is changed is overcome, the matching flexibility of the bevel gears 40 and the bevel gears 20 is good, the borne torsion is large, the movable frame base is small in hand feeling force, reasonable in travelling speed, high in synchronization performance, large in torsion, small in matching friction for bevel gear driving, good in attractive effect, low in cost and simple in process, and the change of the size of the frame body is not restrained, so that the quality and brand power of a product of our company are greatly improved, and the production process efficiency is also greatly increased.

Owner:JIANGXI HUAXIN STEEL YI TECH LTD

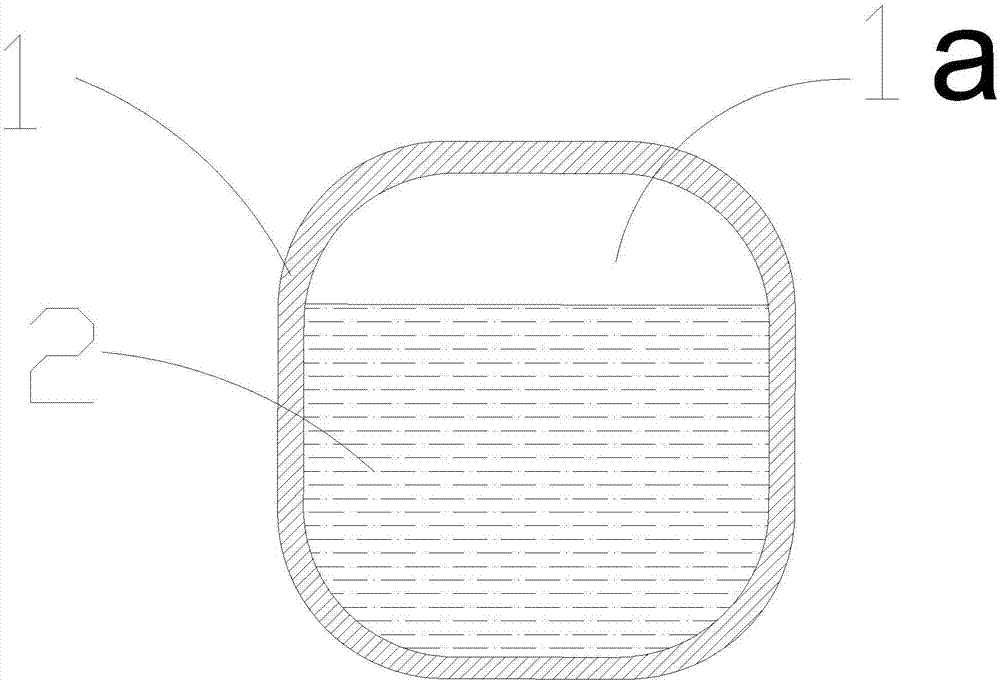

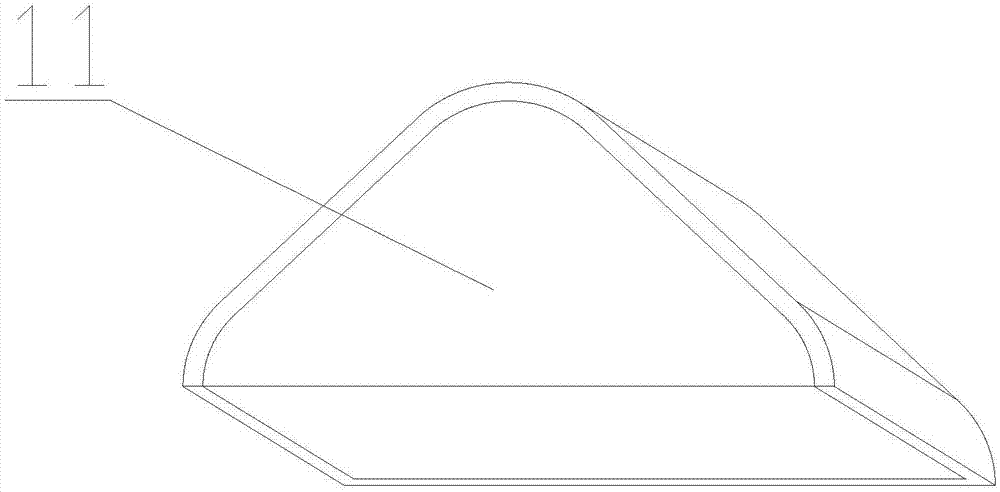

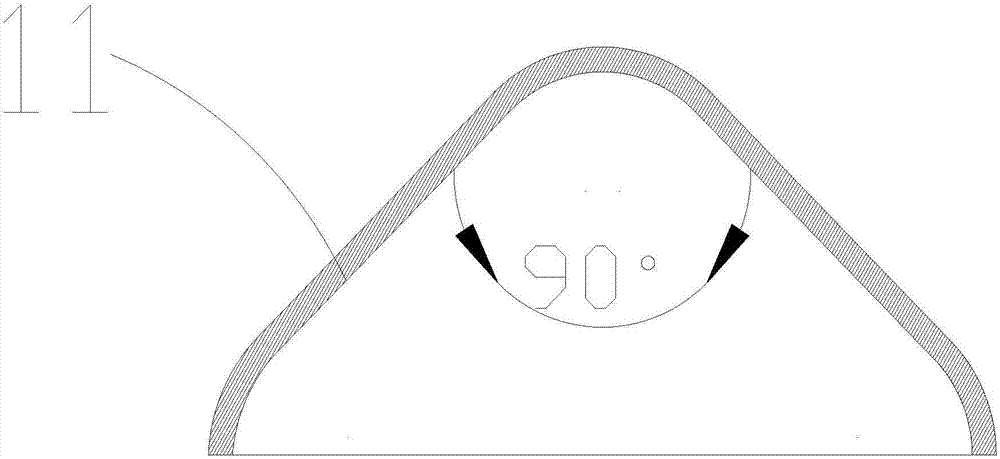

Novel elastic supporting block type foaming base plate for non-slag track and manufacturing process thereof

A foaming base plate is made of a blend. The blend comprises, by weight parts, ethylene propylene diene monomer rubber, zinc oxide, stearic acid, N-isopropyl N'-phenyl p-phenylenediamine, 2,2,4-trimethyl-1,2-dihydroquinoline polymer, microcrystalline wax, fast extruding carbon black, high abrasion resistant carbon black, polyethylene glycol, paraffin oil, sulfur, triallyl isocyanurate, tetramethylthiuram disulfide, 2,2'-dithio-bisbenzothiazole, azodicarbonamide and 4,4'-dioxylbisbenzensulfonyl hydrazide. According to the foaming base plate, a novel formula is adopted, the pass rate of the product is greatly improved, the uniformity of the foaming pore diameter of the product is obviously improved, and the stability of the product is obviously improved.

Owner:湖南昶力轨道交通设备有限公司

Production technology of metal ice particles

ActiveCN107283135AImprove the cooling effectHigh production process efficiencyMetallurgyCooling effect

The invention discloses a production technology of metal ice particles. The production technology comprises the steps of (1) cutting a metal sheet; (2) manufacturing metal components; (3) forming through holes in the side walls of a part of metal outer shells; (4) welding one metal component with through holes and another metal component without through holes, and manufacturing one hollow metal outer shell with an airtight cavity inside which communicates with the exterior through the through holes; (5) injecting a coolant through the through holes; (6) sealing the through holes through welding; and (7) carrying out grinding and polishing. Through the adoption of the technical scheme, the metal ice particles can be produced, reutilization is facilitated, and beverages are not diluted and do not go bad; the coolant is sealed in the metal outer shells, and the cooling effect of the metal ice particles is greatly improved; and production efficiency is high, manufacturing is facilitated, and grinding and polishing treatment intensity is low.

