Method for manufacturing iron-based magnetostrictive coating through thermal spraying technology

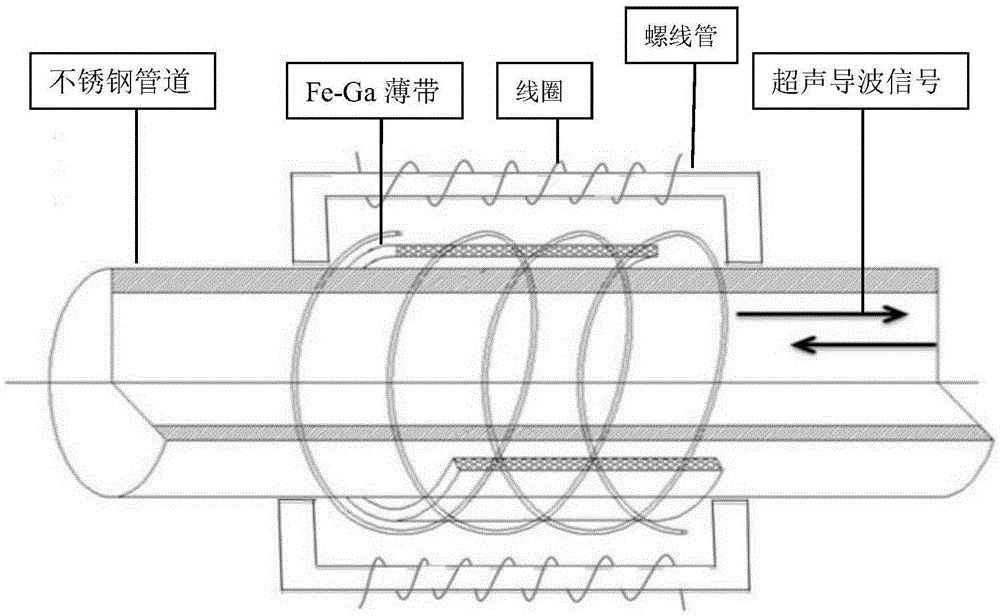

A technology of magnetostrictive and magnetostrictive materials, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of alloy thin strips that cannot be used for a long time, expensive equipment, poor anti-ultraviolet ability, etc. Achieve long-term online monitoring and monitoring, high production process efficiency, and good coating quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

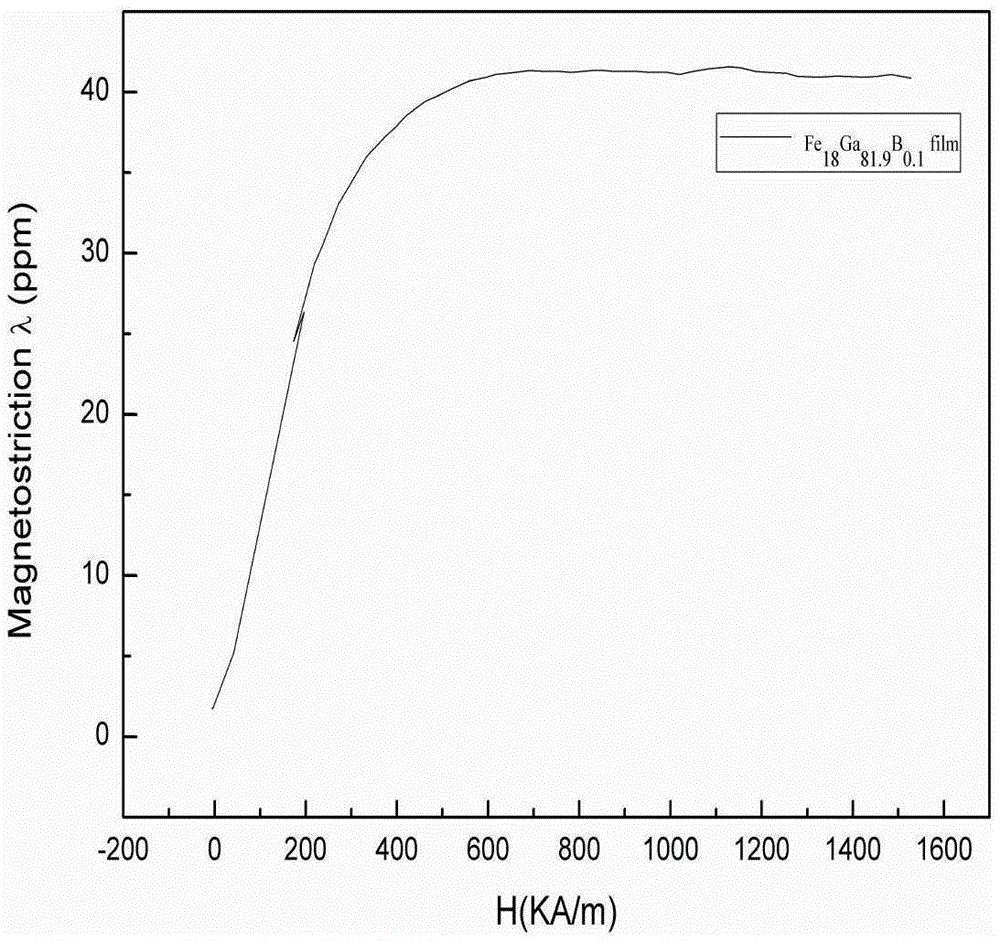

[0040] Embodiment 1: The method for preparing FeGa magnetostrictive coating by thermal spraying technology

