Carbon fiber composite material rib with spiral resin ribs at two ends and preparation method thereof

A composite material and carbon fiber technology, applied in other home appliances, bridge parts, bridges, etc., can solve the problems of the decrease of the tensile strength and elastic modulus of the reinforcement, the fluctuation of the orientation in the length direction, and the unevenness of the surface of the reinforcement. The effect of high production process efficiency, small deviation of outer diameter size and easy control of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

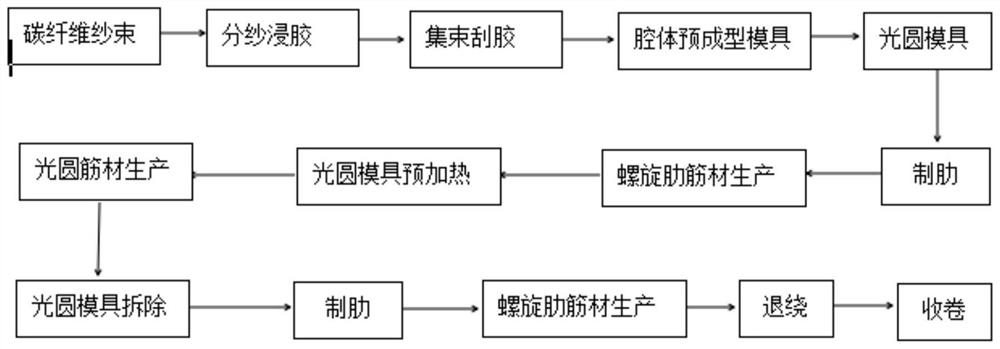

[0037] The preparation process of the above-mentioned carbon fiber composite material is referred to figure 2 , the specific steps are described below.

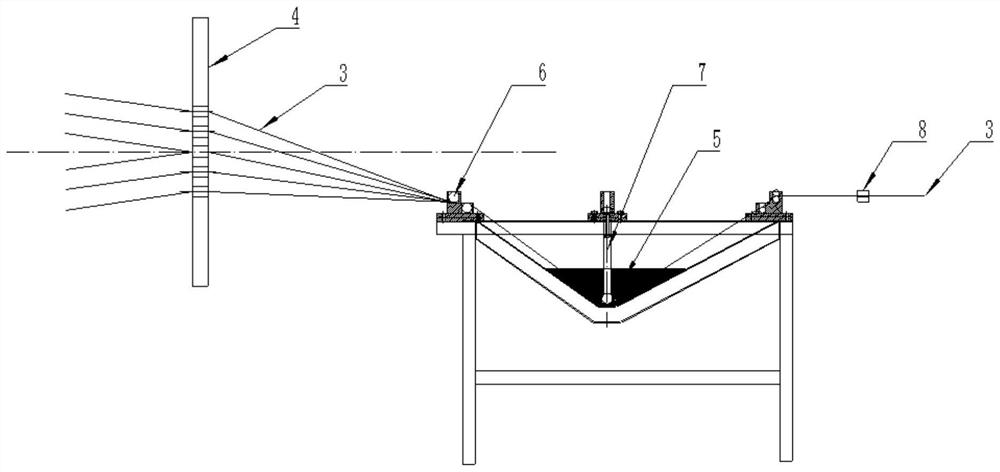

[0038] Step 1: If image 3 Several bundles of carbon fiber bundles 3 are drawn from the yarn splitting plate 4, the quantity of the carbon fiber bundles is adjusted according to the diameter of the reinforcement material as required, and the volume content of the fiber is controlled by the number of fiber bundles to be adjusted in the range of 65%-78%, and the traction speed is Adjust the range of 300mm / min-600mm / min, use the tension controller to control the tension of the thread, in order to ensure that the orientation of the carbon fiber bundle remains straight during impregnation, the tension is adjusted in the range of 20N-60N;

[0039] Step 2: If image 3 The carbon fiber bundle 3 is restrained and immersed in the epoxy resin mixture 5 through the wire arrangement pressure rod 6 and the immersion depth pressure rod 7...

Embodiment 1

[0046] A carbon fiber composite reinforcement material with resin ribs on both ends and a smooth circle in the middle, including carbon fiber and epoxy resin matrix. The diameter of the reinforcement is 7mm. Light round carbon fiber composite ribs. Both ends of the ribbed carbon fiber composite reinforcement are 2000mm in length, the thickness of the resin rib is 0.25mm, the pitch of the resin rib is 2.4mm, and the length of the smooth round carbon fiber composite reinforcement is 20000mm.

[0047] A method for preparing a carbon fiber composite reinforcement with resin ribs on both ends and a smooth circle in the middle includes the following steps:

[0048] Step 1: Draw out 62 carbon fiber bundles 3 from the splitter plate 4, the fiber volume content is 72%, the pulling speed is 300mm / min, and the tension controller is used to control the tension of the wire, in order to ensure that the orientation of the carbon fiber bundles is maintained during impregnation Straight, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com