Patents

Literature

135results about How to "Increase pouring speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

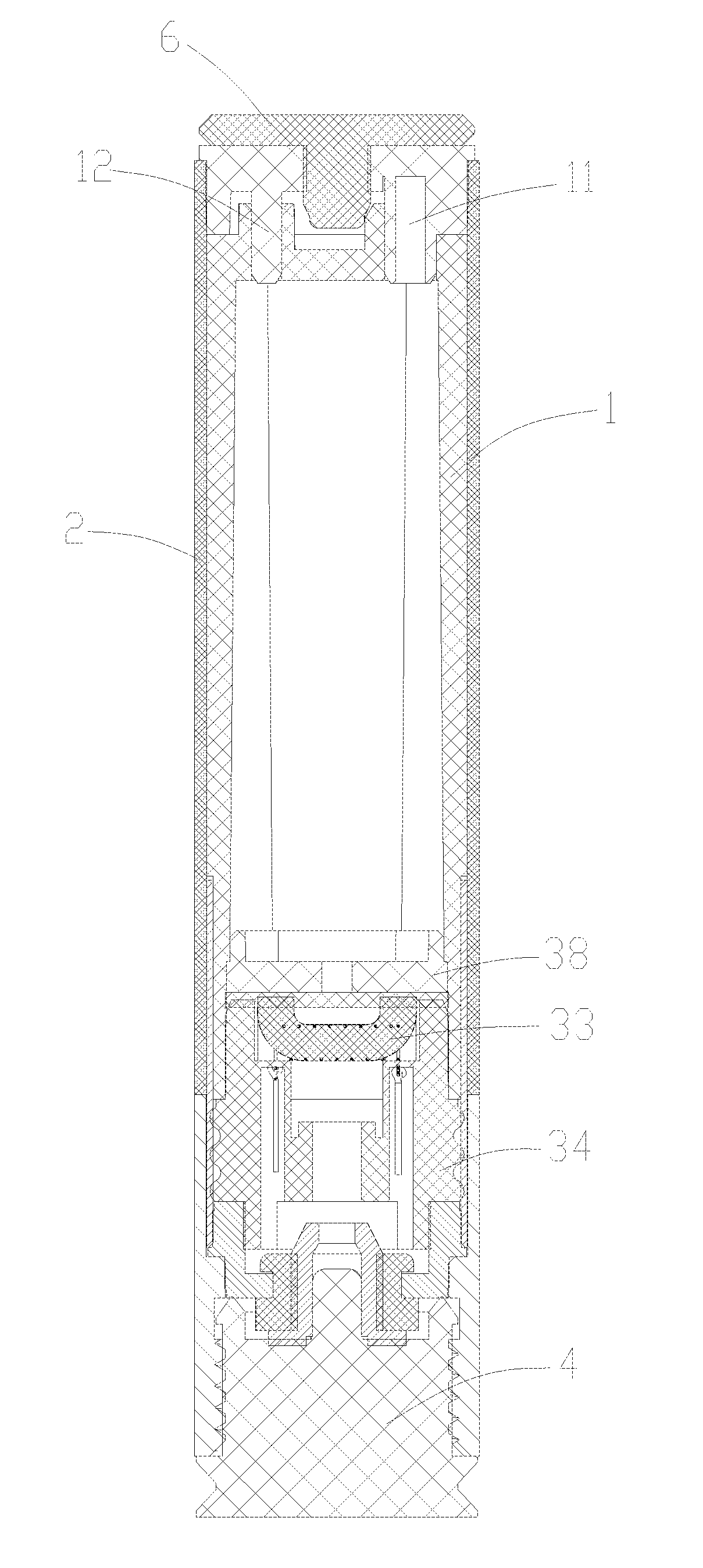

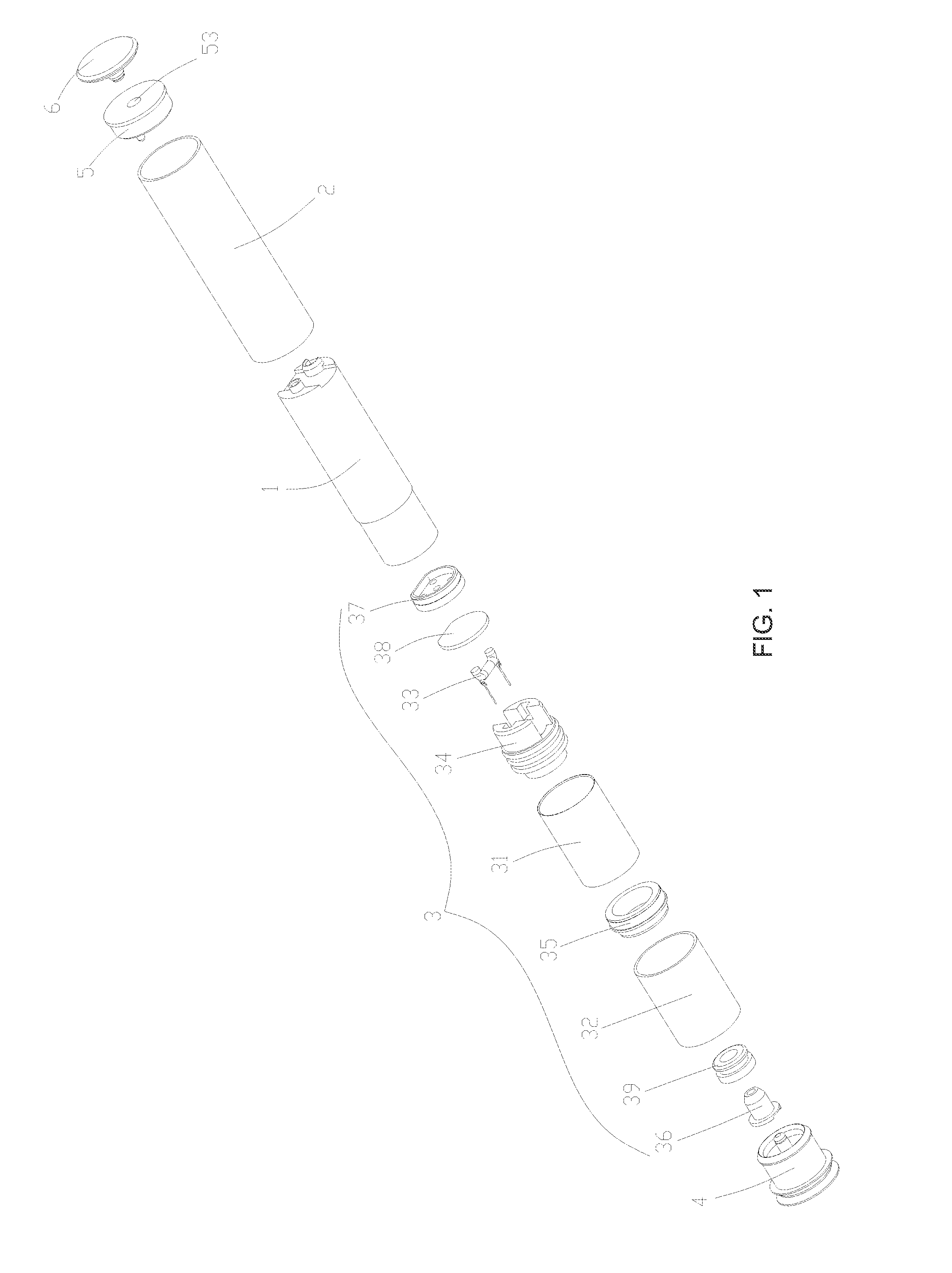

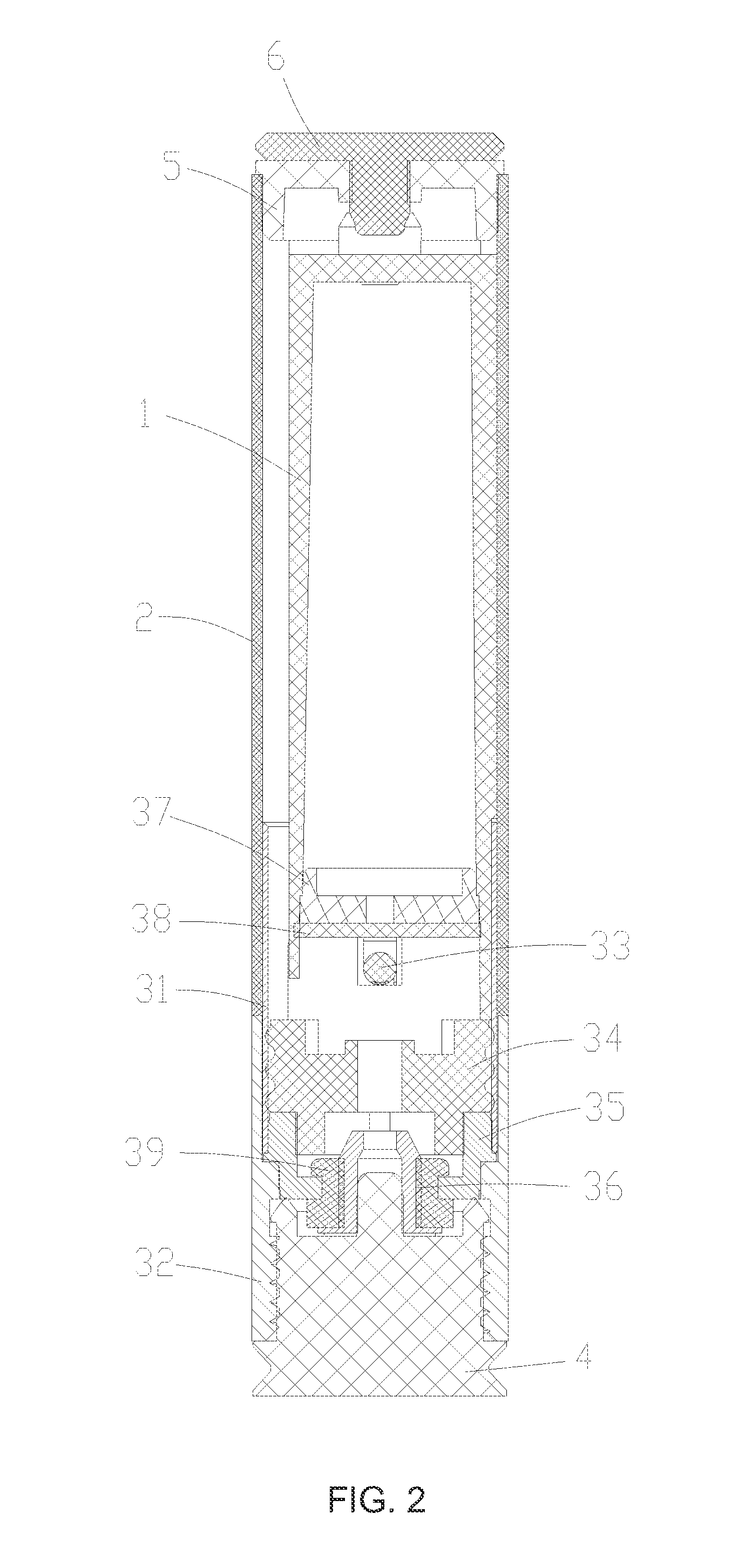

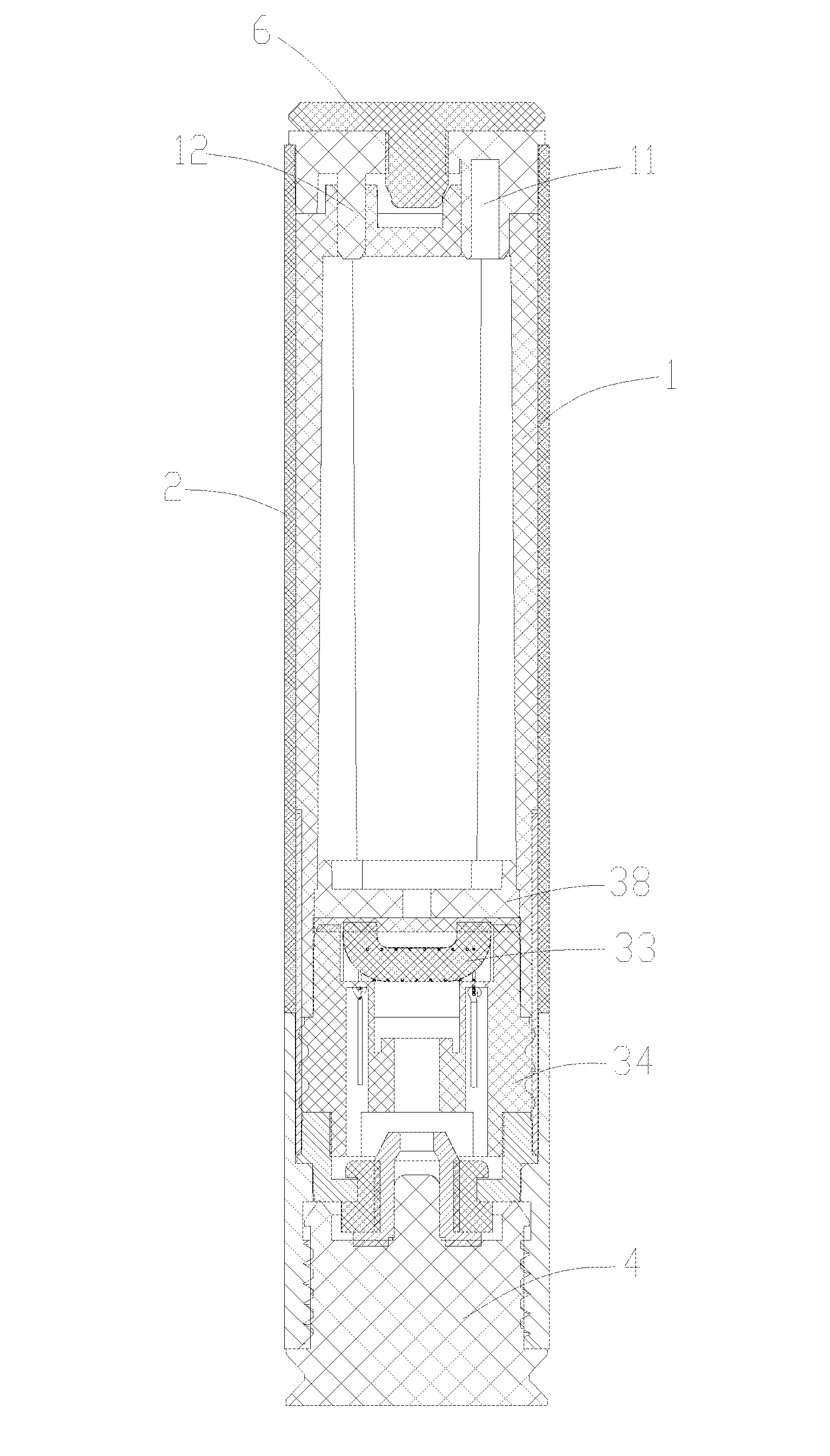

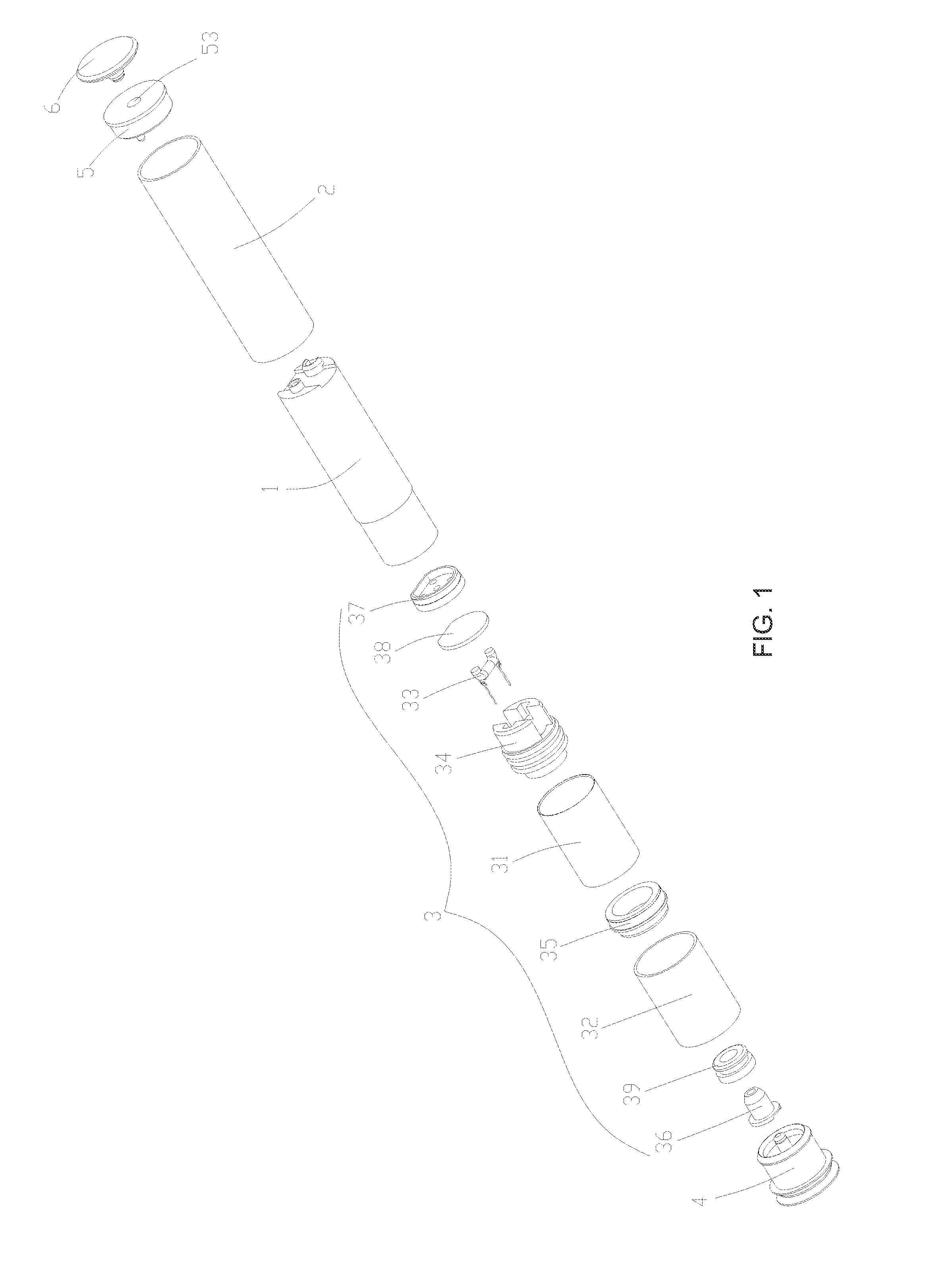

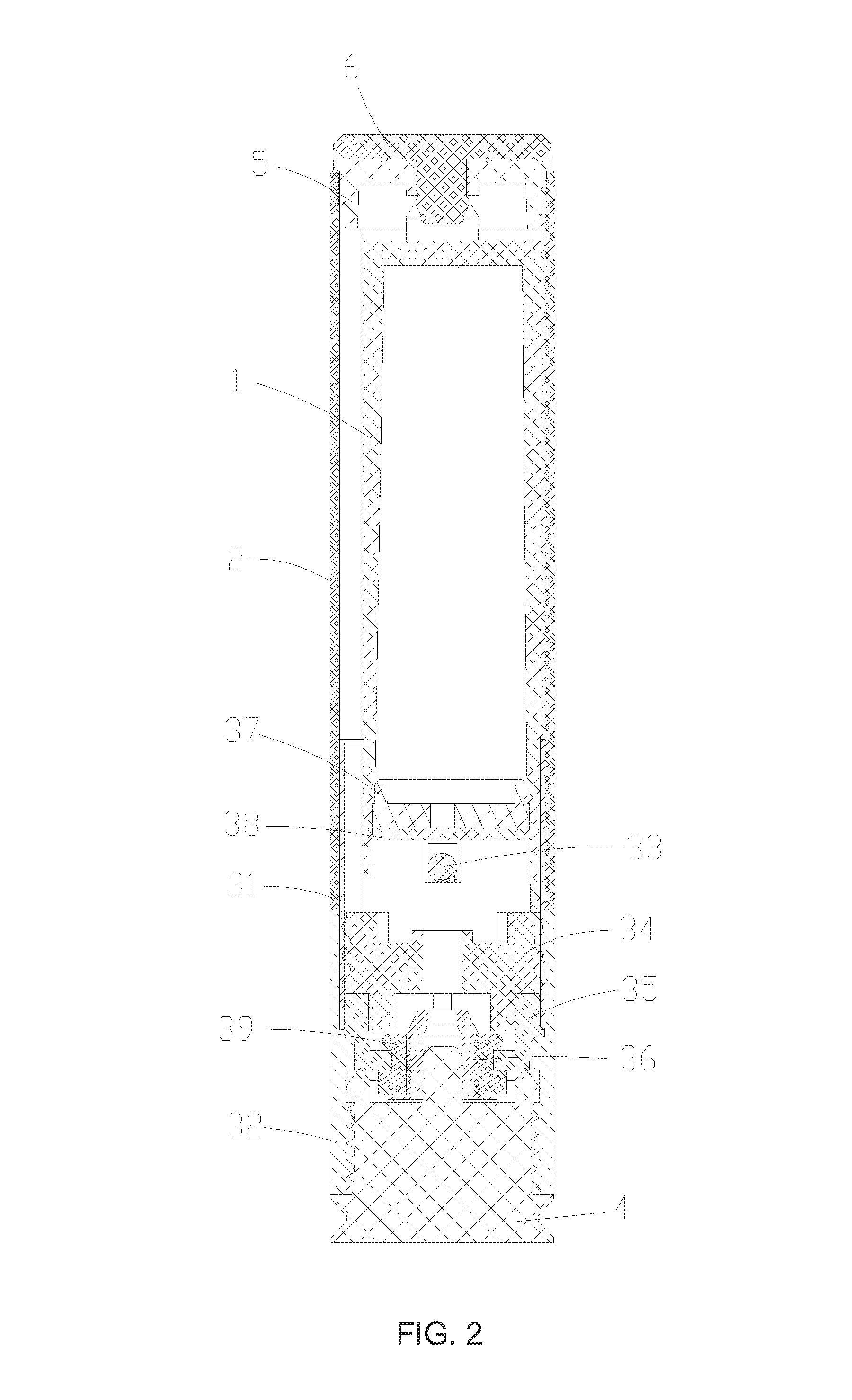

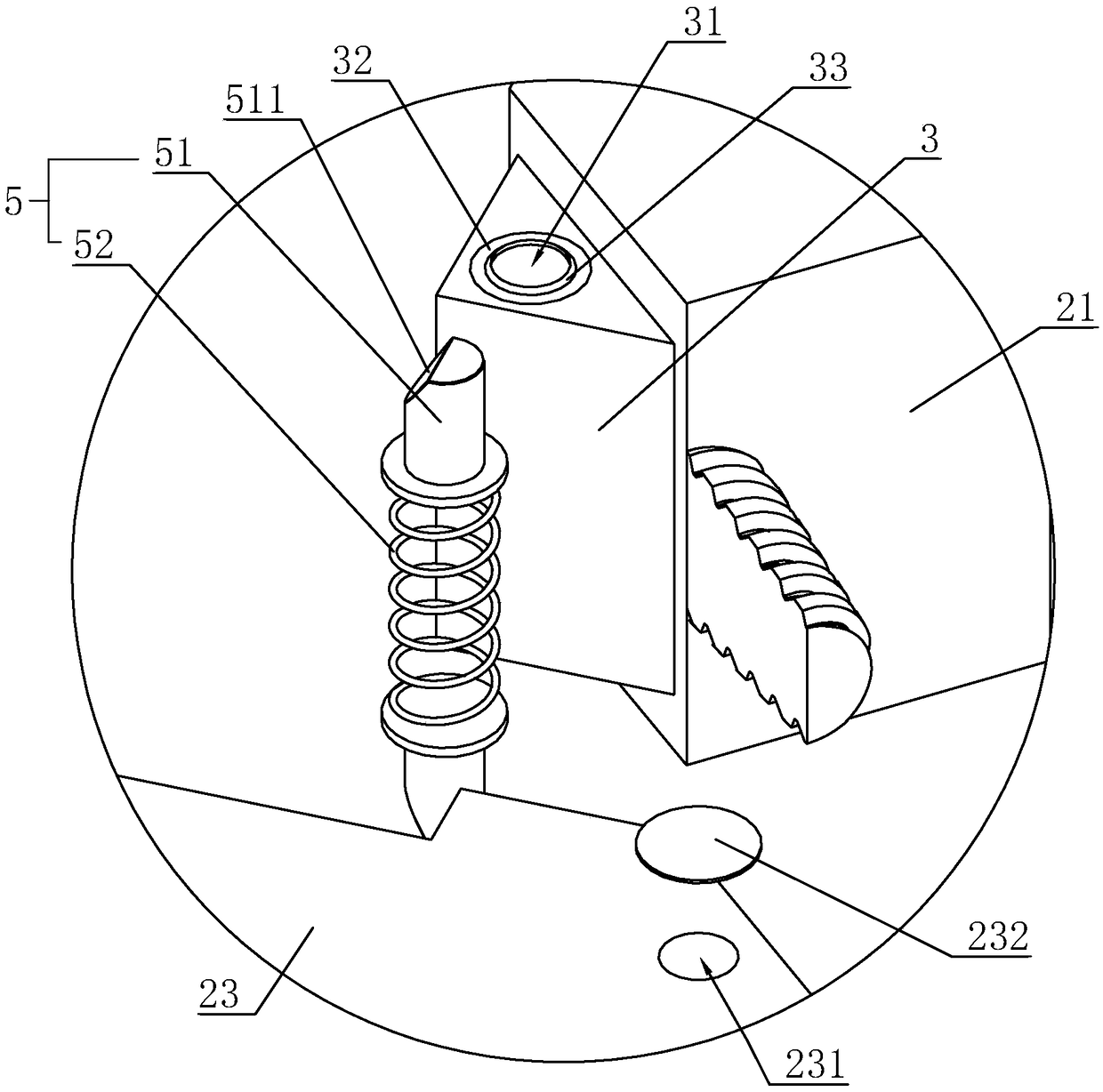

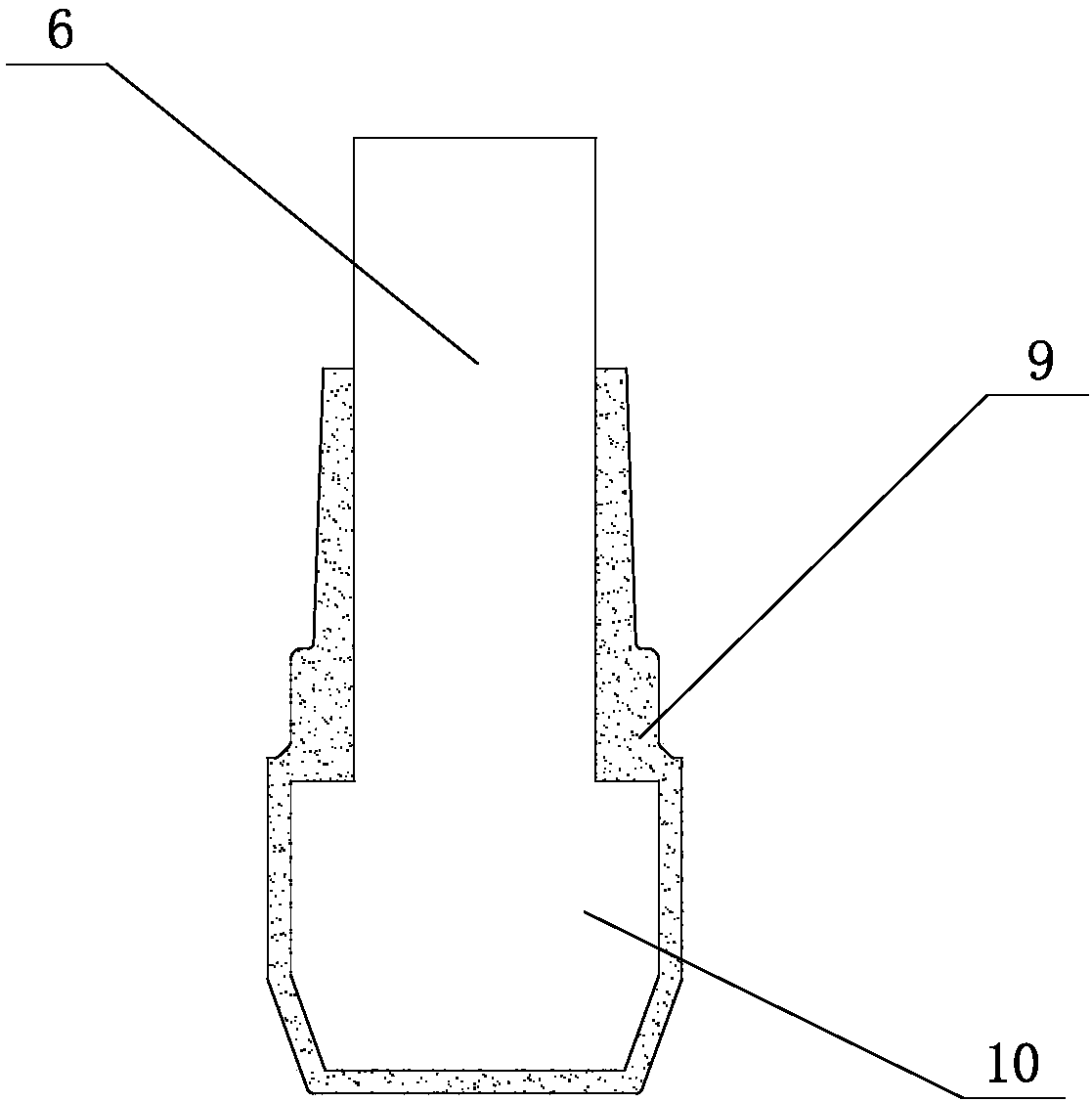

Atomizing device of electronic cigarette

ActiveUS9498001B2Shorten speedIncrease productivityTobacco pipesTobacco devicesEngineeringElectronic cigarette

An atomizing device of an electronic cigarette is disclosed. The atomizing device comprises a liquid cup used for accommodating tobacco liquid, an outer tube wrapped outside the liquid cup and a heating atomizing component disposed at a bottom of the liquid cup. A bottom of the heating atomizing component is sealed by a liquid blocking plug. A top of the liquid cup is provided and disposed with a detachable top cover and a detachable sealing plug used to seal the top of the liquid cup. A liquid filling hole and an exhaust hole are respectively disposed and installed at the liquid cup. The atomizing device of an electronic cigarette of the present invention is able to avoid any difficulty of pouring tobacco liquid due to incapability of exhausting air resided in the liquid cup out, and to accelerate a pouring speed of tobacco liquid so that production efficiency is enhanced.

