Cutting method of honeycomb dried body and honeycomb dried body cutting device

A technology of cutting device and drying body, which is applied in the direction of grinding machines, ceramic molding machines, metal processing equipment, etc., can solve the problems of shedding, increased processing resistance, and abrasive wear of grinding wheels, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

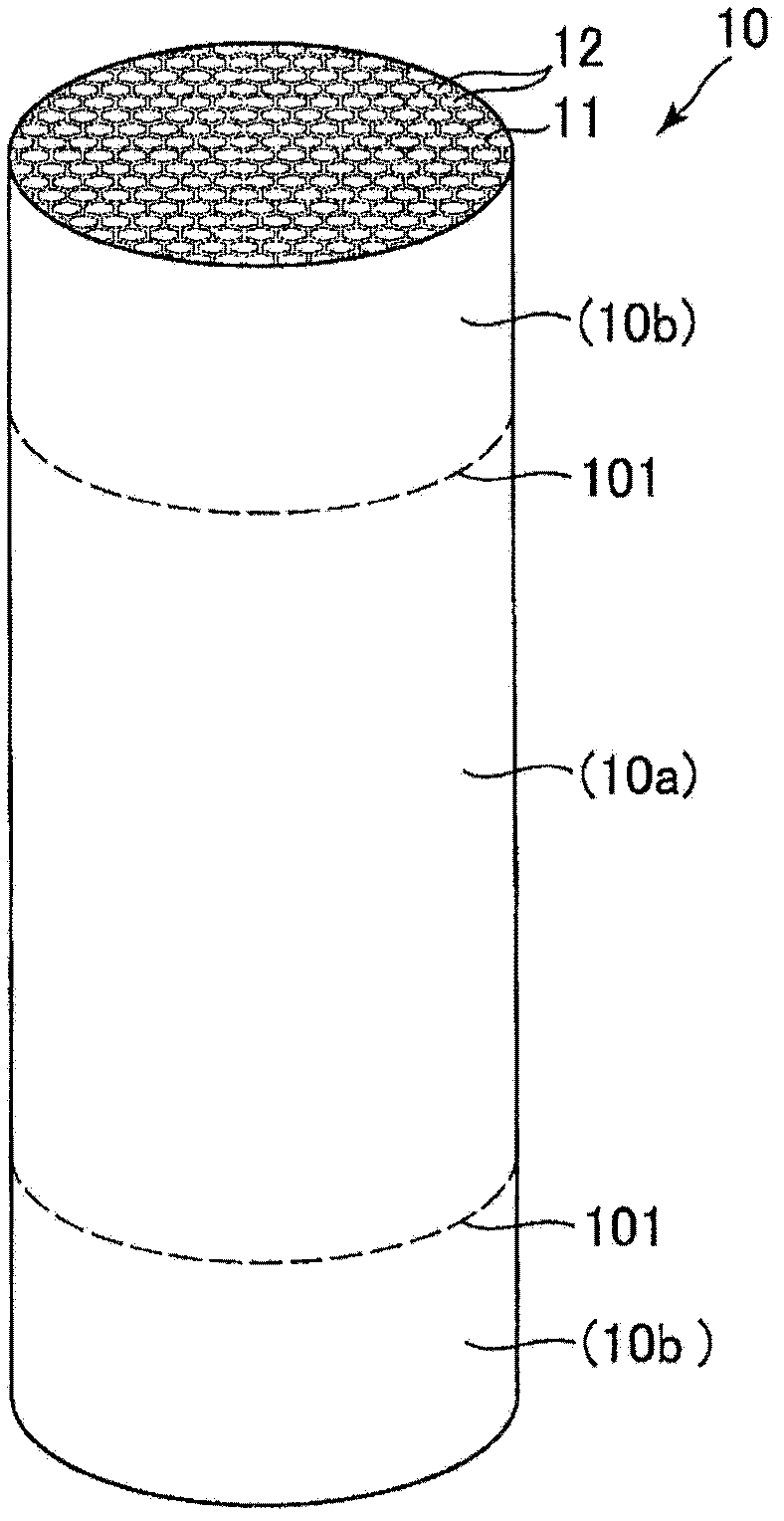

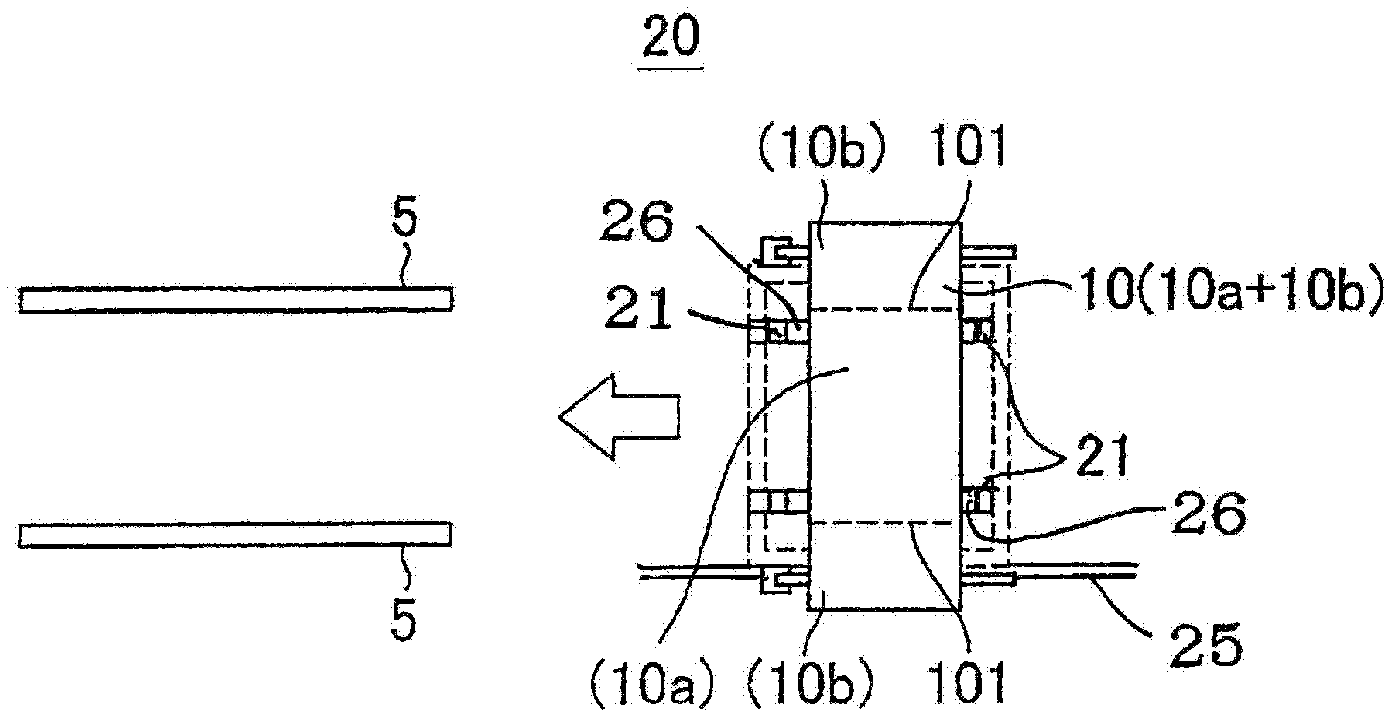

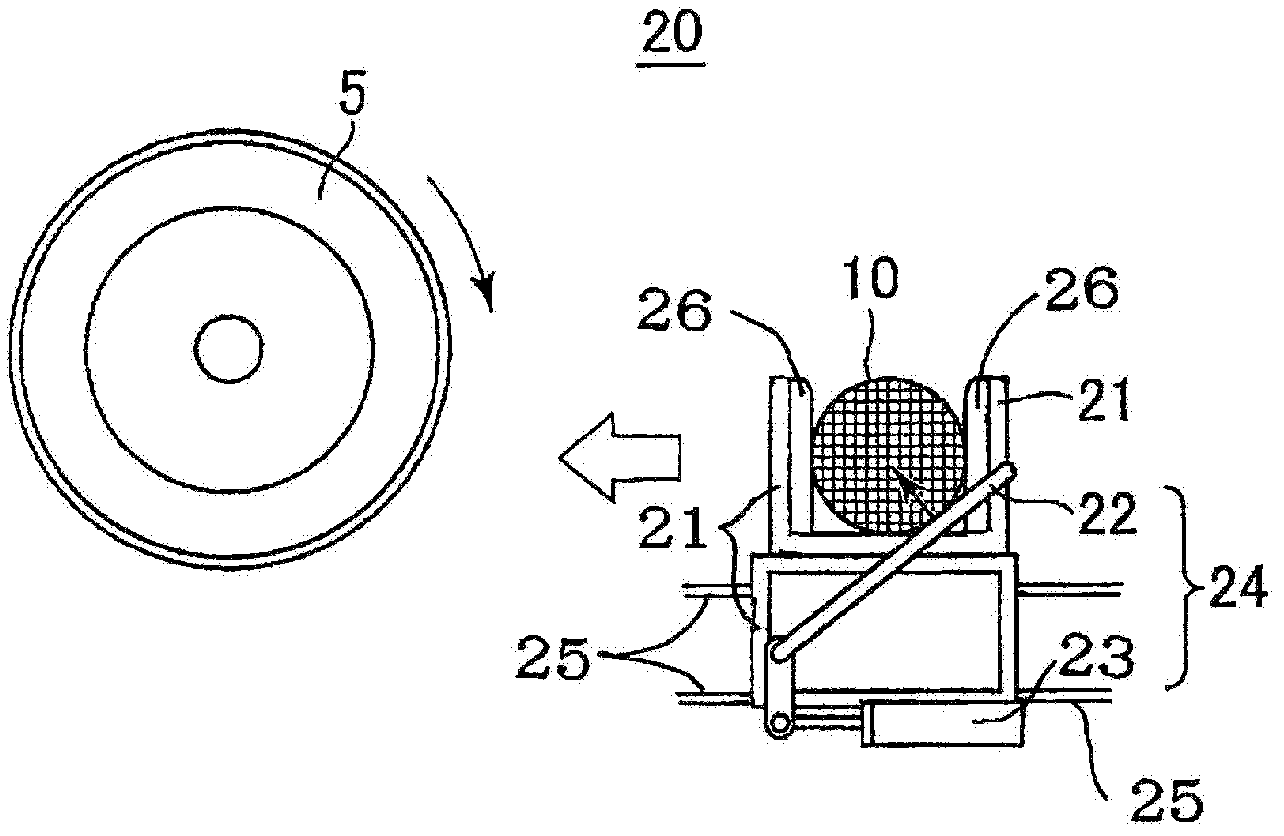

[0081] (Example 1) A cordierite-forming raw material, an organic binder, and water were mixed and kneaded to obtain a clay, and the clay was extruded with an extrusion molding machine to form a peripheral wall to obtain a honeycomb formed body. Then, the