Preparation method of iron-based composite material

A technology of iron-based composite materials and composite powders, which is applied in the field of metal-based composite materials and advanced manufacturing, can solve the problems of waste liquid discharge, poor corrosion resistance, and low surface hardness of ferroalloys, and achieve the effect of simple process and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

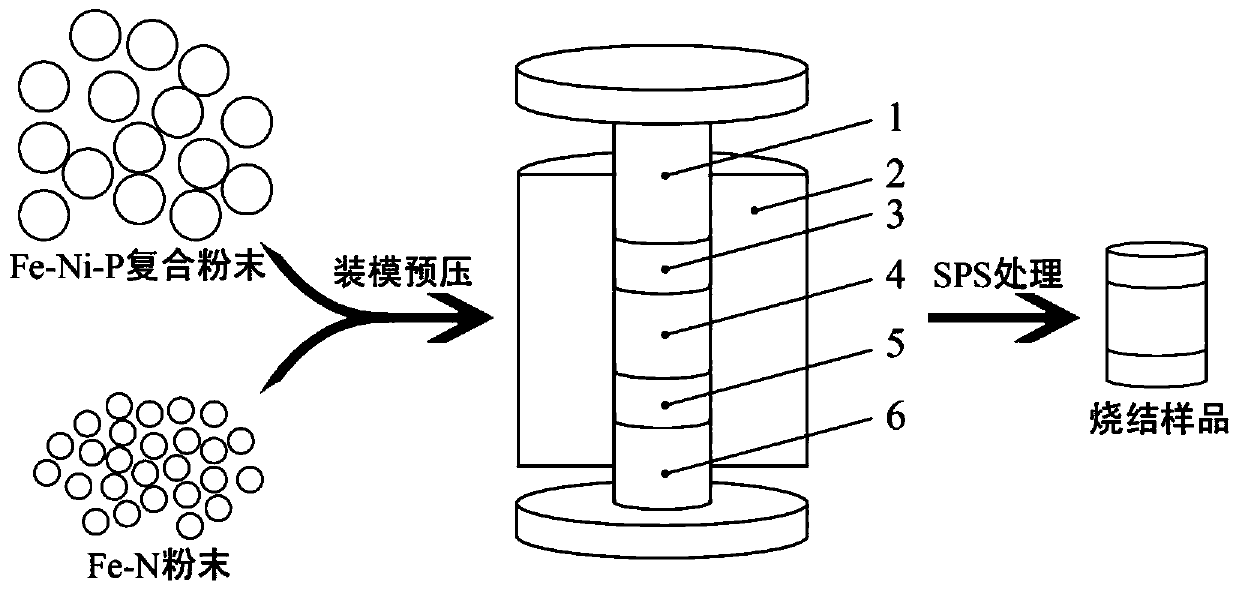

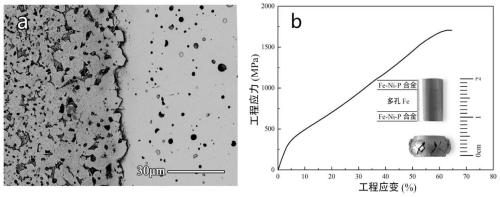

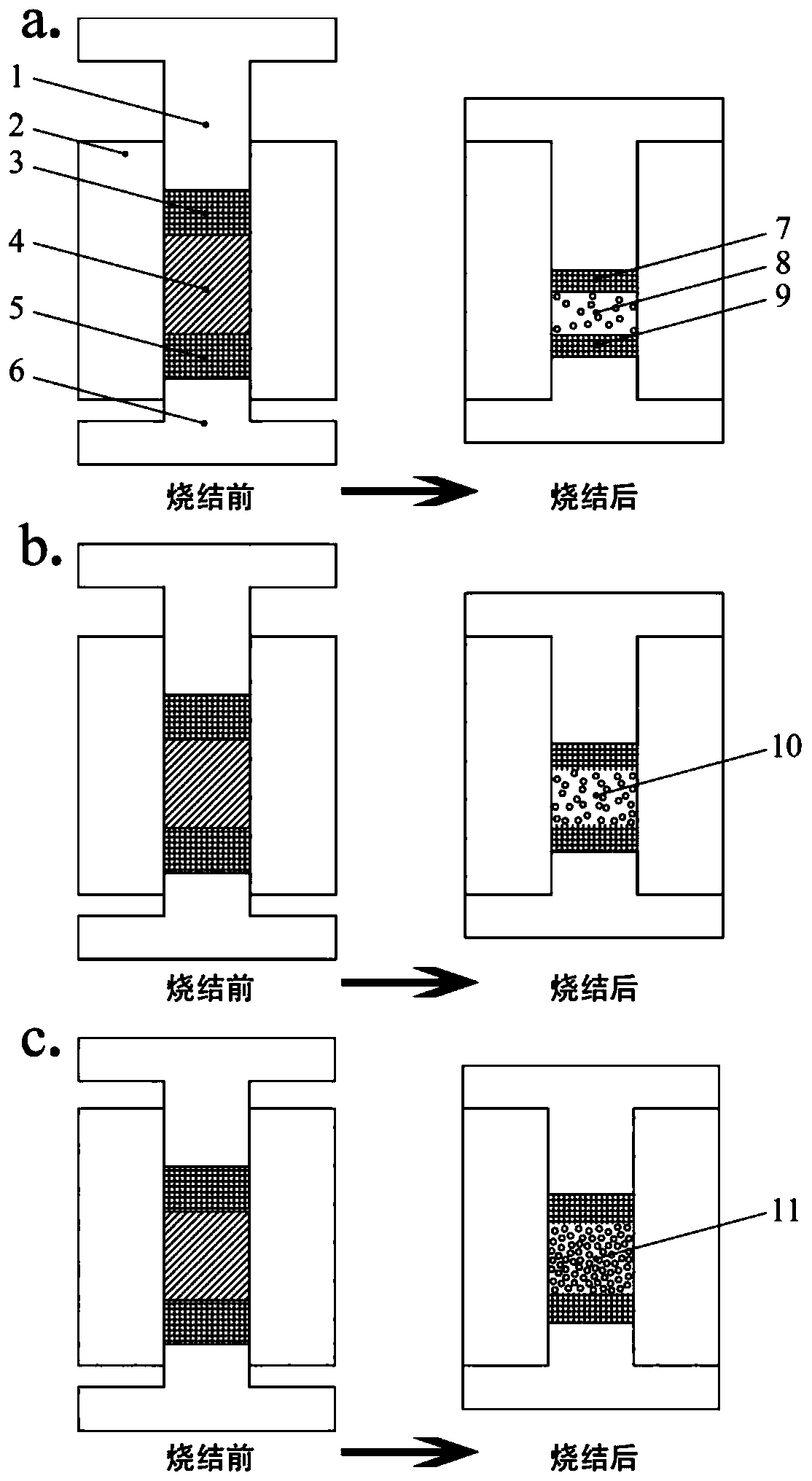

[0026] A kind of preparation method of iron-based composite material, such as image 3 As shown in -a, take 2 parts of Fe-Ni-P composite powder 3 with an average particle diameter of 1 micron, and Ni and P mass percentages of 28% and 1.5%, each with 9 grams; weigh 27 grams of the average Fe—N powder 4 with a particle size of 100 nanometers and a mass percentage of nitrogen of 8% means that the mass proportions of the two powders are 20%*2 and 60% respectively. Put 9 grams of Fe-Ni-P composite powder 3, 27 grams of Fe-N powder 4, and 9 grams of Fe-Ni-P composite powder 3 into a graphite mold 2 with an internal diameter of 2 centimeters and a height of 6 centimeters. The length of the feeding section of the lower pressing head 6 is selected to be 1 cm, and the length of the feeding section of the upper pressing head 1 is 3 cm, and pre-pressing is performed under an axial pressure of 20 MPa to make the powders fully contact. Then use spark plasma sintering (SPS) technology for s...

Embodiment 2

