Movable horse board

A technology of movable boards and main boards, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of non-reusable boards, more dismantling operations, and more consumables, etc., and reduce the workload of repainting , save horse board material, high aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

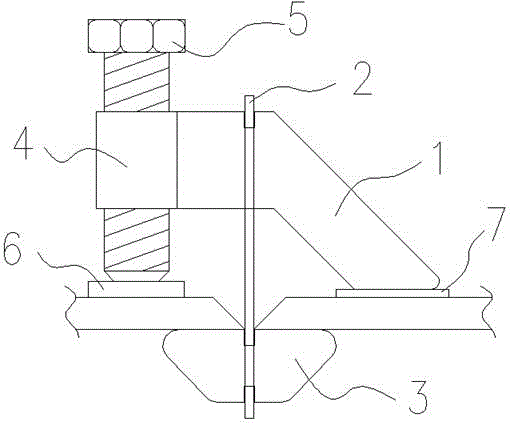

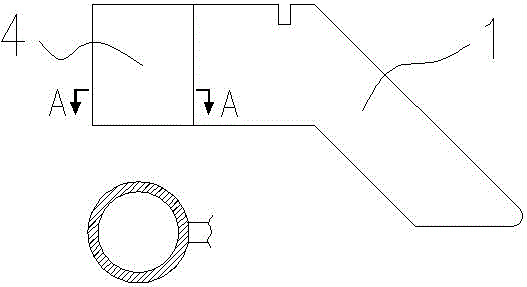

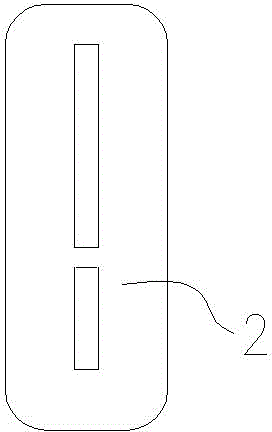

[0015] combined with Figure 1~4 , the movable horse board of the present invention comprises main board 1, inserting board 2, backing plate 3, nut 4, bolt 5, and described main board 1 is made of horizontal part and inclined part, and the horizontal part upper end of main board 1 is provided with a notch; Main board The horizontal part of 1 is arranged in the through hole on the upper part of the board 2, and the notch on the horizontal part of the main board 1 and the through hole of the board 2 are engaged with each other. Notches are respectively arranged on the upper and lower sides of the backing plate 3 , the backing plate 3 is arranged in the through hole at the bottom of the inserting plate 2 , and the notches of the backing plate 3 and the through holes of the inserting plate 2 are engaged with each other. One end of the horizontal part of the main board 1 is connected to the nut 4 , and the other end of the horizontal part is connected to the inclined part; the bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com