Owner:中山市品派生活日用制品有限公司

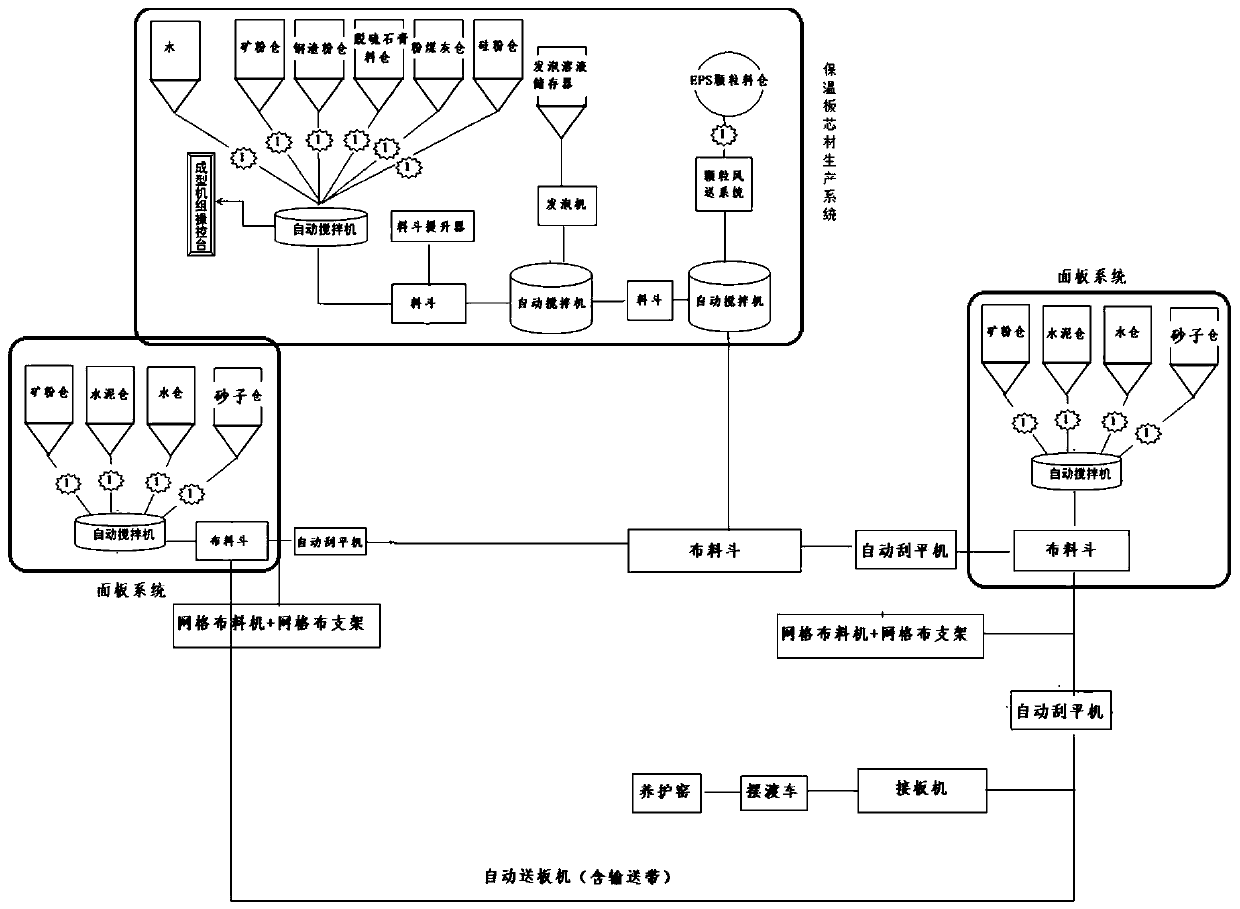

Production method for producing lightweight thermal insulation structure integrated board through flat die process

InactiveCN109747035AIncrease the level of automationImprove efficiencyCeramic shaping plantsCement mixing apparatusSurface layerAdditive ingredient

The invention discloses a production method for producing a lightweight thermal insulation structure integrated board through a flat die process, and belongs to the field of construction. The method comprises the following steps that a flat die system is mounted on a conveyor belt of an automatic board feeding system; ingredients of a structural panel and water are uniformly mixed through a panelproduction system, first structural panel slurry is obtained, a die of the flat die system is conveyed by the automatic board feeding system to a discharge outlet of the panel production system, and afirst structural panel is prepared; ingredients of a foam insulation core board and water are reasonably mixed through an insulation board production system, foaming slurry is prepared, and the foaming slurry is laid on the surface layer of the first structural panel through the discharge outlet; and the ingredients of the structural panel and water are mixed evenly, second structural panel slurry is obtained, the second structural panel slurry is laid on a foaming slurry layer through the discharge outlet, and the thermal insulation structure integrated board is obtained through subsequent curing. The integrally-cast thermal insulation core board and the structural panel are produced automatically, and thus the thermal insulation structure integrated board with firm adhesion is obtained.

Owner:北京新时代寰宇科技发展有限公司

Preparation method of lycopene microemulsion improving fruit quality

InactiveCN106831134AReduce manufacturing costNutritiousNitrogenous fertilisersOrganic fertilisersSodium bicarbonateVegetable oil

The invention relates to preparation and application of a lycopene microemulsion improving fruit quality. The preparation method comprises the following steps: 1) adding vegetable oil to tomato raw materials, heating to 100-150 DEG C, and stirring for 2-3 hours; 2) transferring the solution in the step 1) into an extraction tank, adding a sodium hydrogen carbonate water solution, standing at room temperature for 1-3 hours, discarding the sublayer turbid liquid, and taking the supernate clear liquid for later use; 3) adding D-alpha-Tocopheryl polyethylene glycol 1000 succinate (TPGS) and Tween-80 into the clear liquid in the step 2), and uniformly stirring; 4) adding a right amount of deionized water into the solution in the step 3), and vigorously stirring for 0.5-1 hour; and 5) weighing a right amount of phenylalanine, glutamic acid, leucine and threonine, adding into the solution in the step 4), stirring to dissolution, and filling to obtain a crop nutrient solution. The product exogenously supplements fruit lycopene in a foliage spray manner, obviously improves fruit quality, indirectly increases the income of fruit growers and promotes the production enthusiasm of the fruit growers, thereby having great application value.

