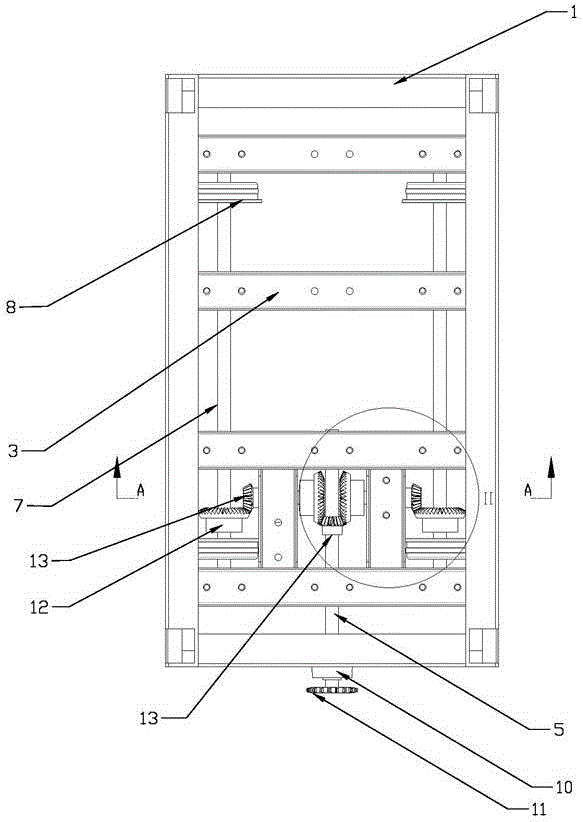

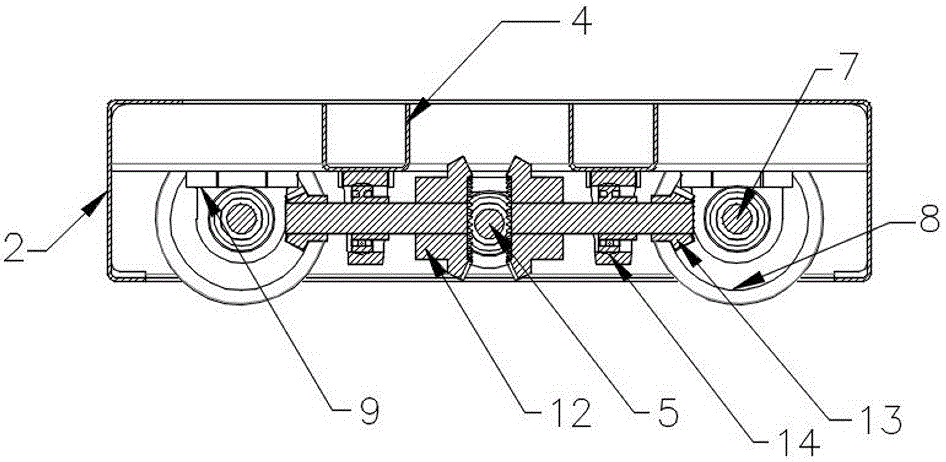

Movable frame base driven by bevel gears

A technology of bevel gears and mobile frames, which is applied in the direction of mobile frames, gear transmissions, engine frames, etc., can solve the problems of poor synchronization performance, easy detachment, slipping, etc., achieve reasonable walking speed, improve product quality and Brand strength, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

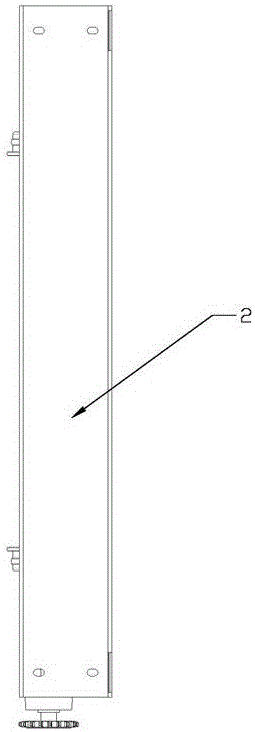

[0012] A base driven by a bevel gear of a mobile frame, the structure includes a straight beam 1, a longitudinal beam 2, a bearing fixing bracket 3, a bearing seat fixing piece 4, a middle driving shaft 5, a straight driving shaft 6, a side driving shaft 7, and a cast iron walking Wheel 8, PA204 bearing 9, UELFLU204 belt diamond seat bearing 10, 21 teeth sprocket 11, conical 40 gear 12, conical 20 gear 13, bearing seat 14. The straight beam 1 and the longitudinal beam 2 form a frame, and four bearing fixing brackets 3 are arranged at intervals between the two longitudinal beams 2, and a bearing seat fixing member 4 is arranged between the two bearing fixing brackets 3 on the right side of the frame, and the bearing fixing bracket The two sides of 3 are provided with PA204 bearing 9, and the side drive shaft 7 passes through the PA204 bearing 9 and is fixed by the PA204 bearing 9. The two sides of the side drive shaft 7 are provided with cast iron walking wheels 8, and the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com