Owner:SHENZHEN SMACO TECHNOLOGY LIMITED

Atomizing device of electronic cigarette

ActiveUS20160255877A1Shorten speedIncrease productivityTobacco pipesTobacco devicesEngineeringElectronic cigarette

An atomizing device of an electronic cigarette is disclosed. The atomizing device comprises a liquid cup used for accommodating tobacco liquid, an outer tube wrapped outside the liquid cup and a heating atomizing component disposed at a bottom of the liquid cup. A bottom of the heating atomizing component is sealed by a liquid blocking plug. A top of the liquid cup is provided and disposed with a detachable top cover and a detachable sealing plug used to seal the top of the liquid cup. A liquid filling hole and an exhaust hole are respectively disposed and installed at the liquid cup. The atomizing device of an electronic cigarette of the present invention is able to avoid any difficulty of pouring tobacco liquid due to incapability of exhausting air resided in the liquid cup out, and to accelerate a pouring speed of tobacco liquid so that production efficiency is enhanced.

Owner:SHENZHEN SMACO TECHNOLOGY LIMITED

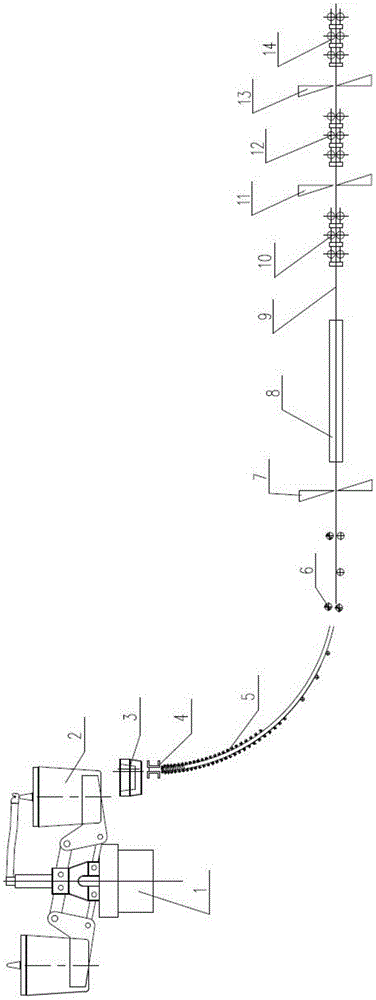

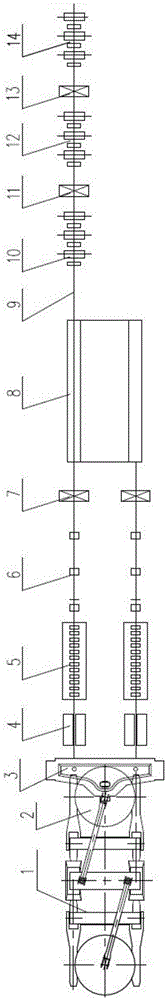

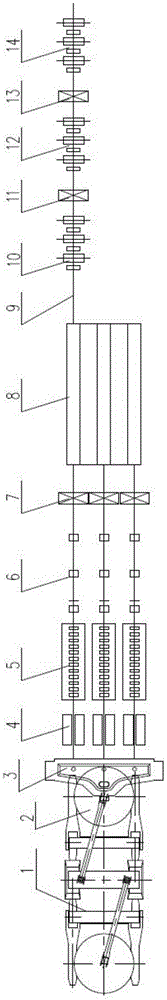

Continuous casting and rolling production line of wire rods and production method of production line

InactiveCN105414185AAchieve seamless connectionRealize construction costMetal rolling arrangementsWire rodProduction line

The invention discloses a continuous casting and rolling production line of wire rods and a production method of the production line. The continuous casting and rolling production line of the wire rods comprises a continuous casting machine, a parallel-flow device and a rolling mill unit. The method comprises the steps that a square casting blank or a circular casting blank is produced by means of the continuous casting machine firstly, the produced square casting blank or circular blank is cut through a cutting machine, parallel flowing is conducted through the parallel-flow device, the parallel flowed square casting blank bodies or circular casting blank bodies are conveyed to an inlet of the rolling mill unit through a conveyor roller way finally, and the rods are prepared by rolling through a rough mill, an intermediate mill and a finishing mill in sequence. According to the continuous casting and rolling production line of the wire rods and the production method of the production line, seamless connection of the continuous casting machine and rolling mills is achieved, the casting blank can be directly hot-delivered into the rolling mill unit to be rolled into the rods, secondary heating through a heating furnace is not needed, and the continuous casting and rolling production line of the wire rods and the production method of the production line have the advantages of being high in pouring speed, small in casting machine flow number, compact in production rhythm, high in efficiency, less in energy consumption and low in construction investment and operation maintenance cost.

Owner:CISDI ENG CO LTD

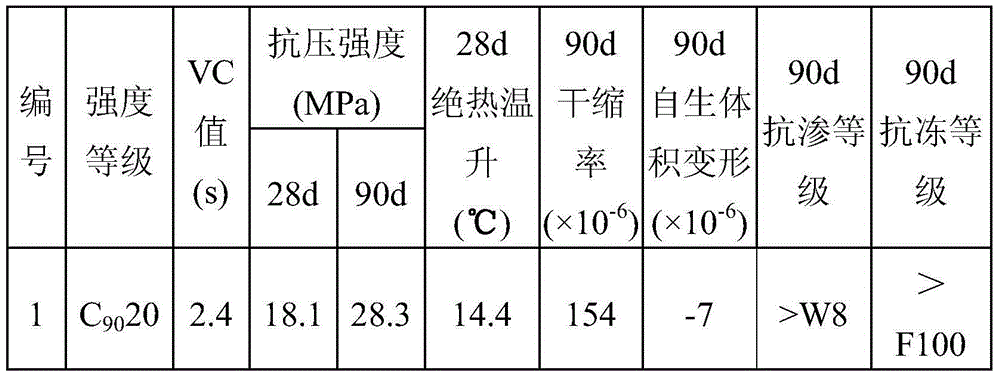

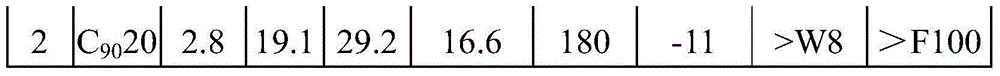

Four-graded roller compacted concrete suitable for water power hydraulic engineering and preparation method thereof

InactiveCN104402352AIncrease dosageReduce dosageSolid waste managementRoller-compacted concreteTemperature control

The invention provides four-graded roller compacted concrete suitable for water power hydraulic engineering, the four-graded roller compacted concrete per cubic meter comprises the following components: 49kg-64kg of cement, 78kg-92kg of fly ash, 70kg-71kg of water, 630kg-700kg of sand, 1520kg-1610kg of gravel, 0.98kg-1.42kg of a high efficiency water reducing agent and 0.07kg-0.14kg of an air entraining agent, the mass ratio of super large stone (80mm-120mm): large stone (40mm-80mm): middle stone (20mm-40m m): small stone (5mm-20mm) is 20:30:30:20. The four-graded roller compacted concrete is low in cementitious material use amount and low in adiabatic temperature rise, has good working performance, mechanical performance and durability, and can simplify the temperature control measures, improve the construction progress, and reduce cost.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

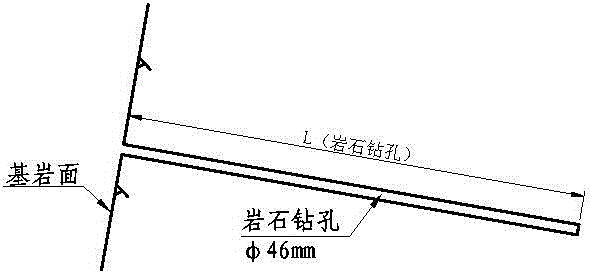

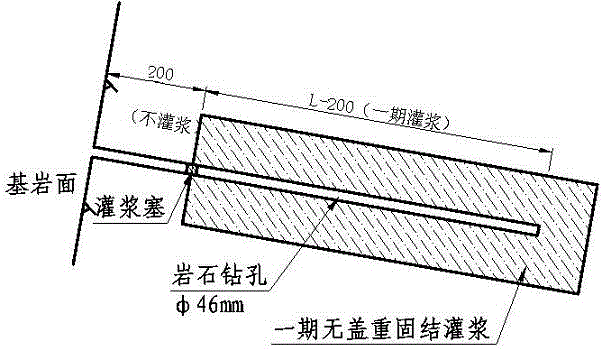

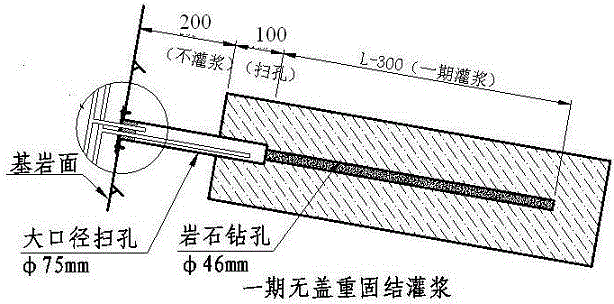

High-mountain narrow-valley arch dam foundation segmented and staged grouting method

The invention relates to a high-mountain narrow-valley arch dam foundation segmented and staged grouting method, and belongs to a foundation treatment method of a rock surface of a high steep bank slope foundation of a high-mountain narrow-valley arch dam foundation. The high-mountain narrow-valley arch dam foundation segmented and staged grouting method comprises the following steps: carrying out consolidation grouting and drilling after acceptance of excavation of the arch dam foundation; carrying out first-stage consolidation on the inside of a consolidation grouting hole; drilling a residual contact segment by the distance of 1 m with a phi 75 mm drilling sleeve after first-stage consolidation grouting is finished; burying a grouting system; pouring dam body concrete after first-stage consolidation grouting is finished; after joint grouting of a dam body is finished or while joint grouting of the dam body is carried out, carrying out second-stage consolidation on a consolidation grouting contact segment of the dam foundation. Consolidation of a bed rock contact segment and contact grouting are combined together, meanwhile, effects of contact segment consolidation and contact grouting are achieved, the work amount of the contact grouting system is reduced, the construction period is shortened, a construction technology is simplified, foundation treatment purposes of a high steep bank slope of the dam foundation of simplicity and convenience in construction, reliable technology, economy and reasonableness of grouting treatment of the high steep bank slope are achieved, and the problems encountered in foundation treatment of a dam segment of a bank slope are solved.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

