Method used for preventing sand adhesion of sand mould castings, and sand mould prefabricated components

A technology of sand casting and prefabrication, which is applied to a method for preventing sand-sticking of sand-casting castings and the field of sand prefabrication. Concessionary effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

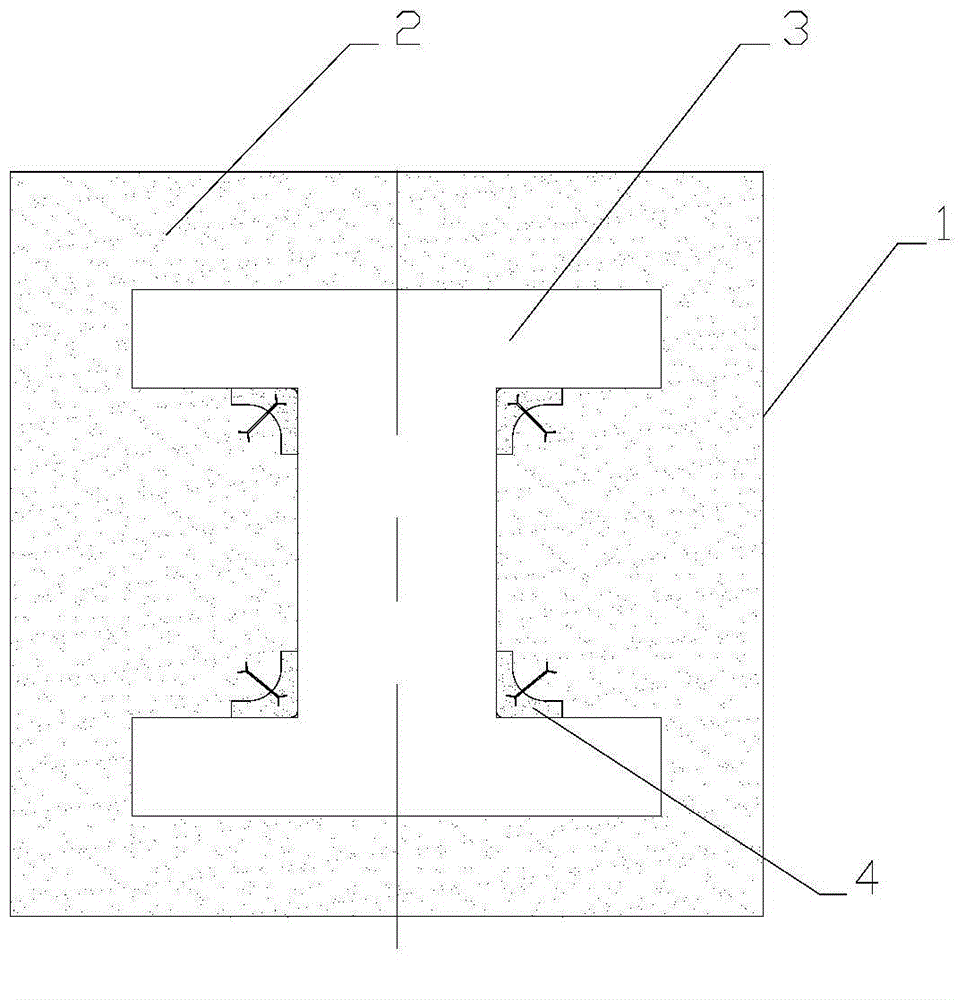

[0030] Such as figure 1 Shown, cast I-beam.

[0031] The method of preventing I-steel mold sand casting I-steel from sticking sand is to prefabricate the corresponding parts of the sand mold prefabricated parts in advance for the sand mold molding. The sand mold prefabricated parts are made of chrome ore in non-silica sand. The molding sand is compacted, and the prefabricated part is naturally fixed by the molding sand; the specific operation is as follows:

[0032] 1) Fill the sand box 1 with part of the molding sand 2;

[0033] 2) Judging from the I-beam structure, the four inner right-angle positions of the I-beam are prone to sand sticking;