[0028]A preparation method of an iron-based composite material, weighing 2 parts of Fe-Ni-P composite powder 3 with an average particle size of 1.17 microns and a Ni and P mass percent content of 28.33% and 1.57%, respectively, 8.68 grams per part; Weighed 27.9 grams of Fe—N powder 4 with an average particle size of 125 nm and a mass percentage of nitrogen of 8.33%, that is, the mass proportions of the two powders were 19.16%*2 and 61.68%, respectively. Put 8.68 grams of Fe-Ni-P composite powder 3, 27.9 grams of Fe-N powder 4, and 8.68 grams of Fe-Ni-P composite powder 3 into a graphite mold 2 with an inner diameter of 2 cm and a height of 6 cm. The length of the feeding section of the lower pressing head 6 is selected to be 1 cm, and the length of the feeding section of the upper pressing head 1 is 2.83 cm. Pre-pressing is performed under an axial pressure of 20 MPa to make the powders fully contact. Then use spark plasma sintering (SPS) technology to carry out sintering and ...

Embodiment 3

[0030] A preparation method of an iron-based composite material, weighing 2 parts of Fe-Ni-P composite powder 3 with an average particle diameter of 1.34 microns, and Ni and P mass percentages of 28.66% and 1.64%, respectively, 8.2 grams per part; Weighed 28.3 grams of Fe—N powder 4 with an average particle size of 150 nm and a mass percentage of nitrogen of 8.66%, that is, the mass proportions of the two powders were 18.33%*2 and 63.34% respectively. Put 8.2 grams of Fe-Ni-P composite powder 3, 28.3 grams of Fe-N powder 4, and 8.2 grams of Fe-Ni-P composite powder 3 into a graphite mold 2 with an inner diameter of 2 centimeters and a height of 6 centimeters. The length of the feeding section of the lower pressing head 6 is selected to be 1 cm, and the length of the feeding section of the upper pressing head 1 is 2.66 cm. The pre-pressing molding is performed under an axial pressure of 20 MPa to fully contact the powders. Then use spark plasma sintering (SPS) technology to car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com