Owner:YANTAI GOODLY BIOTECH

Lithium battery core package structure x-ray detection system and detection method

ActiveCN106945890BImprove detection efficiencyRealize continuous detectionPackaging automatic controlMaterial analysis by transmitting radiationAutomatic transmissionX-ray

The invention discloses a lithium battery core cladding structure X-Ray detection system and a detection method. The lithium battery core cladding X-Ray detection system is characterized in that the lithium battery core cladding X-Ray detection system comprises a transmission device, a feeding and discharging device and an X-Ray detection device. A lithium battery core cladding is transferred and transported to the feeding and discharging device through a transmission device. The X-Ray detection device carries out the structure detection to the lithium battery core cladding transported from the feeding and discharging device. After detection the lithium battery core cladding is transported to a detected area. The X detection device comprises a frame, an automatic door, a display device, a operating table and a detection part. The display device and the operating table are arranged on the side of the frame. The automatic door is arranged on the front side of the frame. The detection part is arranged at the lower end of the frame. According to the lithium battery core cladding structure X-Ray detection system and the detection method, a series of automatic technological process of automatic transmission, automatic feeding and discharging and automatic detection of the lithium battery core cladding is realized. A protective net is adopted in the feeding and discharging device area, and the safety of the system and personnel is protected. In addition, the X-Ray detection device uses a fully enclosed protective cover, and the X Ray radiation is effectively isolated.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +1

A method for preparing iron-based magnetostrictive coatings using thermal spraying technology

ActiveCN105252011BHigh magnetostriction coefficientNot easily oxidizedMolten spray coatingPorosityThermal spraying

The invention discloses a method for preparing an iron-based magnetostrictive coating by using a thermal spraying technology, which belongs to the field of magnetic materials. The iron-based magnetostrictive material is firstly prepared into spherical gas-atomized powder, and then the metal material is used as the substrate, and the spherical gas-atomized powder is sprayed onto the metal substrate by plasma spraying to prepare the iron-based magnetostrictive coating. The specific steps are to first melt the iron-based magnetostrictive material into an ingot in a vacuum melting furnace, remove the scale on the surface by machining, and then send the ingot to a high-pressure atomization powder making device, and melt the ingot through a high-speed argon gas flow. The alloy stream breaks up into small droplets and condenses into powder. Thermal spraying technology adopts plasma spraying. The plasma gas is mainly nitrogen, supplemented by hydrogen. The iron-based magnetostrictive gas atomized powder is sent into the plasma chamber, and the coating is formed by heating, melting, flying, impacting the substrate, cooling and solidification. Its advantages are: high bonding strength of the coating, fine structure, low porosity, and the addition of alloying elements reduces oxide slag inclusions.

Owner:UNIV OF SCI & TECH BEIJING

Production mold and production process of special-shaped prefabricated heat insulating pipe member

PendingCN110394937AHigh densityIncrease productivityTubular articlesEngineeringMechanical engineering

The invention relates to a production mold of a special-shaped prefabricated heat insulating pipe member. The production mold comprises an upper mold, a lower mold and an outer protective pipe; an upper foaming cavity is formed in the lower portion of the upper mold, a lower foaming cavity is formed in the upper portion of the lower mold, upper side plates are arranged at the two ends of the upperfoaming cavity, upper semicircular holes are formed in the centers of the lower positions of the upper side plates, lower side plates are arranged at the two ends of the lower foaming cavity, and lower semicircular holes are formed in the centers of the lower positions of the lower portions of the lower side plates; and a foaming mold cavity with a round cross section is formed by the upper foaming cavity and the lower foaming cavity when the upper mold and the lower mold are closed, inner pipe perforation holes with round cross sections are formed by the upper semicircular holes and the lower semicircular holes, and the foaming mold cavity and the inner pipe perforation holes are concentric; and the outer protective pipe comprises an upper protective shell and a lower protective shell which are buckled into a barrel. By means of the production mold, the density of a polyurethane layer can be improved, the production efficiency of the special-shaped prefabricated heat insulating pipeis improved, and the production mold is easy to learn and easy to use.

Owner:HENAN SANJIE THERMOELECTRIC TECH

Sectional type heat dissipation film with edge sealing design

PendingCN111019548AEasy to operateImprove efficiencyCooling/ventilation/heating modificationsFilm/foil adhesive release linersColloidal silicaCopper foil

The invention provides an edge sealing design sectional type heat dissipation film, which comprises an antistatic silica gel protection layer, a graphite layer, a copper foil double-sided adhesive tape and a PET double-sided antistatic release layer, wherein the antistatic silica gel protection layer, the graphite layer, the copper foil double-sided adhesive tape and the PET double-sided antistatic release layer are sequentially arranged in a stacked mode, the antistatic silica gel protection layer comprises a first protective film and a second protective film, the first protective film and the second protective film are arranged in a split mode, the graphite layer comprises a first graphite flake and a second graphite flake, the first graphite flake and the second graphite flake are integrally arranged, the PET double-sided antistatic release layer comprises a first antistatic release film and a second antistatic release film, the first antistatic release film and the second antistatic release film are arranged in a split mode, the first protective film, the first graphite flake and the first antistatic release film are stacked together to form a first heat dissipation section, and the second protective film, the second graphite flake, the copper foil double-sided adhesive tape and the second antistatic release film are stacked together to form a second heat dissipation section. According to the invention, the heat dissipation film adopts a sectional design, the continuous attachment of different areas on a main board can be realized through the same film product, the attachment operation of the heat dissipation film is simplified, and the efficiency of a production process is improved.