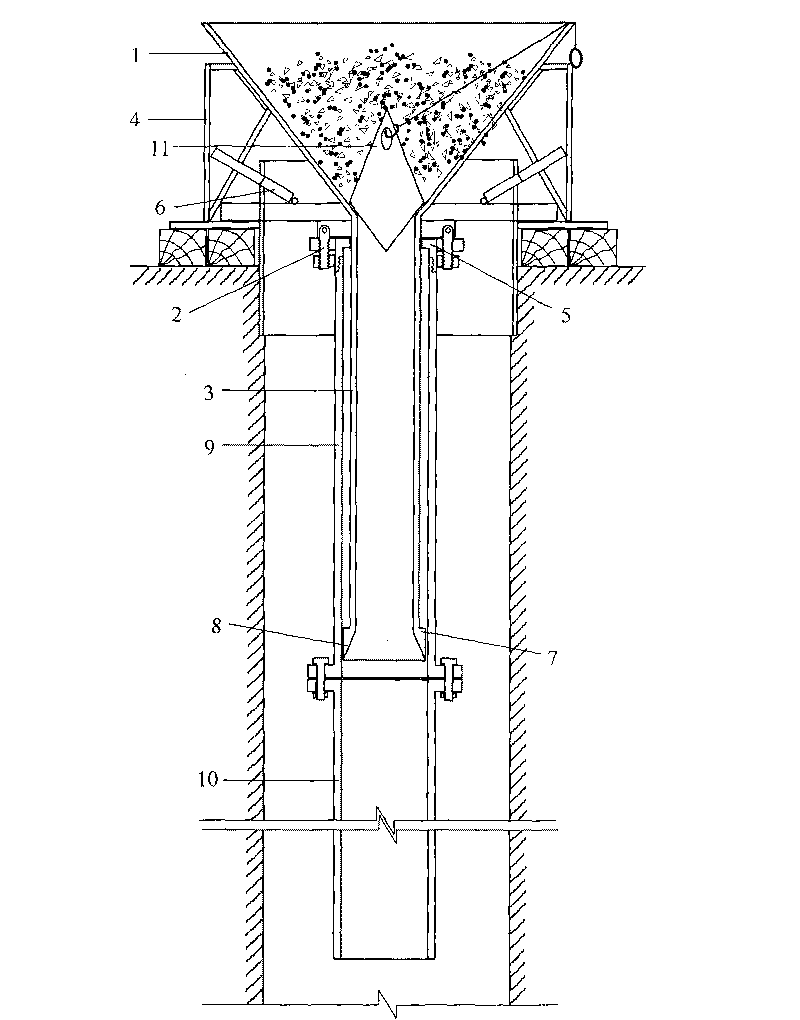

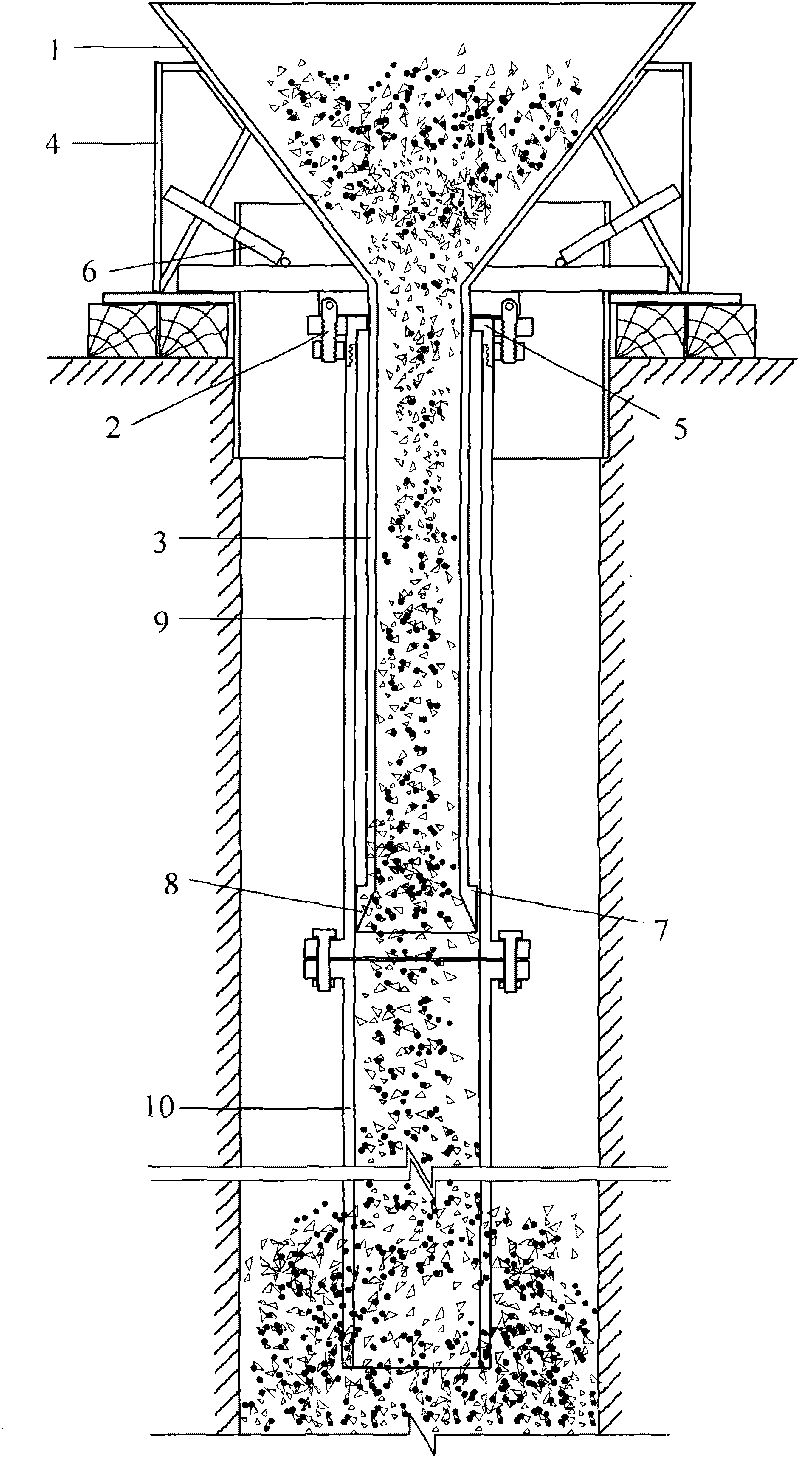

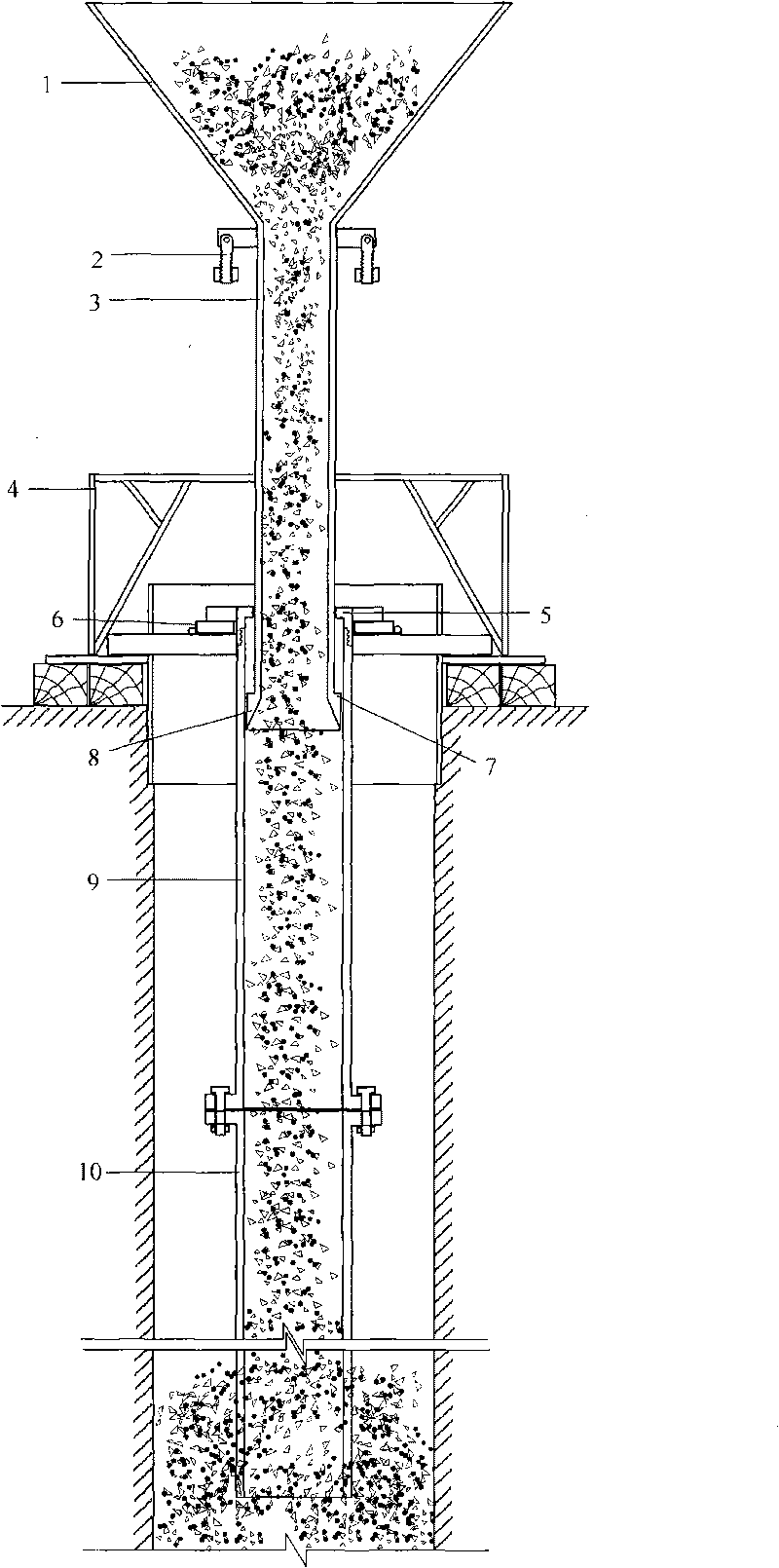

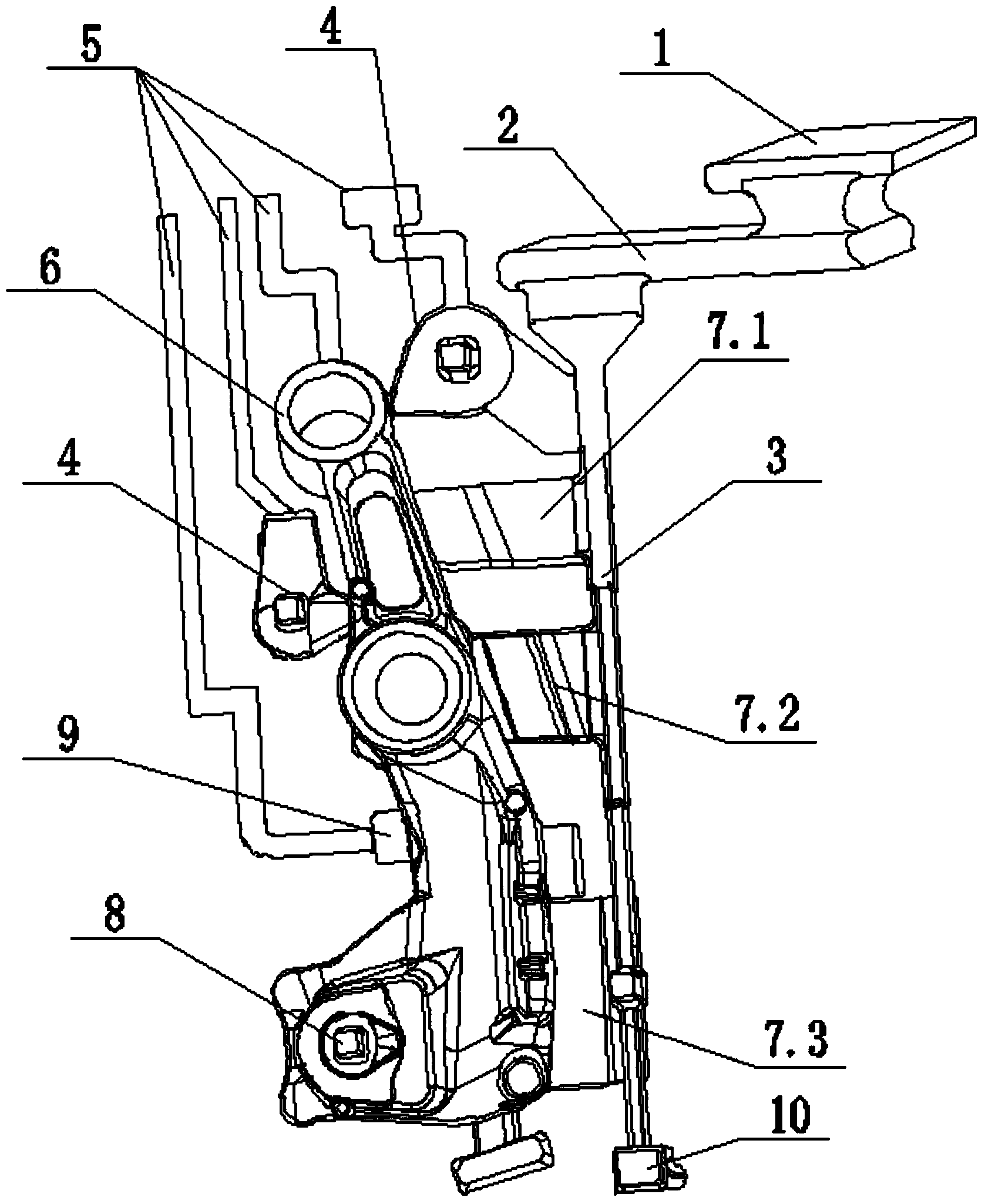

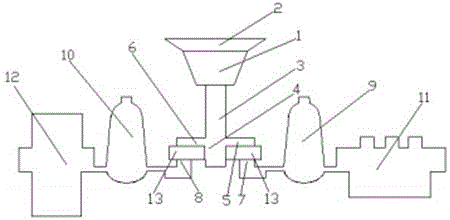

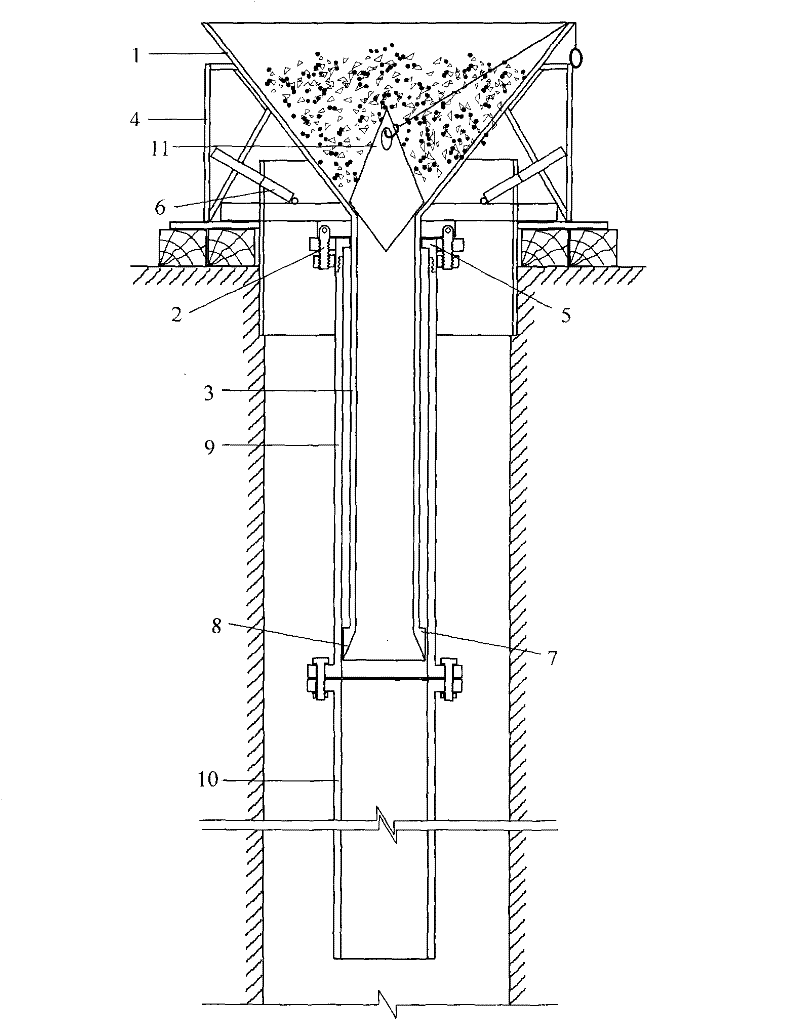

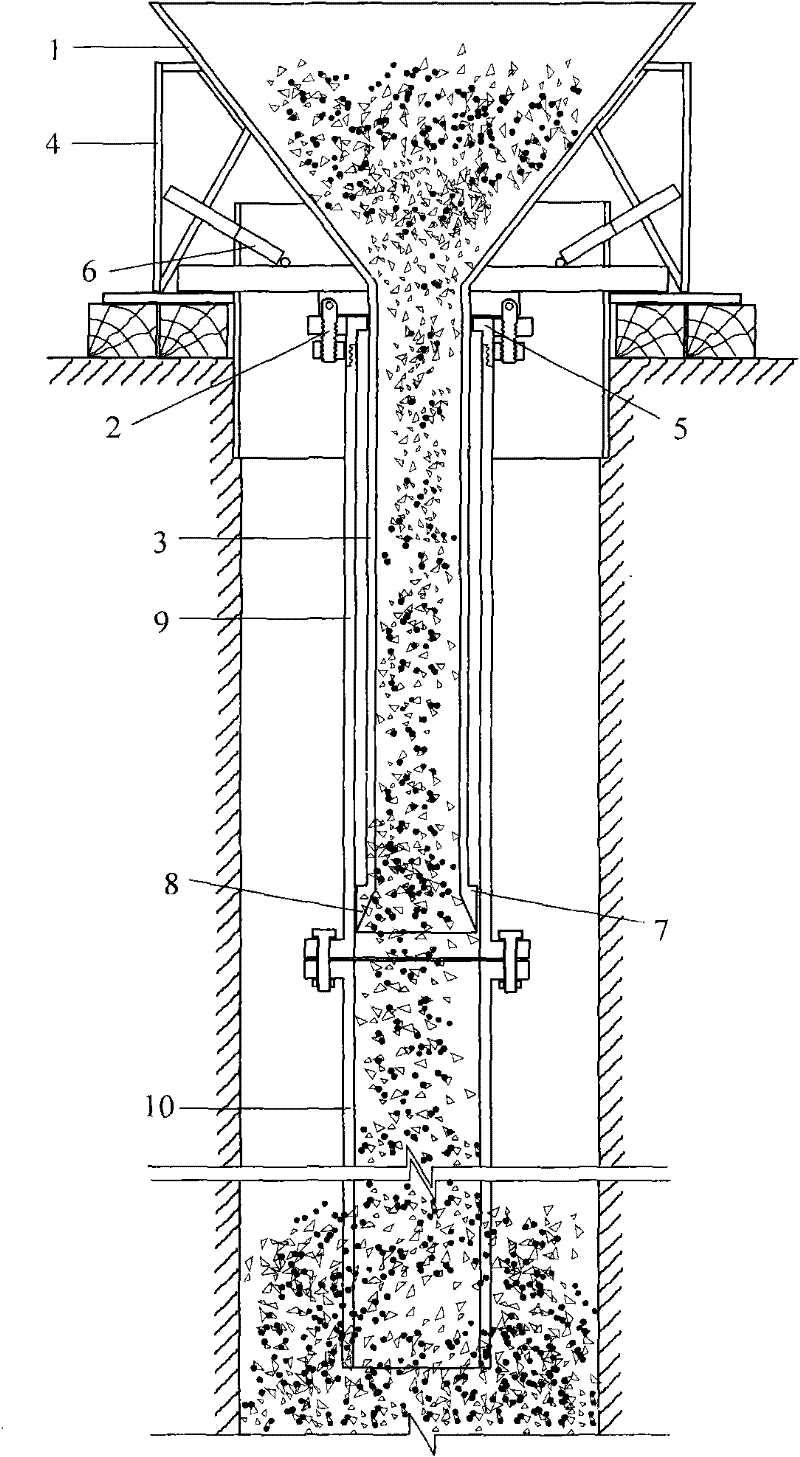

Feeding device of pouring pile underwater concrete and pouring method thereof

InactiveCN101725148AIncrease active pressureSolve the problem that is not easy to fallFoundation engineeringSlurryGuide tube

The invention belongs to the field of building construction, in particular to a feeding device of pouring pile underwater concrete and a pouring method thereof. The device comprises a hopper, a hopper frame, a sleeve pipe, a guide pipe and a hopper plug. The feeding device is characterized in that the lower end of the hopper is provided with the lining guide pipe; fixed bolts are arranged outside a lower port of the hopper; the upper end of the sleeve pipe is provided with a seal cap; bolt grooves are arranged outside the seal cap and respectively correspond to the fixed bolts outside the hopper in position; two folio valves are arranged on a clamping cover and sleeved at the lower port of the outer edge of the seal cap during working; the sleeve pipe is connected with the guide pipe by a flange; and the hopper plug is an iron plug of which both ends are in cone shapes. Compared with the traditional method for reducing the resistance of concrete in a pile and the slurry protecting wall on the concrete in the guide pipe just by lifting the guide pipe in a limited way, the invention greatly improves the active pressure of pouring concrete in the guide pipe, effectively solves the problem of difficult falling of the concrete, improves the pouring speed, ensures the molded pile quality and has obvious economic and comprehensive benefits.

Owner:DALIAN AERBIN GROUP

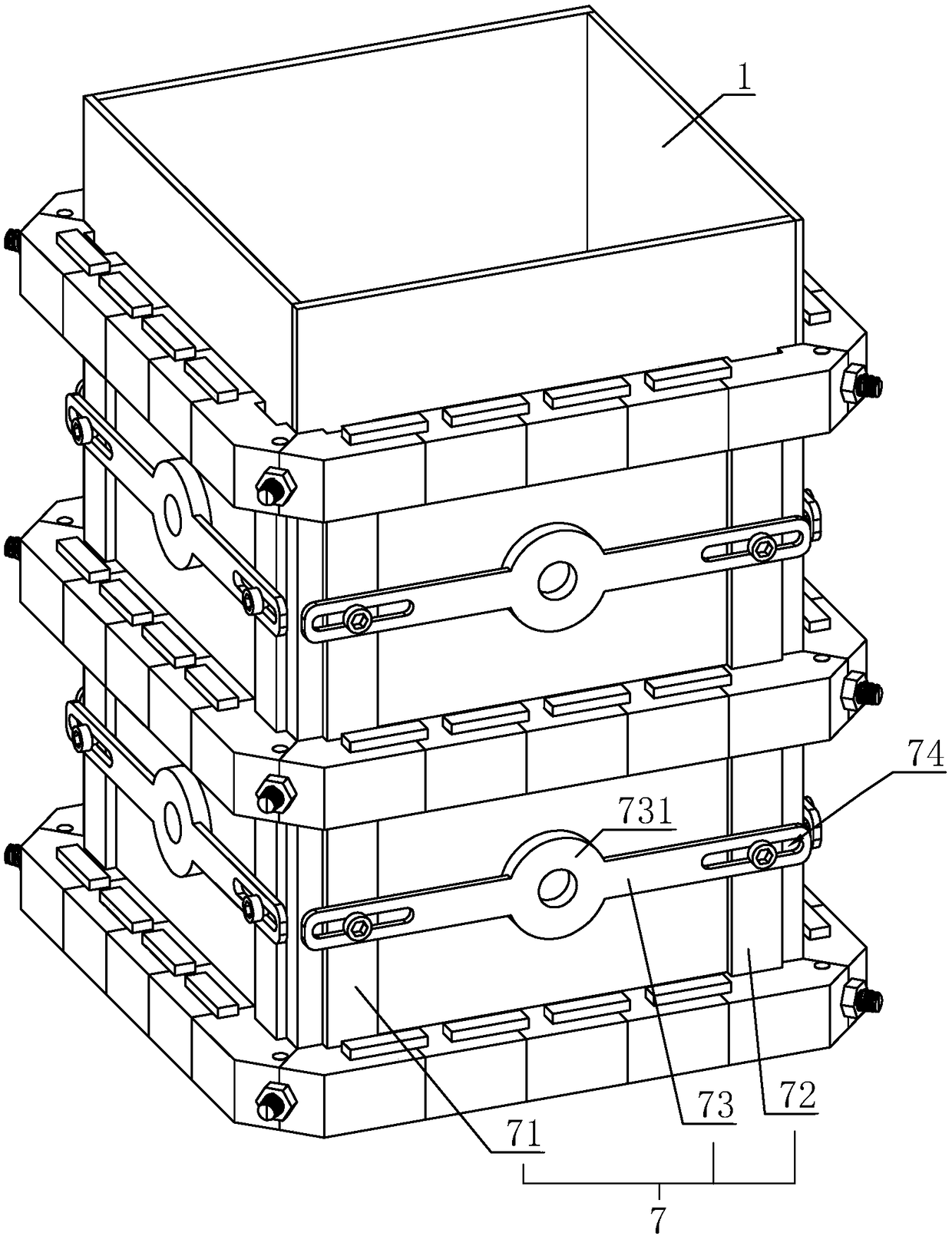

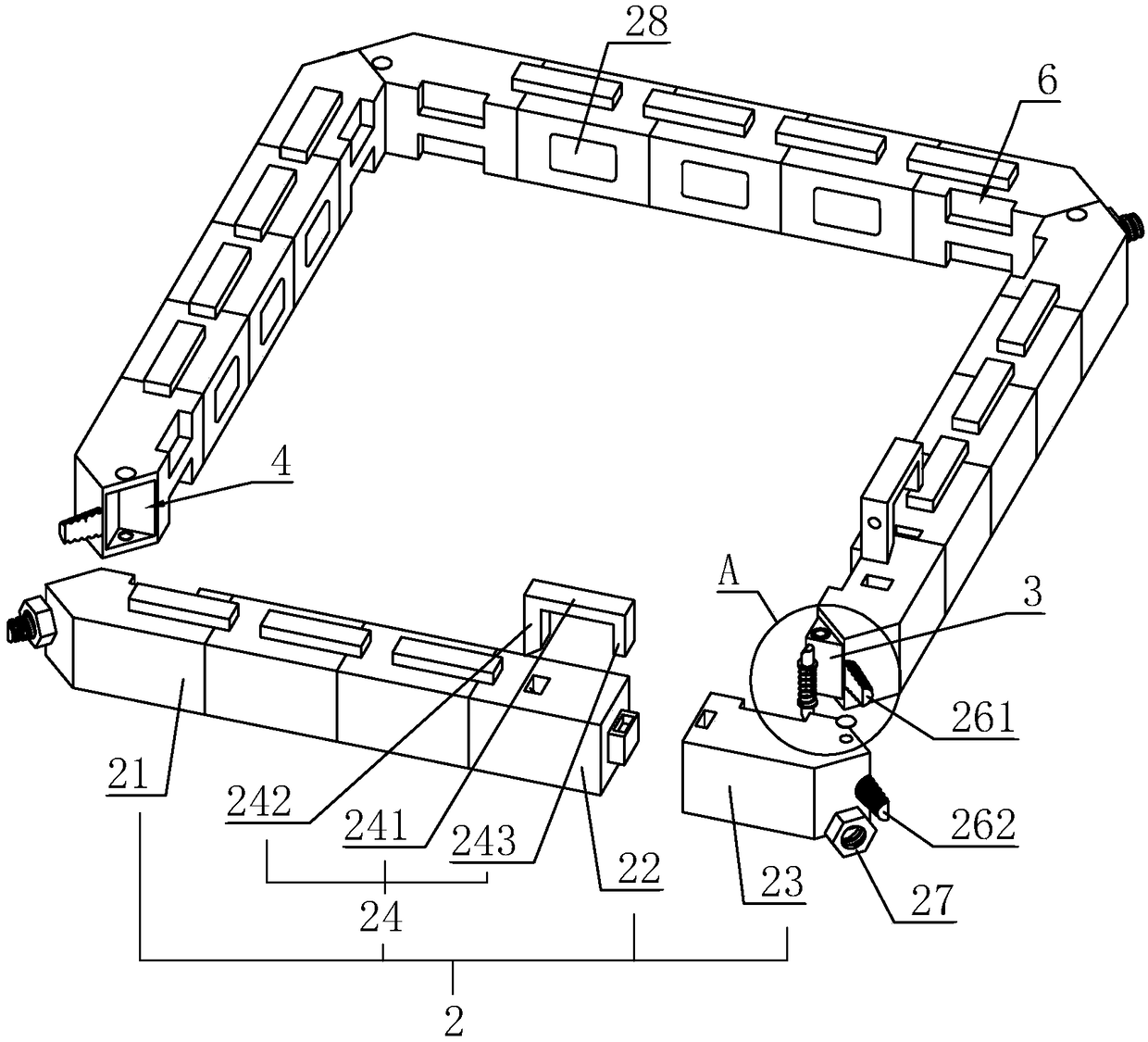

Tightening system of concrete rectangular column formwork and construction method of concrete column

InactiveCN109025272AAchieve fixationImprove efficiencyStrutsForms/shuttering/falseworksRight triangle

The invention discloses a tightening system of a concrete rectangular column formwork and a construction method of a concrete column, and relates to the technical field of concrete building. The system comprises an abutting device mounted on a side wall of a formwork around the concrete column, the abutting device comprises four cross bars which are connected in sequence, are closely adjacent tothe formwork and are provided with isosceles right-angled triangle-shaped two ends, clamping blocks which are disposed on the ends of the cross bars and faced to an oblique surface of one side of theformwork, clamping grooves which are formed in the other ends of the cross bars, faced to the oblique surface of the side of the formwork and clamped and cooperated with the clamping blocks and locking assemblies which connect the clamping grooves and the clamping blocks, and the locking assemblies protrude from the surfaces of the cross bars. By fixing the positions of the clamping blocks and theclamping grooves through the locking assemblies, the fixing between the adjacent cross bars is achieved, thereby achieving the purpose of fixing the concrete formwork, the operation is simple and convenient, and a large amount of time is saved, thereby greatly improving the efficiency of fixing the formwork.

Owner:上海生睿住宅工业有限公司

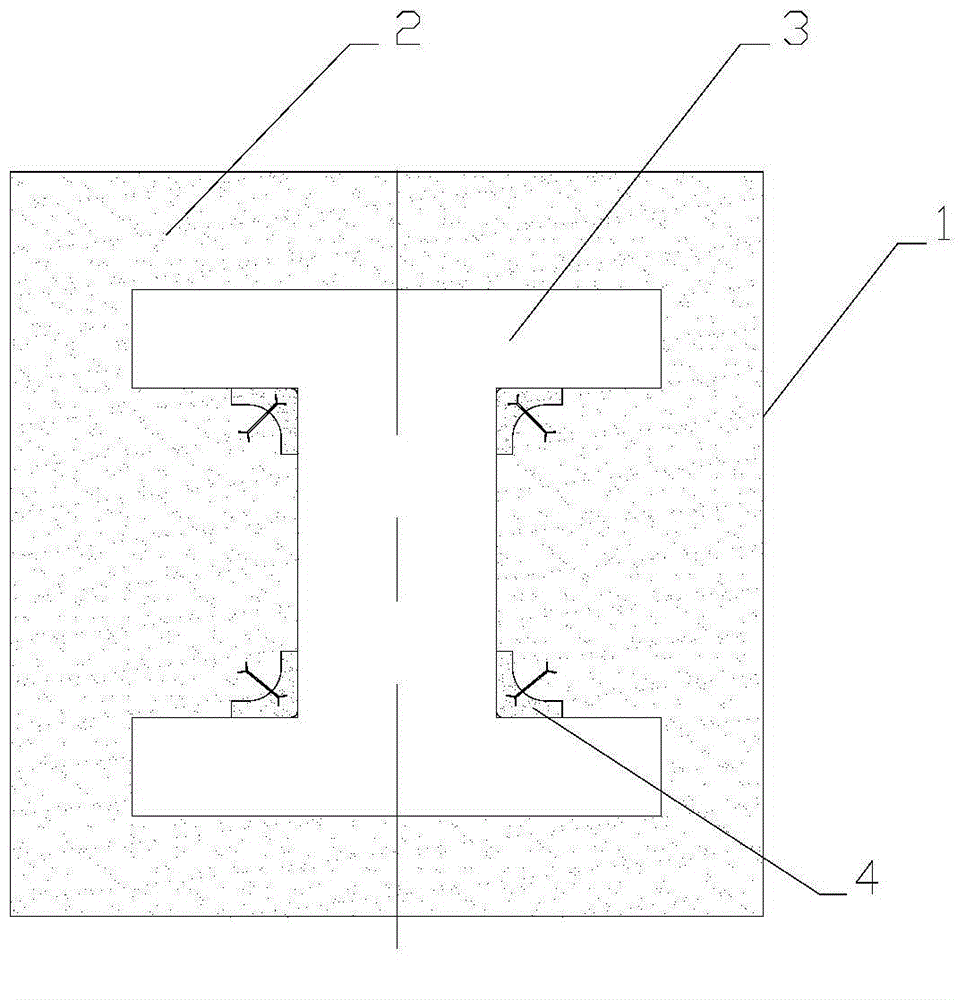

Bean column node unequal strength concrete replacing structure and its construction method

InactiveCN1587559AIncrease pouring speedSimple construction processBuilding constructionsReinforced concrete columnEngineering

The beam-column node construction method is to form beam-column node in the intersection point of beam and column and features that the beam-column node has expanded axils of concrete in the same strength as that of the beam around the node. The expanded axils have height the same as that of highest beam in the node. The node concrete has strength equal to or lower than that of beam; and the expanded axils are diamond shaped, rectangular or circular. The node may be deposited together with the beam. The present invention aims at facilitating beam-column node construction and speeding beam-column node construction.

Owner:北京建工一建工程建设有限公司

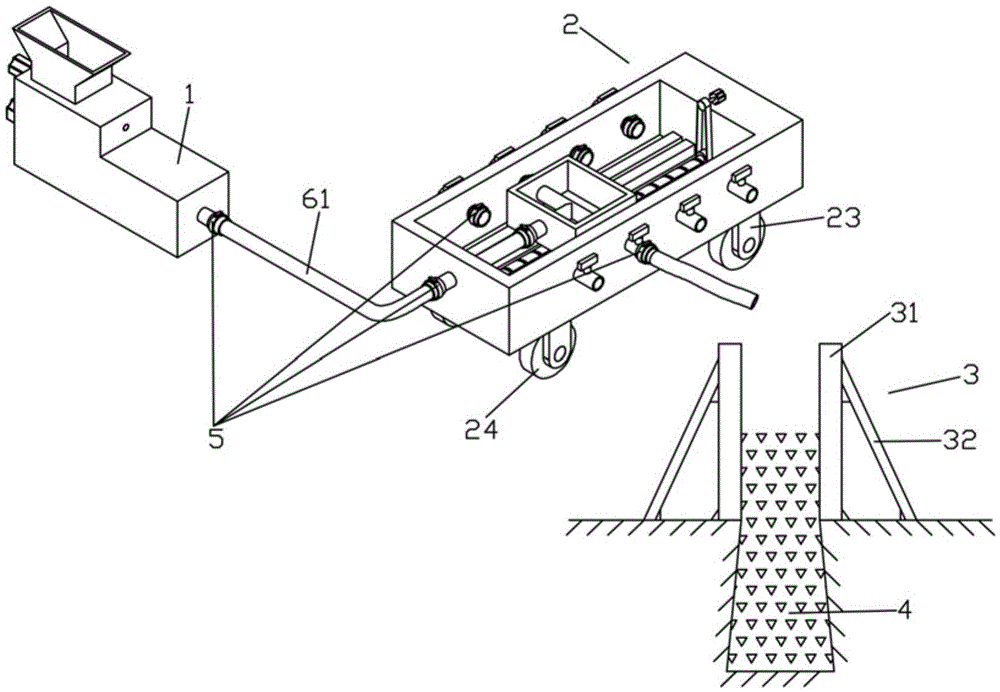

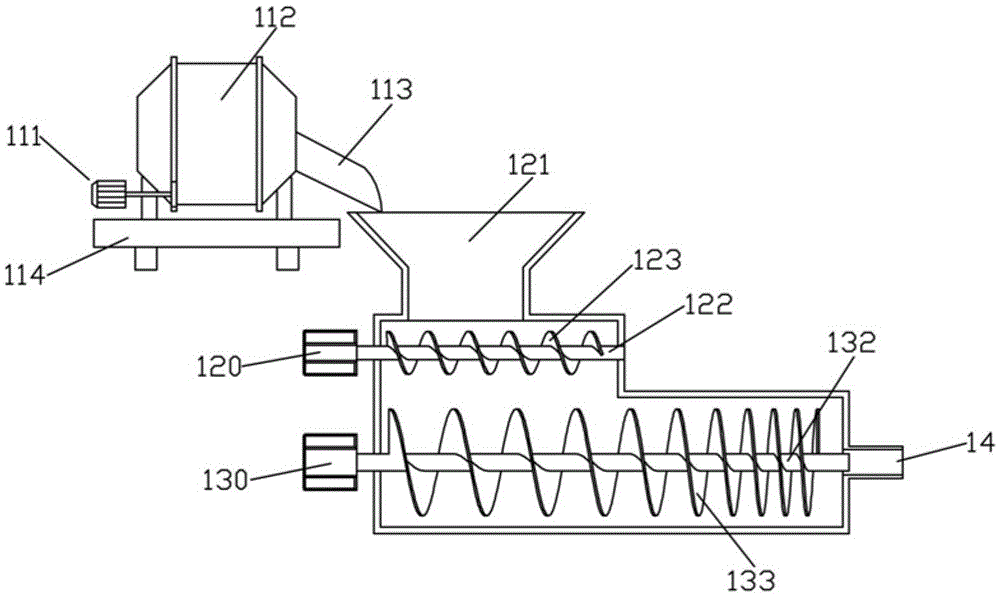

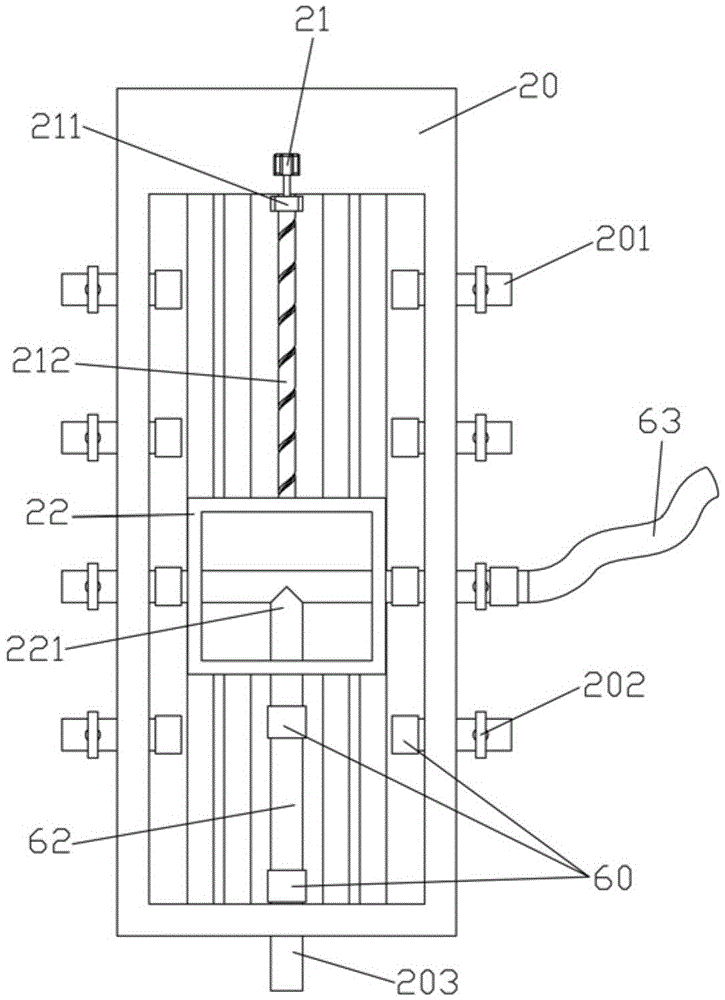

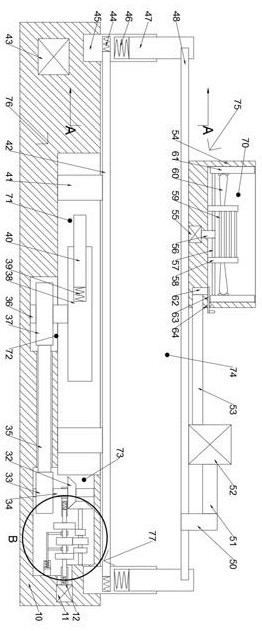

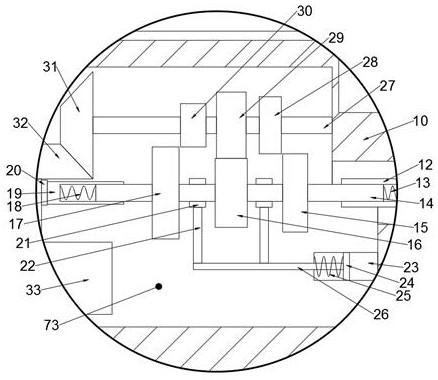

Building concrete on-site pouring device

ActiveCN105672660AImprove liquidityIncrease pouring speedBuilding material handlingStructural engineeringCement

The invention discloses a building concrete on-site pouring device which comprises a concrete stirring pot, a stirring flow device, a pouring trolley, a wall fixing support and a control device.Sand-gravel materials, cement, water and an additive are mixed and stirred through the concrete stirring pot, the rear portion of the concrete stirring pot is connected with the stirring flow device, the stirring flow device is connected with the pouring trolley through a conveying pipeline, the pouring trolley moves back and forth between the stirring flow device and the wall fixing support, and both the concrete stirring pot and the pouring trolley are electrically connected with the control device.According to the building concrete on-site pouring device, the flowability of concrete can be improved in the pouring process, the pouring speed of the concrete can be increased, meanwhile, the pouring amount can be precisely determined, and production efficiency is improved.

Owner:湖南教建集团有限公司

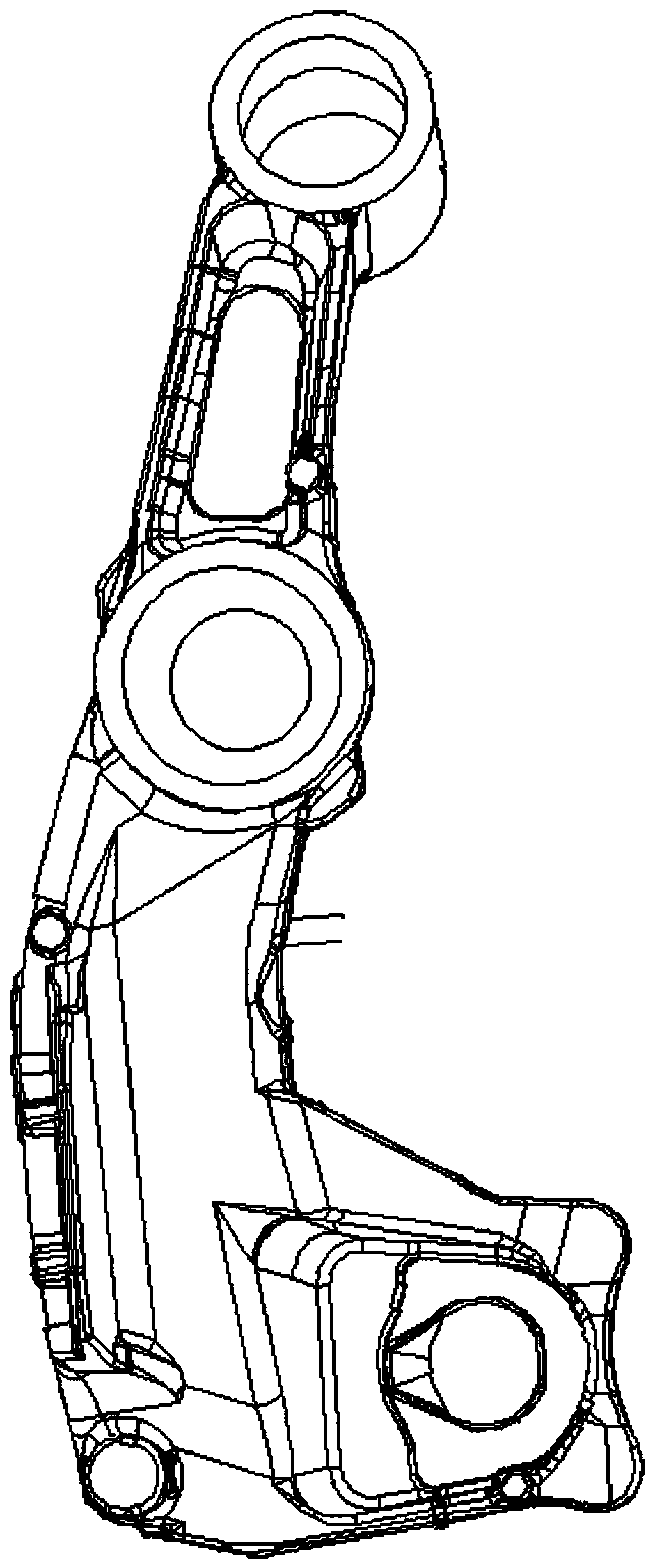

Casting method of steering knuckle of nodular cast iron

ActiveCN103846392AShort stayImprove cooling effectFoundry mouldsFoundry coresDuctile ironRejection rate

The invention discloses a casting method of a steering knuckle of nodular cast iron. The casting method comprises a mold manufacturing step, a sand mold manufacturing step and a pouring molding step, wherein the steering knuckle is vertically arranged, a thick part of a steering knuckle casting is arranged at the upper part, a thin-walled part of the steering knuckle casting is arranged at the lower part; a pouring system of the steering knuckle casting is divided into a pouring cup, a cross pouring gate and a straight pouring gate, the cross pouring gate is connected to the lower part of the pouring cup, the straight pouring gate is connected to the lower part of the cross pouring gate, and a scum riser is arranged at the bottom end of the straight pouring gate; the side wall of the straight pouring gate is connected with a first inner pouring gate, a second inner pouring gate and a third inner pouring gate from top to bottom; the steering knuckle casting is further provided with a hot riser, a cold riser and exhausting pieces; the sectional area ratio of each component of the casting is that F(straight pouring gate):F(cross pouring gate):F(inner pouring gates) is equal to 1:(1.2-1.4):(1.35-1.5); the casting is obtained by controlling the pouring temperature at 1370-1410 DEG C and carrying out pouring for 5-10 seconds. The casting method has the advantages that pouring speed is high, the defects such as shrinkage porosity, shrinkage cavity and the like cannot easily occur, and the casting is high in production efficiency, low in rejection rate and excellent in mechanical property.

