Manufacturing method of light conducting board and light conducting board stamper and manufacturing processing of light conducting board

A manufacturing method and technology for a light guide plate, applied in optics, nonlinear optics, instruments, etc., can solve the problems of high cost, low development efficiency, and difficult microstructure, and achieve the effects of simple manufacturing process, low cost, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

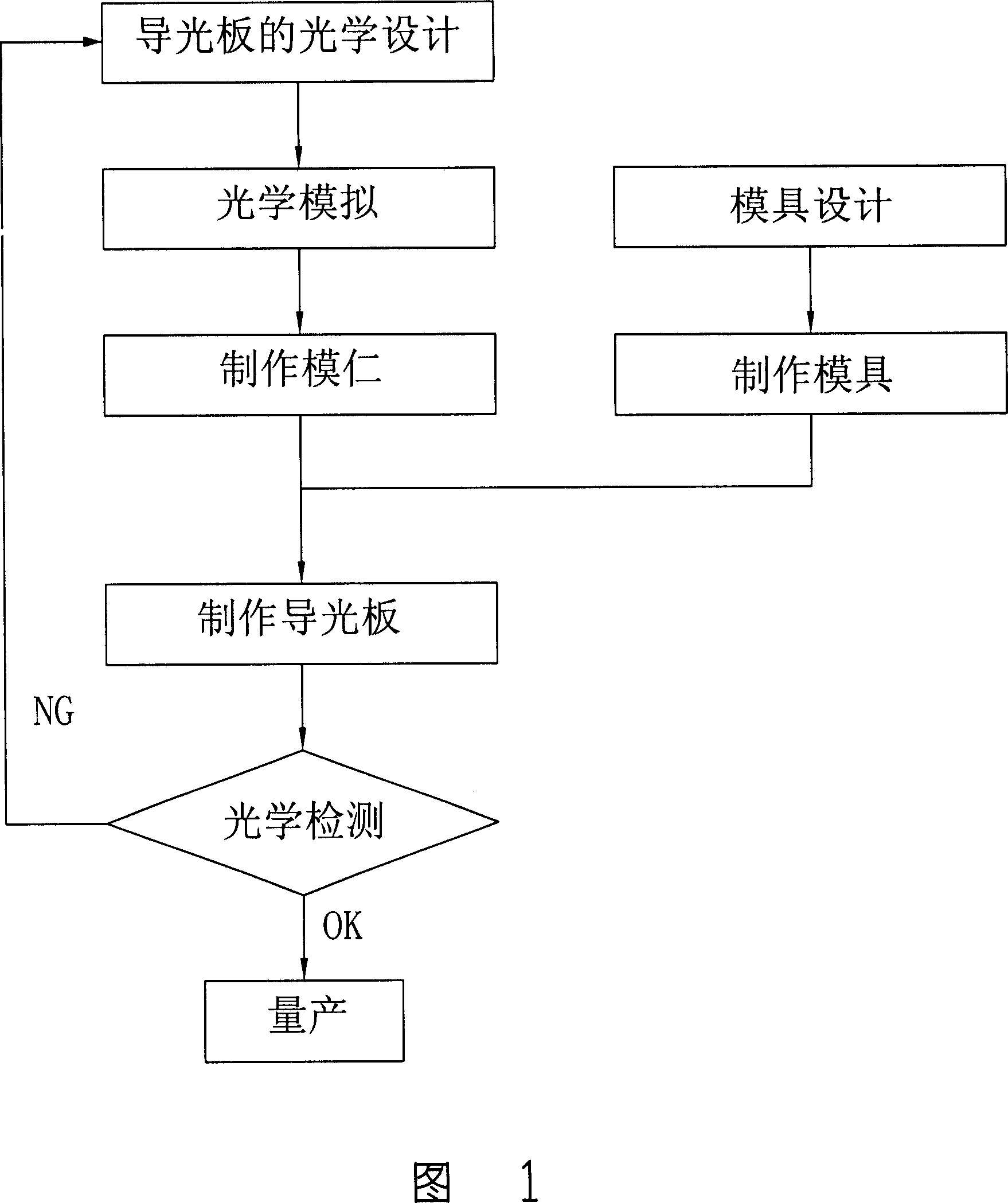

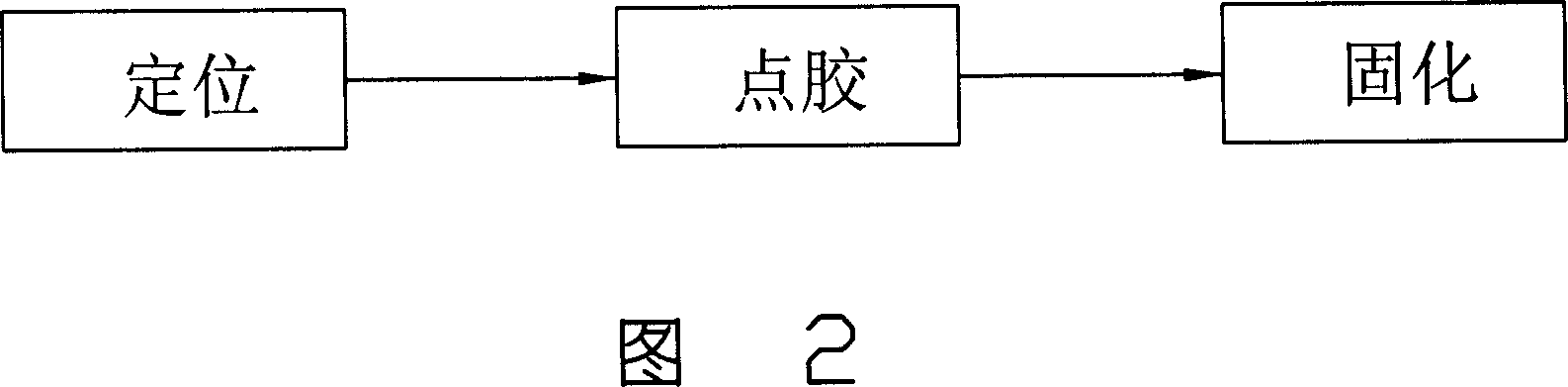

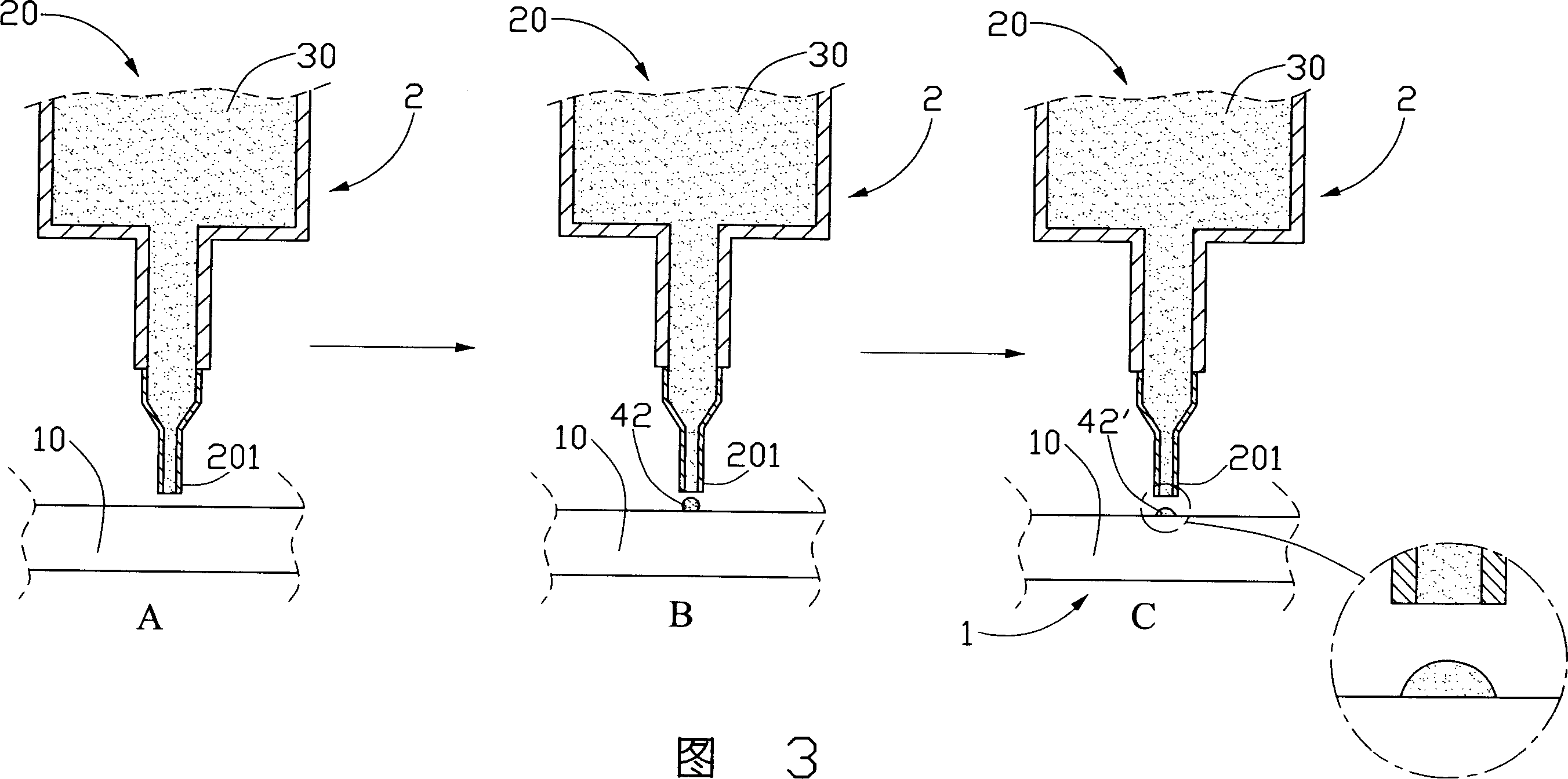

[0019] Please refer to FIG. 2 and FIG. 3 , which are respectively a flow block diagram and a flow diagram of an embodiment of the light guide plate manufacturing method of the present invention.

[0020] The manufacturing method of the light guide plate includes the following steps:

[0021] (1) providing a substrate 10;

[0022] (2) Provide glue dispensing machine 2, this glue dispensing machine 2 comprises a cavity 20 and a syringe 201; Prepare to form the site of network dot, as shown in Figure 3A;

[0023] (3) projecting a certain amount of solution-like curing glue 42 from the syringe 201 at the position where dots are prepared to be formed, so that it is bonded to the substrate 10, as shown in Figure 3B;

[0024] (4) curing the solution-like curing glue 42 bonded on the substrate 10 under certain conditions to obtain a curing glue 42' forming a fixed shape, as shown in Figure 3C;

[0025] (5) Steps (3) and (4) are repeated until all dots on the substrate 10 are comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com