Method for forming Schottky contact on surface of zinc oxide and regulating Schottky contact

A Schottky contact, zinc oxide technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve problems such as complex methods and no reliability, and achieve simple steps, short time, and controllable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

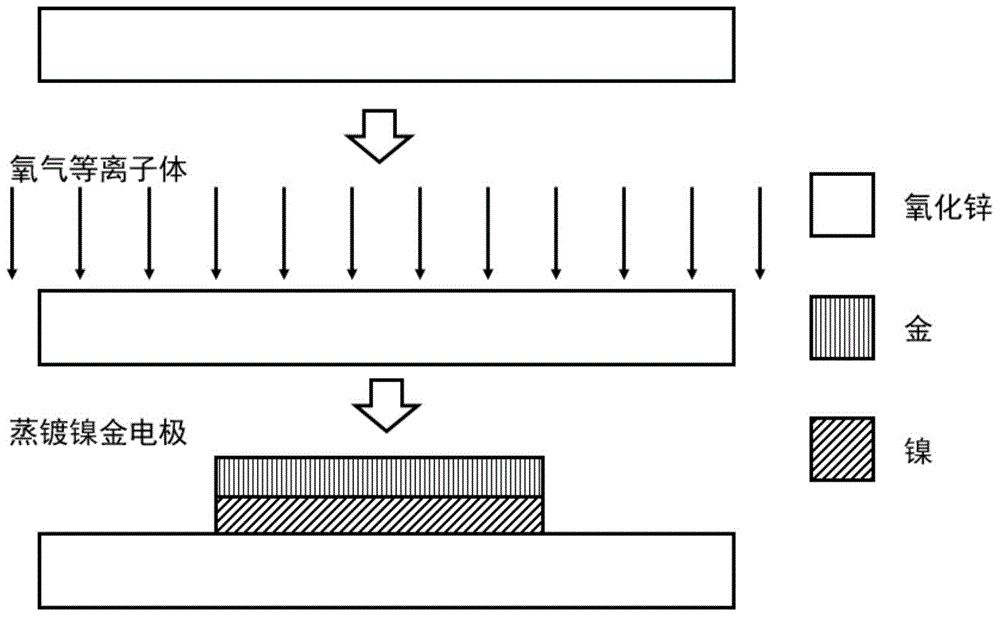

[0041] Put the cleaned zinc oxide sample in the plasma processing chamber, close the chamber and extract the internal gas to 5×10 -3 Pa.

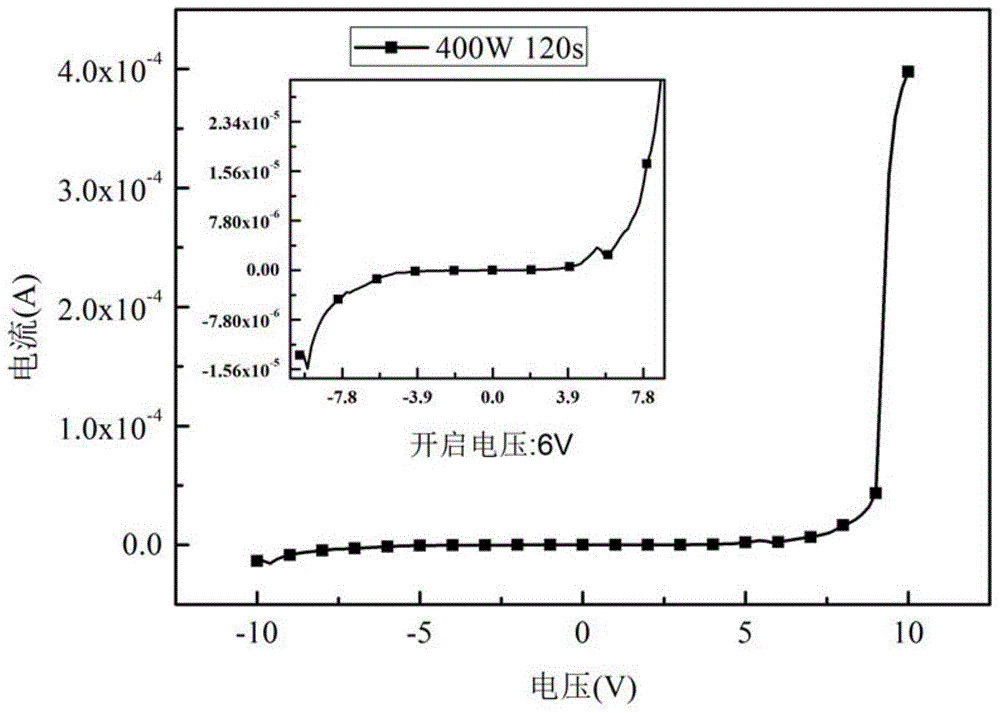

[0042] Introduce oxygen with a flow rate of 100sccm, adjust the internal pressure of the chamber to 3Pa, turn on the radio frequency power supply, ignite the oxygen inside the chamber, and adjust the radio frequency power to 400W, and process for 120s. After the treatment, turn off the radio frequency power supply and take out the sample.