Owner:宁波强盛机械模具有限公司

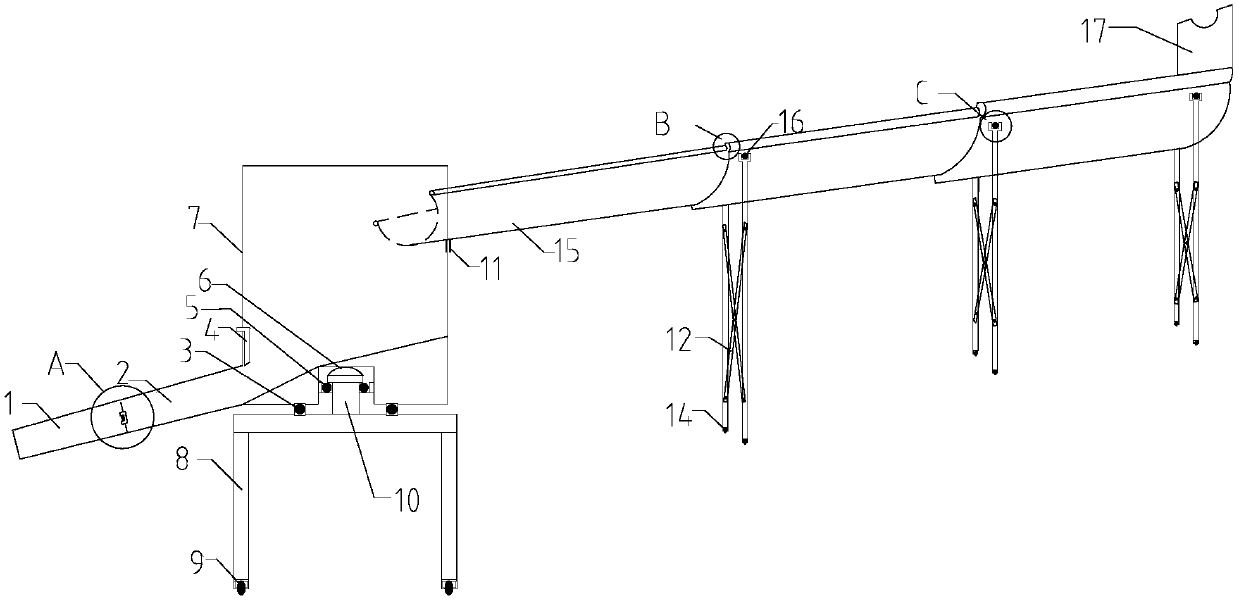

Device for expanding pouring range of ground pump distributing machine

InactiveCN108019043AReduce the number of movesIncrease pouring speedBuilding material handlingDirect controlMaterial supply

The invention relates to a device for expanding the pouring range of a ground pump distributing machine. The device includes a telescopic chute, a distributing bucket, and a sliding track; the telescopic chute is formed by splicing a plurality of chutes, the bottom of the telescopic chute is connected with a shear bracing, a first universal wheel is arranged at the bottom of the shear bracing, thetelescopic chute is connected with the distributing bucket, a fixed material tube is arranged at a discharge port of the distributing bucket, the fixed material tube is also connected with a foldingmaterial tube, and the distributing bucket is mounted on a support frame through a rotating shaft; and a second universal wheel is arranged at the bottom of the supporting frame, the sliding track includes a linear track and an arc track, the first universal wheel and the second universal wheel slide along the linear track and the arc track, and the arc track includes multiple concentric arcs. Thedevice for expanding the pouring range of the ground pump distributing machine can make up for the limitation of the pouring working face of the distributing machine, the number of movements of the distributing machine and the number of times of tube washing are reduced, the slide track enables the pouring surface centered on a tube head of the distributing machine, large-angle rotation pouring is carried out, the speed of concrete pouring is accelerated, and urgent interrupt of material supply on the spot can be directly controlled.

Owner:CHINA FIRST METALLURGICAL GROUP

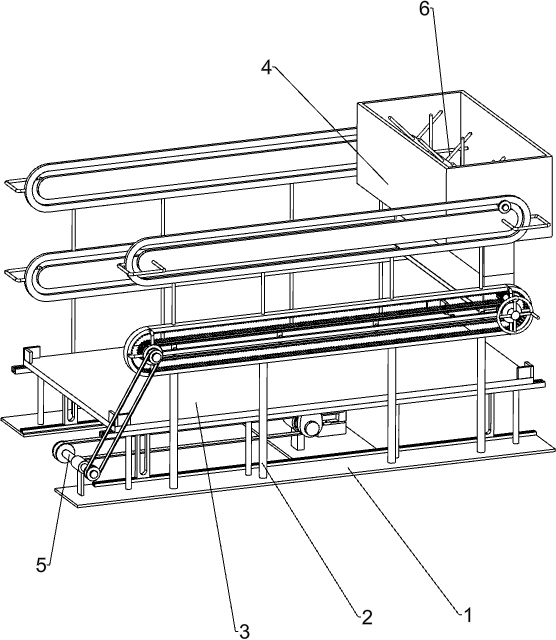

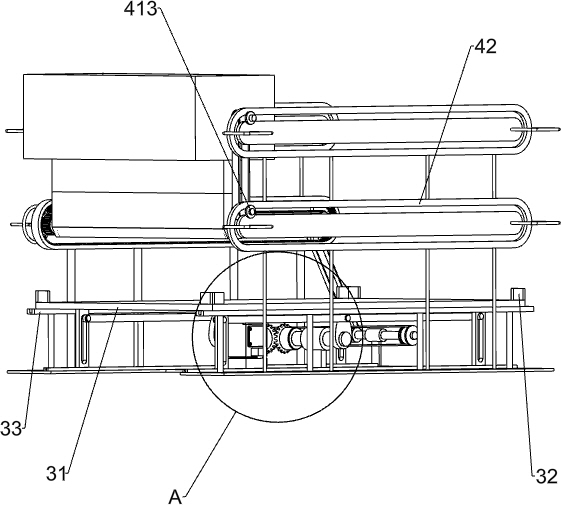

Flat die and stand die combined product line for producing wallboard

InactiveCN103144187ARealize synchronous productionIncrease productivityMixing operation control apparatusCeramic shaping plantsProduction lineElectric machinery

The invention provides a flat die and stand die combined product line for producing a wallboard, comprising a flat die pouring product line, a stand die pouring product line and a combined product line feeding device, wherein the flat die product line and the stand die product line are arranged side by side; the combined product line feeding device comprises an operating floor, a feeder, a water supply metering device, an agitator, a foaming machine, a transverse moving slurry hopper, a flat die bunker and a stand die bunker; a product line channel is arranged at the lower end of the operating floor; the agitator, the foaming machine, a motor and the water supply metering device are arranged at the upper end of the operating floor; the flat die bunker and the stand die bunker are arranged above the product line channel and under the transverse moving slurry hopper; and the transverse moving slurry hopper is driven by a speed reducer to be connected with a rail in a sliding manner. According to the flat die and stand die combined product line for producing the wallboard, the stand mode is reasonably combined with the flat mode, the product line is reasonable in structural layout, the floor space is sufficiently used, the two production modes share one slurry agitating system, the product line can produce four types of boards, the board production efficiency is greatly improved, and the flat die and stand die combined product line is multipurpose.

Owner:TAIAN KUNTAI CHANGRONG NEW BUILDING MATERIAL

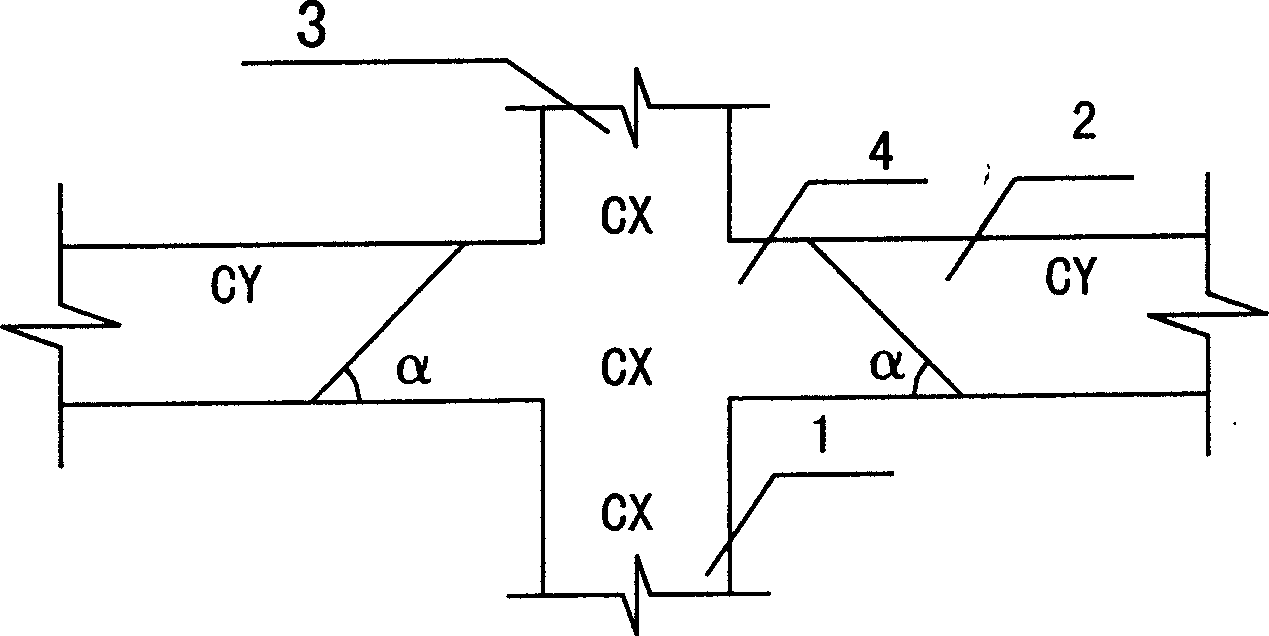

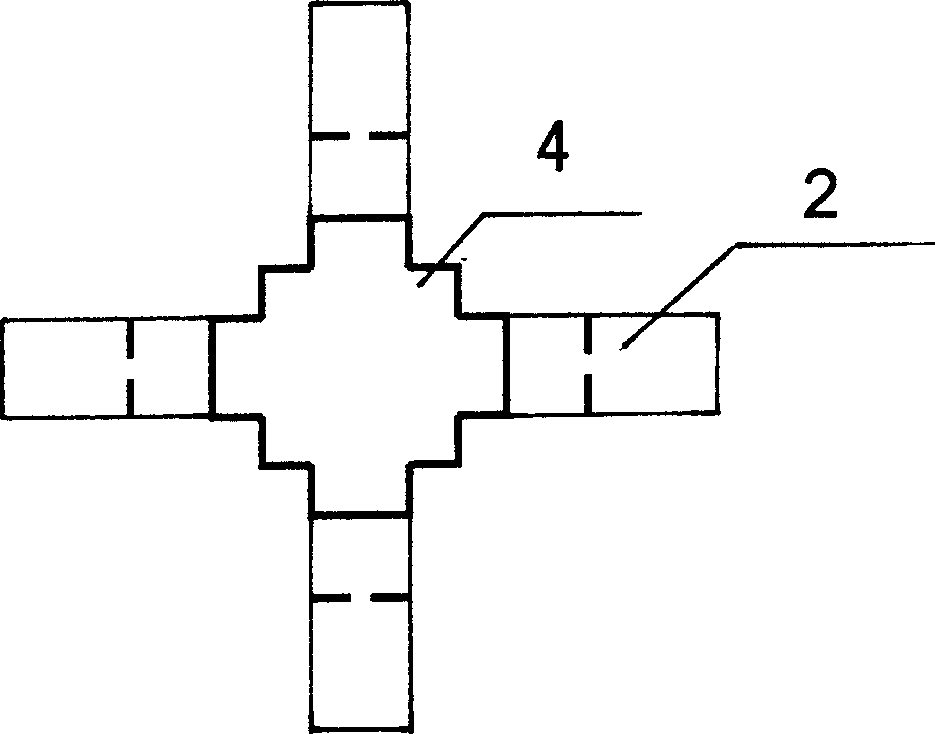

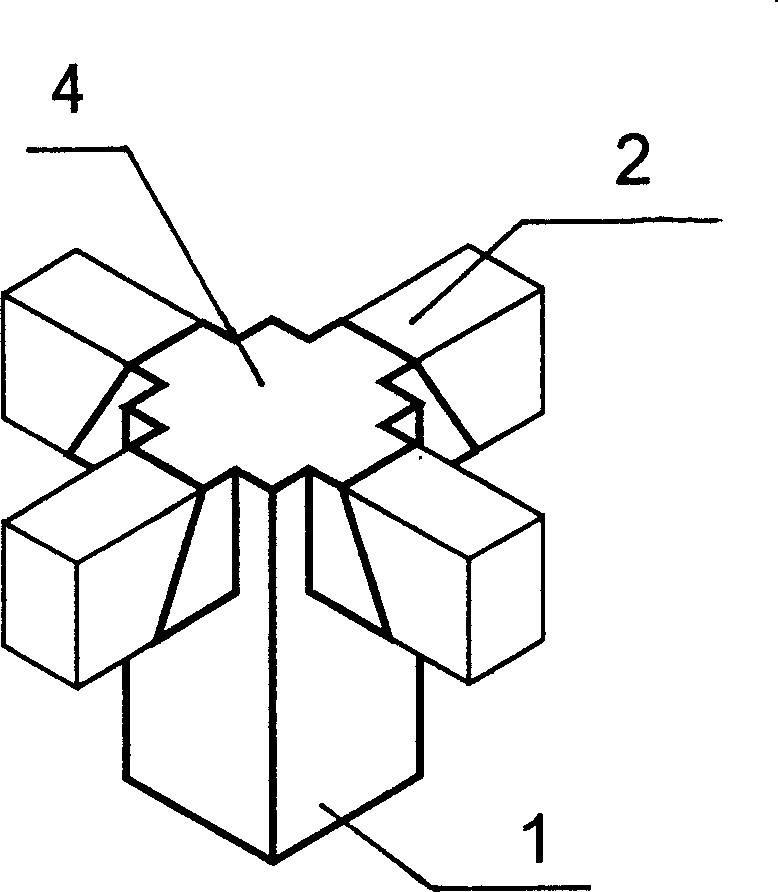

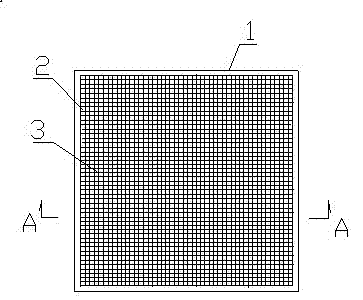

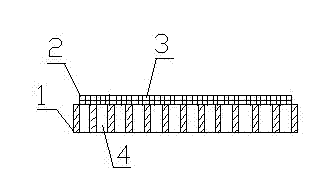

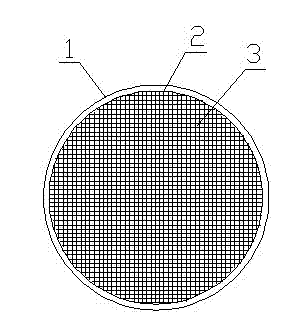

Multilayer casting filter

ActiveCN102350134AShort flow distanceLow flow resistanceFiltration separationPore diameterHoneycomb like

The invention discloses a multilayer casting filter, comprising a support layer (1) made of a ceramic material and a filtering layer (2) made of a ceramic material and arranged on the support layer. The filtering layer contains alveolate filtering holes (3); the support layer contains grid liquid flow holes (4); a hole density of the filtering layer is larger than that of the support layer; an aperture of a filtering hole is smaller than that of a liquid flow hole; a porosity of the support layer is larger than that of the filtering layer (2); and a thickness of the filtering layer is smaller than that of the support layer. The invention can simplify a pouring system, increase produce rate of a cast technology, reduce cast costs, enhance flow velocity and continuity of pouring, facilitate cast mold filling, improve high temperature impact resistance and high temperature bearing capacity of the filter, ensure integrity of the filter in the whole pouring process, facilitate filtering purification of metal liquid and improve inner quality and comprehensive performances of a cast product, and is suitable for pouring of multiple-part mold and large and medium size cast.

Owner:JIANGXI BAOAN NEW MATERIAL TECH

Casting gating system

InactiveCN105642833ASmall volumeDoes not affect pouring qualityFoundry mouldsFoundry coresEngineeringCasting

The invention relates to a casting gating system which comprises a pouring cup. A buffer pit is arranged in the upper portion of the pouring cup. The lower portion of the pouring cup is connected with a main pouring gate, and the bottom end of the main pouring gate is provided with a T-type tee joint. A sprue in the right end of the T-type tee joint is connected with a first transverse pouring gate. A sprue in the left end of the T-type tee joint is connected with a second transverse pouring gate. The first transverse pouring gate is connected with a first straight pouring gate. The second transverse pouring gate is connected with a second straight pouring gate. The first straight pouring gate is connected with a first riser which communicates with a cavity of a first sand mould. The second straight pouring gate is connected with a second riser which communicates with a cavity of a second sand mould finally. According to the casting gating system, on the premise of not affecting the pouring quality, the two cavities share one main pouring gate, and the volume of the buffer pit is reduced while pouring of molten iron, so that the pouring speed is increased, internal defects are reduced, the rate of finished molten iron castings is increased, and the casting cost is lowered.

Owner:四川逢顺商贸有限公司

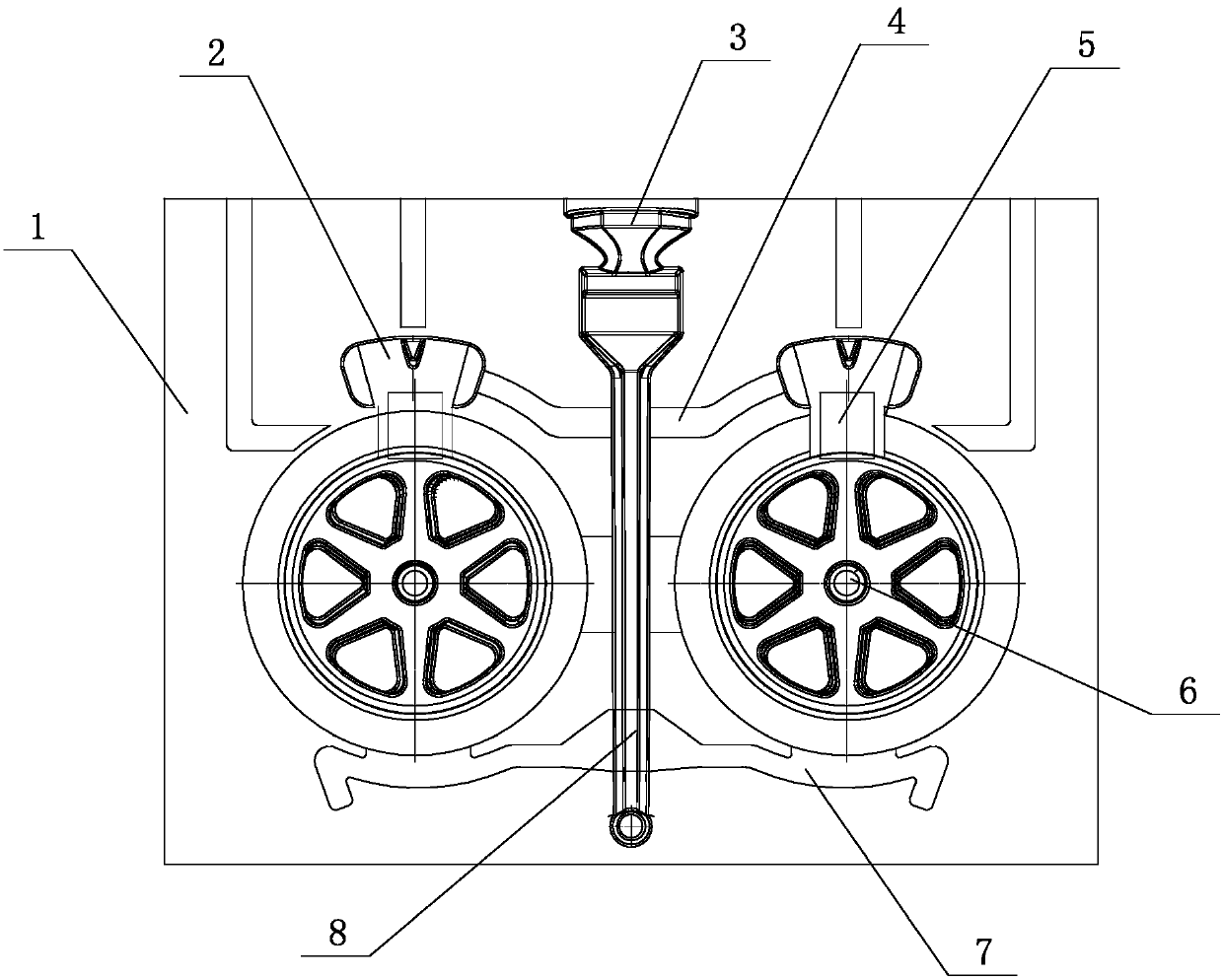

Hub template and hub casting process

InactiveCN107695306AHigh precisionEasy to separateFoundry mouldsFoundry coresBody PatterningEngineering

The present invention relates to the technical field of wheel hub casting, in particular to a wheel hub pattern plate and a wheel hub casting process. The lower end is connected with the middle sprue, the upper sprue is arranged on both sides of the upper part of the middle sprue, the end of the upper sprue is connected with the riser, the riser is connected with the hub shape through the riser neck, and the two sides of the lower part of the middle sprue are set The down runner is connected with the hub shape; the center hole of the hub shape is provided with a cold iron; the invention enlarges the riser, increases the down runner, speeds up the pouring speed, improves the feeding effect, and the product is qualified The rate is high; there are few rough processing parts, only the iron supplement parts need to be processed; the cooling iron is added, and measures to accelerate the cooling of castings can be used to improve the internal shrinkage and shrinkage defects of the product.

