A combination method of fluorine-containing resin prepreg for high-frequency copper-clad laminates

A technology of fluorine-containing resin and prepreg, which is applied in the field of communication materials, can solve the problems of high peel strength, high transmission loss, and high dielectric constant, and achieve the effects of high peel strength, high cross-linking density, and low dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

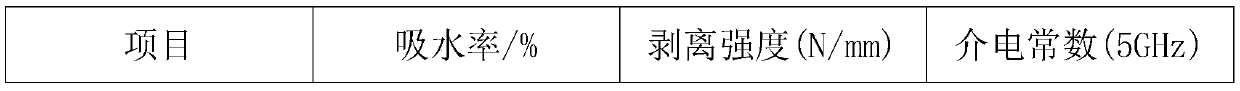

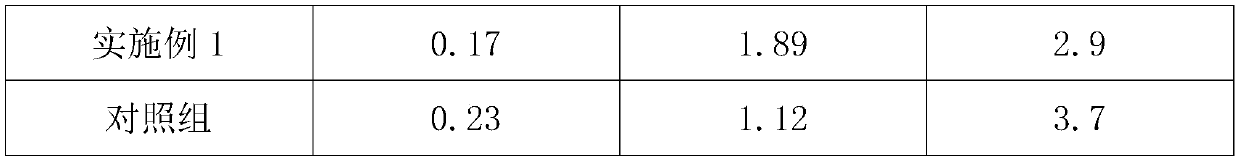

Examples

Embodiment 1

[0031] The thickness of the copper foil used in this example is 13 μm, the number of prepregs used is 5, the models of the prepregs used are prepreg 2116 and prepreg 7628, the number of copper foils is 2, and the combination sequence is from top to The following are copper foil, 40 μm PTFE film, prepreg 2116, 35 μm PTFE film, prepreg 7628, prepreg 2116, prepreg 7628, 35 μm PTFE film, prepreg 2116, 40 μm PTFE film, and copper foil. The pressing temperature is 150°C and the pressure is 150kg / cm 2 , The pressing time is 52h.

[0032] The combination method of fluorine-containing resin prepregs for high-frequency copper-clad laminates in this embodiment includes the following steps:

[0033] A. Put the glass fiber cloth in an oven and bake at 430°C for 10 minutes to remove the paraffin wax on the surface;

[0034] B. Preparation of fluorine-containing resin impregnating solution: put polytetrafluoroethylene, tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer and water into...

Embodiment 2

[0040] The thickness of the copper foil used in this example is 13 μm, the number of prepregs used is 5, the models of the prepregs used are prepreg 2116 and prepreg 7628, the number of copper foils is 2, and the combination sequence is as follows To the bottom are copper foil, 70μm PTFE film, prepreg 2116, prepreg 7628, prepreg 2116, prepreg 7628, prepreg 2116, 70μm PTFE film, copper foil. The pressing temperature is 150°C and the pressure is 150kg / cm 2 , The pressing time is 52h.

[0041]The combination method of fluorine-containing resin prepregs for high-frequency copper-clad laminates in this embodiment includes the following steps:

[0042] A. Put the glass fiber cloth in an oven and bake at 420°C for 9.5 minutes to remove the surface paraffin;

[0043] B. Preparation of fluorine-containing resin impregnating solution: put tetrafluoroethylene-perfluoroalkyl vinyl ether copolymer and tetrafluoroethylene-hexafluoropropylene copolymer with water in a stirrer, and stir for...

Embodiment 3

[0049] The thickness of the copper foil used in this embodiment is 16 μm, the number of sheets of prepreg used is 5 sheets, the number of sheets of copper foil is 2 sheets, the model of the prepreg used is prepreg 106, prepreg 7628, the number of sheets of copper foil It is 2 sheets, and the combination sequence from top to bottom is copper foil, 35 μm PTFE film, prepreg 106, 40 μm PTFE film, prepreg 7628, prepreg 106, prepreg 7628, 40 μm PTFE film, prepreg 2116, 35 μm PTFE film, and copper foil. The pressing temperature is 430°C, the pressure is 100kg / cm2, and the pressing time is 24h.

[0050] The combination method of fluorine-containing resin prepregs for high-frequency copper-clad laminates in this embodiment includes the following steps:

[0051] A. Put the glass fiber cloth in an oven and bake at 410°C for 9 minutes to remove the surface paraffin;

[0052] B. Preparation of fluorine-containing resin impregnation solution: put the fluorine-containing resin tetrafluoroet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com