Patents

Literature

40results about How to "Speed up pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

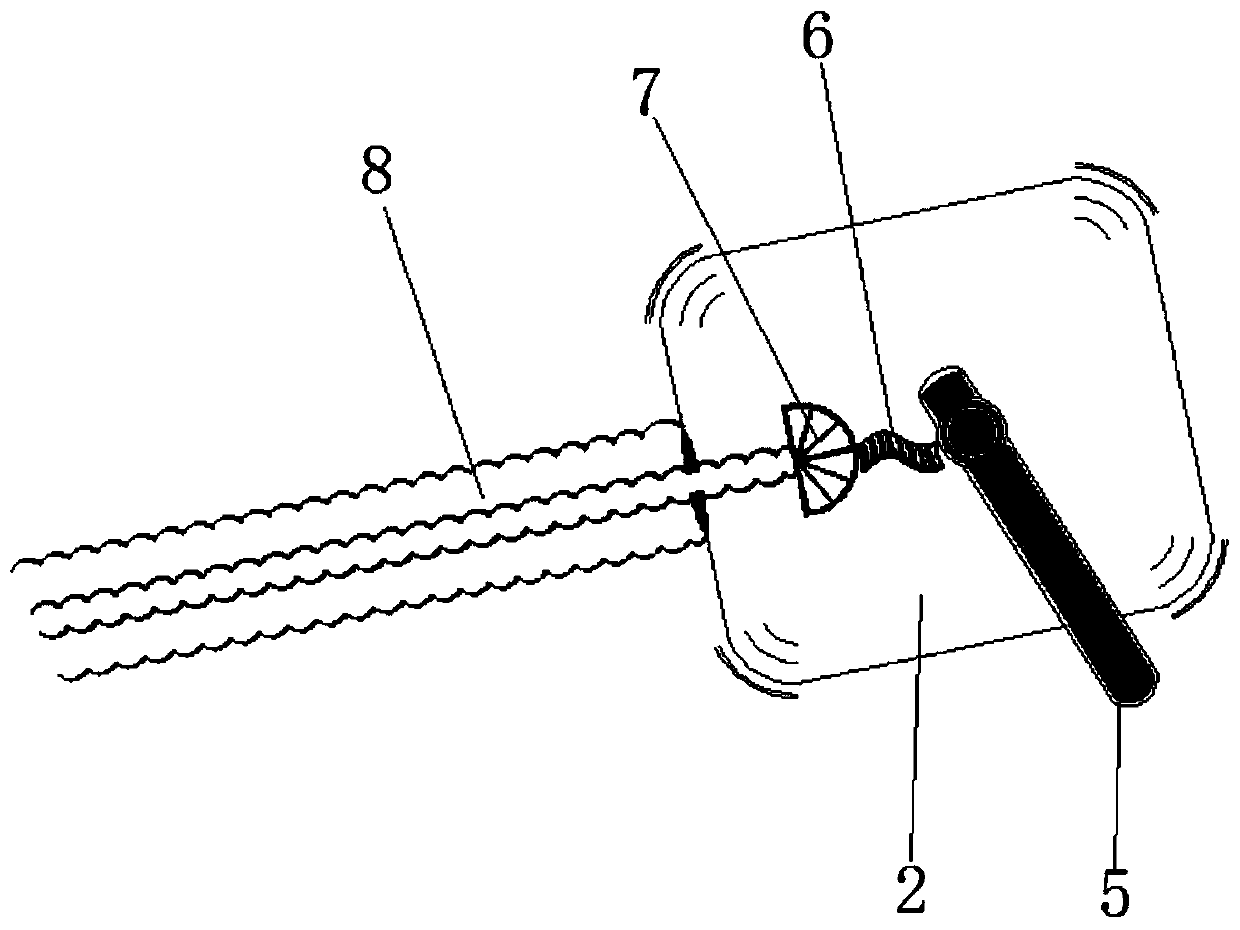

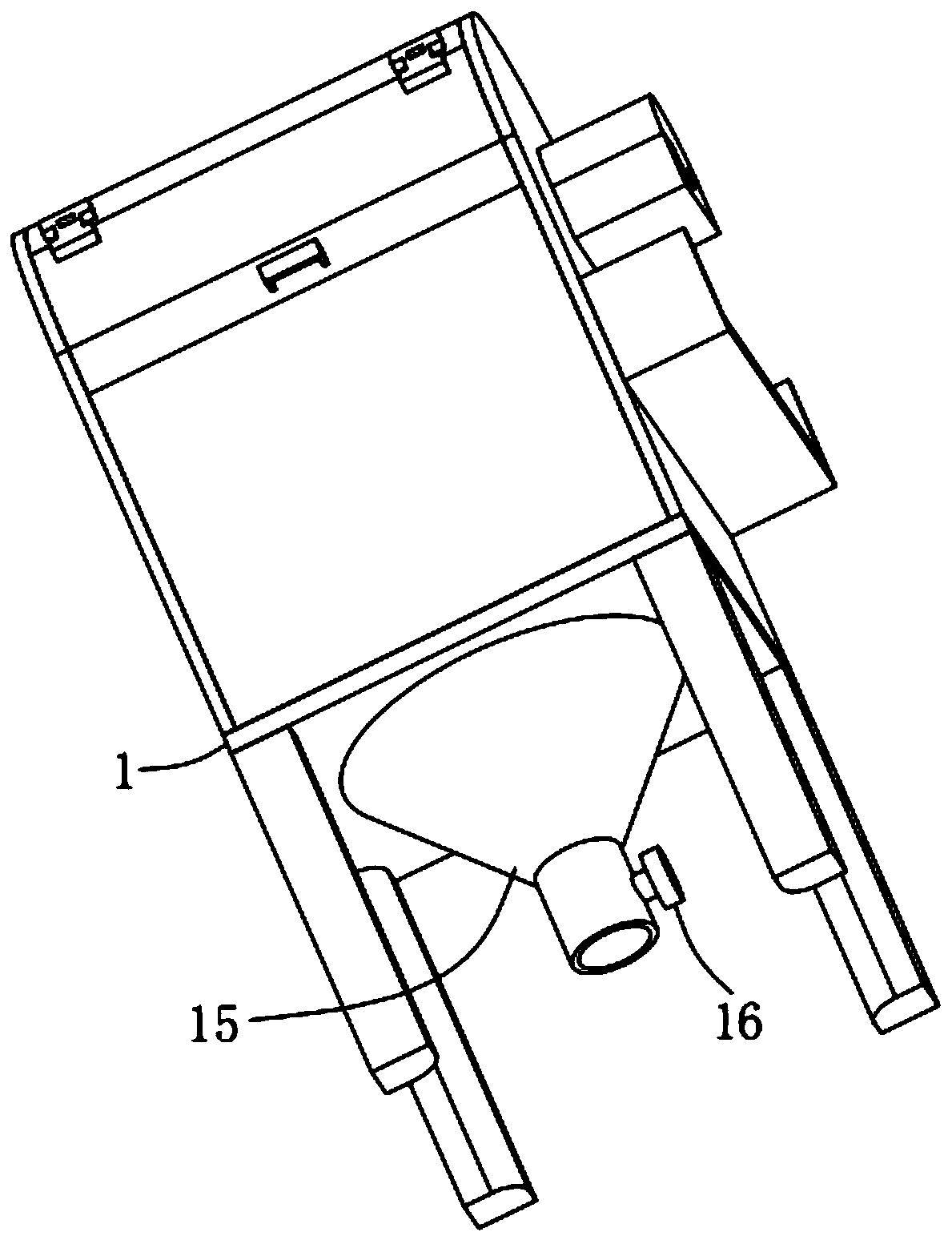

Compaction forming construction method of concrete poured on the base of structure and device thereof

InactiveCN101566010ASimple Engineering TransformationSimple Reinforcement DesignBuilding repairsFoundation repairSquare cross sectionPiston