Owner:SHANDONG MEILING CHEM EQUIP

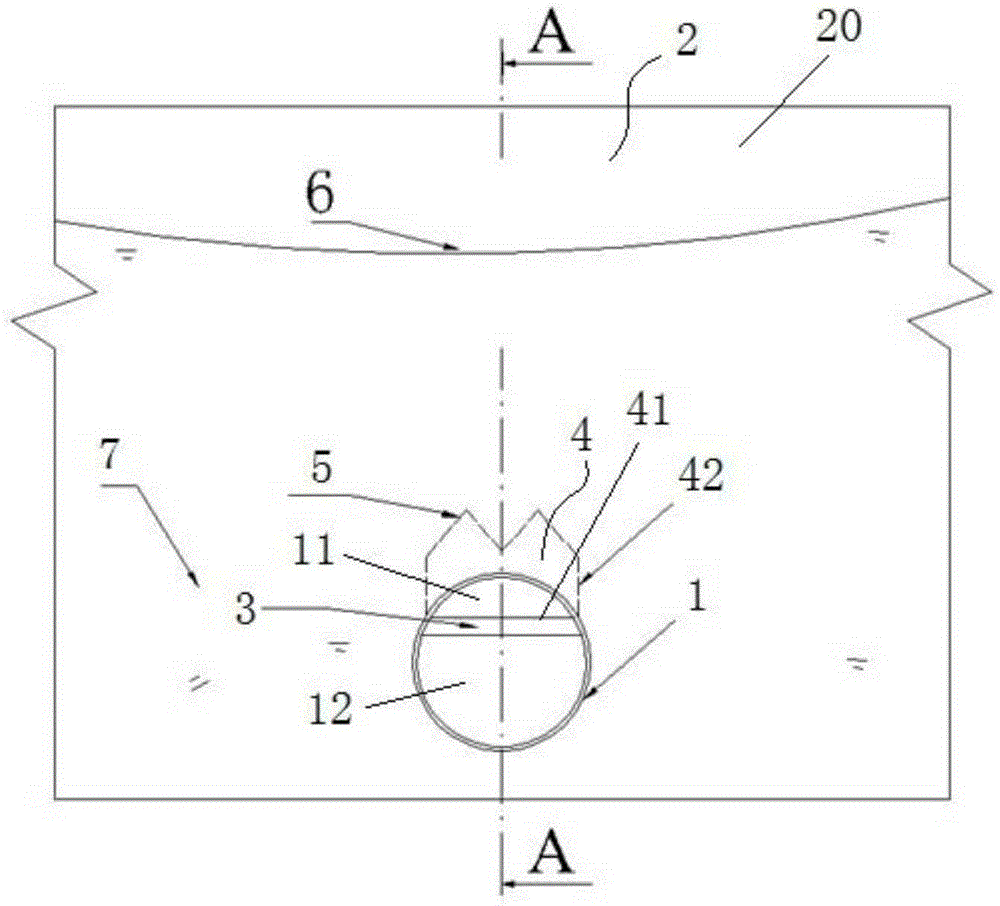

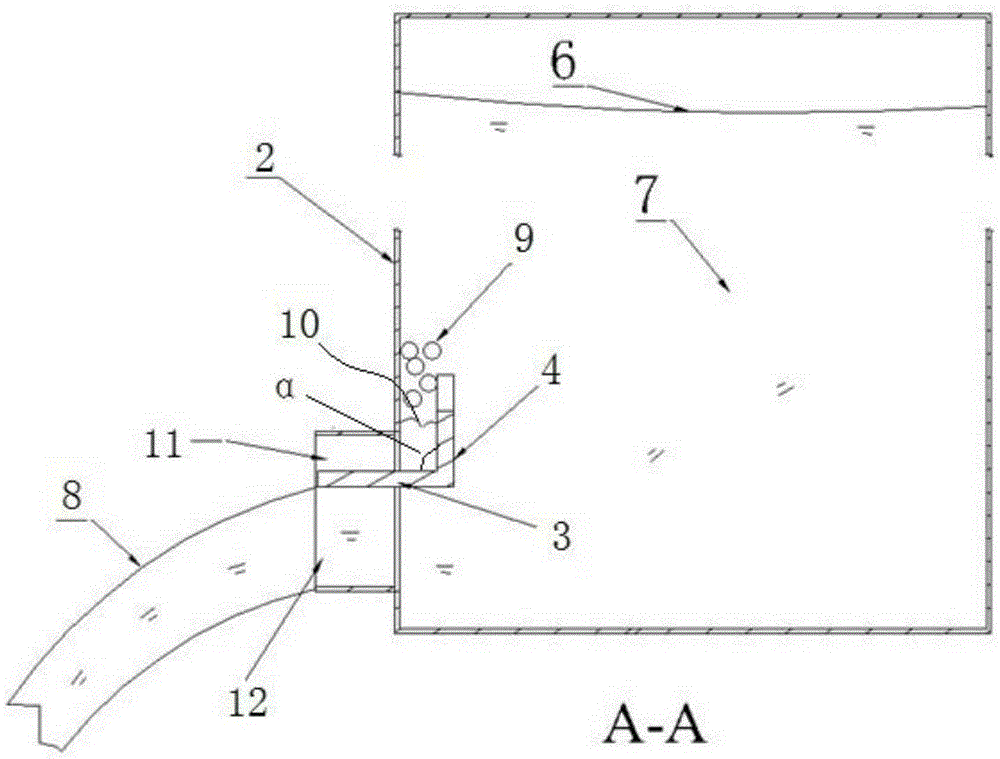

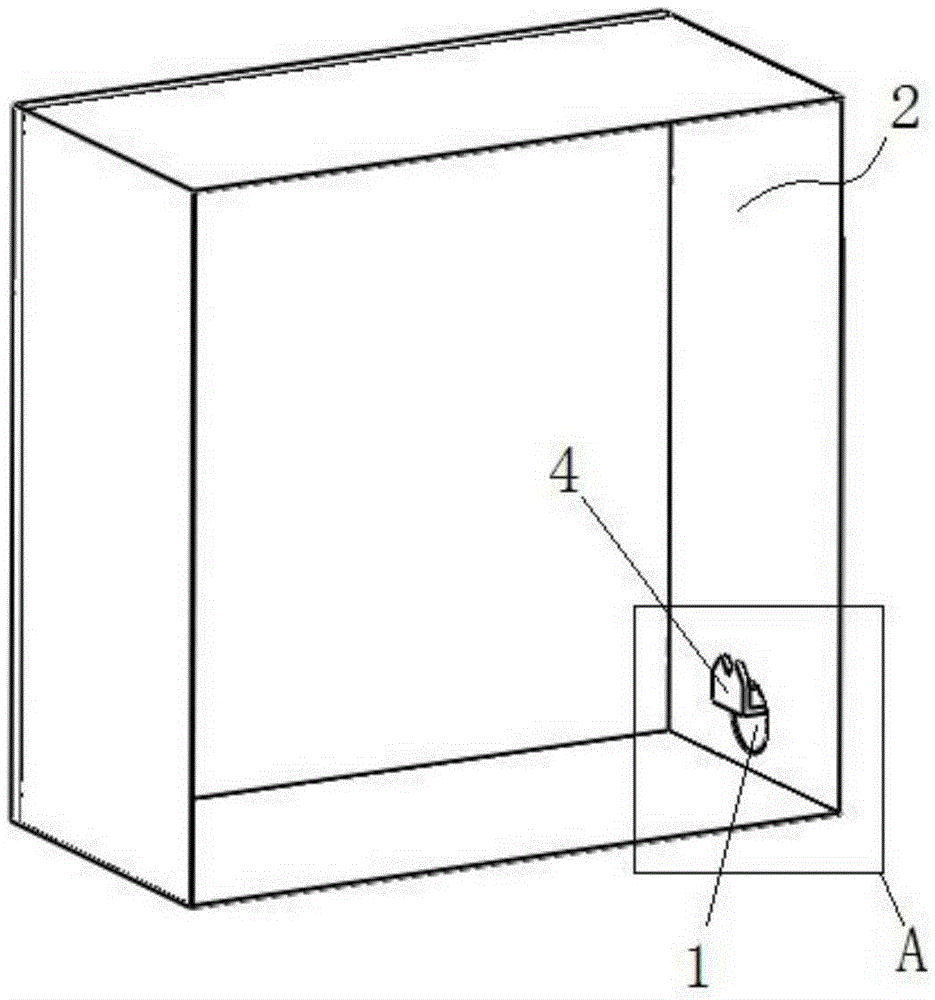

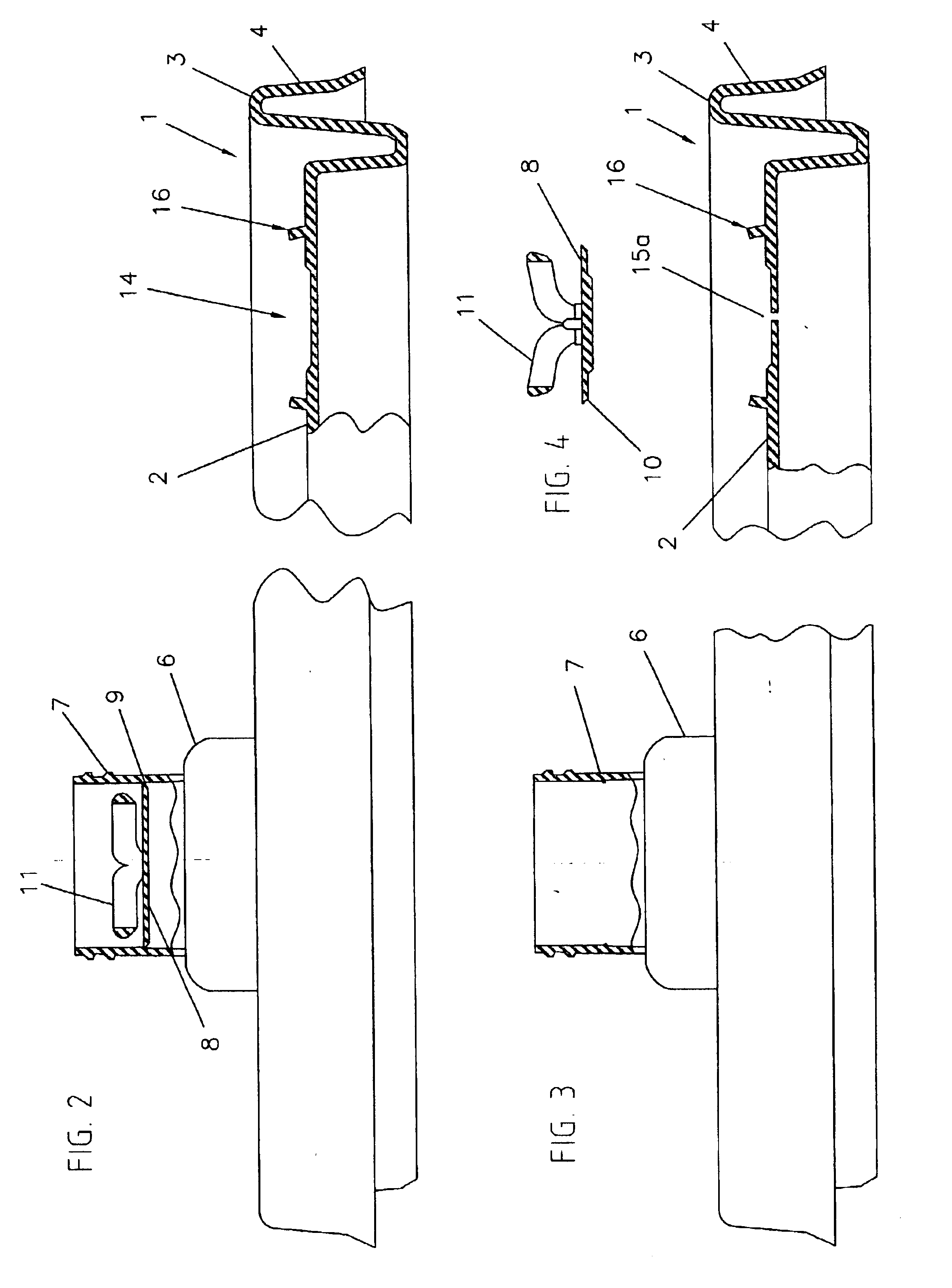

Liquid discharging structure and closed container with same

The invention provides a liquid discharging structure and a closed container with the same. The liquid discharging structure comprises a liquid outlet arranged on the closed container, and a partition board arranged inside the liquid outlet to divide the liquid outlet into an air inlet channel and a liquid discharging channel; the part, located inside an inner cavity of the closed cavity, of the partition board is fixedly provided with a baffle used for preventing liquid from directly impacting on the air inlet channel. During using, when the closed container with the liquid discharging structure pours liquid outwards, liquid flows outwards from the liquid discharging channel, external airflow stably and continuously flows into the closed container from the air inlet channel and a gas runner to balance the inner and outer pressure difference, so that the flowing interface of liquid flowing beams is stabilized conveniently, fluctuation and splashing of the liquid flowing beams are reduced, and the pouring speed is increased.

Owner:TSINGHUA UNIV

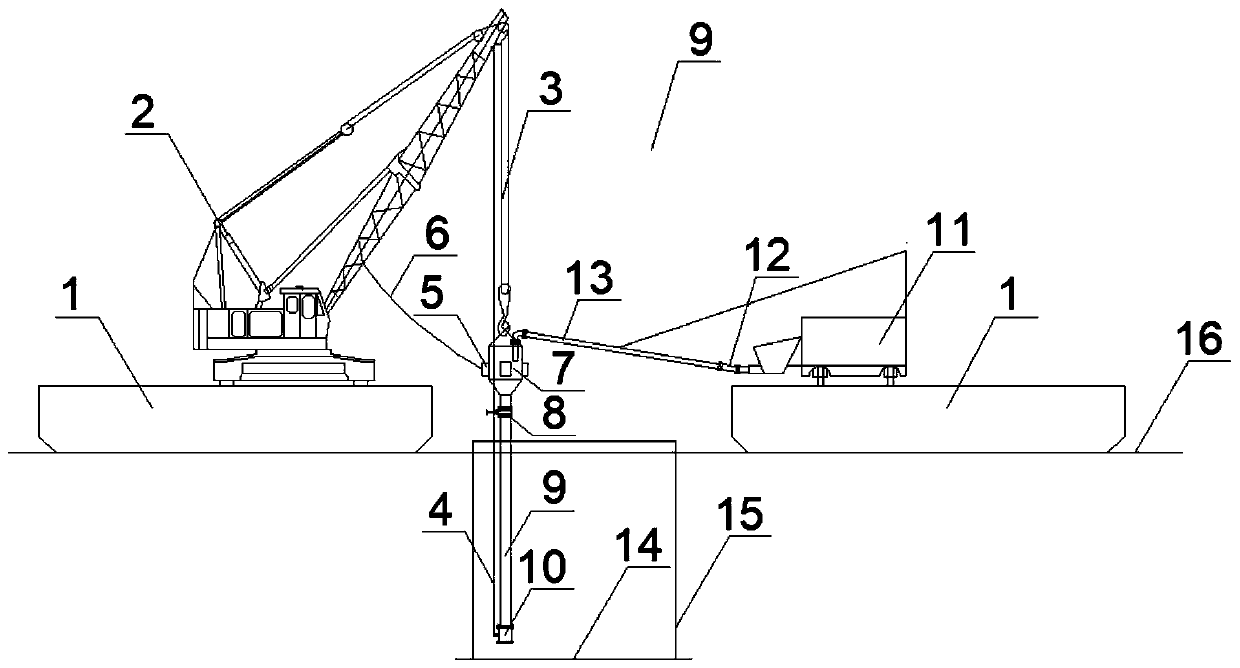

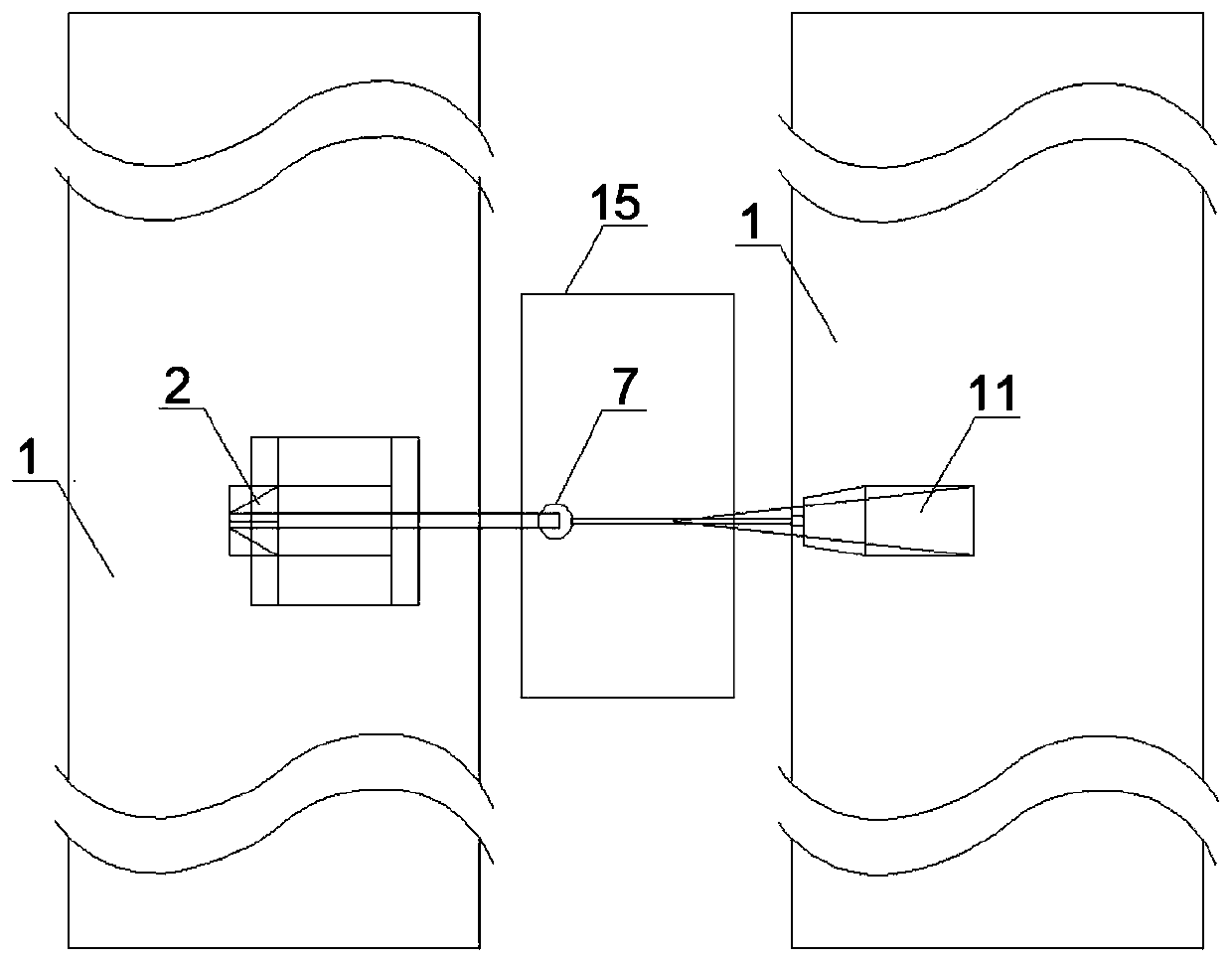

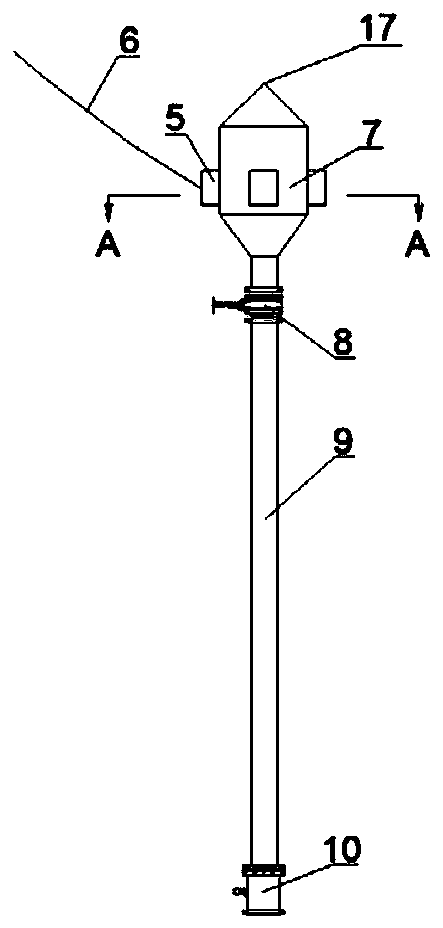

Concrete warehousing pouring construction equipment and method

PendingCN111424671AQuality assuranceQuality improvementFoundation engineeringBridge erection/assemblyArchitectural engineeringWater transport

The invention provides concrete warehousing pouring construction equipment and method. A main winch of the construction equipment is connected with a vibration hopper lifting lug, an auxiliary winch is connected with a guide pipe valve, a clamp-on vibrator is mounted in a vibration hopper, a vibration hopper valve is connected with the lower end of the vibration hopper and connected with a guide pipe, the guide pipe is connected with the guide pipe valve, a concrete pump truck is connected with a concrete delivery pipe through a braided rubber tube, and an outlet end of the concrete delivery pipe is in butted joint with the vibration hopper. The construction method comprises steps as follows: (1), performing preparation of pre-construction; (2), enabling the equipment to be in place; (3),feeding the vibration hopper by the concrete pump truck; (4), pouring the concrete; (5), moving and adjusting positions of the vibration hopper and the guide pipe to finish concrete pouring. In the concrete pouring construction process of marine traffic engineering buildings, the problems of backward flowing and pipe blocking can be solved, the poured concrete quality is high, the construction efficiency is high, and environmental pollution is reduced.

Owner:GUANGXI NEWHARBOR ENG CO LTD

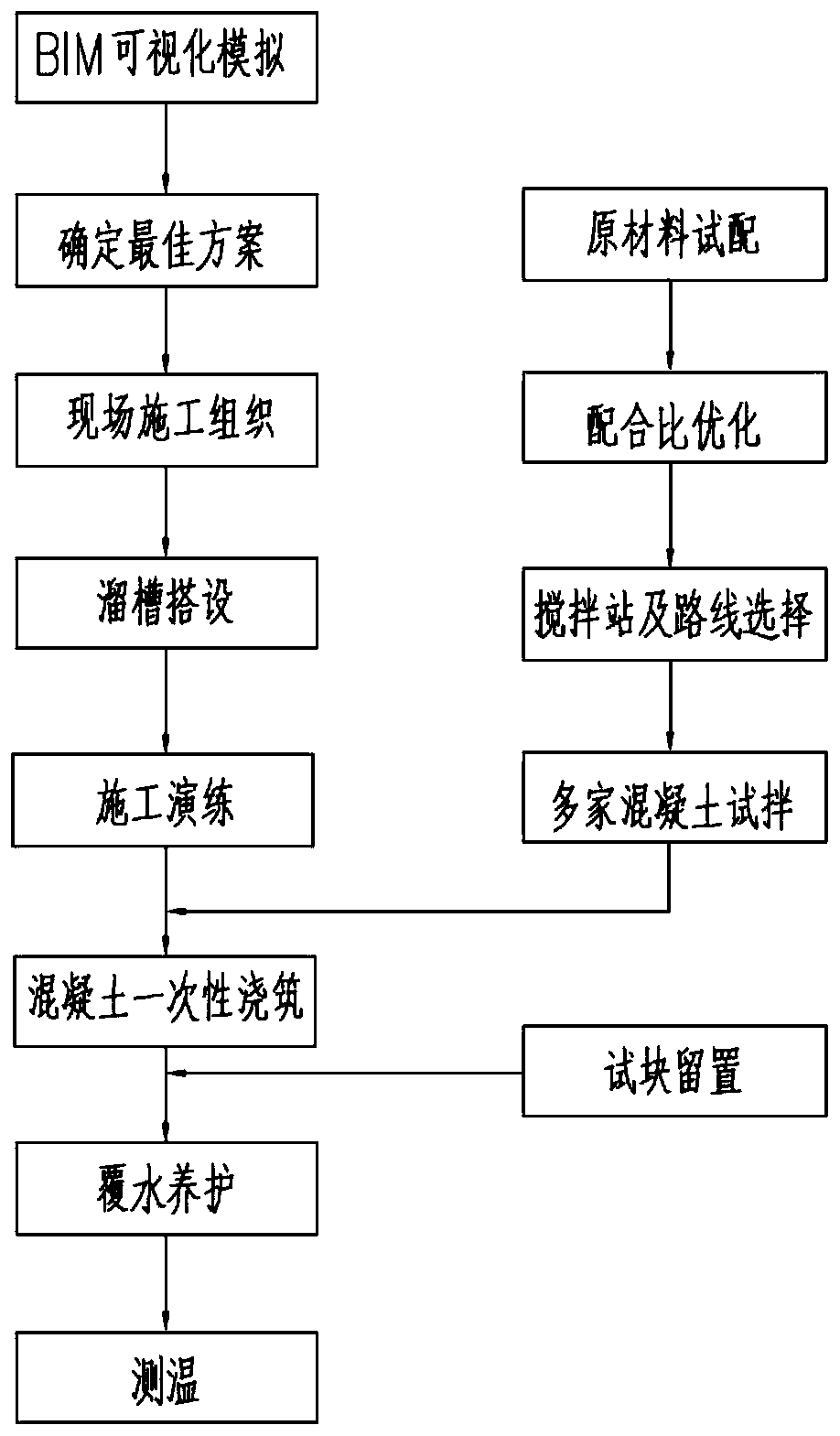

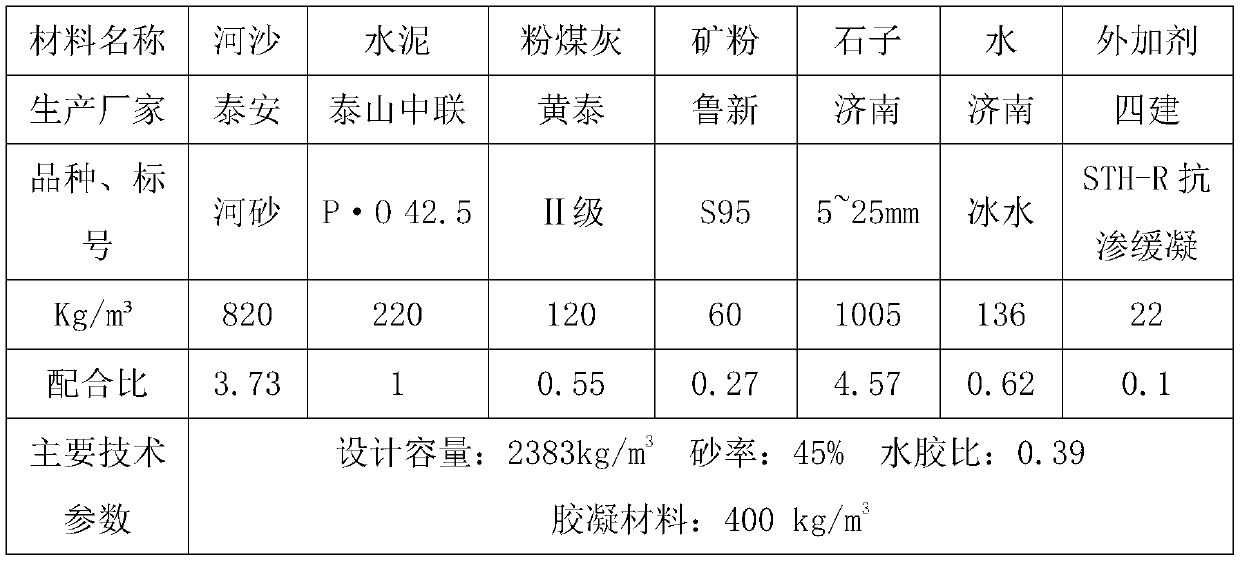

BIM (Building Information Modeling)-based super-high-rise super-thick mass concrete one-time pouring construction method in hot weather

PendingCN111368361AIncrease pouring speedImprove construction qualityGeometric CADDesign optimisation/simulationTemperature controlHot weather

The invention discloses a BIM (Building Information Modeling)-based super high-rise super-thick mass concrete one-time pouring construction method in hot weather, and belongs to the technical field ofbuilding construction, and the method comprises the steps of establishing an engineering visualization model through a BIM technology, simulating a super-high-rise super-thick mass concrete construction process through model simulation, and optimizing a construction scheme; by optimizing the concrete mix proportion, reducing the cement consumption and increasing the fly ash mixing amount, the generated hydration heat is reduced, and the generation of temperature cracks is reduced; a chute method is adopted for one-time pouring; construction organization is optimized, continuous supply of concrete in the construction process is guaranteed, and generation of cold joints is reduced; concrete curing is conducted through a water covering method, the concrete out-of-machine temperature and theconcrete in-mold temperature are reduced, and the temperature rise in the pouring process is controlled. The method is suitable for super-thick mass concrete engineering construction of various building forms under hot conditions, the construction period can be effectively shortened, the cost is reduced, and the construction efficiency and the construction quality are improved.

