Agricultural machinery part casting device

A technology for accessories and agricultural machinery, applied in casting equipment, equipment for transporting casting molds, equipment for feeding molten metal into casting molds, etc. , The effect of convenient height adjustment and shortening of casting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

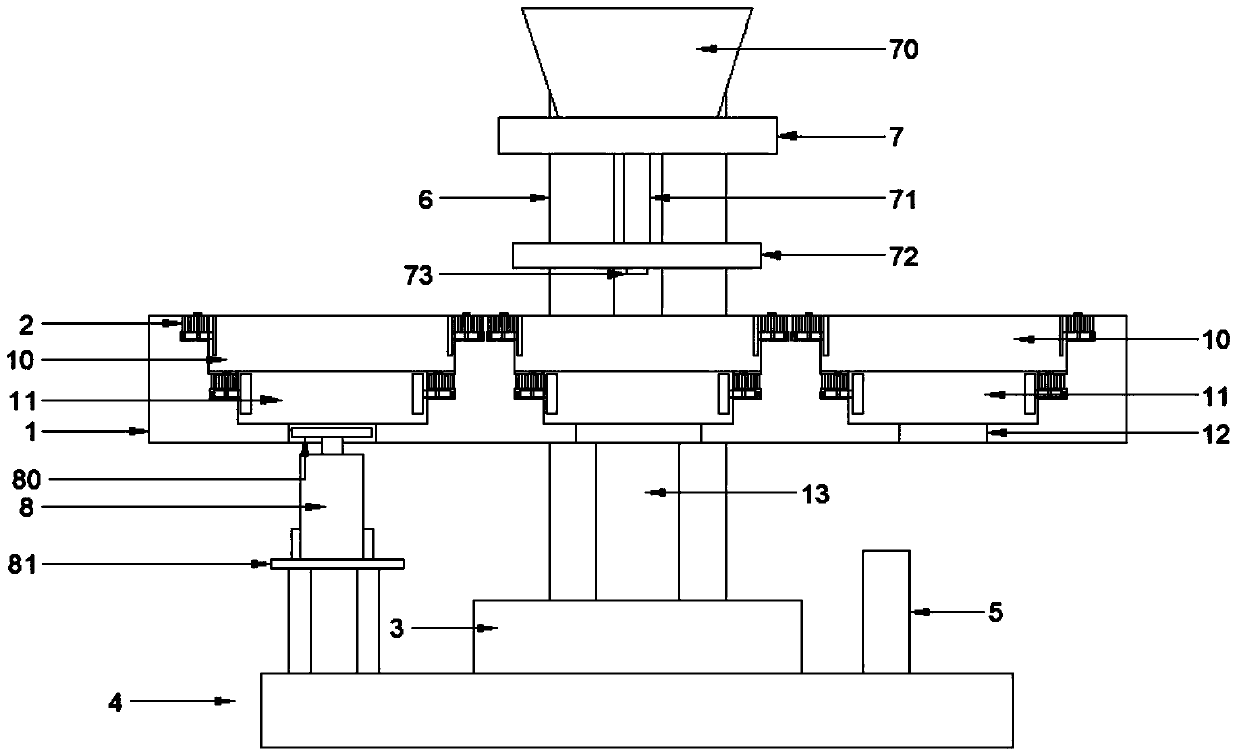

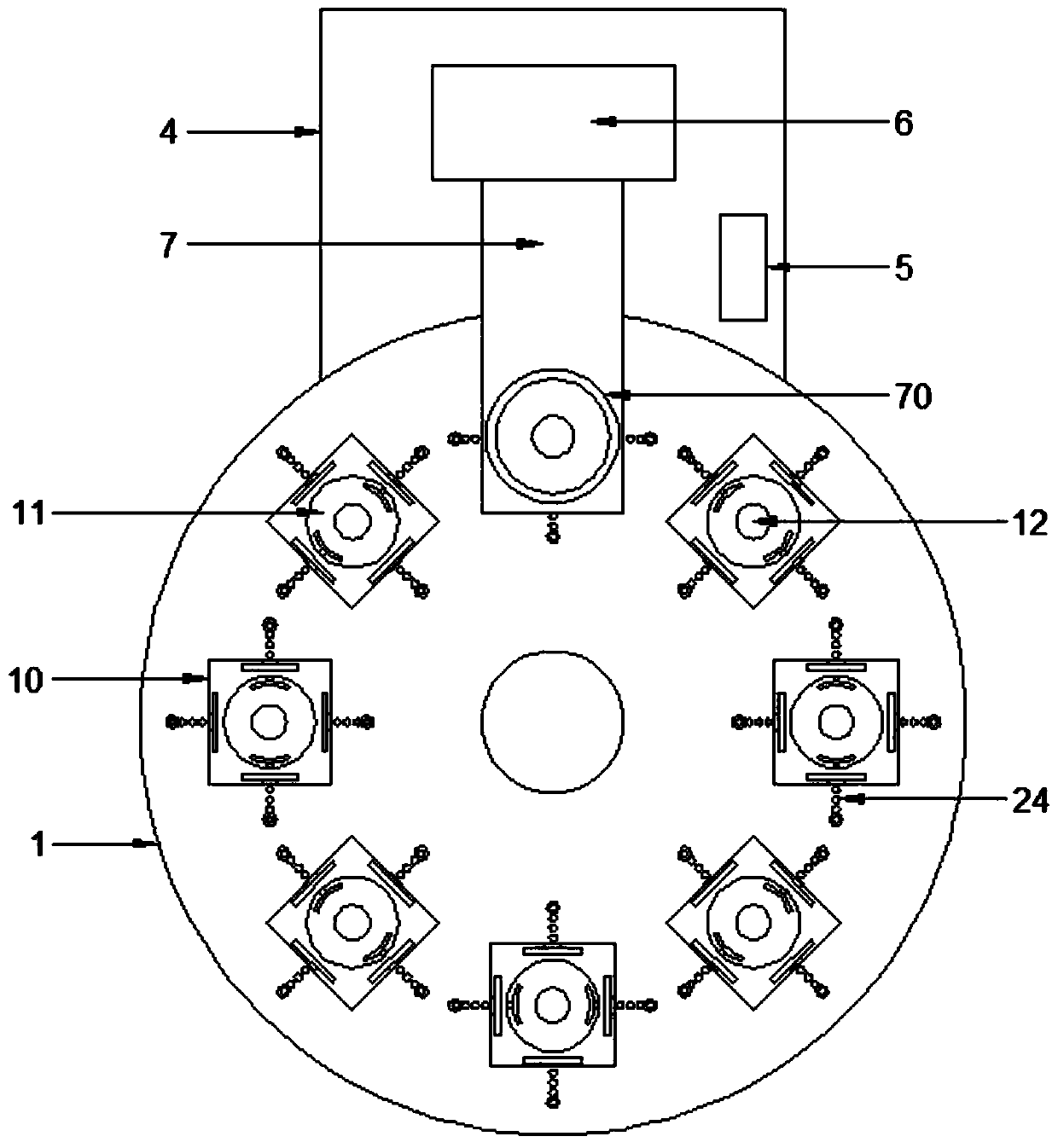

[0023] see Figure 1~5 , in an embodiment of the present invention, a casting device for agricultural machinery accessories includes a casting turntable 1, the center of the bottom surface of the casting turntable 1 is rotatably supported on the top surface of the base 4 by a vertically arranged rotating spindle 13, and the base 4 A console 5 is provided on the top surface, and a melt leakage furnace 70 for downward casting of molten material is provided directly above the casting turntable 1, and a plurality of flat accessory molds are arranged on the top surface of the casting turntable 1 The slot 10, the bottom of the flat accessory mold slot 10 is provided with a plurality of special-shaped mold slots 11, the bottom of the special-shaped mold slot 11 is provided with a lifting device for lifting the mold upward, and the flat accessory mold The inner wall of the draw-in slot 10 and the special-shaped mold draw-in slot 11 is provided with a clamping structure 2 for clamping ...

