Polishing machine with 3D hook face

A technology of polishing machine and curved surface, applied in the field of polishing machine, can solve the problems of grinding, polishing force, excessive edge part of the workpiece, etc., to reduce wear, improve polishing effect, and reduce the effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention provides a polishing machine for 3D curved surfaces.

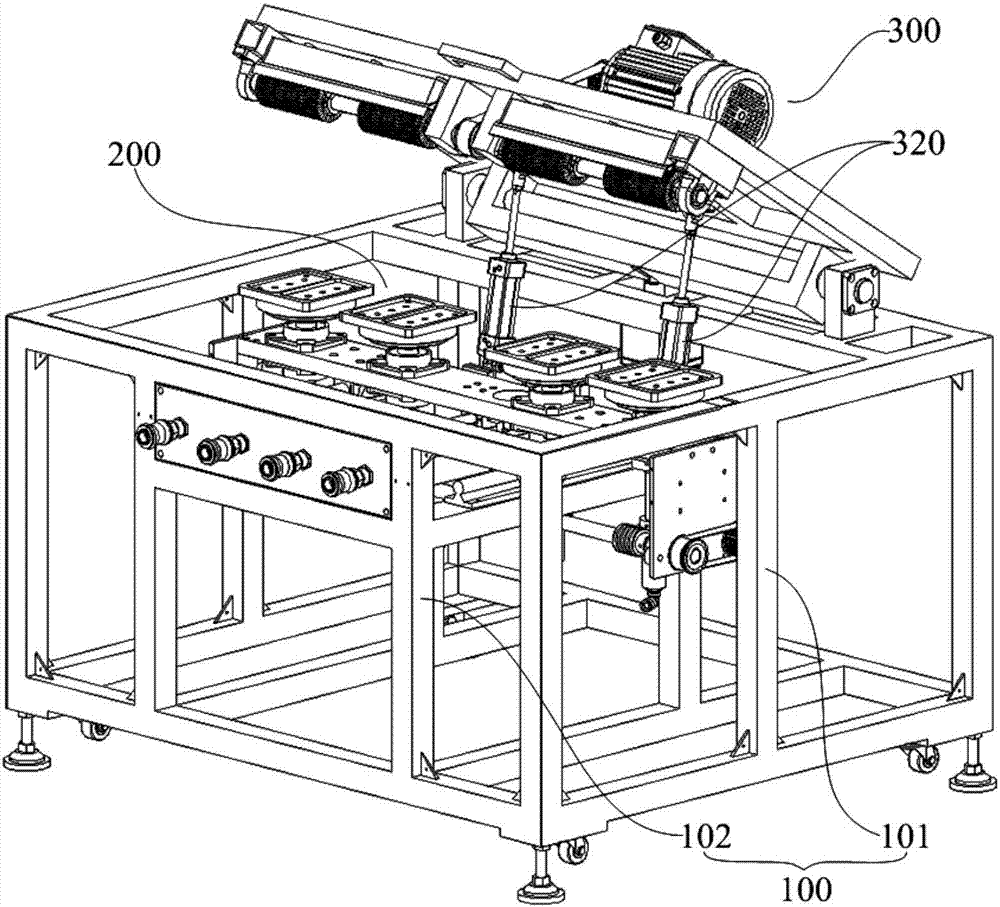

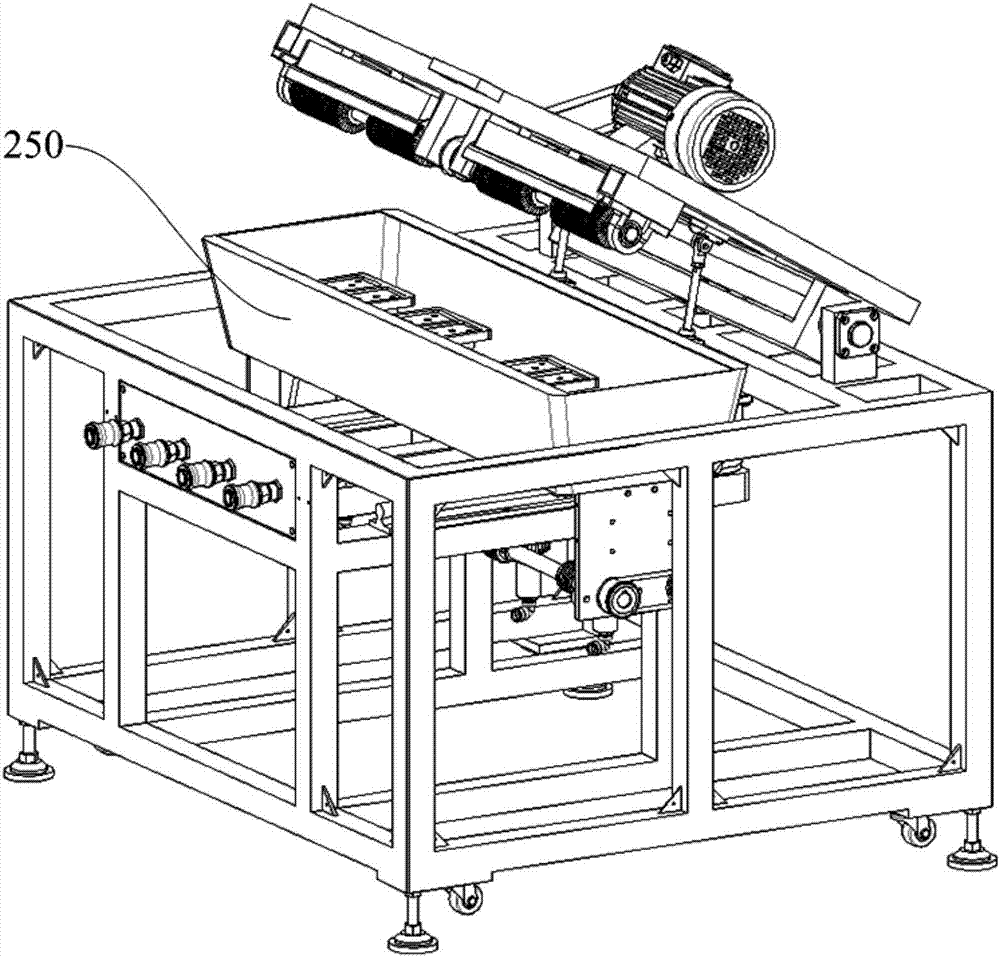

[0037] refer to figure 1 , figure 1 It is a structural diagram of the present invention in the state of replacing the workpiece in the first embodiment, figure 2 It is a structural diagram of the present invention in the processing state in the first embodiment.