Owner:CHINA CONSTR EIGHTH ENG DIV

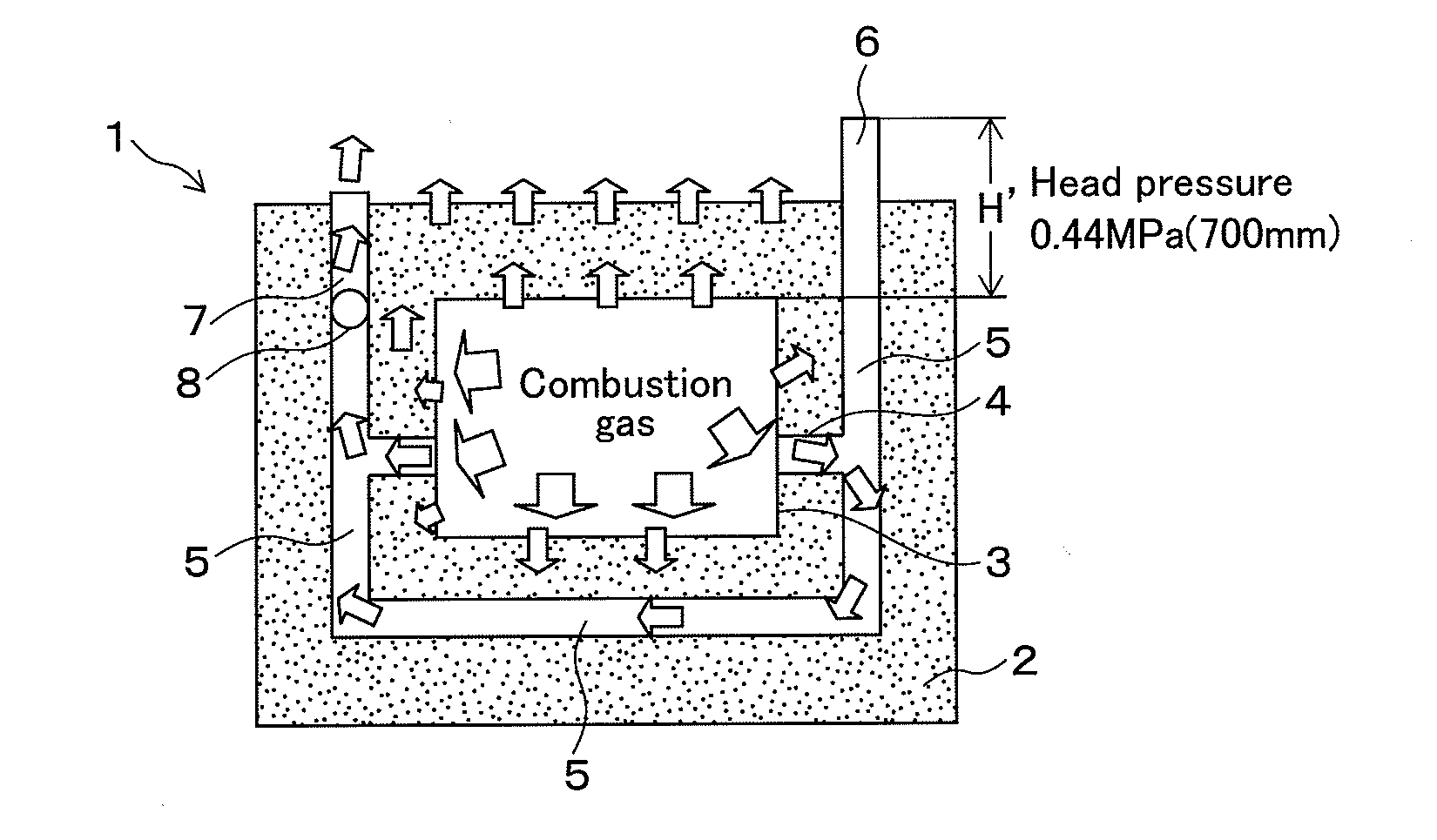

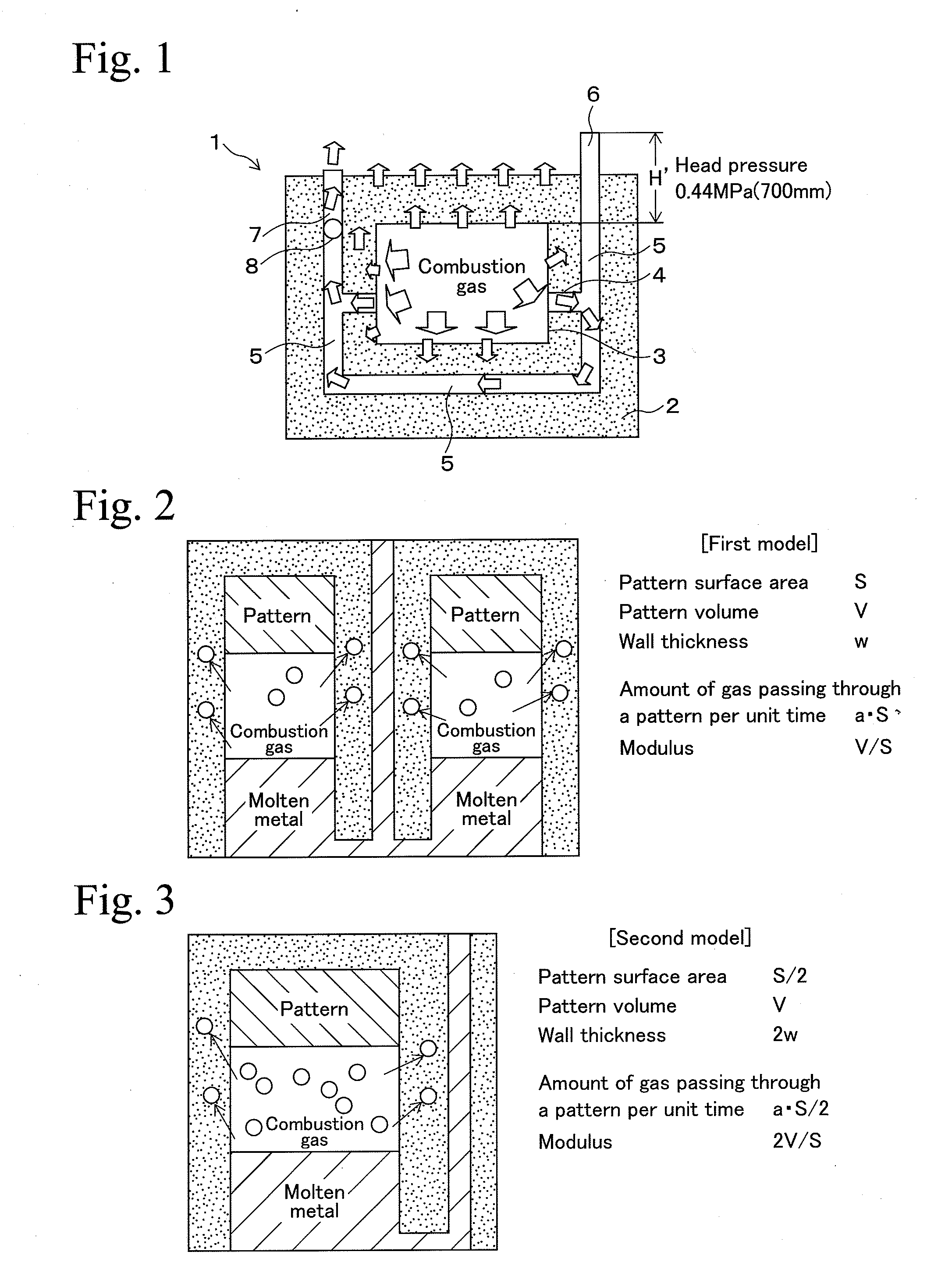

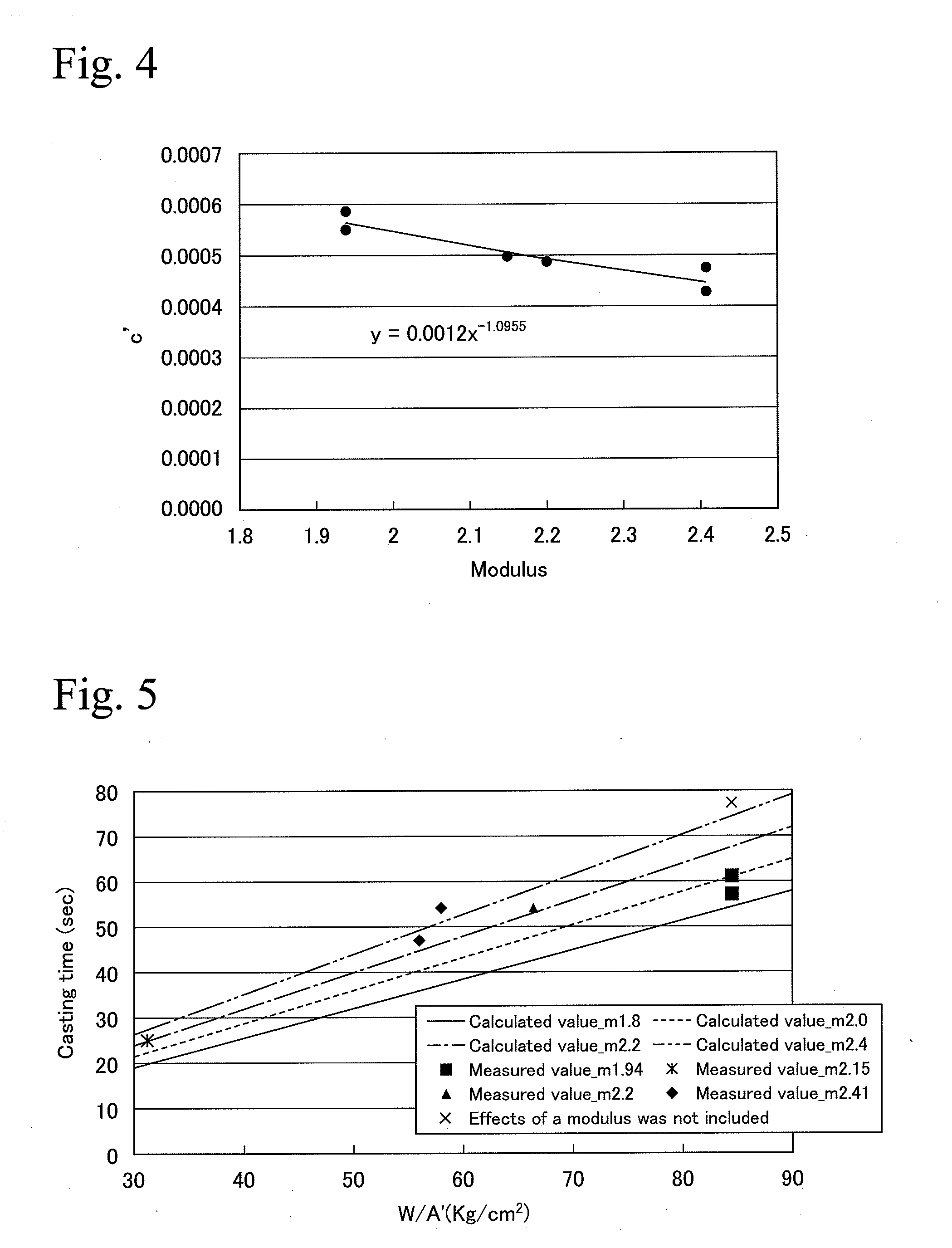

Evaporative pattern casting process

ActiveUS20120273151A1Accurate settingQuality improvementFoundry mouldsFoundry coresMetallurgyMaterials science

An evaporative pattern casting process includes forming a mold by burying a pattern made of resin foam in casting sand, pouring molten metal into the mold, and evaporating the pattern with the molten metal and thereby casting a product. In the evaporative pattern casting process, casting time during founding is set according to a modulus (pattern volume÷pattern surface area) of the pattern. Accordingly, the casting time in the evaporative pattern casting process is accurately set with high precision.

Owner:HONDA MOTOR CO LTD

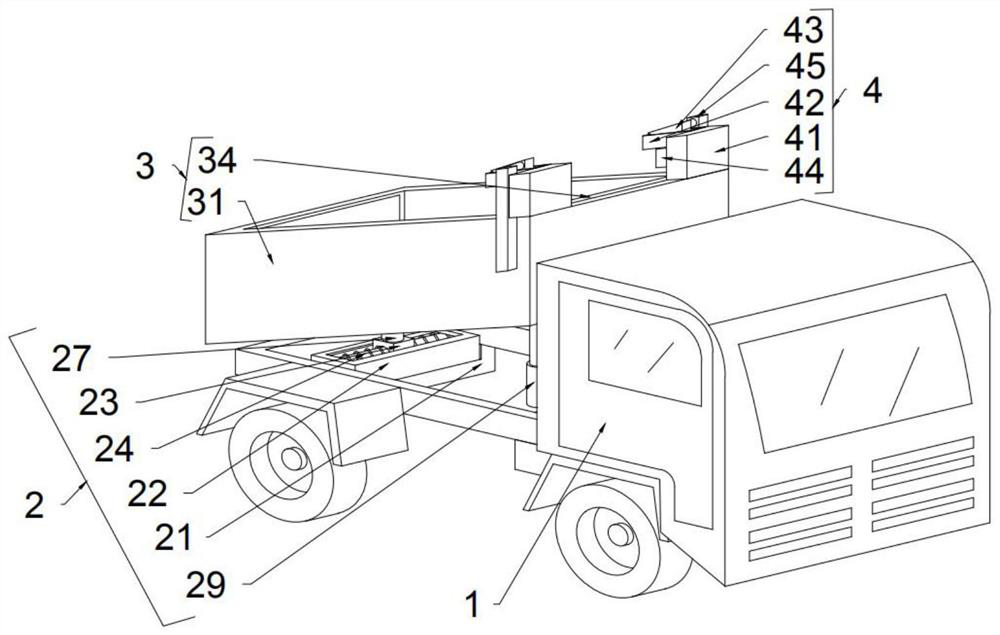

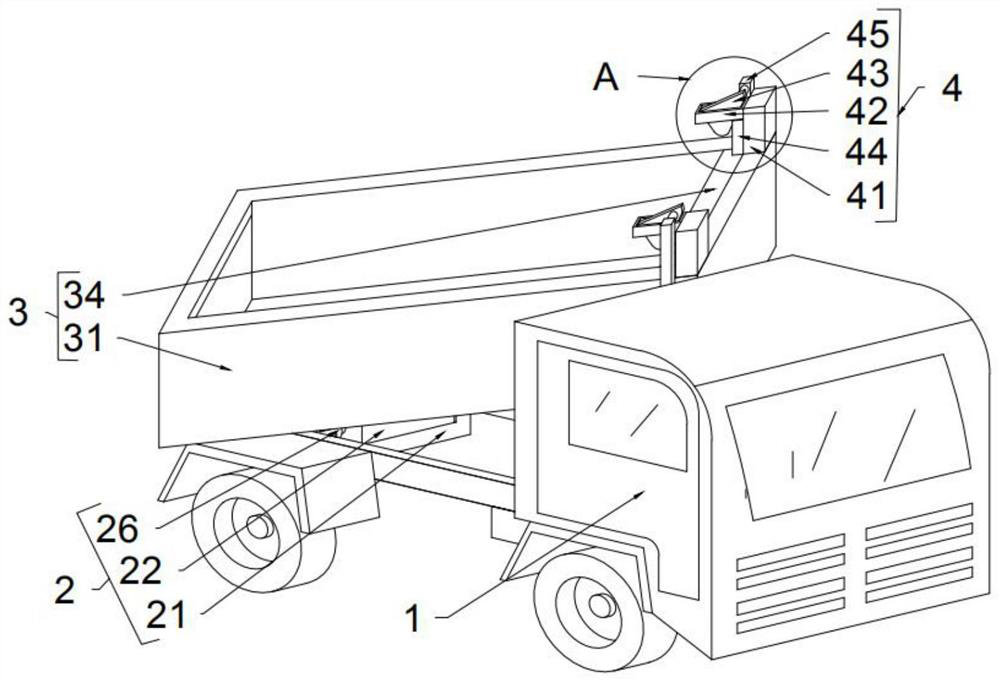

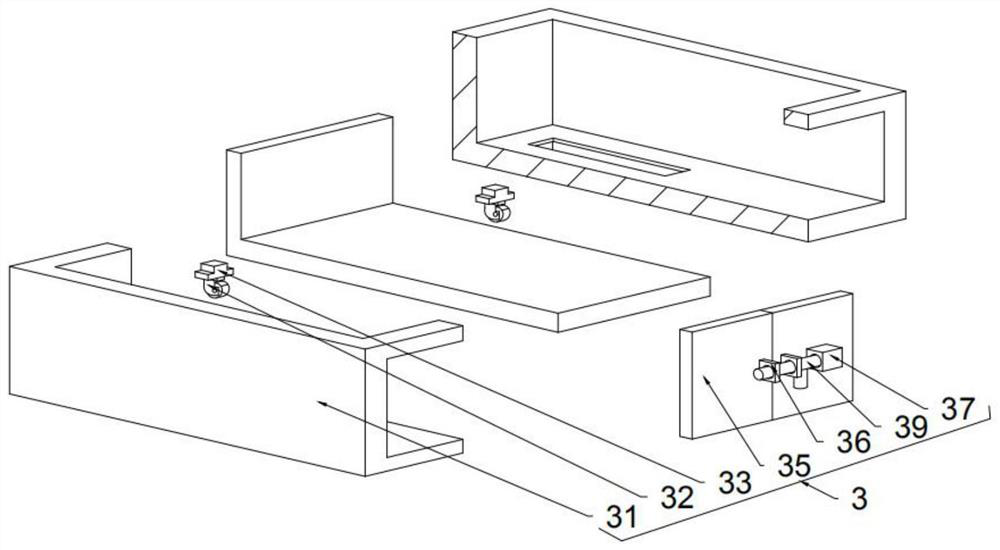

Garbage transfer vehicle with adjustable turnover angle

ActiveCN112320171ASpeed up pouringIncrease pouring speedRefuse vehiclesControl theoryMechanical engineering

The invention discloses a garbage transfer vehicle with an adjustable turnover angle. The garbage transfer vehicle comprises a vehicle body, a supporting structure fixedly arranged on the vehicle body, a dumping structure fixedly arranged on the supporting structure, and a clamping and locking structure fixedly arranged on the dumping structure, wherein the rear side of a car hopper is rotated leftwards and rightwards by a certain angle through the supporting structure, the garbage dumping angle of the car hopper can be adjusted conveniently when garbage dumping is inconvenient under normal conditions, and the garbage dumping position does not need to be changed through vehicle movement; through the dumping structure, dumping of garbage in the vehicle is accelerated, the garbage dumping isaccelerated, garbage residues in the car hopper are reduced, and the car hopper and a sliding plate can be fixed through cooperation of the clamping and locking structure; and the design is differentfrom other garbage vehicles, when the normal garbage damping is inconvenient, the garbage dumping position can be changed by adjusting the angle of the rear side of the car hopper, the situation thatthe dumping speed is affected due to too high garbage accumulation is prevented, the garbage dumping is accelerated through sliding-out of the sliding plate, and the garbage residues in the car hopper are reduced.

Owner:浙江金实乐环境工程有限公司

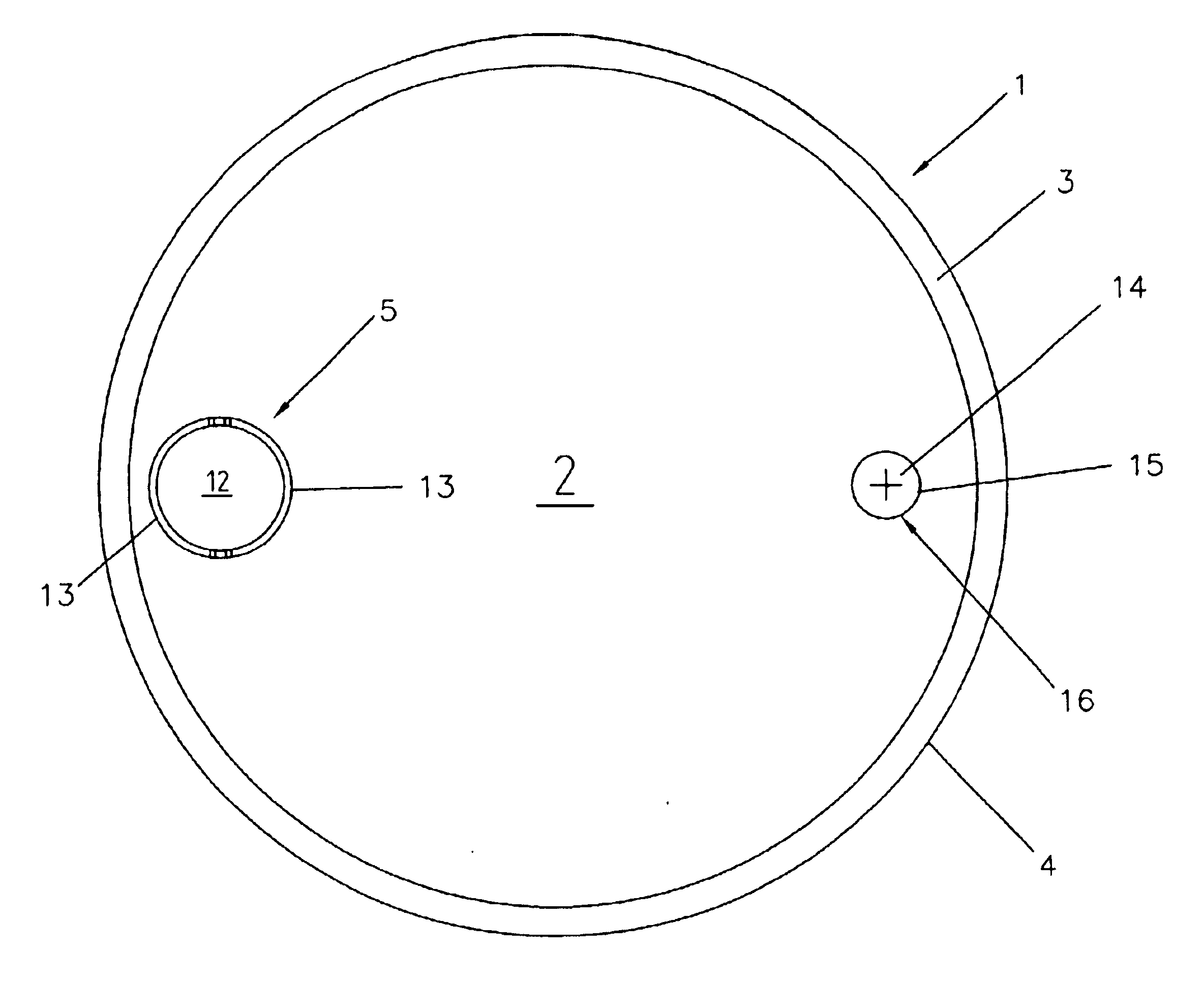

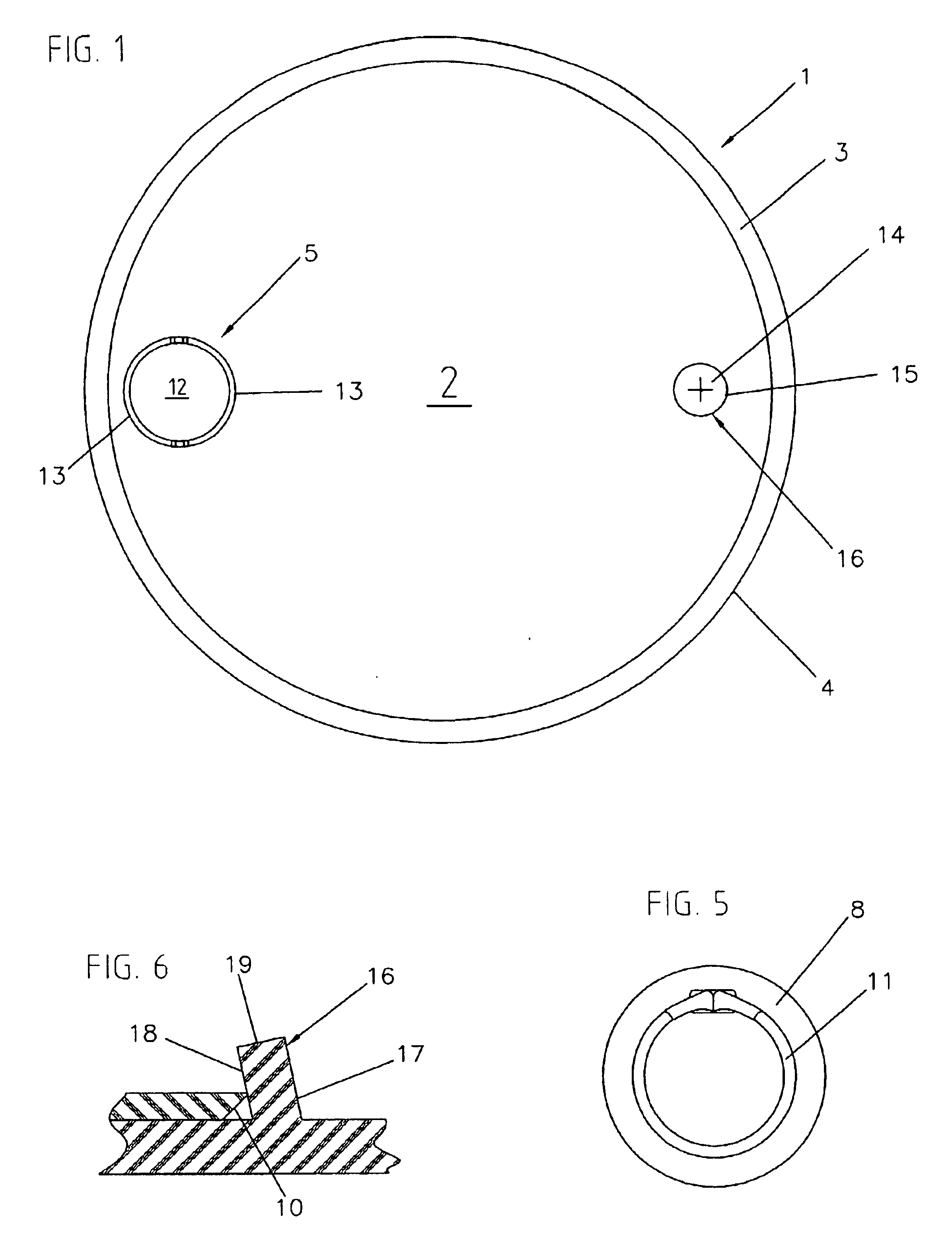

Pail vent and method

InactiveUS6868993B2Increase pouring speedImprove smoothnessClosuresLiquid flow controllersEngineeringMechanical engineering