Owner:苏州佳值电子工业有限公司

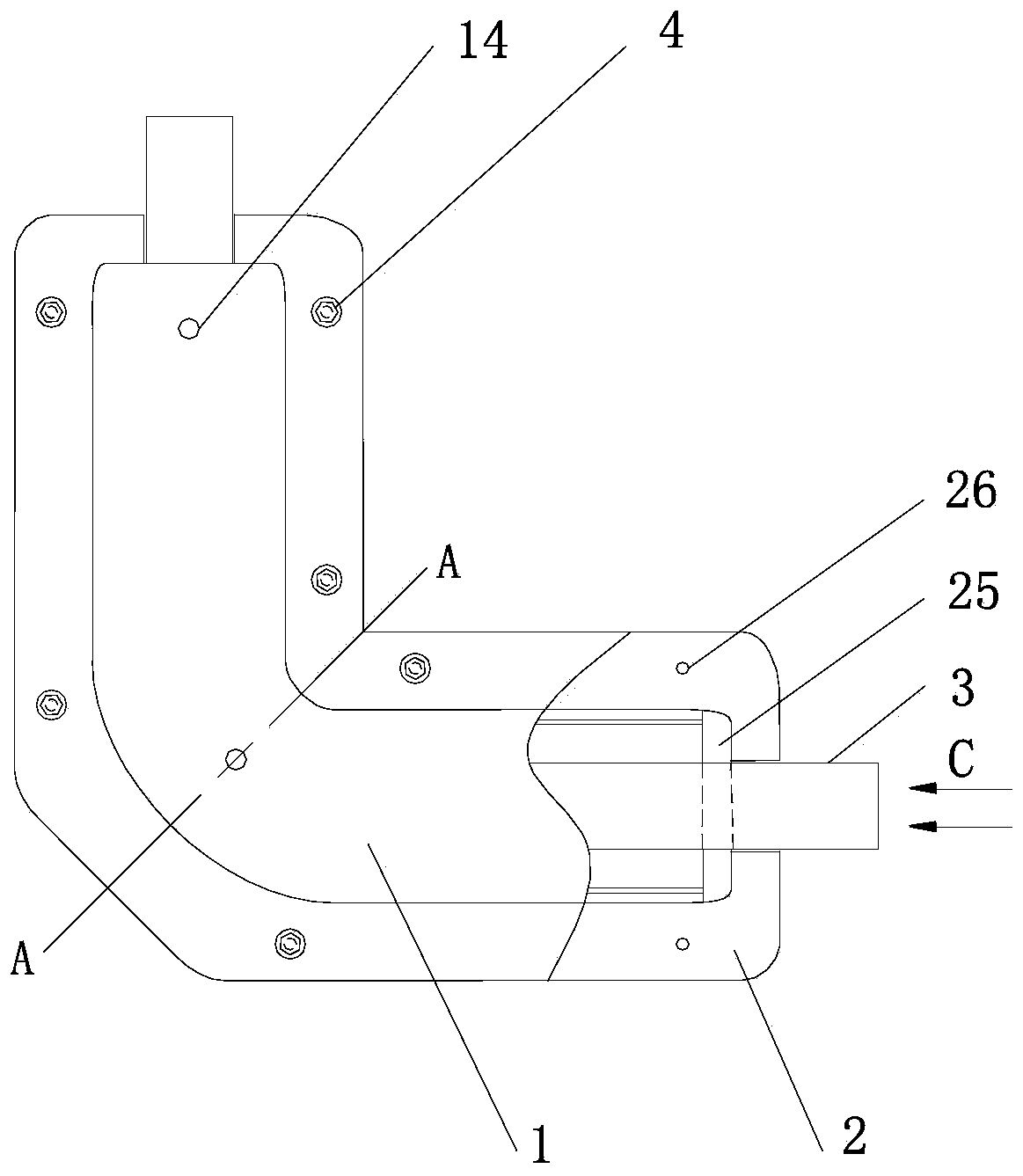

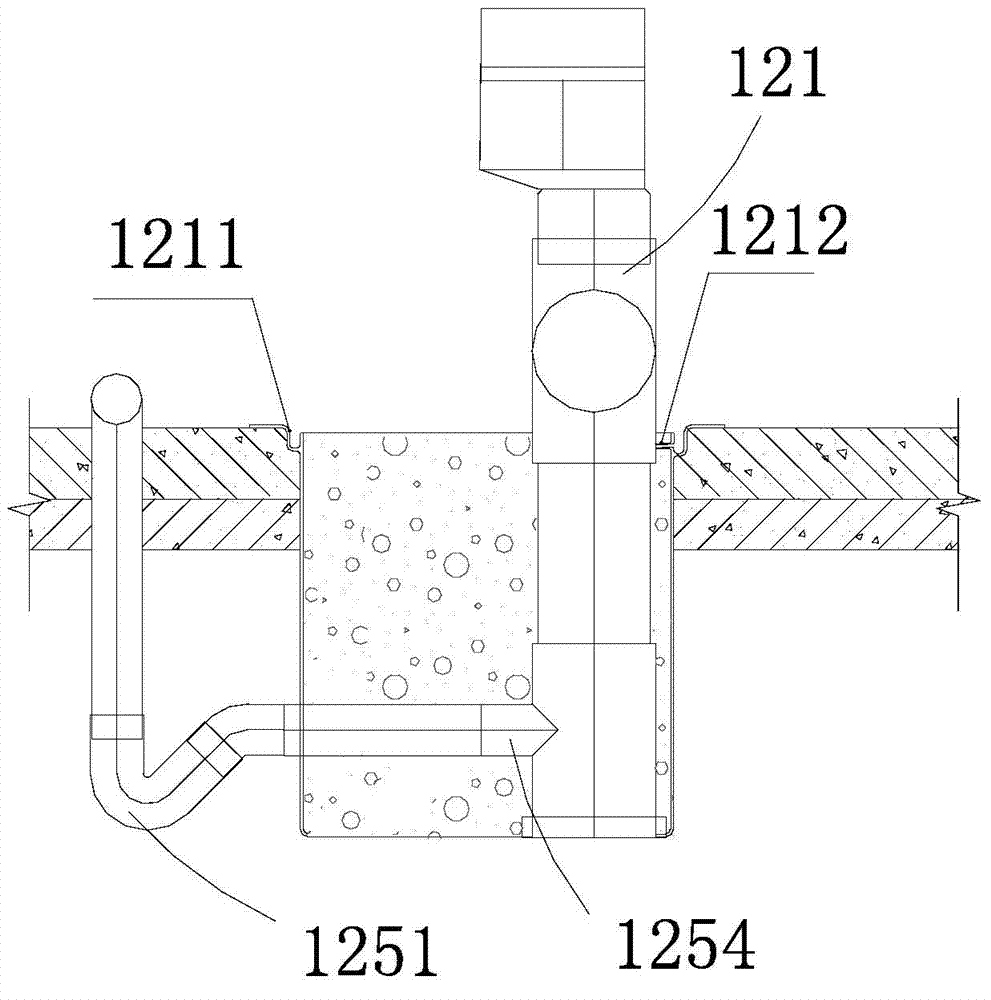

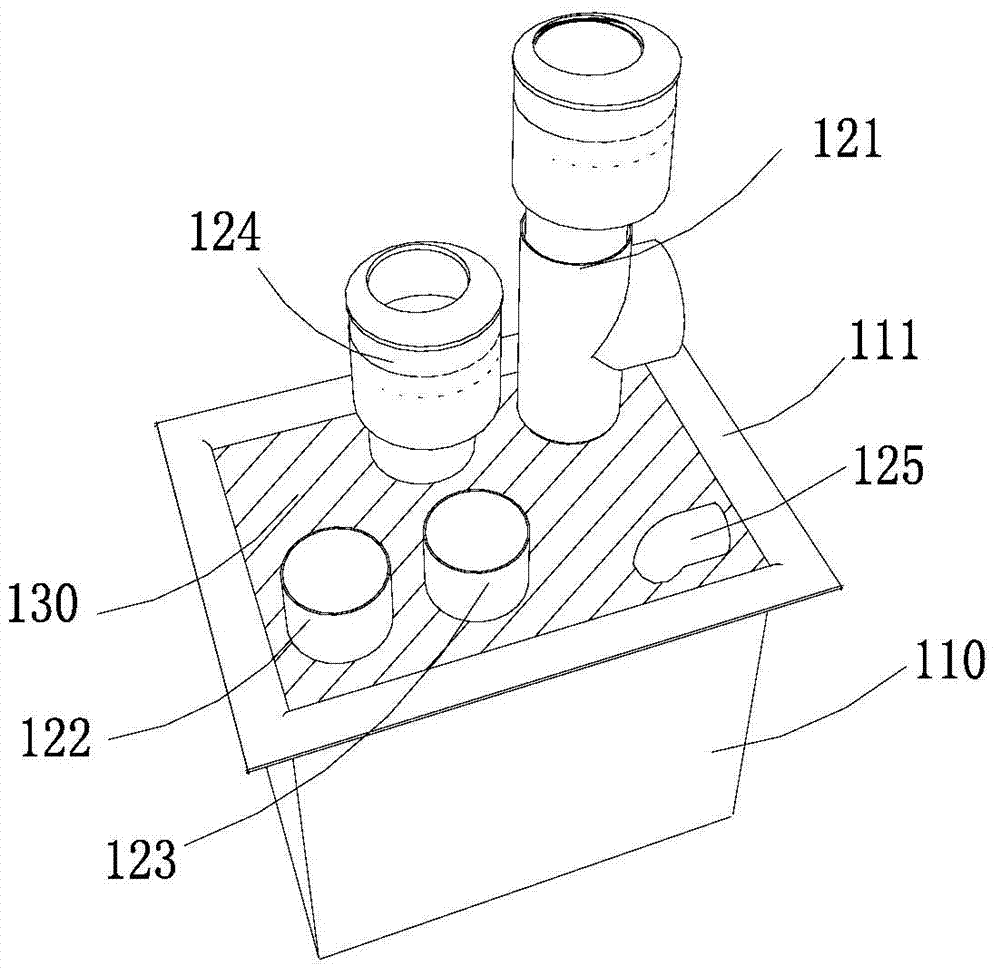

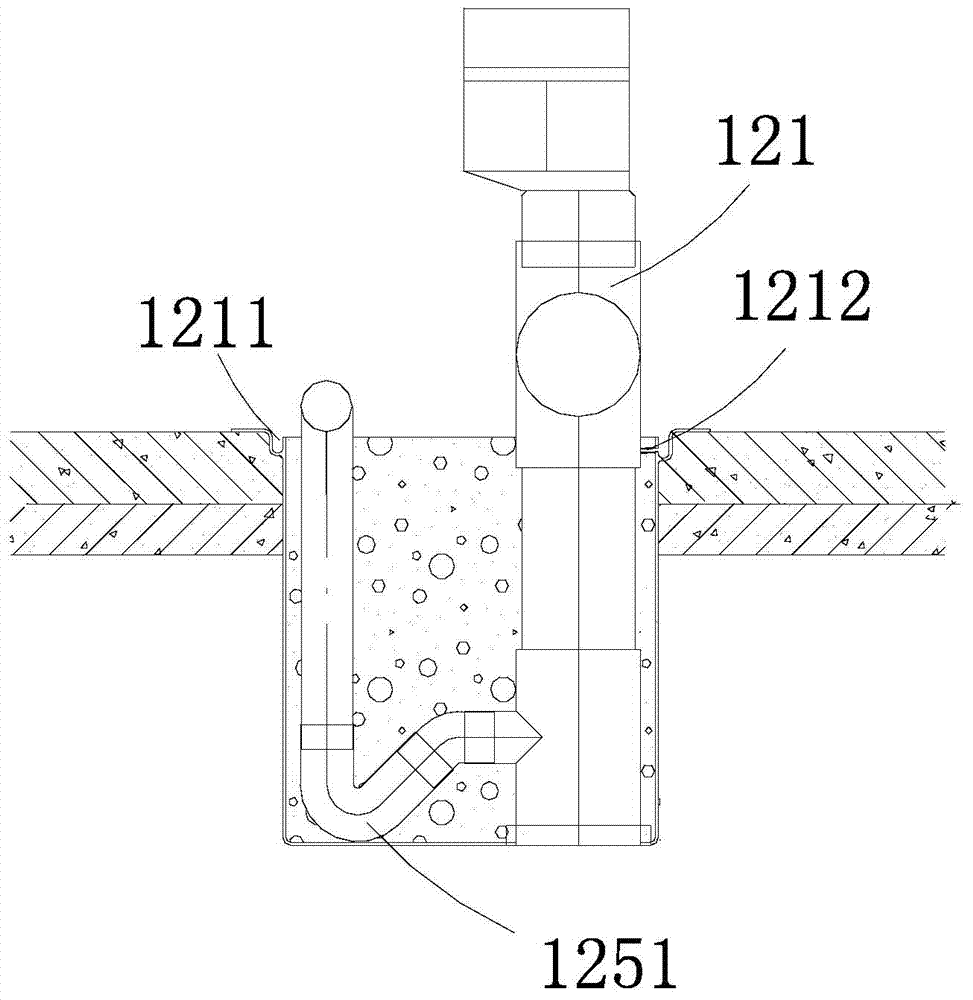

Bathroom

ActiveCN104727391ASolve the blockageSolve the problem of stagnant waterDomestic plumbingSpecial buildingWater storageOperating energy

The invention provides a bathroom comprising a water supply and drainage system and a sinking caisson, wherein the water supply and drainage system comprises a drainage riser, a water supply riser, floor drain water storage elbows and a water supply and drainage integrated module; the water supply and drainage integrated module comprises a module body and preset pipelines, and the preset pipelines are preset and integrated in the module body; the floor drain water storage elbows are arranged in the sinking caisson; and all the floor drain water storage elbows, the drainage riser and the water supply riser are connected with the preset pipelines. According to the scheme, various pipelines in a building are preset and integrated together by using the water supply and drainage integrated module, the water supply and drainage integrated module is only needed to be mounted in a reserved hole (for example, an equipment well hole) of each floor in building construction, and then, the riser between an upper floor and a lower floor is mounted, so that the works of mounting and connecting pipelines in the building are finished, the mounting speed is very high, the environment pollution is little, few accessories are needed to be assembled on site, and the assembling workload is small.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

Copper wire production process capable of reducing oxidation and production line thereof

InactiveCN113333493ADoes not affect deliveryEfficient removalDrying solid materials without heatFurnace typesProduction lineCopper wire