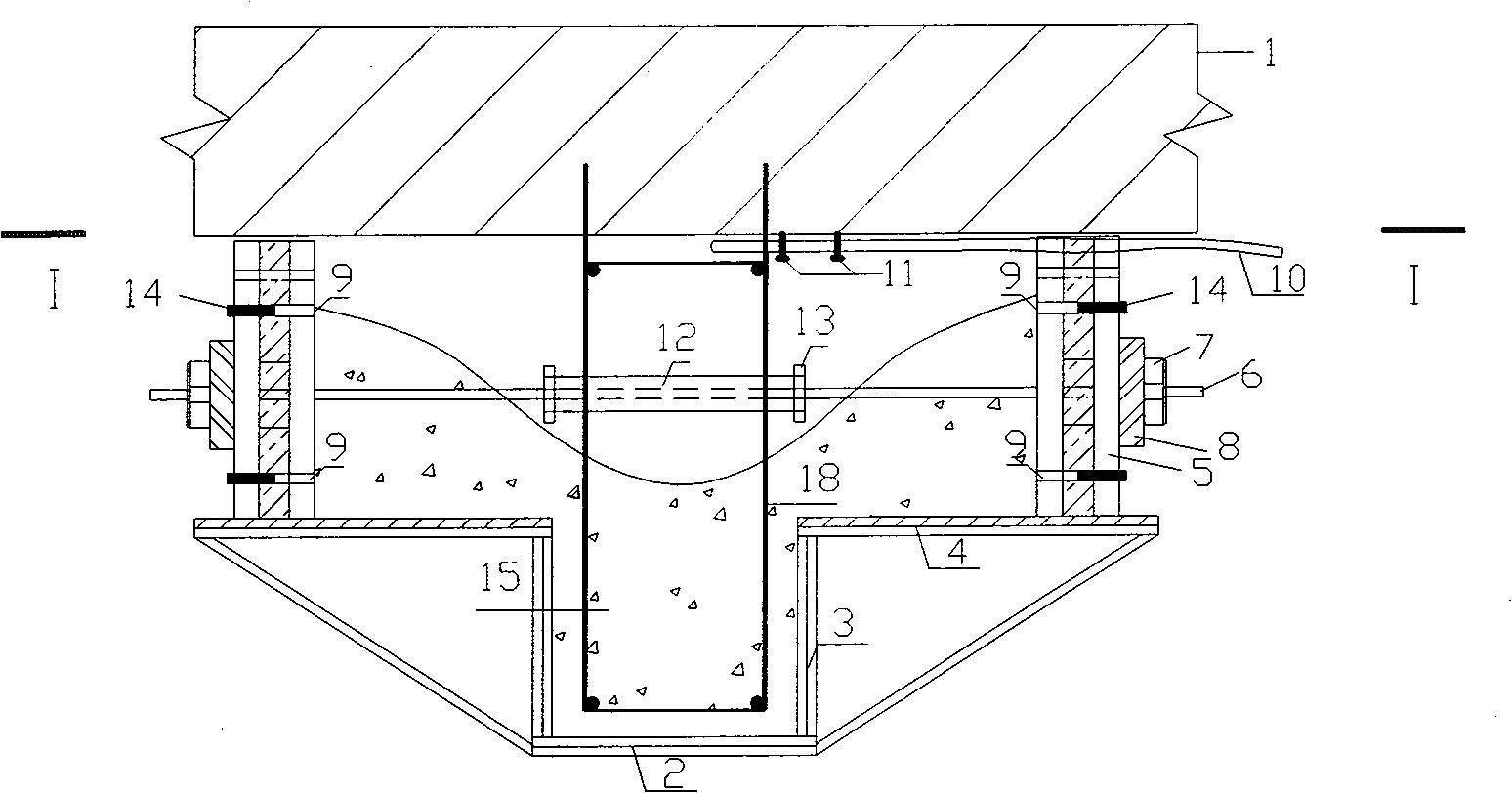

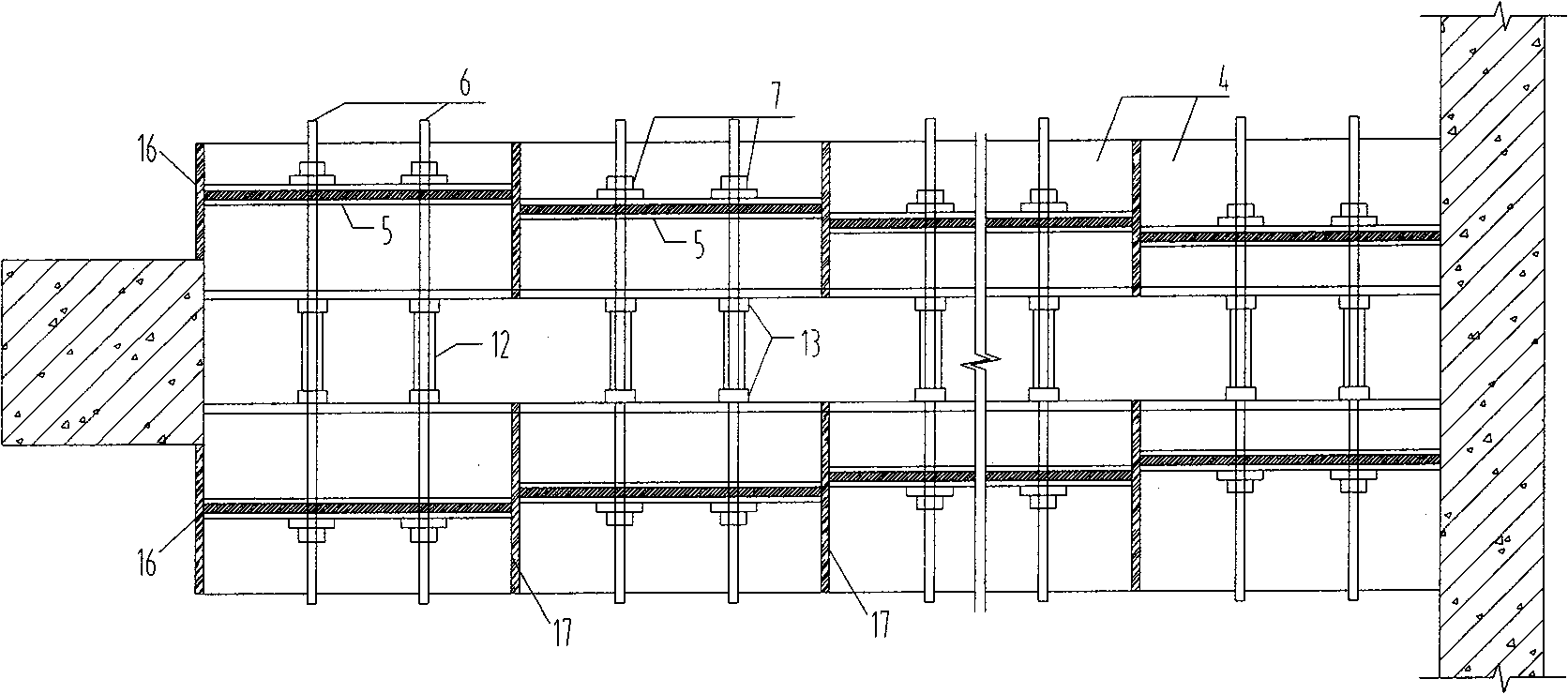

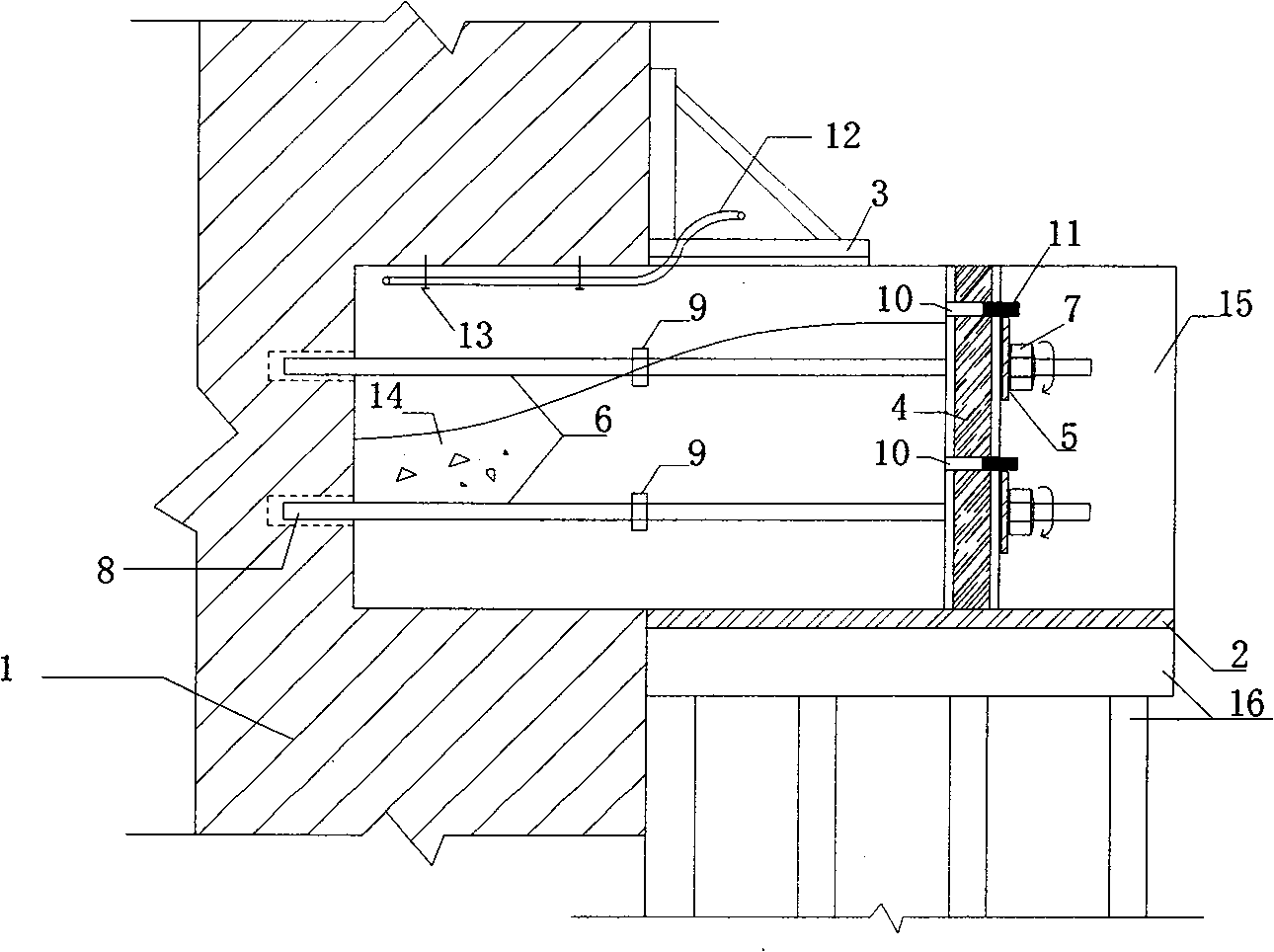

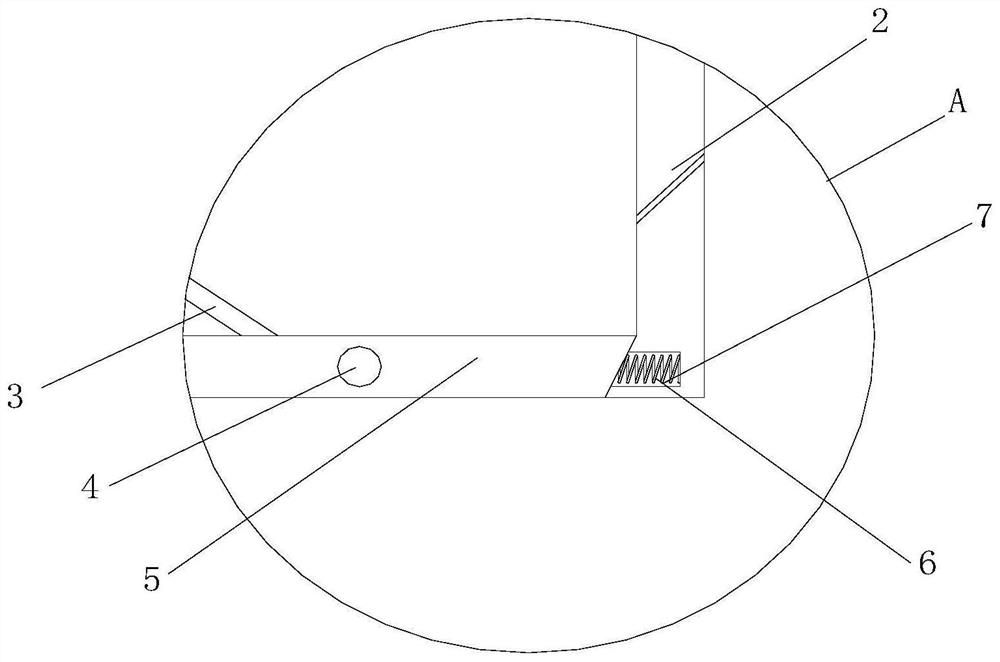

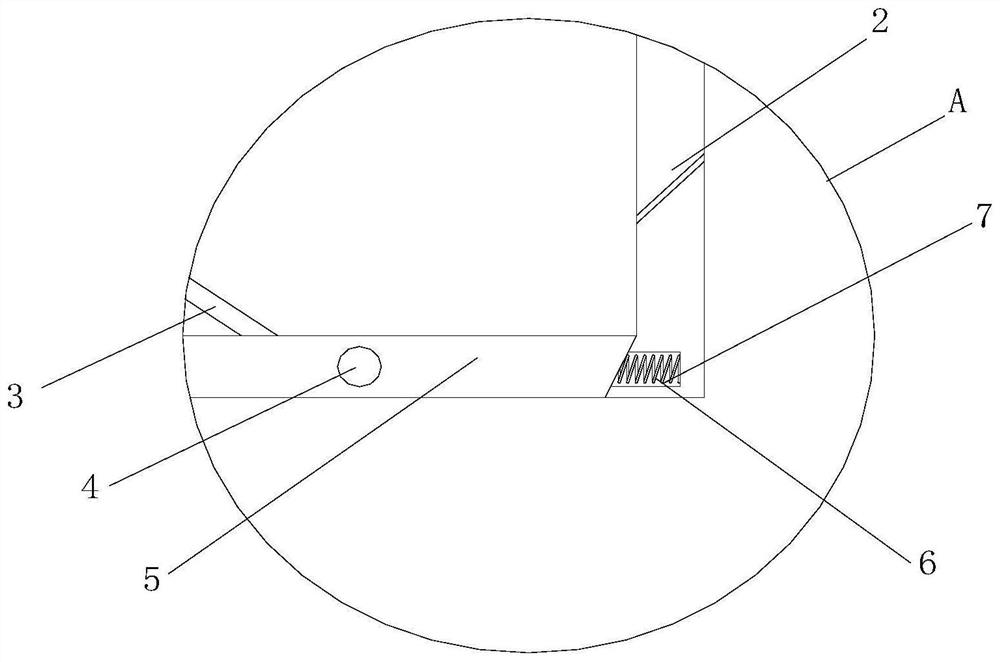

A compaction forming construction method of the concrete poured on the base of the structure and a device thereof belong to the field of civil engineering. The invention relates to the compaction forming construction method for directly pouring concrete on the lower part of prior structure and the device thereof. The method and the device of the invention are not restricted by the obstruction of the upper structure. The concrete can be extruded and pushed to a formwork to be poured and extruded to compact for forming in a horizontal direction of the side surface or a vertical direction from bottom to up. The bearing capacity of the prior structure is improved or the prior structure is reinforced. The extruding device is installed to the bottom or side surface of the existing structure. The concrete to be poured is filled in a cylinder body (4). After an extruding plate (5) is pushed for squeezing the concrete (15) forwards in the horizontal direction or upwards in the vertical direction through a force applying nut (11) or a jack, the stable pushing force is kept for extruding the new concrete to compact in one time for completing the pouring task. The device of the invention is composed of a cylinder body (4) with circular or square cross section, a piston type pushing extraction plate (5), a force transmitting screw bolt (6), the force applying nut (11), etc.