Embodiment 2

[0032] The difference between this embodiment and embodiment 1 is:

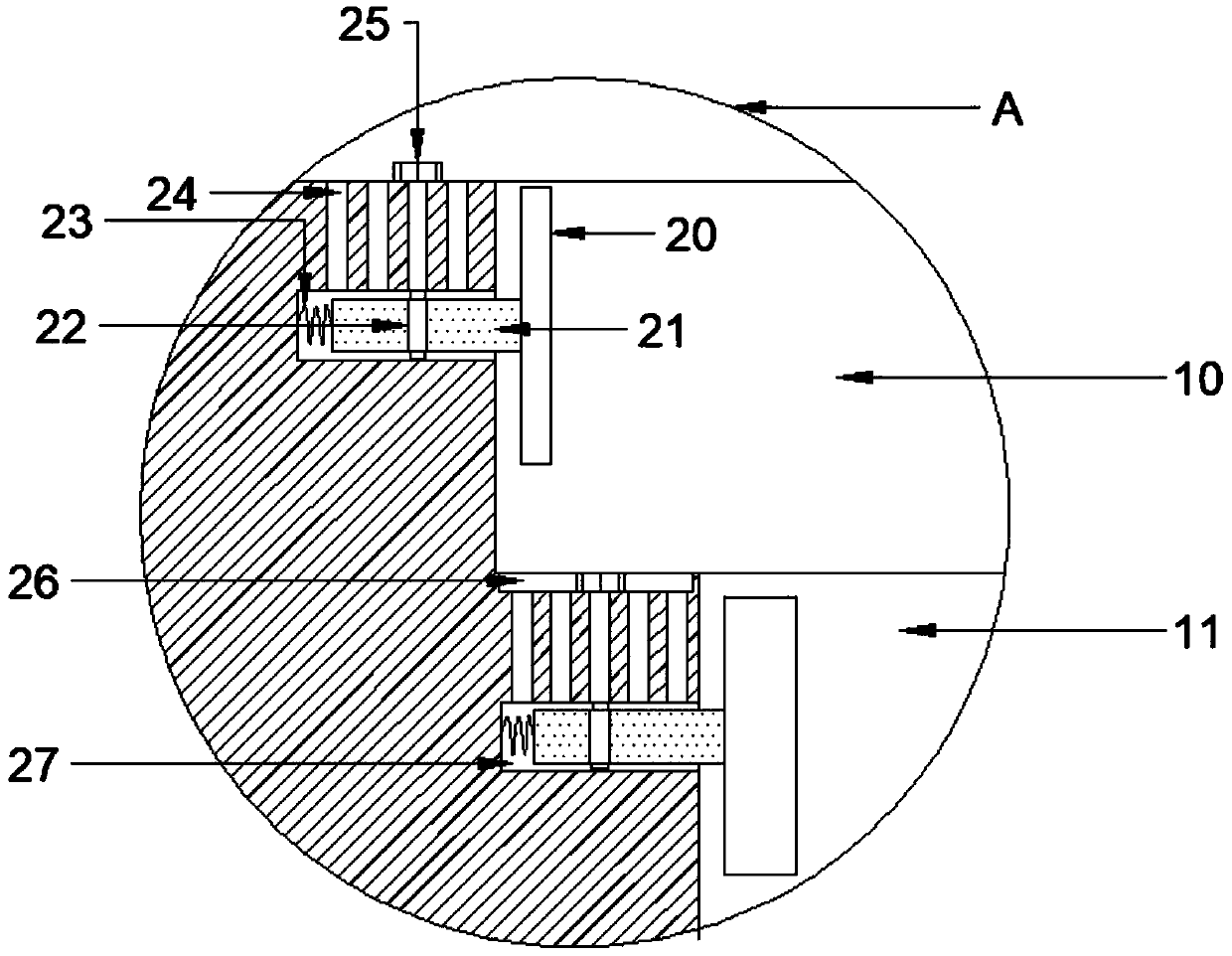

[0033] The top of the clamp telescopic cavity 27 is provided with a plurality of adjusting screw holes 24 arranged at intervals, and the middle section of the splint telescopic rod 21 is provided with a rod fixing screw hole 22, and the rod fixing screw hole 22 and the adjusting screw hole 24 pass through Fixing bolt 25 threads are fixedly connected.

[0034] The groove bottom of the plate accessory mold slot 10 is provided with a plurality of countersinks 26 , and the adjusting screw holes 24 of the special-shaped mold slot 11 are opened in the countersunk 26 .

[0035] The working principle of the present invention: the fixed bolts 25 provided can further ensure that the splint 20 will not shift and ensure the clamping stability of the clamping structure 2, and the set inner countersunk 26 mainly prevents the fixed bolts 25 from being scratched by the plate accessory mold The bottom of the mold in the slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com