Owner:AMERICAN FLANGE & MFG CO INC

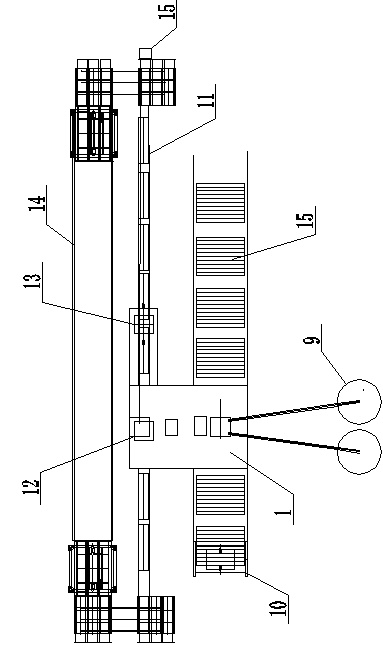

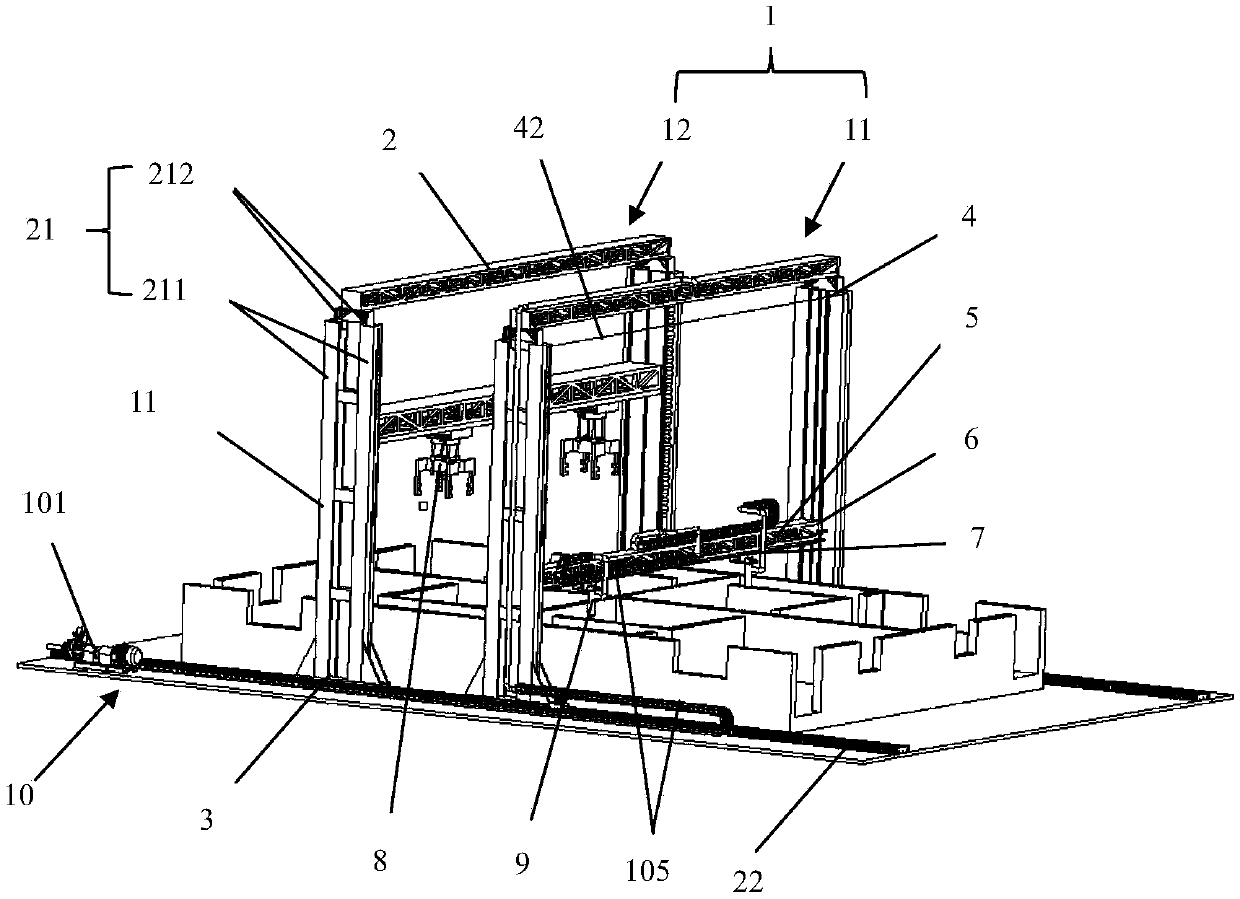

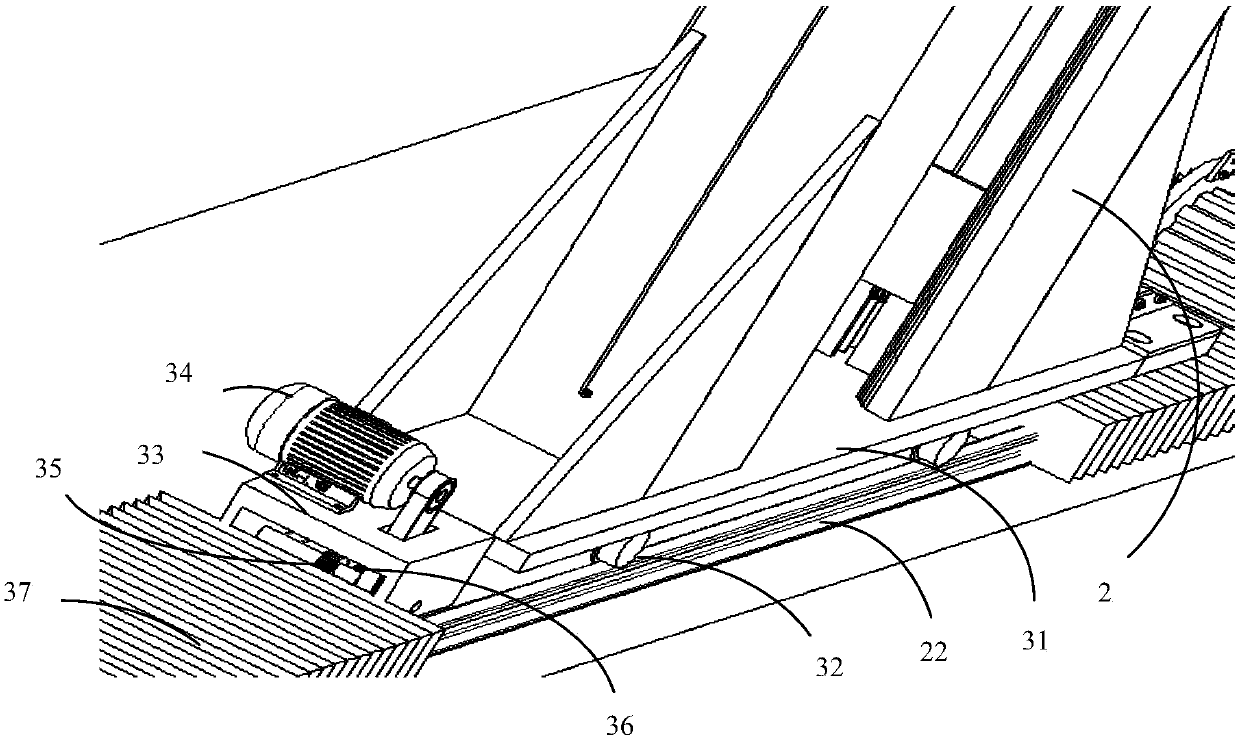

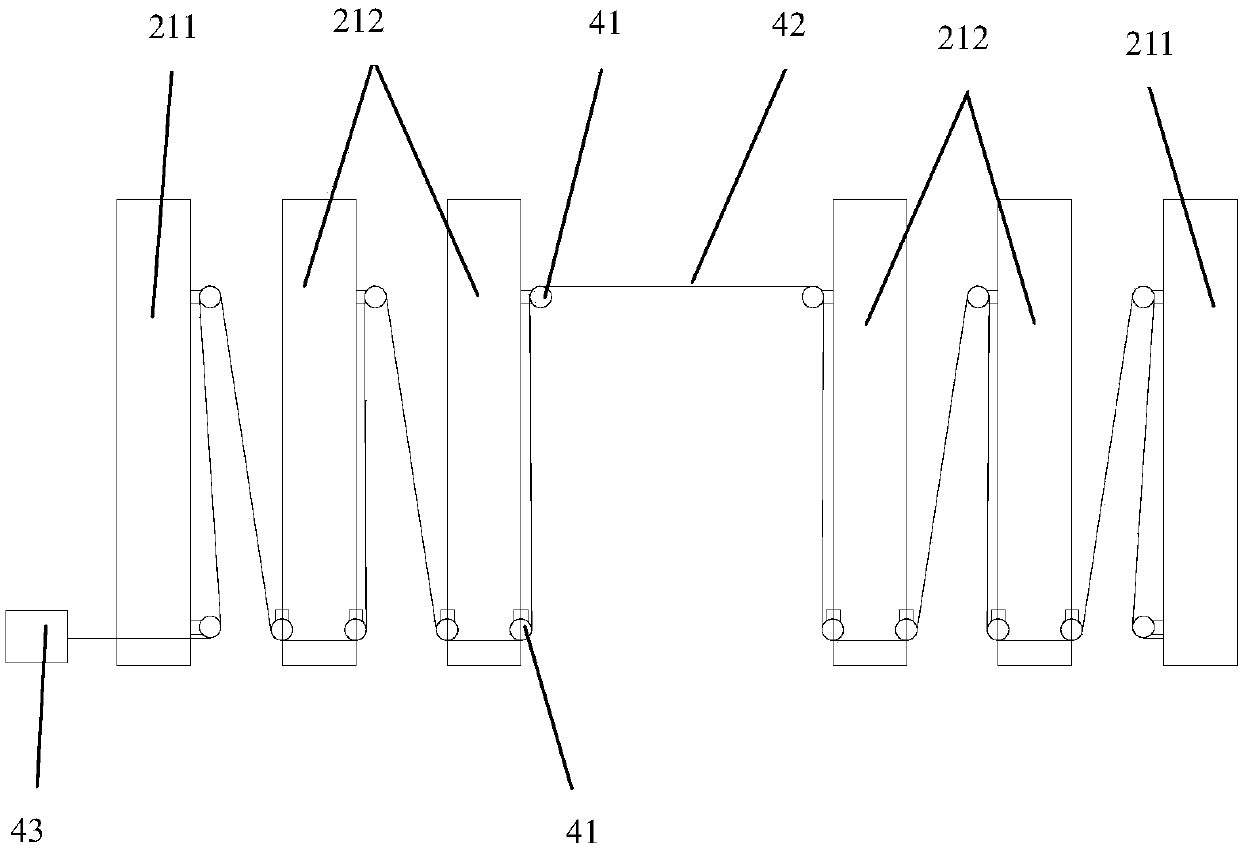

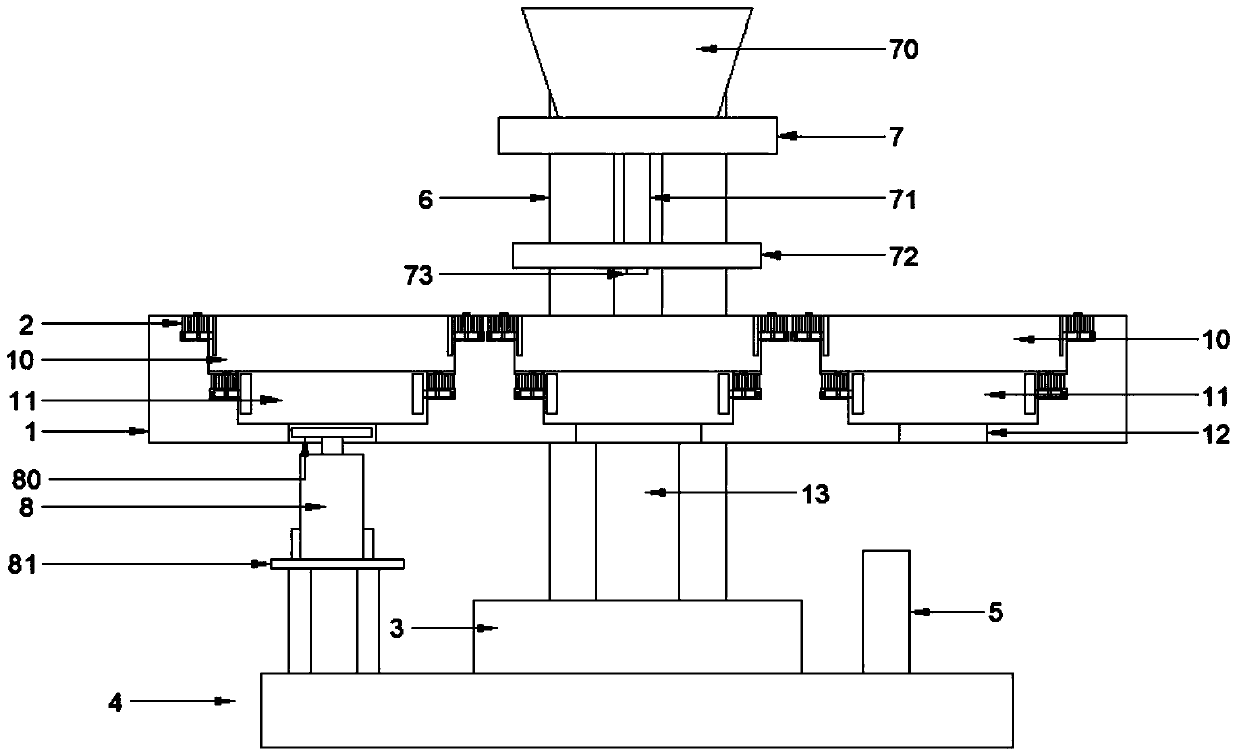

3D house printing machine

ActiveCN107553687AIncrease pouring speedHigh speedAdditive manufacturing apparatusAuxillary shaping apparatusFloor levelManipulator

The invention discloses a 3D house printing machine which comprises a truss assembly, a mechanical arm, a discharging port and a feeding mechanism. The truss assembly comprises a truss, a truss walking mechanism, a truss lifting mechanism, a lifting cross beam and a cross beam lifting mechanism. A truss is installed on two parallel rails. The truss walking mechanism is used for controlling the truss to move horizontally in the direction of the rails. The truss lifting mechanism is used for controlling self pulling of the truss. The lifting cross beam is connected to the truss. A transverse moving mechanism is arranged on the lifting cross beam. The cross bean lifting mechanism is used for controlling the lifting cross beam to ascend and descend along the truss. The truss assembly is provided with two assemblies including a mechanical arm truss assembly and a printing machine truss assembly. The mechanical arm is fixed below the transverse moving mechanism of the mechanical arm truss assembly, the discharging port is fixed below the transverse moving mechanism of the printing machine truss assembly, and the feeding mechanism is used for conducting feeding on the discharging port. The 3D house printing machine can be used for automatically printing and building a house, automation of building of the house is improved, and the 3D house printing machine is suitable for printing ofhouses with high floors.

Owner:李尚明

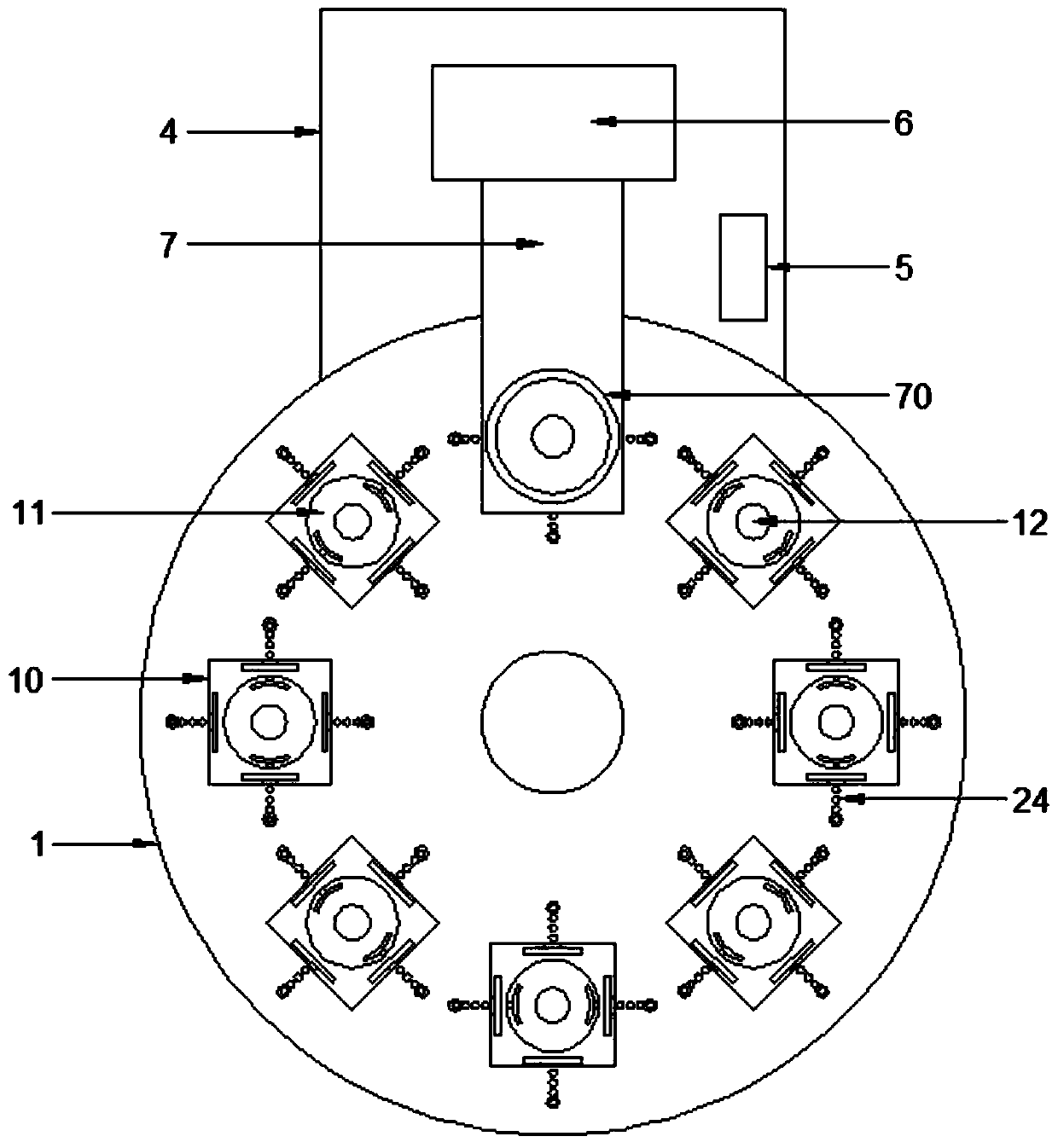

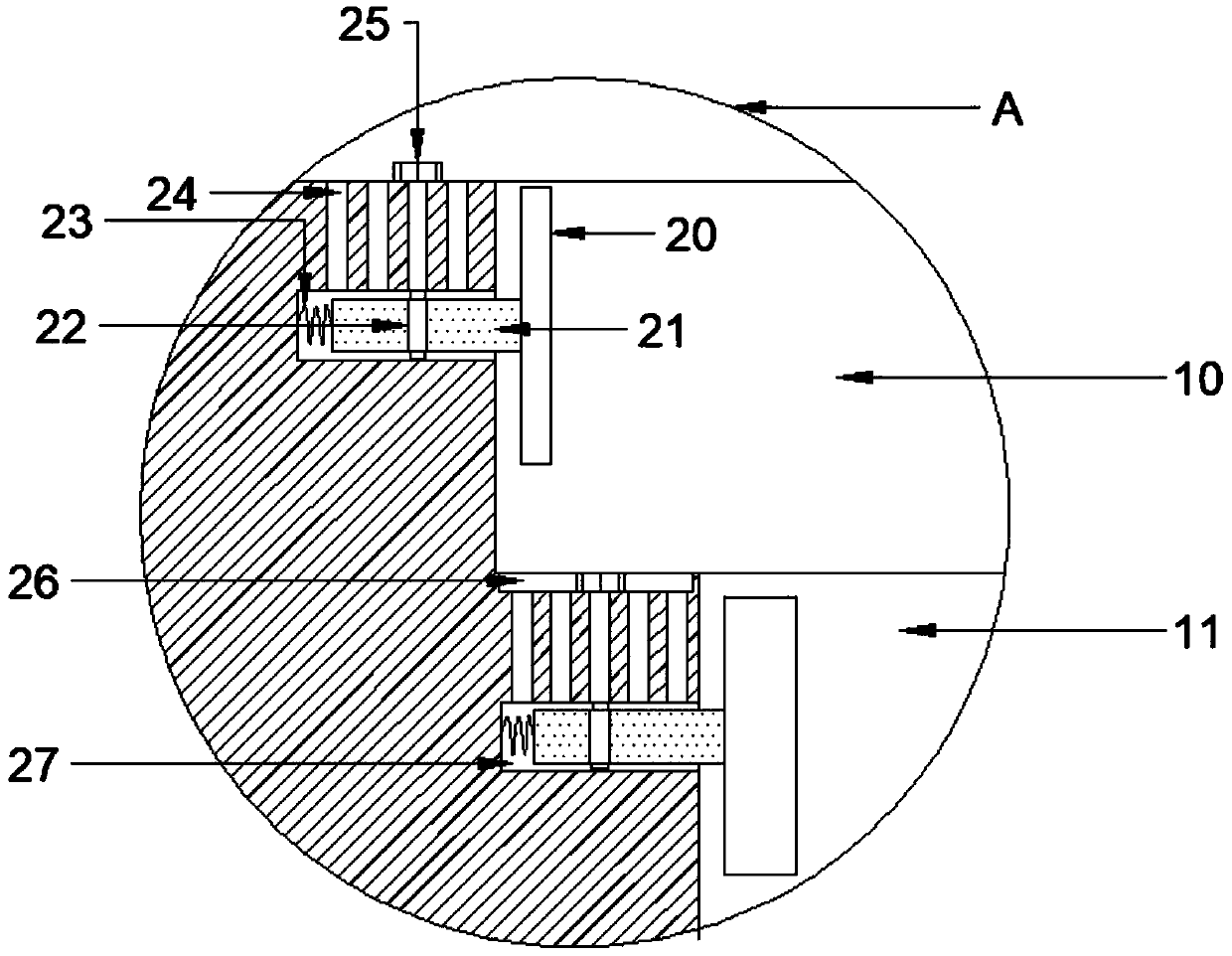

Agricultural machinery part casting device

ActiveCN109530665AEasy to take outEasy height adjustmentMould handling equipmentsMolten metal conveying equipmentsFarm machineInjection port

The invention discloses an agricultural machinery part casting device. The agricultural machinery part casting device comprises a casting rotating table, a plurality of flat plate part mold clamping grooves are formed in the top surface of the casting rotating table, the bottoms of the flat plate part mold clamping grooves are provided with a plurality of special-shaped mold clamping grooves, thebottoms of the special-shaped mold clamping grooves are provided with a jacking device used for upwards jacking molds, the bottom rod wall of a discharging guide pipe at the bottom of a melt leakage furnace is fixedly provided with a pressure plate used for pressing and covering the flat plate part mold clamping grooves, the bottom surface of the pressure plate is provided with an injection port which communicates with the discharging guide pipe and is connected with the molds, and the melt leakage furnace is overall supported on a base through a lifting mechanism. According to the agricultural machinery part casting device, casting positioning and automatic jacking can be rapidly performed through the flat plate part mold clamping grooves and the special-shaped mold clamping grooves whichare arranged on the casting rotating table, so that later-stage taking-out of the molds is greatly facilitated, the height adjustment of the injection port can be facilitated, the applicability is better, the casting time of casting of multiple parts is shortened, the casting efficiency is improved, and the casting speed is increased.

Owner:湖南省金峰机械科技有限公司

Feeding device of pouring pile underwater concrete and pouring method thereof

InactiveCN101725148BIncrease active pressureSolve the problem that is not easy to fallFoundation engineeringArchitectural engineeringEconomic benefits

Owner:DALIAN AERBIN GROUP

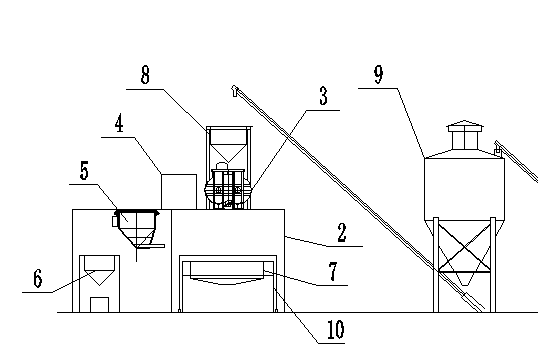

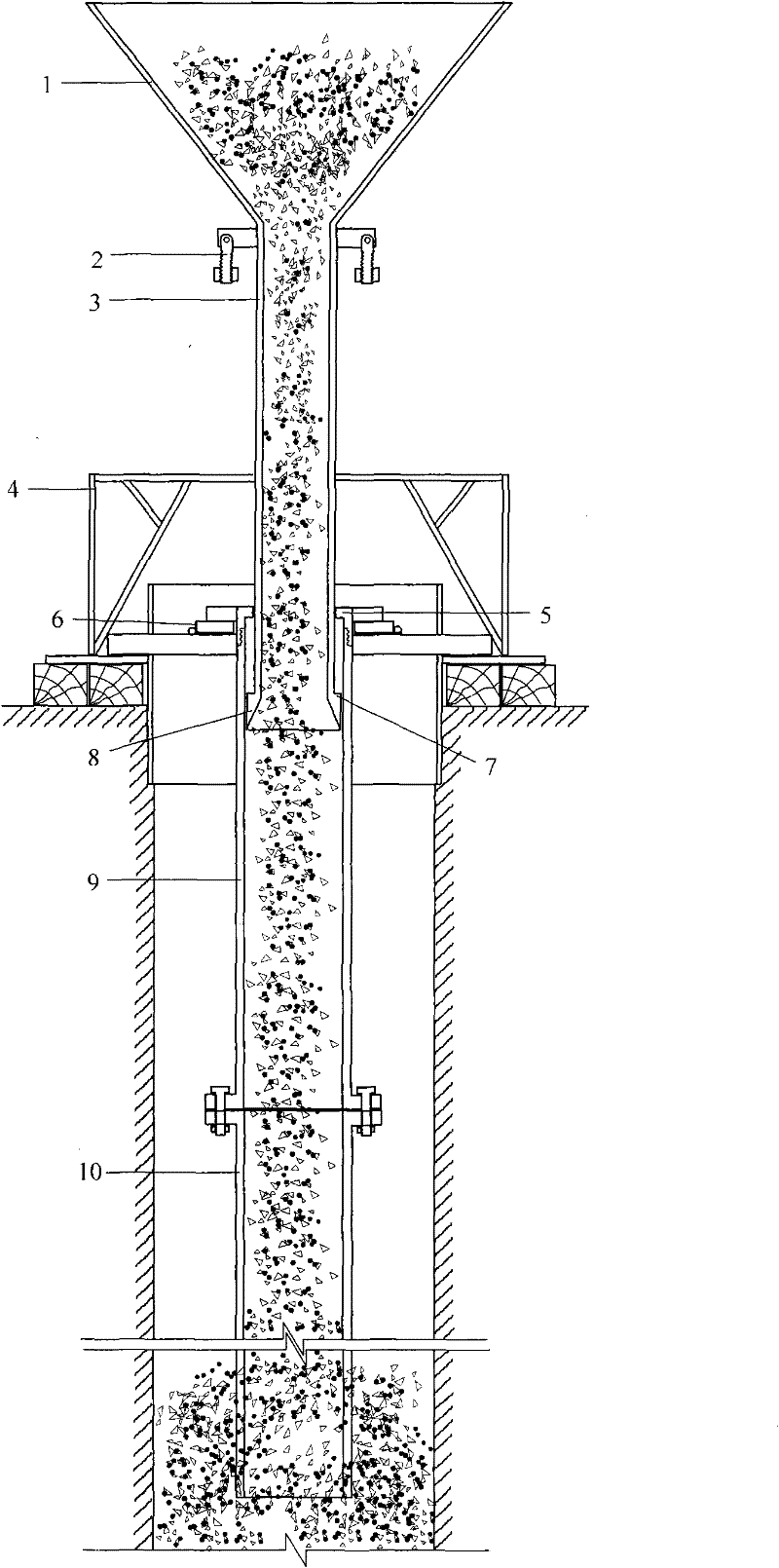

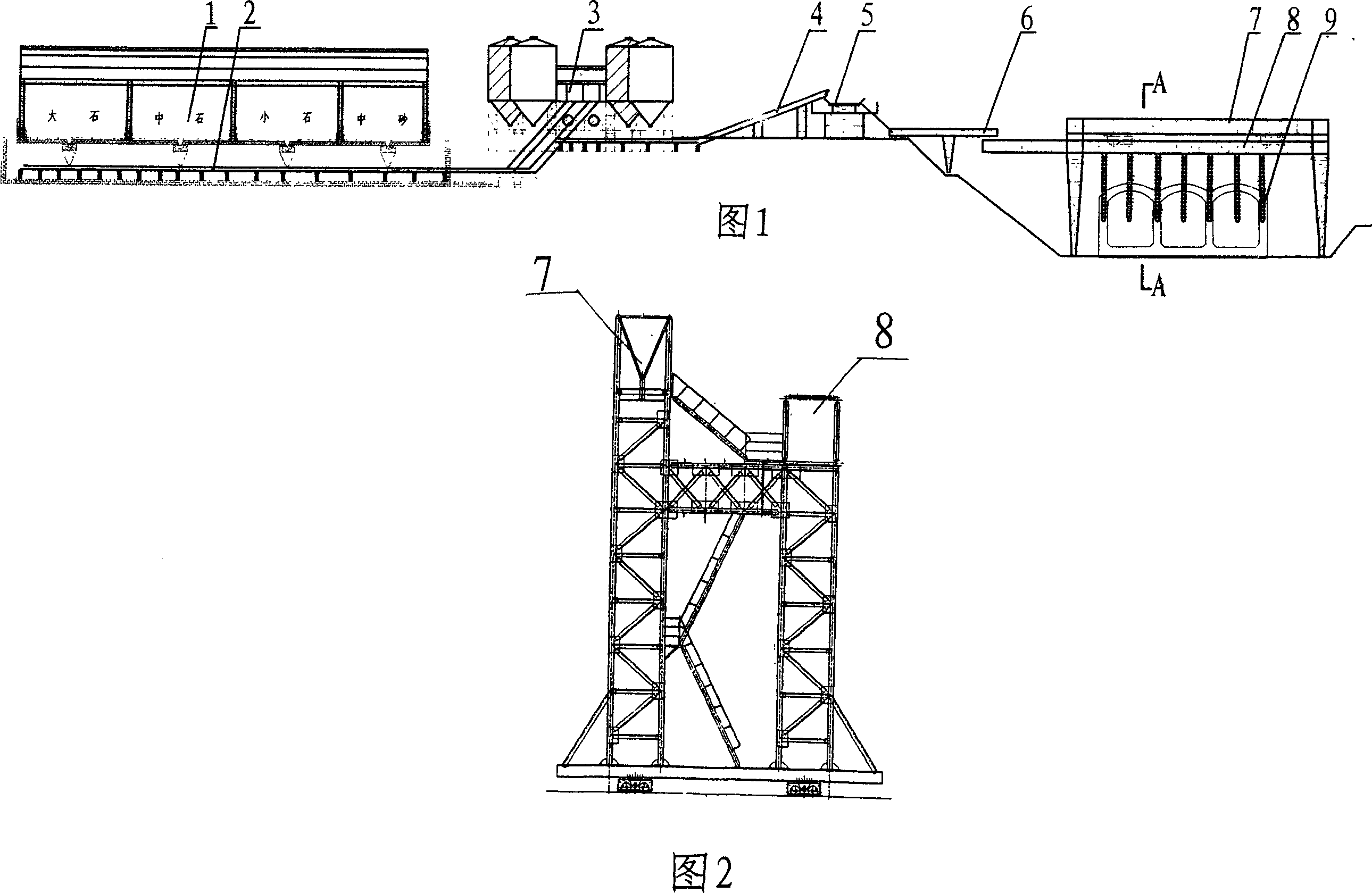

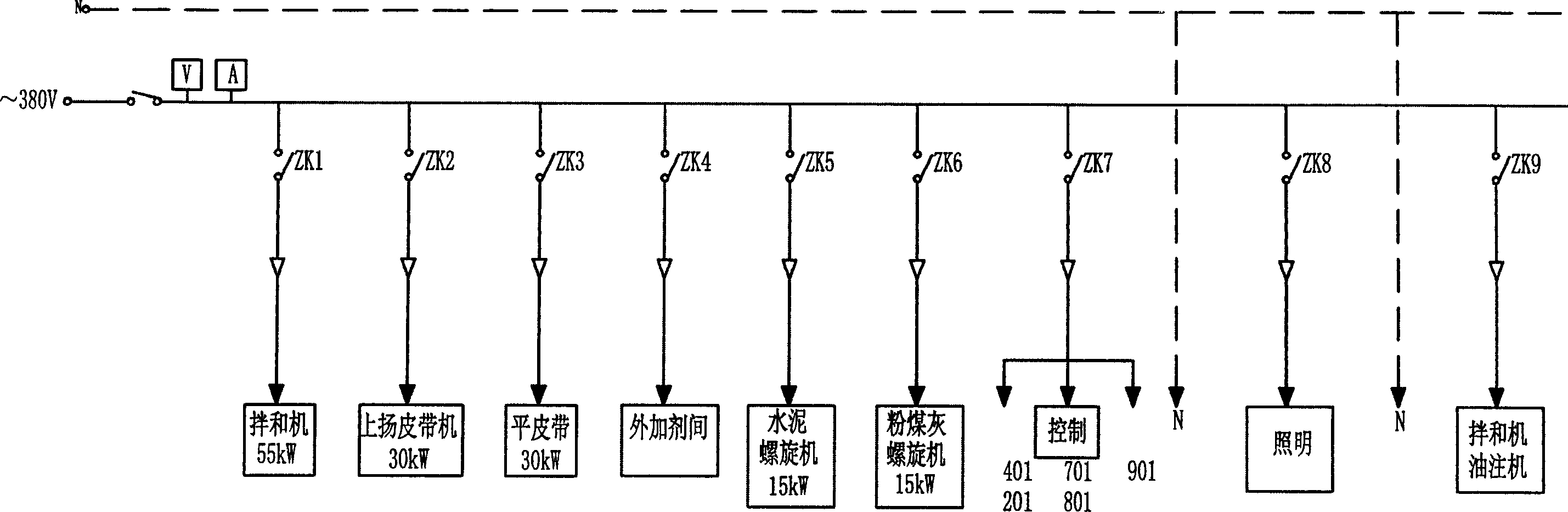

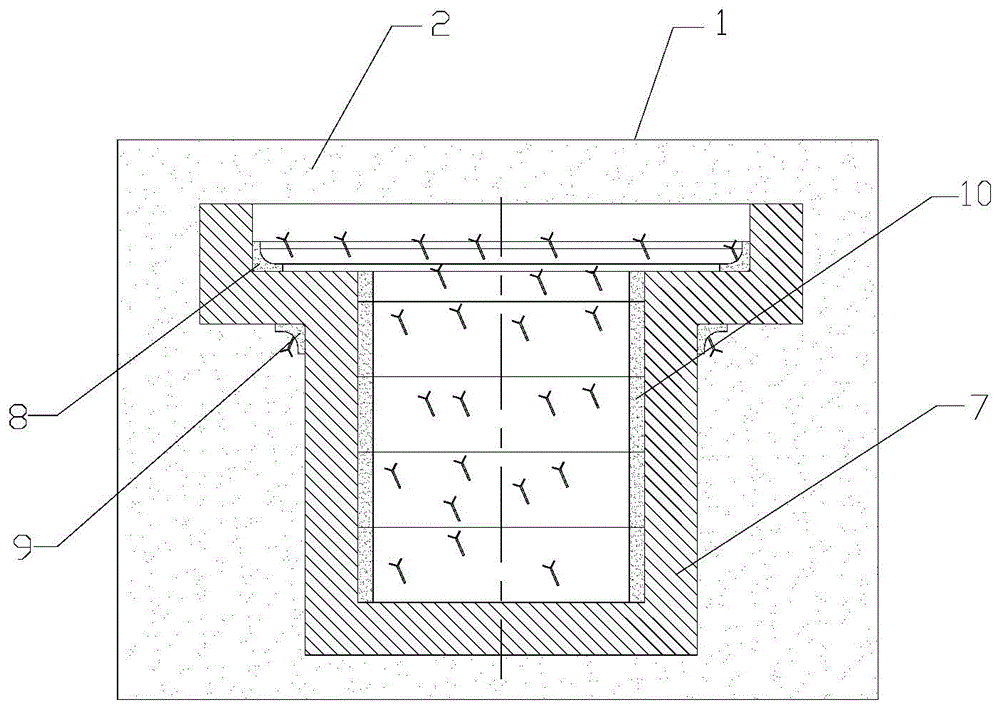

Integrated continuous construction system device for large-scale concrete engineering

ActiveCN1804226AReasonable site layoutCompact layoutArtificial water canalsBuilding material handlingEngineeringUltimate tensile strength

The invention relates to a device of integrated continuous constructing the large concrete project, belonging to the aqueduct, bridge, culver and other concrete projects. It mainly comprises the devices for measuring, feeding and mixing the concrete raw material, wherein, the concrete mixing device is connected to the main driver via the concrete transition feeding device while the feeding belt of main driver has several material-transfer outlets; the material-transfer outlet is connected to the concrete feeding device on the walking lifting distributing and feeding device; and the concrete feeding device comprises several outlets. The invention has following characters: (1) it can realize integrated continuous construction system; (2) it can increase the irrigation speed of concrete project to confirm the construction strength and quality; (3) the distribution of said device is reasonable and tight; (4) it can improve the working efficiency, reduce the cost and shorten the construction period. The invention can be used in artificial aqueduct, bridge, culver and other concrete projects.