Owner:JIANGSU JIANHUA CONSTR

Electric control system of rubbish dumping transport car

InactiveCN102837923AImprove pouring efficiencyImprove working environmentProgramme control in sequence/logic controllersRefuse vehiclesEngineeringProportional valve

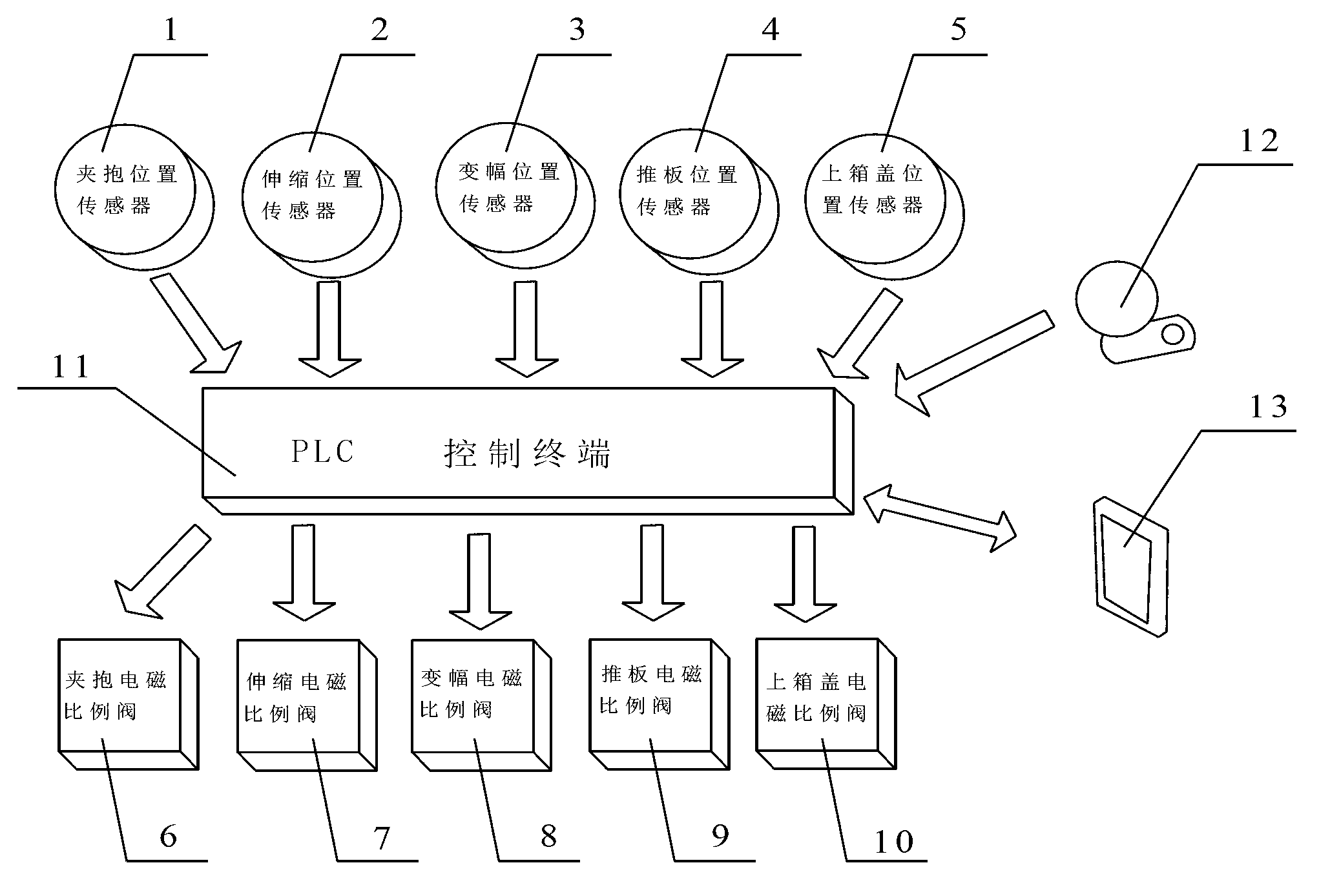

The invention belongs to the field of a rubbish transport car. Particularly, the invention relates to an electric control system of the rubbish dumping transport car. The electric control system comprises a control terminal, an operation mechanism, a telescopic executing mechanism, a holding clamp executing mechanism, a dumping executing mechanism and a compression executing mechanism. The holding clamp executing mechanism arranged on the telescopic executing mechanism is used for holding a trash can and mainly consists of a holding position sensor, a holding electromagnetic proportional valve; specific to various square trash cans, circular trash cans and irregular trash cans, the holding position sensor can detect the relative position of the trash can, then the holding trash can of the holding electromagnetic proportional valve is controlled; the dumping efficiency is high, and workers can finish the dumping work without contacting the trash can with various bacteria; the working environment of sanitation workers is improved and praised by everyone. The compression executing mechanism is arranged and used for compressing rubbish, thereby improving the transferring efficiency.

