Color-varying and color-coated aluminum strip and production technology thereof

A production process and aluminum plate technology, applied in the field of color-changing aluminum strip and its production process, can solve the problems of poor color consistency between the central area and the surrounding area, environmental pollution, low efficiency, etc., achieve high production process efficiency and reduce environmental pollution , Good effect of color consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

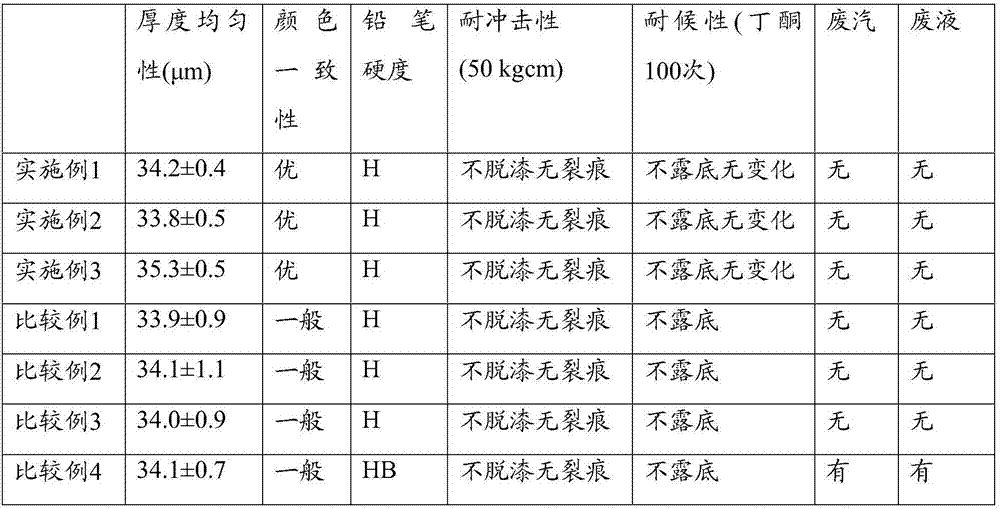

Examples

Embodiment 1

[0057] The invention relates to a production process of color-changing coated aluminum strips, which includes the steps of cleaning, production process, primer coating and baking, surface coating and baking, cooling and packaging.

[0058] The production process includes degreasing and passivation steps, and the degreasing agent used in the degreasing step is a biological degreasing agent.

[0059] The biological degreasing agent comprises the following components: 2.5 wt% of biological enzyme, 5 wt% of EDTA, 2.5 wt% of surfactant, and the balance is water; the biological enzyme is selected from protein enzymes.

[0060] The degreasing step further includes the steps of pre-cleaning, mechanical brushing, degreasing agent rinsing, hot water spraying and hot air drying.

[0061] Both the pre-cleaning and degreasing agent rinsing steps use a nozzle to spray the biological degreasing agent to the surface of the aluminum strip, the nozzle pressure is 0.2MPa, and the time is 5s.

...

Embodiment 2

[0072] The invention relates to a production process of color-changing coated aluminum strips, which includes the steps of cleaning, production process, primer coating and baking, surface coating and baking, cooling and packaging.

[0073] The production process includes degreasing and passivation steps, and the degreasing agent used in the degreasing step is a biological degreasing agent.

[0074] The biological degreasing agent comprises the following components: 3 wt% of biological enzyme, 6 wt% of EDTA, 3 wt% of surfactant, and the balance is water; the biological enzyme is selected from protein enzymes.

[0075] The degreasing step further includes the steps of pre-cleaning, mechanical brushing, degreasing agent rinsing, hot water spraying and hot air drying.

[0076] Both the pre-cleaning and degreasing agent rinsing steps use a nozzle to spray the biological degreasing agent to the surface of the aluminum strip, the nozzle pressure is 0.2MPa, and the time is 5s.

[007...

Embodiment 3

[0087] The invention relates to a production process of color-changing coated aluminum strips, which includes the steps of cleaning, production process, primer coating and baking, surface coating and baking, cooling and packaging.

[0088] The production process includes degreasing and passivation steps, and the degreasing agent used in the degreasing step is a biological degreasing agent.

[0089] The biological degreasing agent comprises the following components: 2 wt% of biological enzyme, 6 wt% of EDTA, 2 wt% of surfactant, and the balance is water; the biological enzyme is selected from protein enzymes.

[0090] The degreasing step further includes the steps of pre-cleaning, mechanical brushing, degreasing agent rinsing, hot water spraying and hot air drying.

[0091] Both the pre-cleaning and degreasing agent rinsing steps use a nozzle to spray the biological degreasing agent to the surface of the aluminum strip, the nozzle pressure is 0.2MPa, and the time is 5s.

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com