Atomizing rotary spray disc for fertilizer production and granulator

The technology of a granulator and spray disc is applied to the spray device with movable outlet, the spray device, the liquid is divided into bead droplets and other directions, which can solve the problems of easy nozzle blockage, nozzle blockage, inability to adapt to the high viscosity of the melt, etc. To achieve the effect of reducing the probability of solid impurity blockage and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

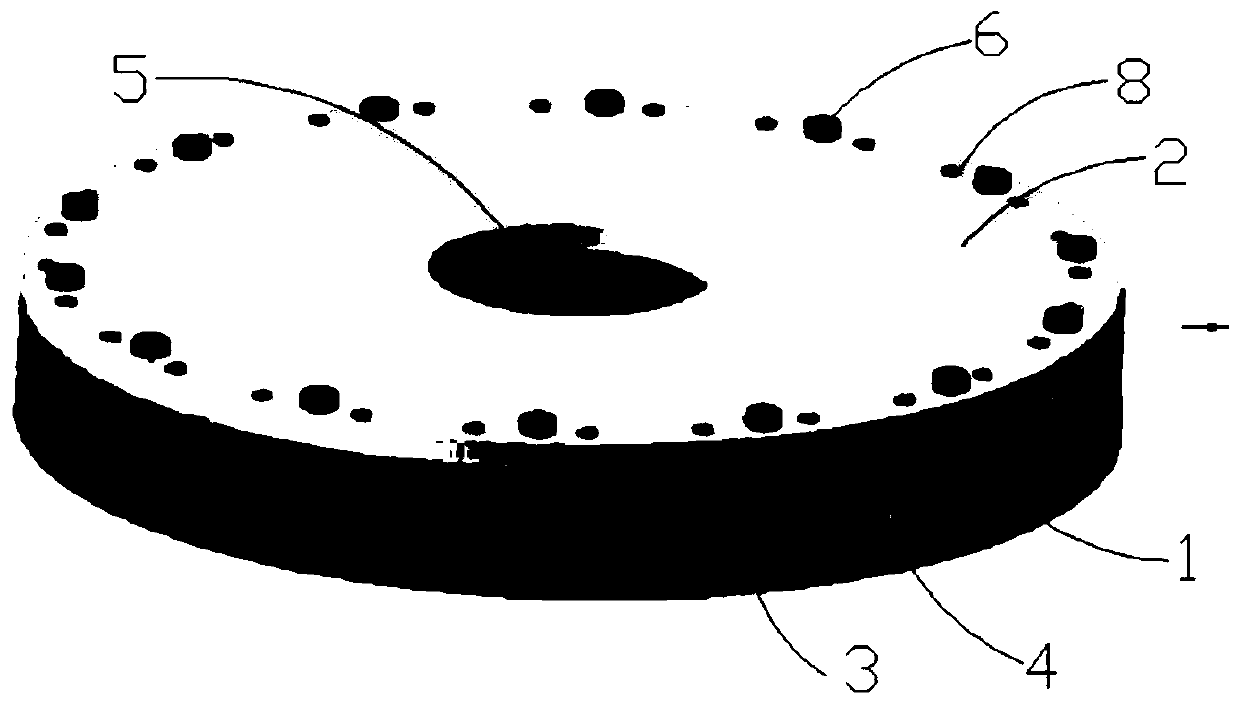

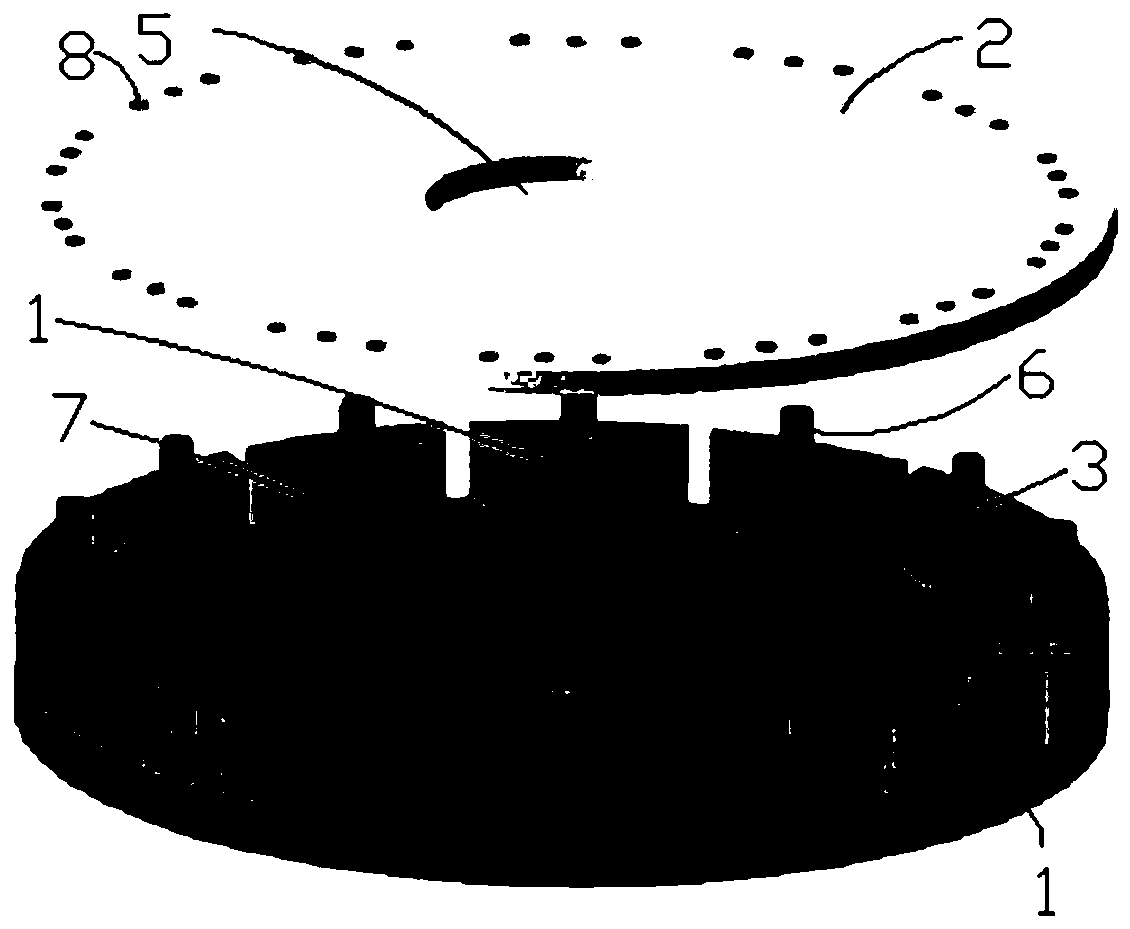

[0035] Such as Figure 1-5 As shown in and 7, an atomizing rotary spray pan 101 includes an upper end plate 2, a lower end plate 1 and a plurality of indexing blocks 3, and a plurality of indexing blocks 3 are evenly distributed at the peripheral edge positions of the lower end plate 1 , the upper end plate 2 is arranged on the indexing block 3 and fixedly connected with the indexing block 3 and the lower end plate 1, specifically, rivets are provided on the upper end plate 2, the lower end plate 1 and the indexing block 3 The hole 8, the upper end plate 2, the indexing block 3 and the lower end plate 1 are fixedly connected by rivets 6 to form a whole.

[0036] The side of the indexing block 3 facing the center of the lower end plate 1 is a protrusion 31, and the protrusion 31 gradually becomes wider from the center to both sides. In this embodiment, the protrusion 31 is a smooth arc protrusion Its cross-section is arc-shaped.

[0037] After the upper end plate 2, the lower...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that the indexing block 3 is integrally formed with the lower end plate 1 , and then the indexing block 3 and the lower end plate 1 are fixed together with the upper end plate 2 by rivets 6 .

Embodiment 3

[0046] The difference between this embodiment and the above embodiment is that, if Figure 6 As shown, the protrusion 31 is a V-shaped protrusion with an isosceles triangle cross section, and the indexing block 3 and the lower end plate 1 are fixedly connected by rivets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com