Owner:上海派恩科技有限公司

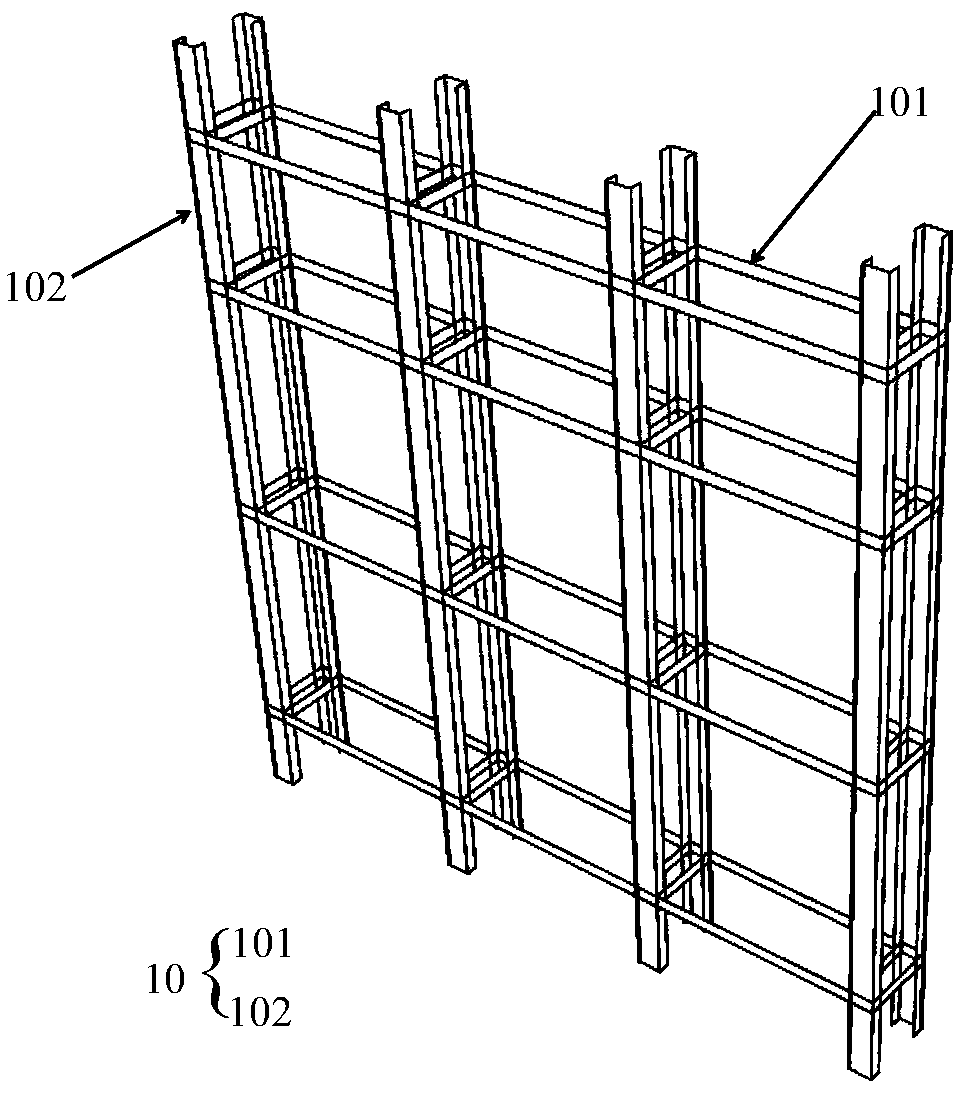

