Production process of continuous artificial board production line

A production process and production line technology, which is applied in the production process field of wood-based panel continuous production lines, can solve the problems of no pre-cured layer, quality problems, material drop, etc., and achieve the effects of reducing production costs, stable product quality, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

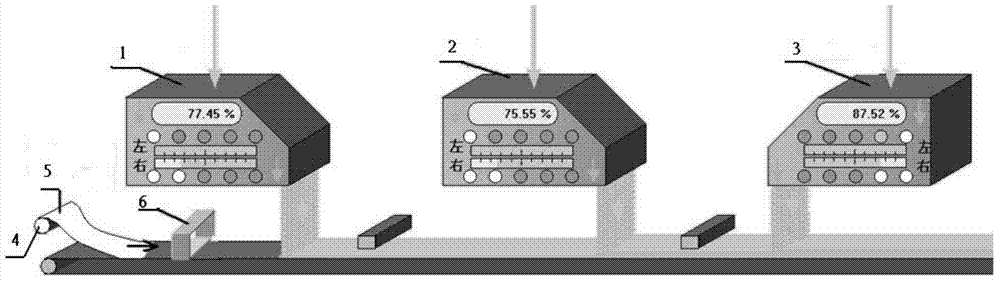

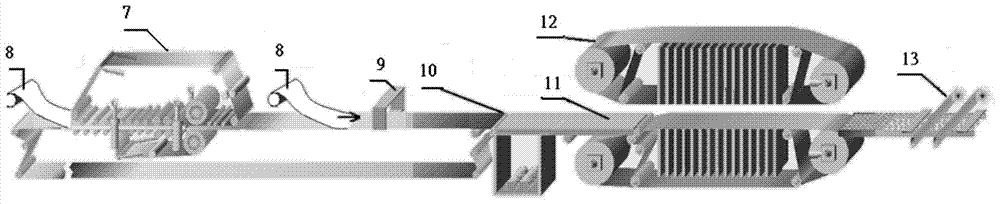

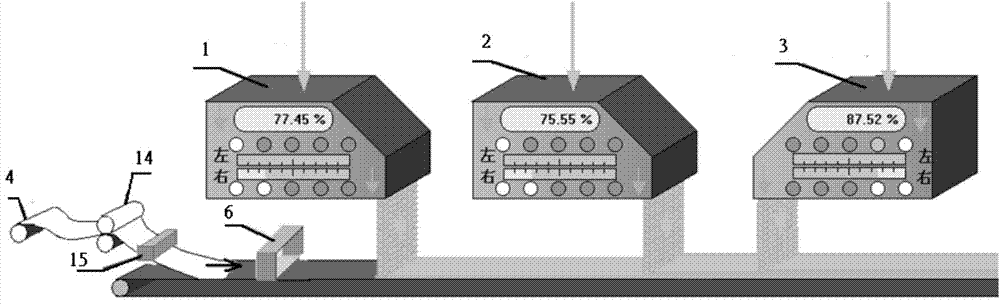

[0022] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0023] Aiming at the problems in the production process of the continuous wood-based panel production line due to the low initial viscosity of the glue, such as chipping, lower surface material drop, and steel strip sticking, the solution provided by the invention is to use the lower surface of the slab on the continuous wood-based panel production line ( or upper and lower surfaces) plus release paper (or wear-resistant paper, printing paper and other special paper, or spray release agent), hot melt adhesive film, special plastic film or bark, to solve material drop, sticky steel belt, sticky belt , high production cost, unstable quality, etc.; and by adding wear-resistant paper, printing paper, balance paper and other impregnated paper, hot melt adhesive film, special plastic film or bark on the lower surface (or upper and lower surfaces) of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com