Production method for producing lightweight thermal insulation structure integrated board through flat die process

A production method and integrated board technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve problems such as fire spread, large construction area, and no fire protection, and achieve waste reduction, high efficiency, and good thermal insulation and fire performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

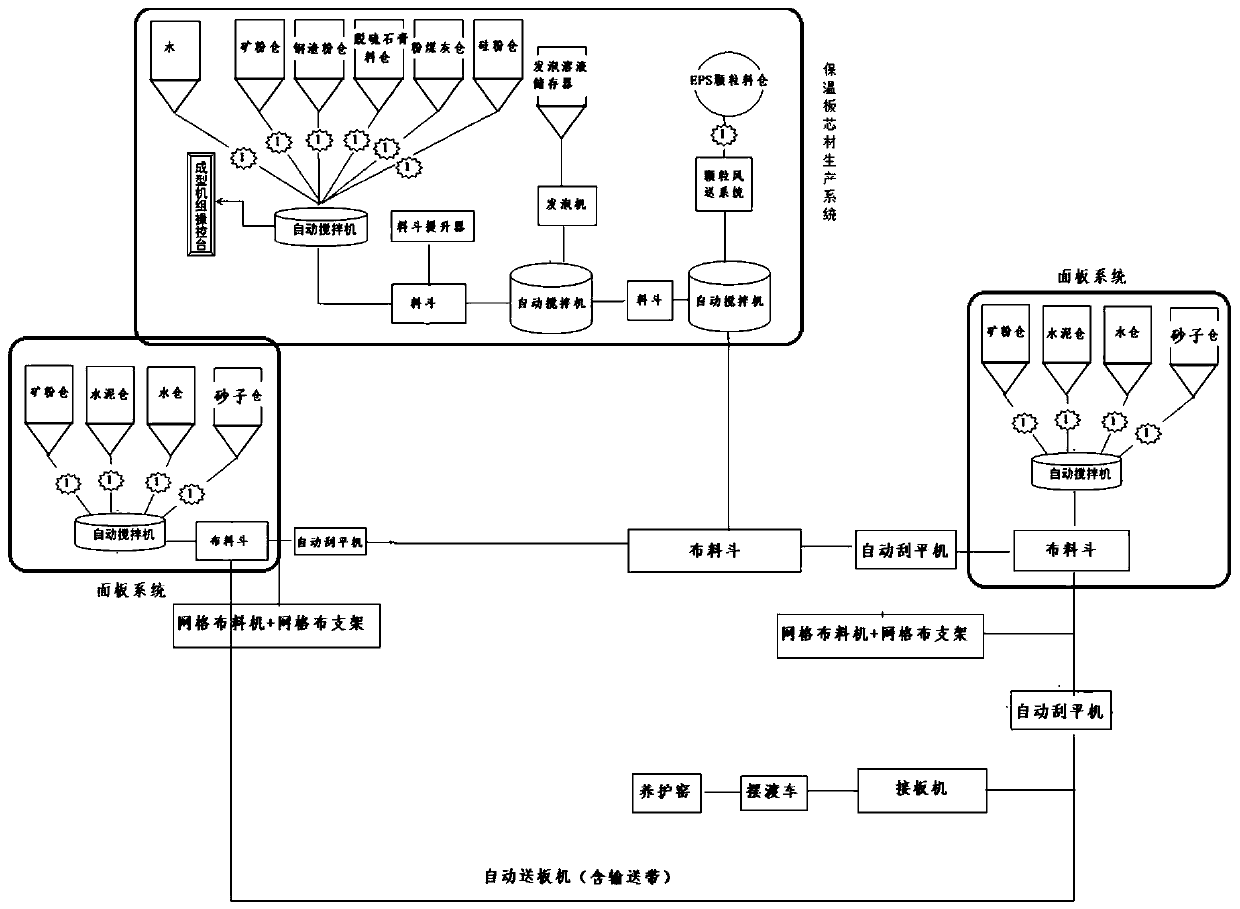

Method used

Image

Examples

Embodiment 1

[0068] The composition formula of the thermal insulation structure integrated board 1 is:

[0069]The formulation of the foam insulation core board includes the following raw materials in parts by weight: 100 parts by weight of gelling material A, 1 part by weight of mineral activator, 0.16 parts by weight of fiber, 3 parts by weight of foaming agent, 0.02 parts by weight of water reducing agent and foam stabilizer 0.1 parts by weight; the composition of the cementitious material includes the following parts by weight of micropowder raw materials: 30 parts of slag micropowder, 40 parts of steel slag micropowder, 15 parts of desulfurized gypsum, 10 parts of fly ash, 5 parts of silicon powder and 3 parts by weight of polyphenylene particles.

[0070] The formula composition of the structural panel includes the following raw materials by weight: 100 parts by weight of cementitious material B, 300 parts by weight of sand, 1 part by weight of water reducing agent, 3 parts by weight ...

Embodiment 2

[0072] The composition formula of the thermal insulation structure integrated board 2 is:

[0073] The formulation of the foam insulation core board includes the following raw materials by weight: 100 parts by weight of gelling material A, 1 part by weight of mineral activator, 0.2 parts by weight of fiber, 3 parts by weight of foaming agent, 2 parts by weight of water reducing agent and foam stabilizer 0.1 parts by weight; the composition of the cementitious material A includes the following parts by weight of micropowder raw materials: 50 parts of slag micropowder, 14 parts of steel slag micropowder, 10 parts of desulfurized gypsum, 25 parts of fly ash, 1 part of silicon powder and 3 parts by weight of polyphenylene particles .

[0074] The formula composition of the structural panel includes the following raw materials by weight: 100 parts by weight of cementitious material B, 300 parts by weight of sand, 1 part by weight of water reducing agent, 3 parts by weight of lime p...

Embodiment 3

[0076] The composition formula of the thermal insulation structure integrated board 3 is:

[0077] The formulation of the foam insulation core board includes the following raw materials in parts by weight: 100 parts by weight of gelling material, 5 parts by weight of mineral activator, 0.16 parts by weight of fiber, 0.5 part by weight of foaming agent, 0.1 part by weight of water reducing agent and foam stabilizer 0.2 parts by weight; the composition of the cementitious material A includes the following parts by weight of micropowder raw materials: 70 parts of slag micropowder, 10 parts of steel slag micropowder, 9 parts of desulfurized gypsum, 8 parts of fly ash, 3 parts of silicon powder and 3 parts by weight of polyphenylene particles .

[0078] The composition of the structural panel includes the following raw materials by weight: 100 parts by weight of cementitious material B, 300 parts by weight of sand, 0.6 parts by weight of water reducing agent, 5 parts by weight of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com