[0043] The metal mask plate is covered on the zinc oxide sample, and 25nm nickel and 65nm gold are evaporated by electron beam to form electrodes. The Schottky contact characteristics of its electrodes are shown in figure 2 . Depend on figure 2 It can be seen that the electrode exhibits rectification characteristics, and the turn-on voltage is 6V.

Embodiment 2

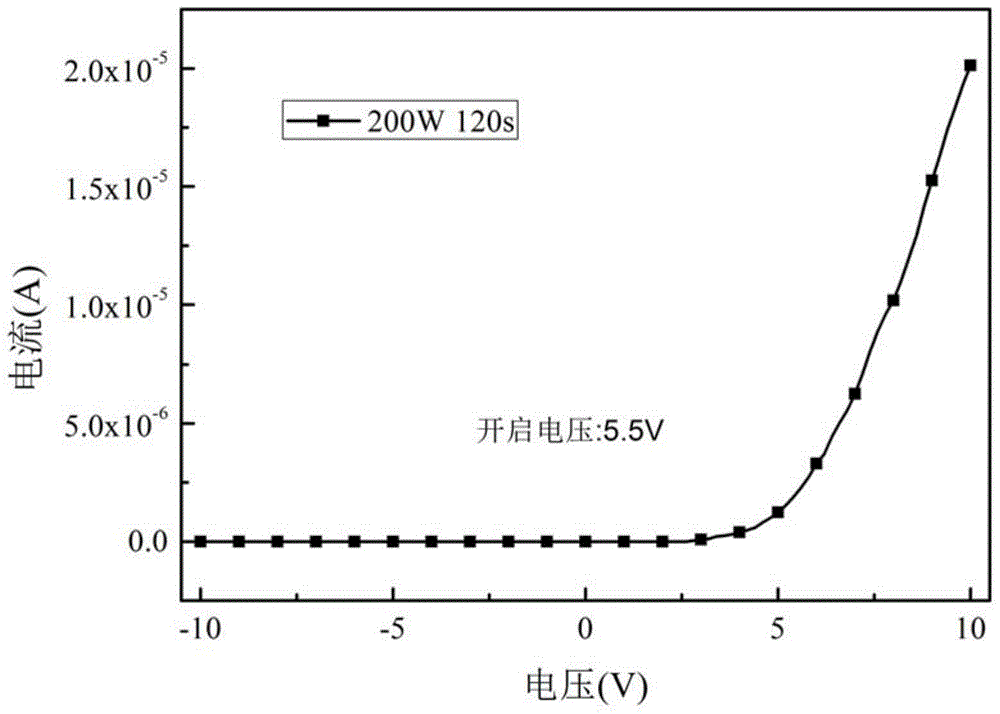

[0045] Put the cleaned zinc oxide sample in the plasma processing chamber, close the chamber and extract the internal gas to 3×10 -3 Pa.

[0046] Introduce oxygen with a flow rate of 120sccm, adjust the internal pressure of the chamber to 2.8Pa, turn on the radio frequency power supply, start the oxygen inside the chamber, and adjust the radio frequency power to 200W, and process for 120s. After the treatment, turn off the radio frequency power supply and take out the sample .

[0047] The metal mask plate is covered on the zinc oxide sample, and 25nm nickel and 65nm gold are evaporated by electron beam to form electrodes. The Schottky contact characteristics of its electrodes are shown in image 3 . Depend on image 3 It can be seen that the electrode exhibits rectification characteristics, and the turn-on voltage is 5.5V.

Embodiment 3

[0049] Put the cleaned zinc oxide sample in the plasma processing chamber, close the chamber and extract the internal gas to 5×10 -3 Pa.

[0050] Introduce oxygen with a flow rate of 140sccm, and adjust the internal pressure of the cavity to 2.9Pa, turn on the radio frequency power supply, start the oxygen in the cavity, and adjust the radio frequency power to 100W, process for 120s, after the treatment, turn off the radio frequency power supply, and take out the sample .

[0051]The metal mask plate is covered on the zinc oxide sample, and 25nm nickel and 65nm gold are evaporated by electron beam to form electrodes. The Schottky contact characteristics of its electrodes are shown in Figure 4 . Depend on Figure 4 It can be seen that the electrode exhibits rectification characteristics, and the turn-on voltage is 5.1V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com