[0038] Such as figure 1 As shown, in this embodiment, the 3D curved surface polishing machine includes: a frame 100 , a jig assembly 200 , and a polishing wheel assembly 300 .

[0039] Wherein, the frame 100 includes an outer frame 101 and an inner frame 102 disposed inside the outer frame 101 .

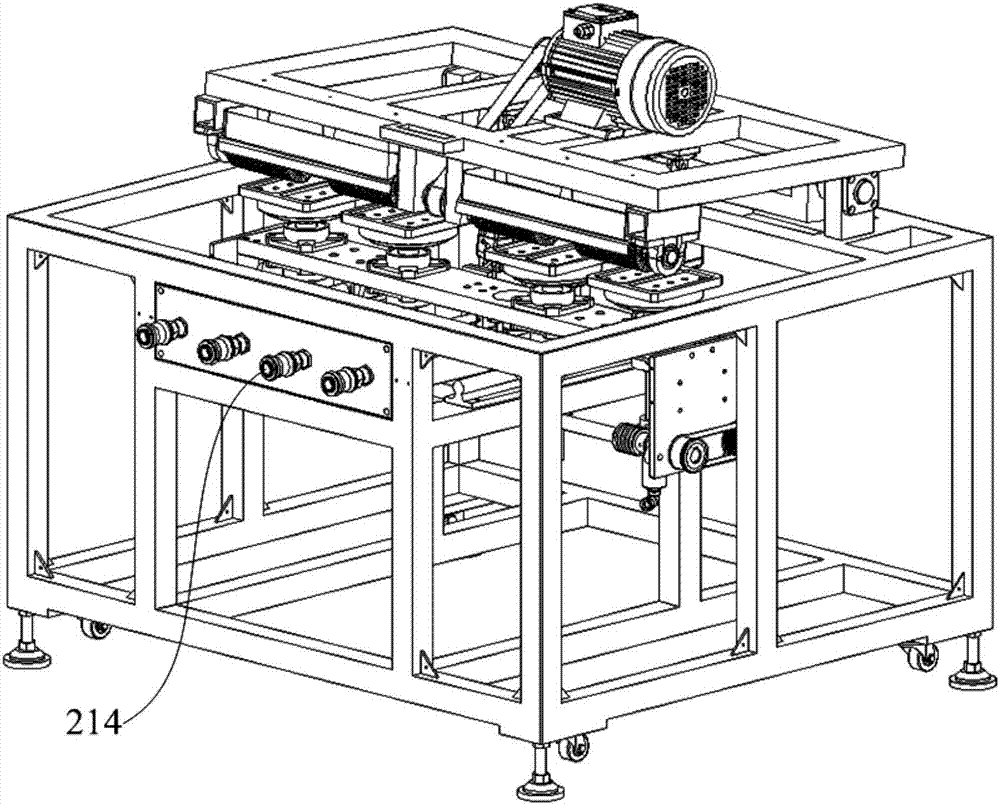

[0040] The jig assembly 200 is used to place workpieces and is disposed on the inner frame 102 . Specifically, such as Figure 5 As shown, the jig assembly 200 includes: several workpiece plates 210 , a mounting plate 220 , two parallel linear guide rails 230 , and a first driving mechanism 240 . Several workpiece trays 210 are arranged side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com