Coating and drying method for pole belts, pole piece preparation method and pole piece preparation system

A preparation system and coating technology, applied in the field of electrodes, can solve the problems of low efficiency, lamination problems, automation difficulties, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

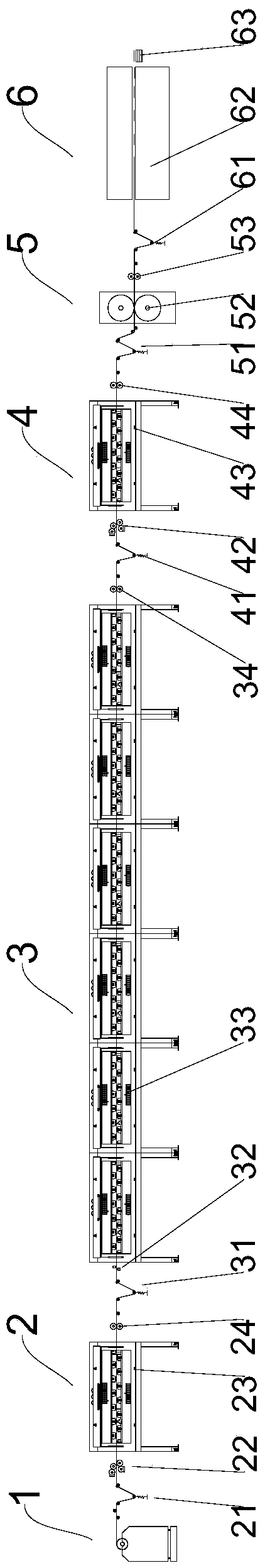

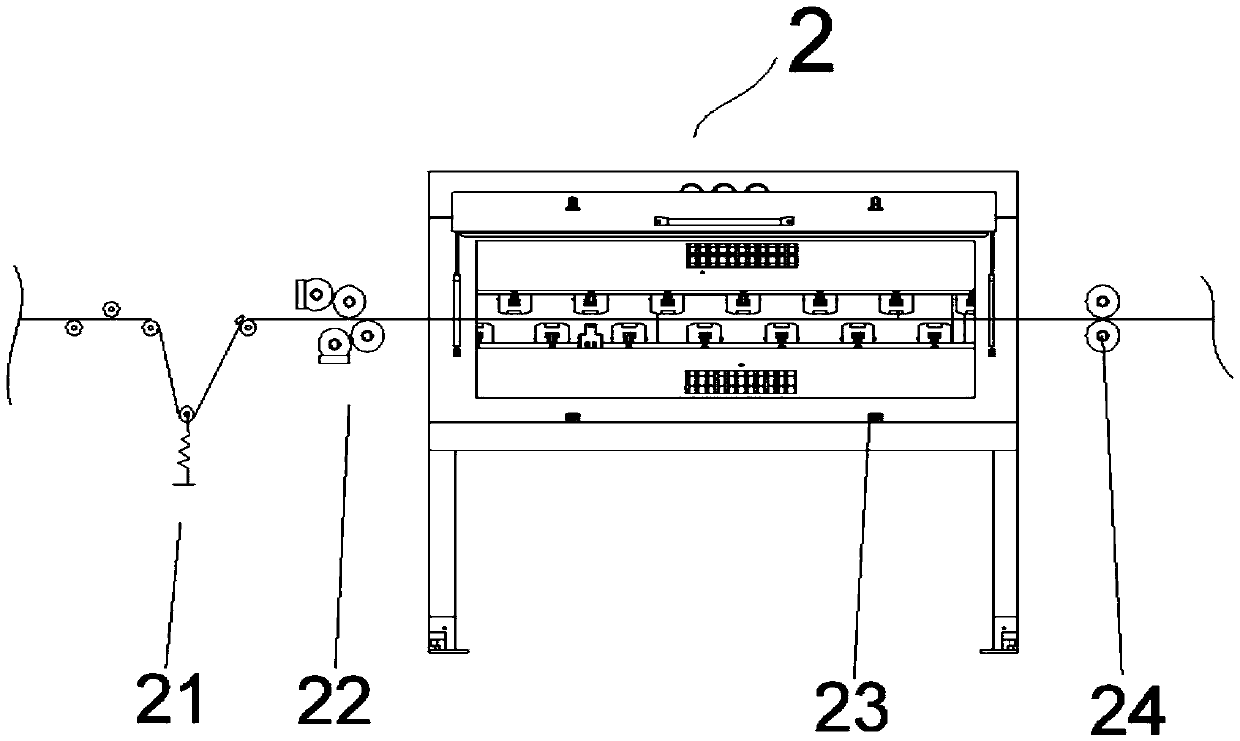

[0032] refer to Figure 1 to Figure 5 , in this embodiment, the pole piece preparation system includes at least one set of coating and drying devices, and each coating and drying device includes a tension control and deviation correction module, a double-sided coating module, and at least one suspension oven arranged in sequence , and the roll-pressed tension belt module. Among them, the tension control correction module is used to correct the deviation and tension control of the pole belt, the double-sided coating module is used to coat the slurry on both sides of the pole belt simultaneously, and the suspension oven is used to simultaneously coat both sides of the pole belt. Drying is carried out, and the roller-pressed tension belt module is used to provide traction for the pole belt. The tension control correction module, the roller pressure belt guide module and the suspension oven jointly control the suspension of the pole belt through the suspension oven. In other wor...

Embodiment 2

[0050] refer to Figure 6 , in the second embodiment, the difference from the first embodiment above is that the rolling device 5 is arranged on the feeding side of the last coating and drying device (the third coating and drying device 4) and the tableting device 6 is arranged on the discharge side of the last coating and drying device (the third coating and drying device 4).

[0051] The process of preparing the pole piece using the pole piece preparation system of the present embodiment is described as follows:

[0052] S1. Put the pole belt into the unwinding device 1;

[0053] S2, the pole belt passes through the double-sided coating module 22 and the suspension oven 23 in the first coating and drying device 2, and the double-sided coating module 32 and the suspension oven 33 in the second coating and drying device 3 , forming two coating layers;

[0054] S3, the pole strip that has formed two layers of paint layers enters the rolling device 5 for rolling;

[0055] S4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com