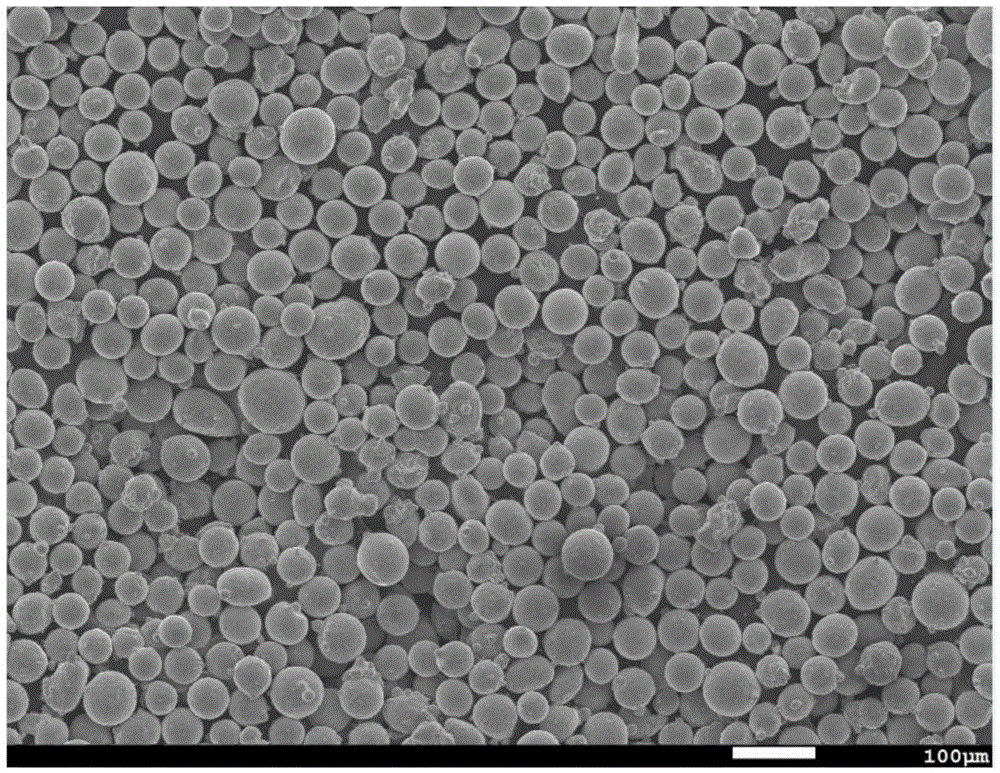

[0041] 1. Preparation of Fe 81 Ga 18.8 B 0.2 (x=13-29) (above x is the atomic fraction), in the vacuum smelting furnace of alumina crucible, carry out melting for the first time to prepare alloy ingot, machine processing removes ingot surface scale, the ingot of pretreatment Put it into the high-pressure gas atomization powder making device for secondary melting, heat it to 1650°C in vacuum for 10 minutes, use high-purity argon as the atomizing gas, atomize the pressure at 3.9Mpa, and spray the powder at 0.5mbar. The high-speed airflow collides with the alloy liquid flow and breaks into spherical aerosolized powders of different particle sizes;

[0042] 2. Clean and remove the oxide skin on the surface of the stainless steel substrate, preheat at 180°C, and the maximum temperature shall not exceed 250°C;

[0043] 3. The plasma gas nitrogen (≥99.995%) and auxiliary g...

Embodiment 2

[0048] Embodiment 2: The method for preparing iron-aluminum magnetostrictive coating by thermal spraying technology

[0049] 1. Preparation of Fe 80 al 19.7 Si 0.3 (x=10-25) (above x is the atomic fraction), in the vacuum smelting furnace of alumina crucible, carry out melting for the first time to prepare alloy ingot, machine processing removes ingot surface scale, the ingot of pretreatment Put it into the high-pressure gas atomization powder making device for secondary smelting, heat it to 1680°C in vacuum for 10 minutes, use high-purity argon as the atomizing gas, the atomizing pressure is 3.7Mpa, and the powder spraying pressure is 0.23mbar. The high-speed airflow collides with the alloy liquid flow and breaks into spherical aerosolized powders of different particle sizes;

[0050] 2. Clean and remove the oxide skin on the surface of the stainless steel substrate, preheat at 200°C, and the maximum temperature shall not exceed 250°C;

[0051] 3. The plasma gas nitrogen ...

Embodiment 3

[0056] Embodiment 3: Utilize the method for preparing iron-cobalt magnetostrictive coating by thermal spraying technology

[0057] 1. Preparation of Fe 50 co 49.9 B 0.1 (x=40-75) (above x is the atomic fraction), in the vacuum smelting furnace of alumina crucible, carry out melting for the first time to prepare alloy ingot, machine processing removes ingot surface scale, the ingot that pretreated Put it into the high-pressure gas atomization powder making device for secondary smelting, heat it to 1700°C in vacuum for 10 minutes, use high-purity argon as the atomizing gas, the atomizing pressure is 3.6Mpa, and the powder spraying pressure is 0.18mbar. The high-speed airflow collides with the alloy liquid flow and breaks into spherical aerosolized powders of different particle sizes;

[0058] 2. Clean and remove the oxide skin on the surface of the stainless steel substrate, preheat at 190°C, and the maximum temperature shall not exceed 250°C;

[0059] 3. Pass the plasma gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com