The invention discloses a copper wire production process capable of reducing oxidation and a production line thereof. The production line comprises a treatment chamber, a wire gathering chamber, a condensation chamber, a conveying chamber and an annealing furnace, wherein a plurality of inlets and outlets are formed in the two side walls of the treatment chamber; a supporting frame is installed in an inner cavity of the treatment chamber; a turnover cylinder is rotationally arranged on the supporting frame; a scraping ring is installed on the inner wall of the turnover cylinder; two first mounting pipes and two second mounting pipes are installed on the inner wall of the turnover cylinder; and a plurality of nozzles are installed on the first mounting pipes and the second mounting pipes. According to the production line, surface oxides of a plurality of steel wires can be treated at the same time, the oxides on the surfaces of the steel wires are efficiently removed through pickling solution spraying, oxide scraping and three times of surface oxide removal treatment before and after pickling solution spraying, conveying of the steel wires is not affected while removal is conducted, the efficiency of the whole production process is improved, the prepared pickling solution has a good treatment effect on the oxides on the surfaces of the steel wires, and the wire drawing effect is improved.

Owner:杭州普昌科技有限公司

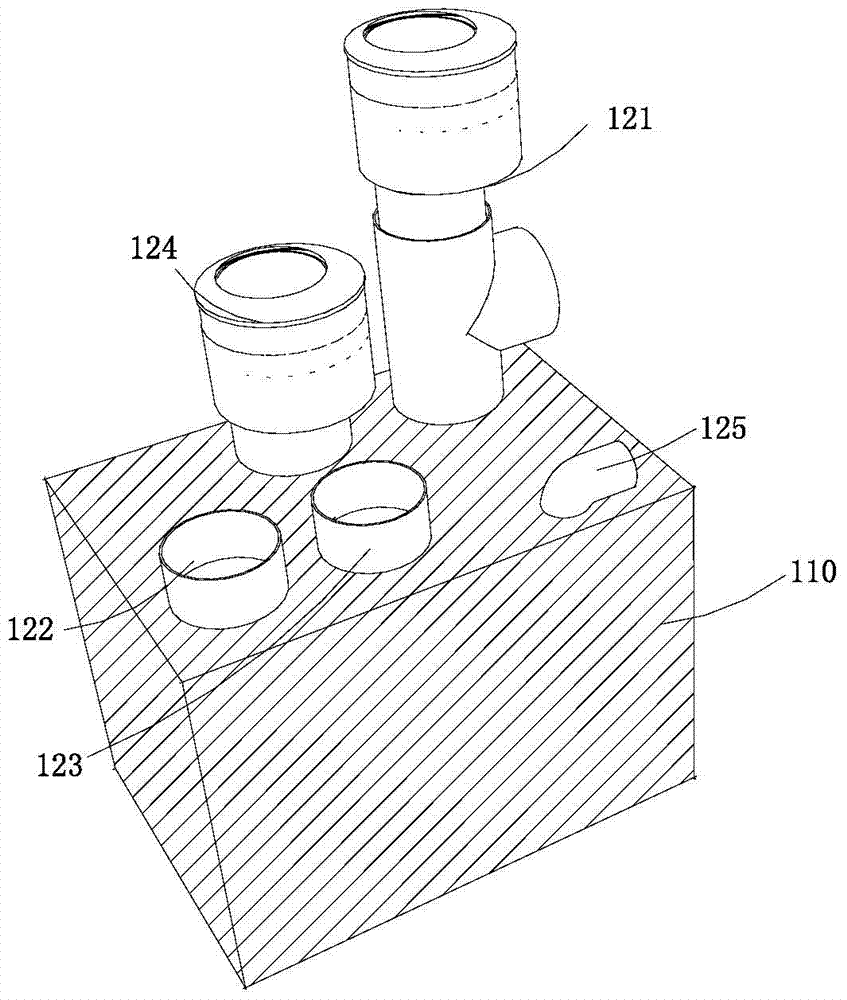

Bathroom

InactiveCN104727396ASolve the blockageSolve the problem of stagnant waterDomestic plumbingSpecial buildingWater storageEngineering

The invention provides a bathroom comprising wall bodies and a water supply and drainage system, wherein the water supply and drainage system comprises a drainage riser, a water supply riser, side wall floor drains and a water supply and drainage integrated module; the water supply and drainage integrated module comprises a module body, floor drain water storage elbows and preset pipelines, and both the preset pipelines and the floor drain water storage elbows are preset and integrated in the module body; the side wall floor drains are arranged at the lower parts of the wall bodies; and both the drainage riser and the water supply riser are connected with the preset pipelines, one ends of the floor drain water storage elbows are connected with the side wall floor drains, the other ends of the floor drain water storage elbows are connected with drain pipes, and a storage space formed by a connecting interlayer is arranged at a corner of the adjacent wall bodies. The side wall floor drains are adopted and are arranged at the lower parts of the wall bodies of the bathroom, so that drain pipelines of the floor drains can be arranged in the wall bodies, and furthermore, the problem of complex construction caused by arranging pipelines below the bottom plate of the bathroom is solved.

Owner:CHINA MINSHENG ZHUYOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com