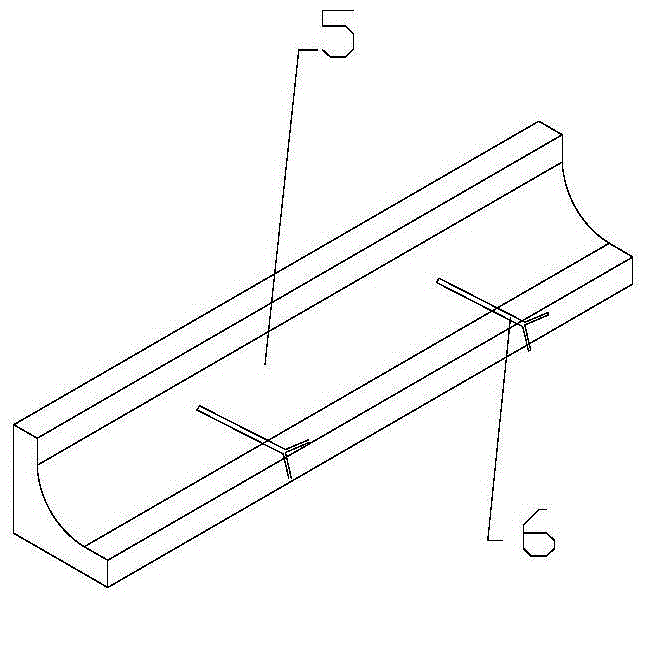

[0034] 3) Make I-steel sand mold prefabricated part 4 according to the inner right angle shape of I-steel, and I-steel sand mold prefabricated part 4 is a strip-shaped right-angled prefabricated part. Due to the long length of I-steel, the prefabricated parts are made into several fixed-length standards parts for splicing;

[0035...

Embodiment 2

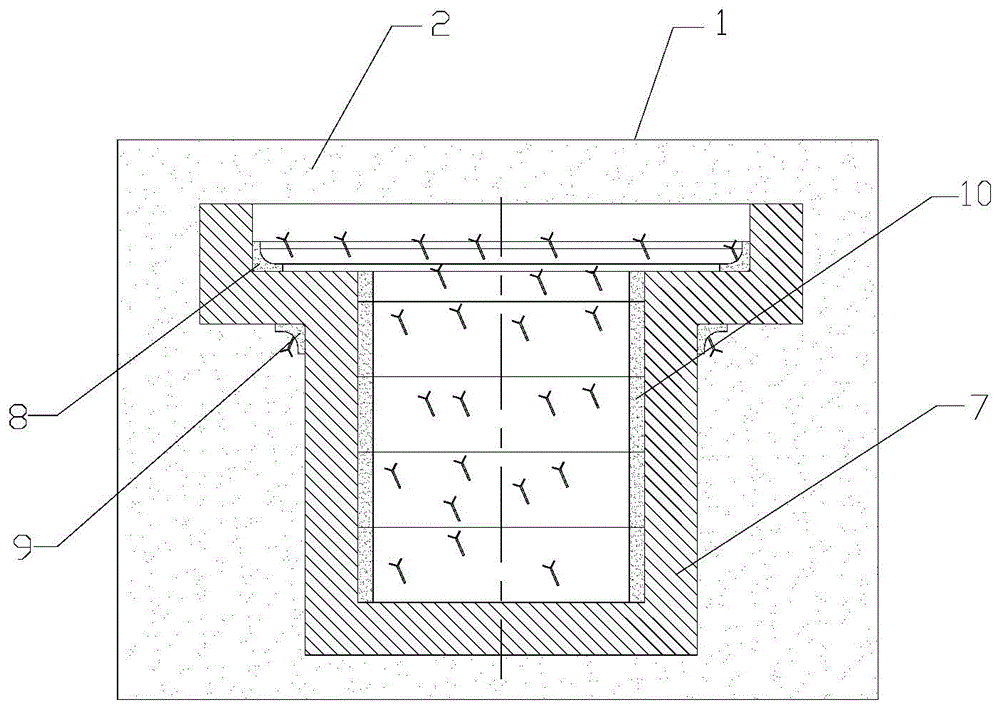

[0040] Such as image 3 As shown, casting stepped rotary workpiece

[0041] The method of preventing the sand casting of the stepped rotary part mold from sand casting is to prefabricate the sand mold prefabricated part in advance for the sand mold molding. The sand mold prefabricated part is made of zircon sand other than silica sand. The molding sand is compacted, and the prefabricated part is naturally fixed by the molding sand; the specific operation is as follows:

[0042] 1) Fill the sand box 1 with part of the molding sand 2;

[0043] 2) According to the structure of the stepped rotary workpiece, it is judged that the inner and outer stepped straight mouths of the stepped rotary workpiece and the inner wall of the cylinder are prone to sand sticking;

[0044] 3) Make inner and outer annular right-angle prefabricated parts 8 and 9 according to the shape of the inner and outer ladder straight mouths of the workpiece. The annular right-angle prefabricated parts can be cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com