A kind of slime flotation agent and preparation method thereof

A coal slime flotation and selection technology, which is applied in flotation, solid separation and other directions, can solve the problems of complex preparation process, reduce the amount of collectors, high cost, etc., achieve good selection performance, enhance flotation efficiency, improve Environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

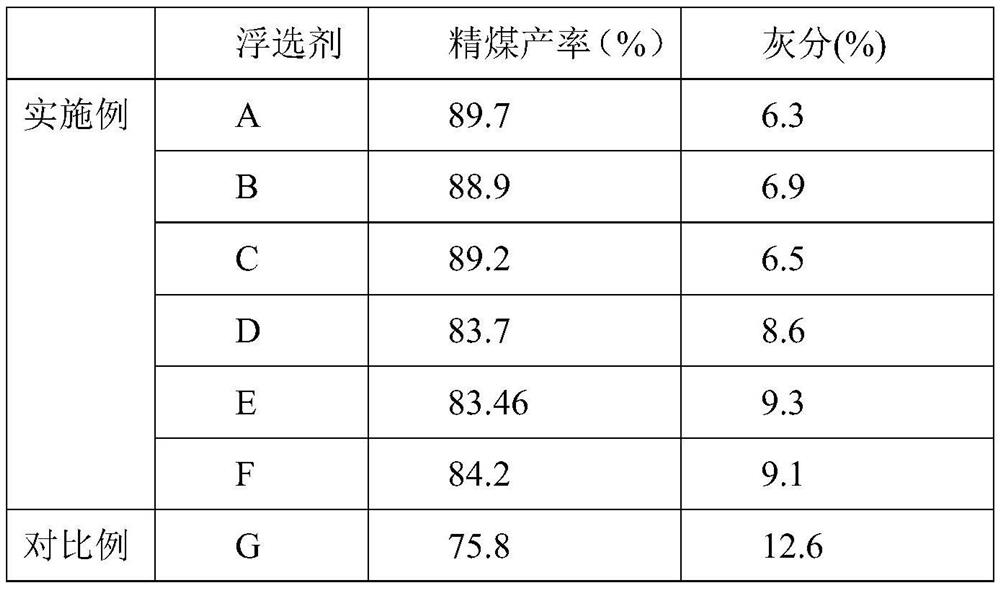

Examples

Embodiment 1

[0039] Preparation of Hydrophobically Modified Polyvinyl Alcohol A

[0040] Dissolve polyvinyl alcohol and hexanoyl chloride in an appropriate amount of dichloromethane according to the mass ratio of 1:6, add triethylamine with 1.1 times the molar amount of hexanoyl chloride, and react for 1-2 hours; the product is washed in turn to remove impurities to obtain hydrophobic modification polyvinyl alcohol.

[0041] Preparation of flotation agent A

[0042] Flotation Agent A is made of the following components:

[0043] Rapeseed Oil: 20 servings

[0044] Kerosene: 40 servings

[0045] Ethylene glycol: 15 parts

[0046] Dodecyldimethylamine: 5 parts

[0047] Dimethyl sulfate: 10 parts

[0048] Hydrophobically modified polyvinyl alcohol A: 5 parts

[0049] 33wt% NaOH: 2.5 parts

[0050] Sodium sulfosalicylate: 2.5 parts

[0051] Its preparation process is as follows:

[0052] (1) under the ice-water mixture temperature, the rapeseed oil, ethylene glycol, dodecyl dimethy...

Embodiment 2

[0055] Preparation of flotation agent B

[0056] Other conditions and operations are the same as in Example 1, except that the same mass of octanoyl chloride is used instead of hexanoyl chloride.

Embodiment 3

[0058] Preparation of flotation agent C

[0059] Other conditions and operations are the same as in Example 1, except that the same mass of decanoyl chloride is used instead of hexanoyl chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com