formed honeycomb body was dried with a dryer to obtain a dried honeycomb body having a cylindrical shape, and the dried honeycomb body 10 which could be cut was obtained. The axial length of the honeycomb drying body 10 is 400 mm, the cross-sectional diameter perpendicular to the axis is 152 mm, the cross-sectional shape of the cells is quadrilateral, and the cell density is 46.5 cells / cm 2 , the thickness of the partition wall is 300 μm.

[0082] In addition, the back component force Pt (cutting resistance) at the time of cutting was obtained in advance, and it was 300 [gf]. In addition, the weight Pw of one cutout portion 10b is 160 [gf]. The sum of the back component force Pt and the weight Pw of the cutout portion is 460...

Example Embodiment

[0084] (Example 2) The dried honeycomb body 10 was cut|disconnected similarly to Example 1 except having made force Pm into 520 [gf]. For three dried honeycomb bodies 10 of the same specification, cutting was carried out under the same conditions, and there was no chipping (no edge chipping) in all three pieces. The result is expressed in Figure 11 middle.

Example Embodiment

[0085] (Example 3) The dried honeycomb body 10 was cut|disconnected similarly to Example 1 except having made force Pm into 1070 [gf]. For three dried honeycomb bodies 10 of the same specification, cutting was carried out under the same conditions, and there was no chipping (no edge chipping) in all three pieces. The result is expressed in Figure 11 middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com