Owner:河北省水利工程局集团有限公司

Concrete wall rapid pouring equipment

InactiveCN111730752AReduce manual laborIncrease pouring speedDischarging apparatusCeramic shaping apparatusPhysicsEngineering

The invention discloses concrete wall rapid pouring equipment. The concrete wall rapid pouring equipment comprises a machine body, two side plates which are in front and back symmetry are fixedly mounted on the upper side face of the machine body, two fixing columns in bilateral symmetry are fixedly mounted on the upper side of the machine body, a lifting rod is in sliding connection into each fixing column, a lifting spring is connected between each lifting rod and the corresponding fixing column, an upper cover plate is in sliding connection between the lifting rods, the upper side face ofthe upper cover plate is fixedly provided with a stirring body and a high-pressure pump, a stirring cavity is formed in the stirring body, a vibration cavity is formed in the upper side of the machinebody, a belt wheel cavity is formed in the lower side of the vibration cavity, a speed adjusting cavity is formed in the right side of the vibration cavity, a solidifying cavity is formed between theupper cover plate and the machine body, a stirring device for stirring concrete is arranged in the stirring cavity, a vibrating device for vibrating the concrete is arranged in the vibration cavity,a speed adjusting device for speed adjusting is arranged in the speed adjusting cavity, according to the equipment, stirring forming of the concrete can be automatically finished, rapid filling is carried out, concrete is flatly paved in a sense manner, manpower can be reduced, the pouring speed is quickened, and the building construction efficiency is improved.

Owner:缙云松弛自动化科技有限公司

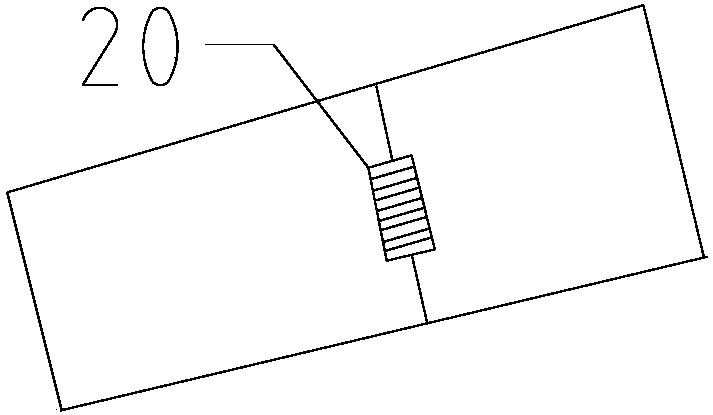

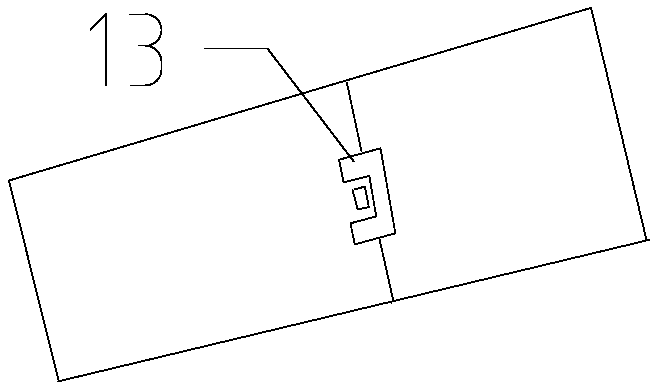

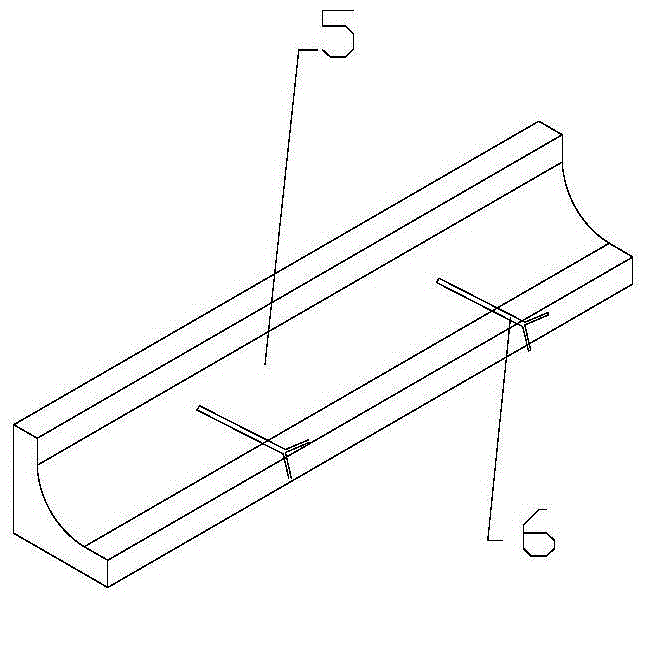

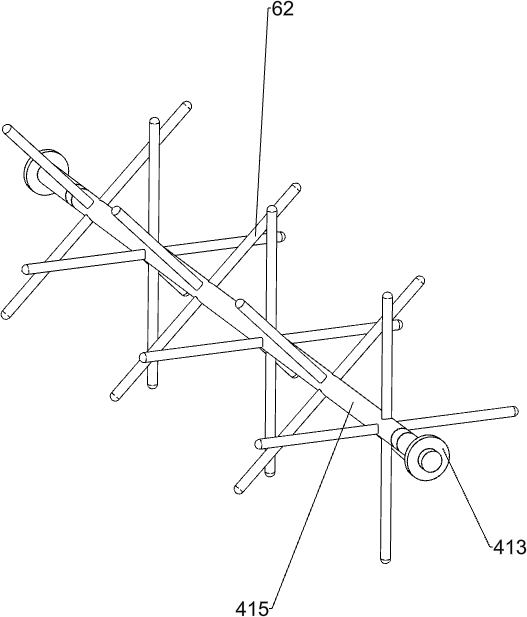

Method used for preventing sand adhesion of sand mould castings, and sand mould prefabricated components

InactiveCN104826986AReduce sticky sandReduce sandingFoundry mouldsFoundry coresMaterials sciencePrefabrication

The invention relates to a method used for preventing sand adhesion of sand mould castings, and sand mould prefabricated components. Each of the sand mould prefabricated components comprises a prefabricated block and connecting claws; the connecting claws are embedded in the prefabricated block, and are firmly connected with the prefabricated block; and the two ends of each connecting claw are provided with Y-shaped support legs. According to the method, prefabrication of the sand mould prefabricated components corresponding to certain parts in sand mould modeling is carried out; in modeling processes, the sand mould prefabricated components are placed at corresponding parts, filling of moulding sand and pressing are carried out, and the connecting claws on the sand mould prefabricated components are mixed with the moulding sand so as to realize integration of the sand mould prefabricated components with the moulding sand. The special-type prefabricated components are fixedly arranged at the preset parts of sand moulding, so that casting sand adhesion and sand filling are avoided, local deformability and collapsibility are improved, local temperature is controlled, casting quality is increased, production cost is reduced, and operation is convenient. The sand mould prefabricated components are provided with universal R angles; plane standardization can be realized; and cutting and splicing can be carried out.

Owner:鞍山千钢机械制造有限公司

Excrement leaking plate pouring equipment for livestock breeding

The invention relates to excrement leaking plate pouring equipment, in particular to excrement leaking plate pouring equipment for livestock breeding. According to the excrement leaking plate pouringequipment for livestock breeding, an excrement leaking plate mold does not need to be shaken manually. The excrement leaking plate pouring equipment for livestock breeding comprises a bottom plate, ashaking mechanism and a discharging mechanism; one side of the upper part of the bottom plate is connected with a mounting frame; the shaking mechanism is installed on the side, close to the mountingframe, of the bottom plate; and the discharging mechanism is installed between the mounting frame and the bottom plate. According to the excrement leaking plate pouring equipment for livestock breeding, the shaking mechanism works to drive a linkage mechanism to work, the linkage mechanism can drive the discharging mechanism to work, the discharging mechanism works to discharge cement paste in thedischarging mechanism so that the cement paste can evenly fall into the excrement leaking plate mold, and the shaking mechanism can shake the excrement leaking plate mold left and right, so that theexcrement leaking plate mold does not need to be shaken manually.

Owner:吴星佳

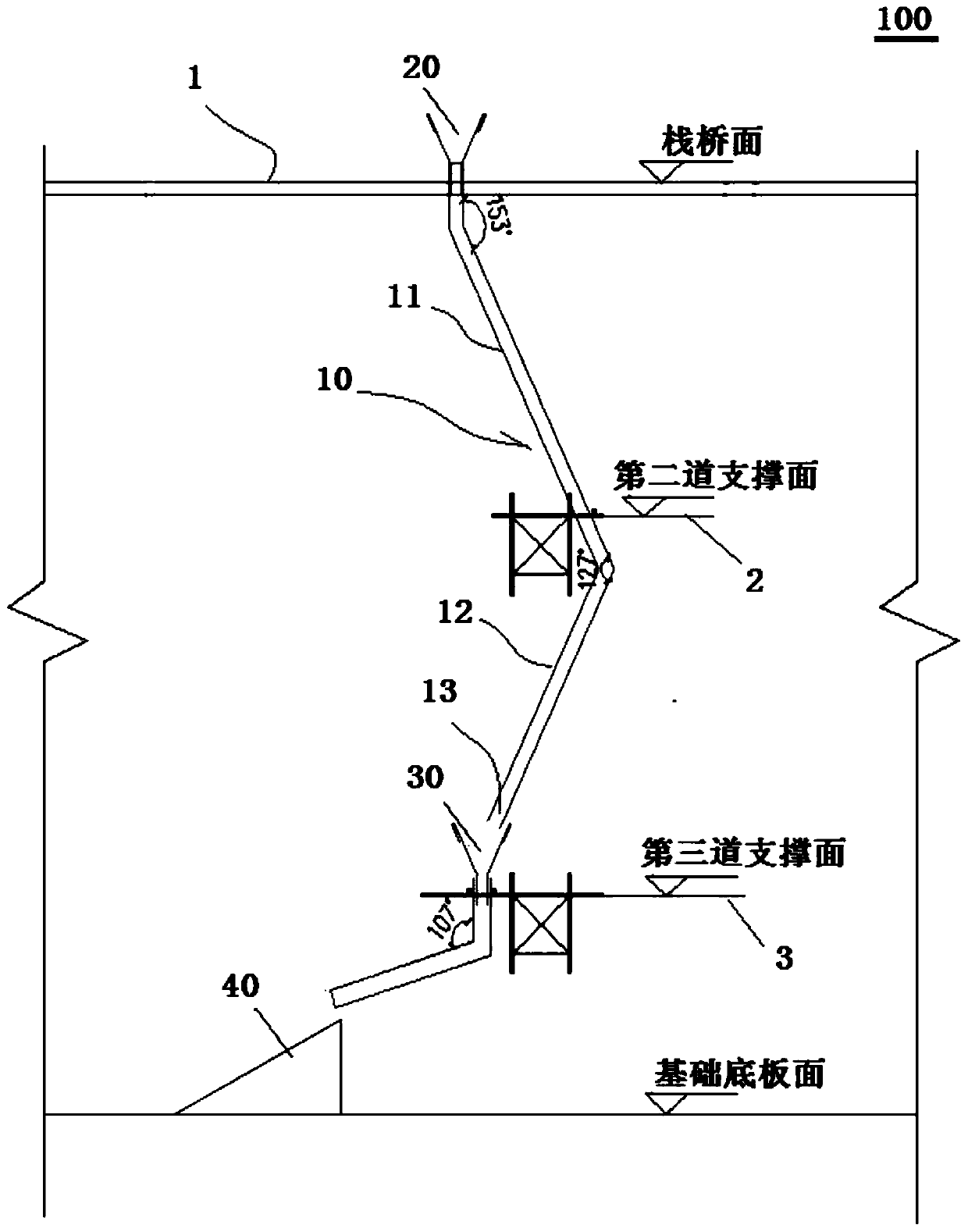

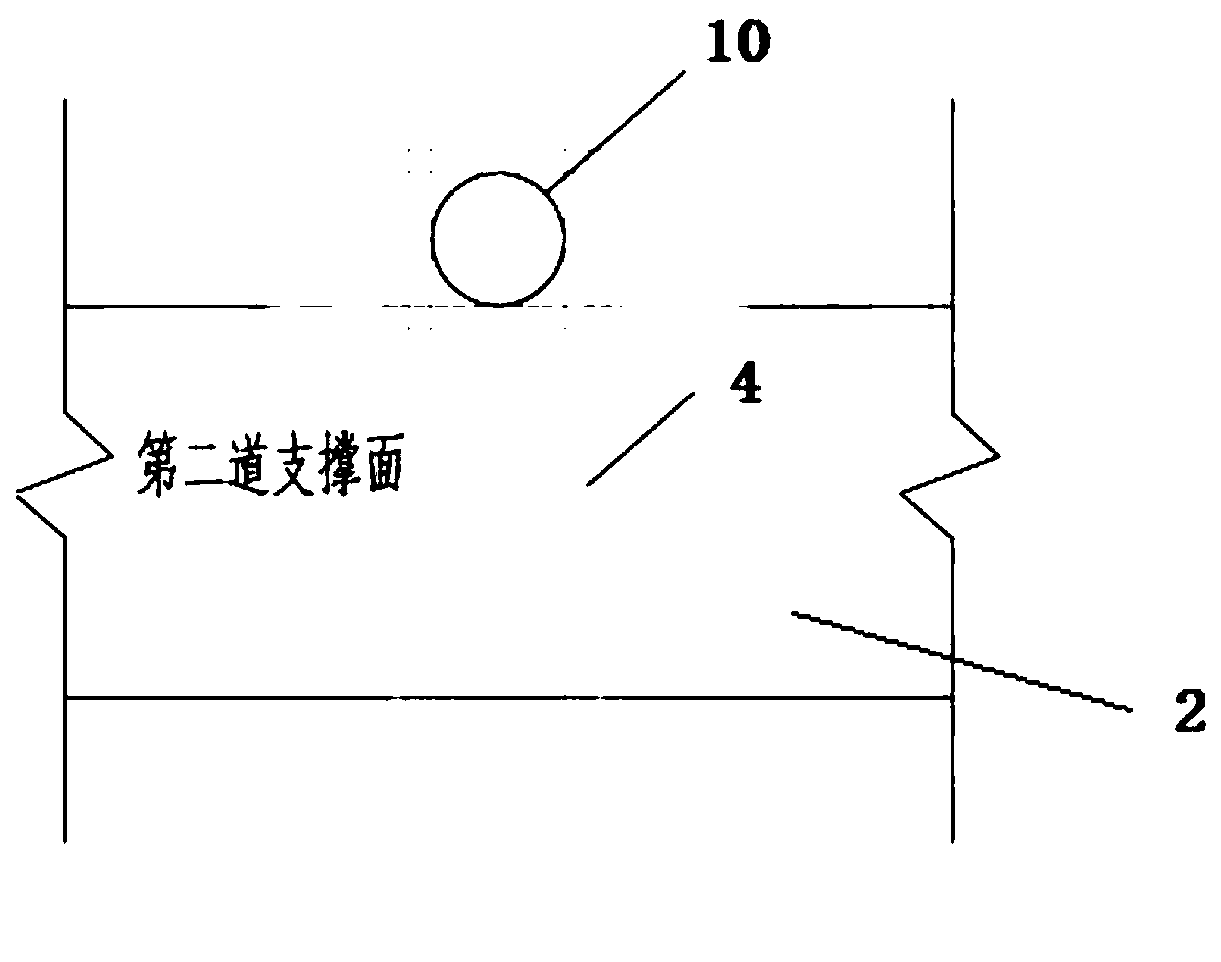

Tool type chute and construction method

PendingCN110565962AOptimize componentsSimple wayFoundation engineeringBuilding material handlingSupport pointBuilding construction

The invention discloses a tool type chute and a construction method, and belongs to the field of building construction. The tool type chute is mounted on a foundation pit enclosure structure; a support and a trestle in the foundation pit enclosure structure are used as support points of the tool type chute; and a trestle plate is provided with a trestle hole for lifting the chute. The tool type chute comprises the chute, an unloading hopper, a movable unloading hopper and a small chute. The chute is fixed in the corresponding support place through channel steel and a hoop, and is provided withan inclined angle. The chute is formed by welding two iron pipes; and an included angle is formed between the two iron pipes. The unloading hopper is arranged in the trestle hole. The movable unloading hopper is arranged in a chute lower port. The small chute is arranged in the chute lower port, and is freely rotated along with the movable unloading hopper. The tool type chute saves the labor andmaterial consumption needed by rack building, accelerates the construction speed, guarantees the safety in the construction process, widens the casting range, improves the flexibility, reduces the noise pollution, and meets green construction requirements.

Owner:SHANGHAI CONSTR NO 1 GRP

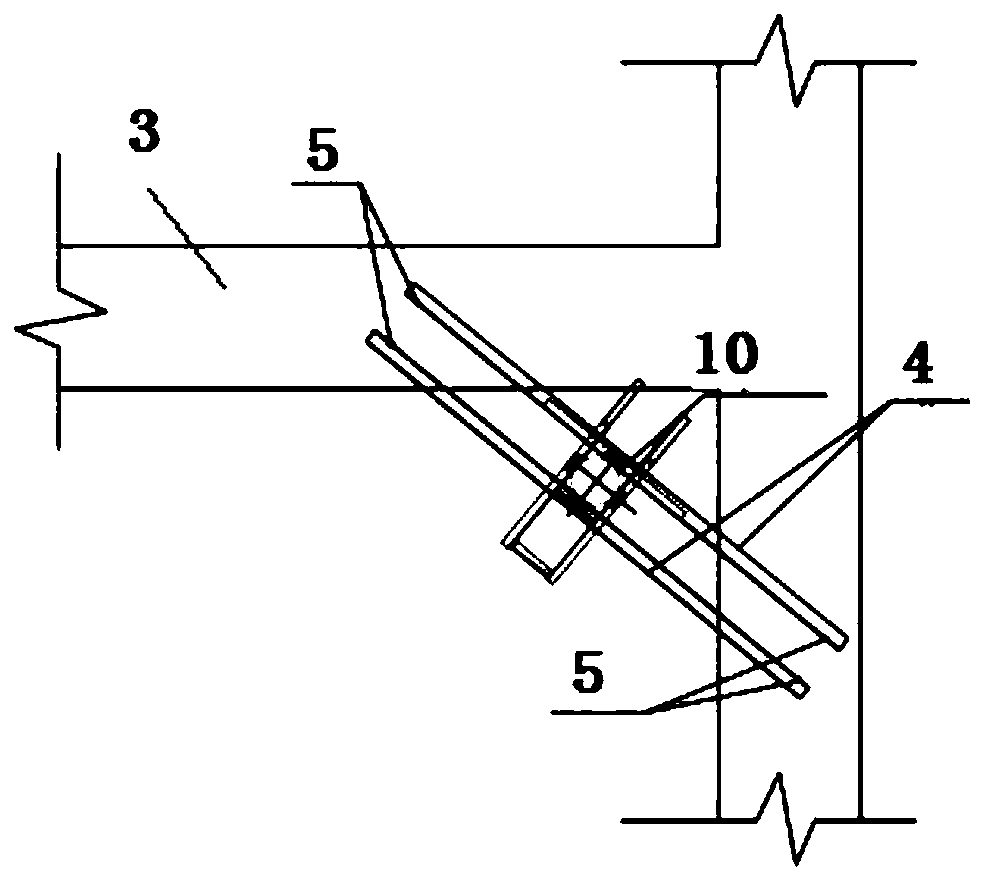

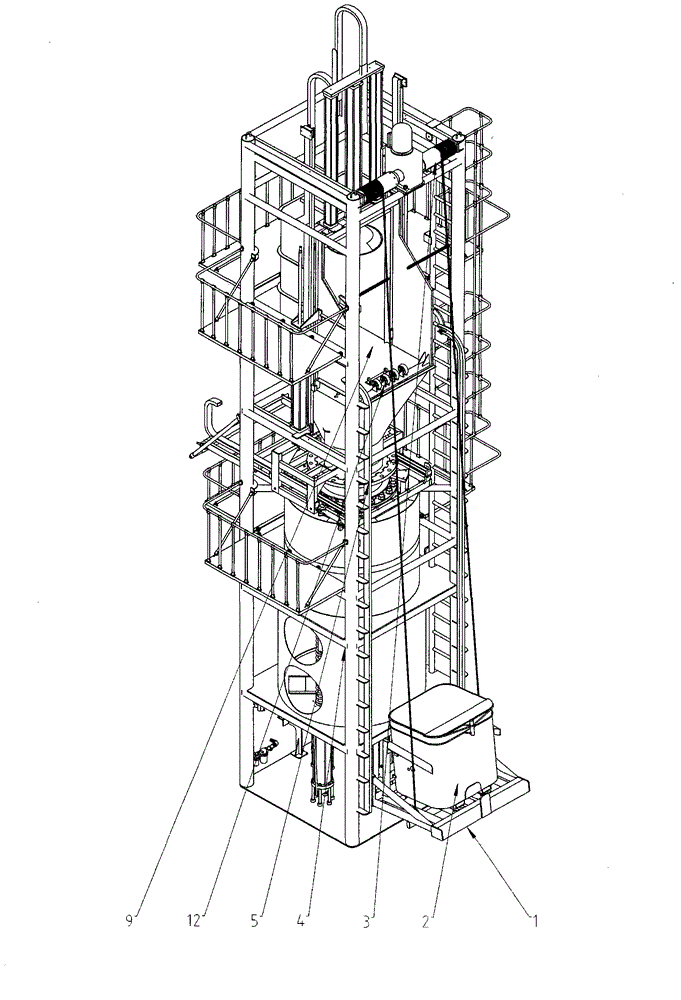

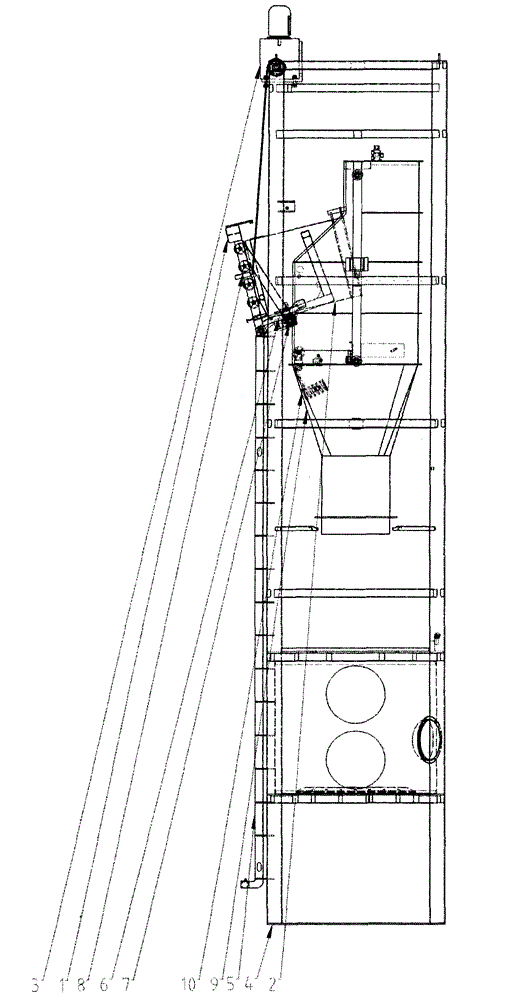

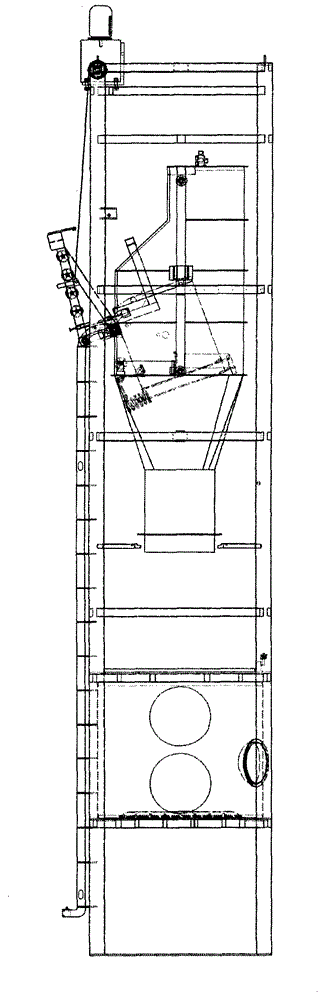

Elevator matched with steam blasting machines

The invention relates to a material elevator matched with steam blasting machines, and belongs to material conveying devices. The elevator matched with the steam blasting machine provided by the invention only adopts a steel wire rope roller as a driving component to lift and drag a bracket to move up and down in a vertical track, and can permit a large-size circulating hopper to be dumped for angles of more than 150-170 degrees and reset. Since the dumping angle is more than 150 degrees, dumping speed is rapid, and thereby light biomass can be dumped completely. A steel wire rope is directly used for vertically hoisting materials without any moving accessories, so that additional energy consumption is avoided. The elevator is attached to the vertical frame of the steam blasting machine, thus being capable of saving occupied space as much as possible. In addition, the machine is simple in structure, few in moving parts, and being capable of fully adapting to various kinds of biomass materials and hostile working environments, and stable and reliable in operation. The circulating hopper can be rapidly assembled and disassembled by forklifts, and the plurality of circulating hoppers can be configured, thus being capable f greatly improving whole logistics efficiency.

Owner:于政道 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com