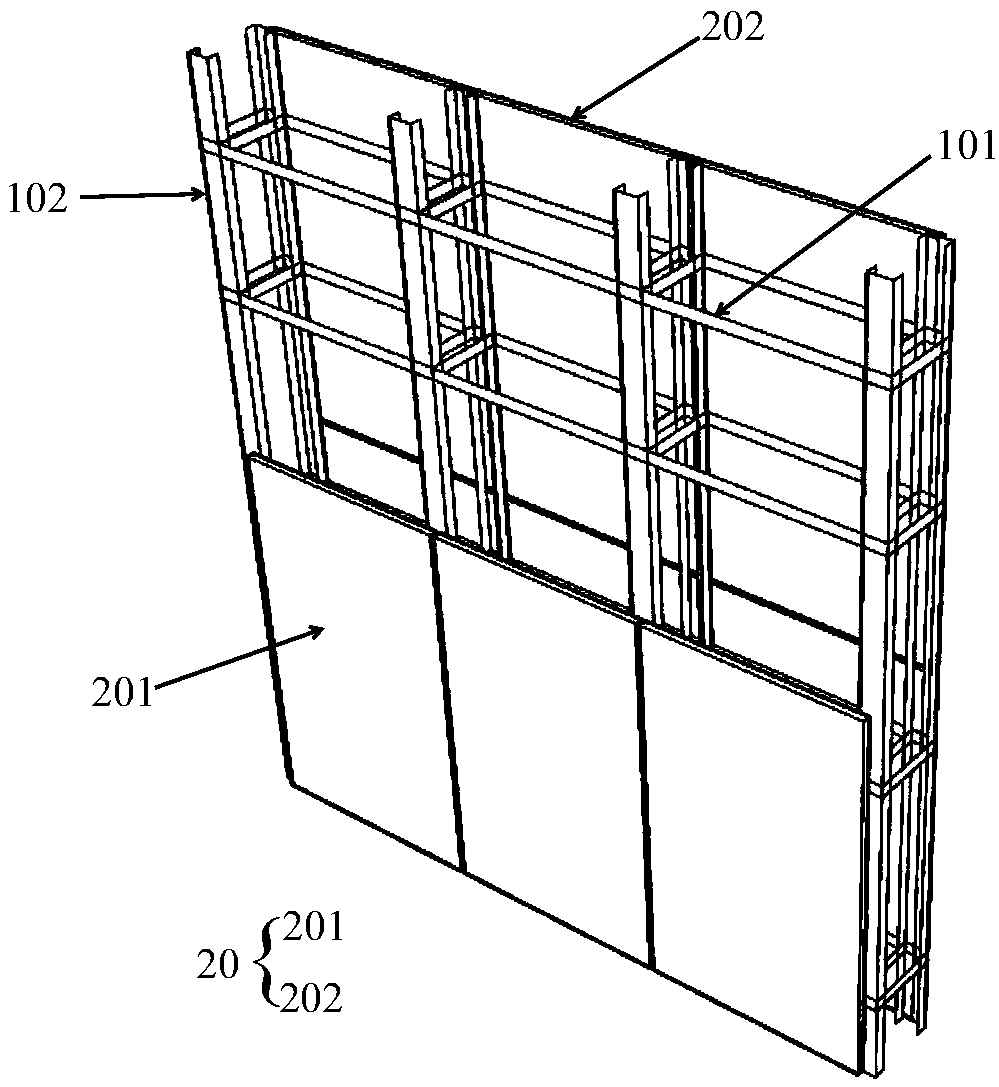

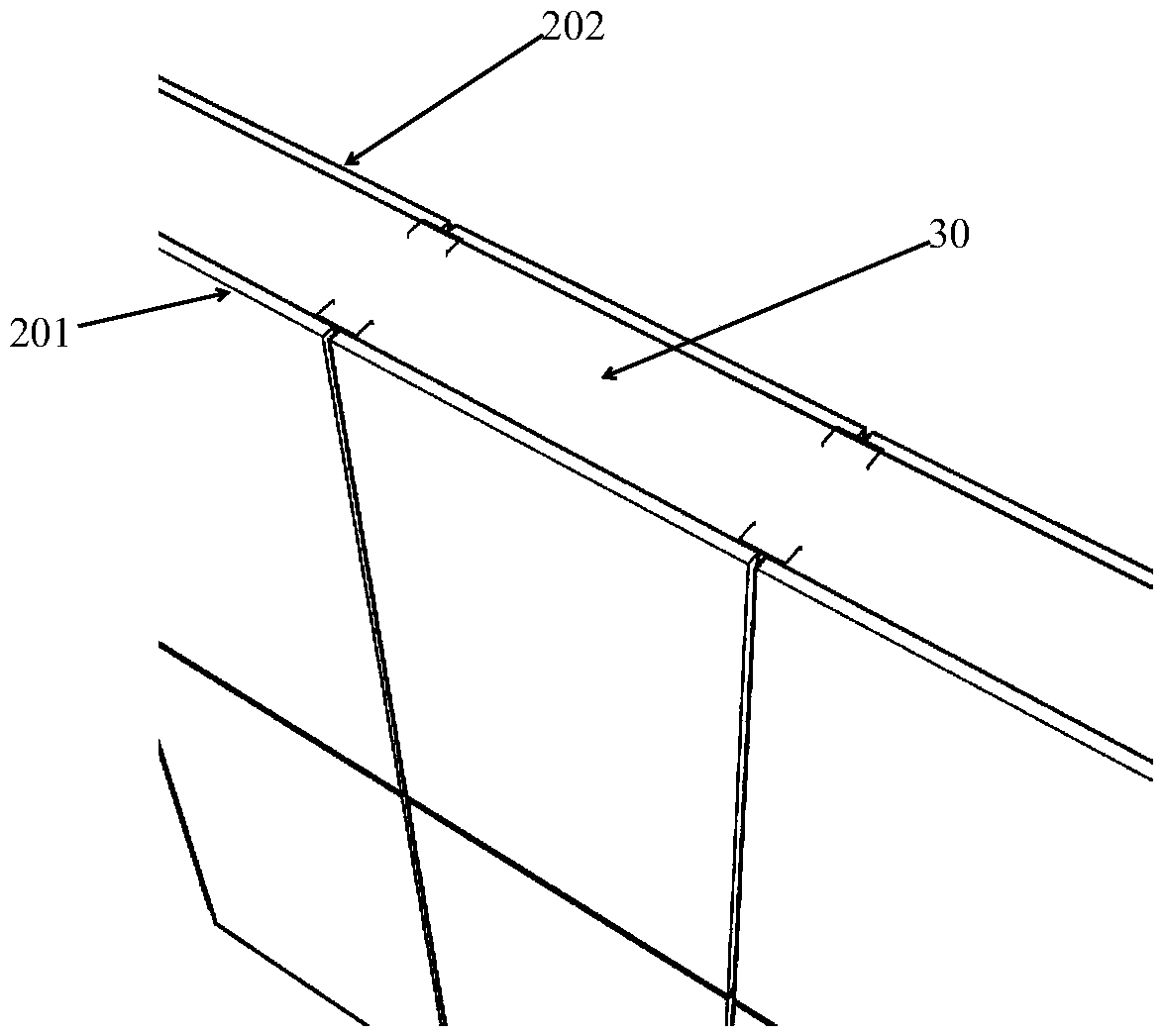

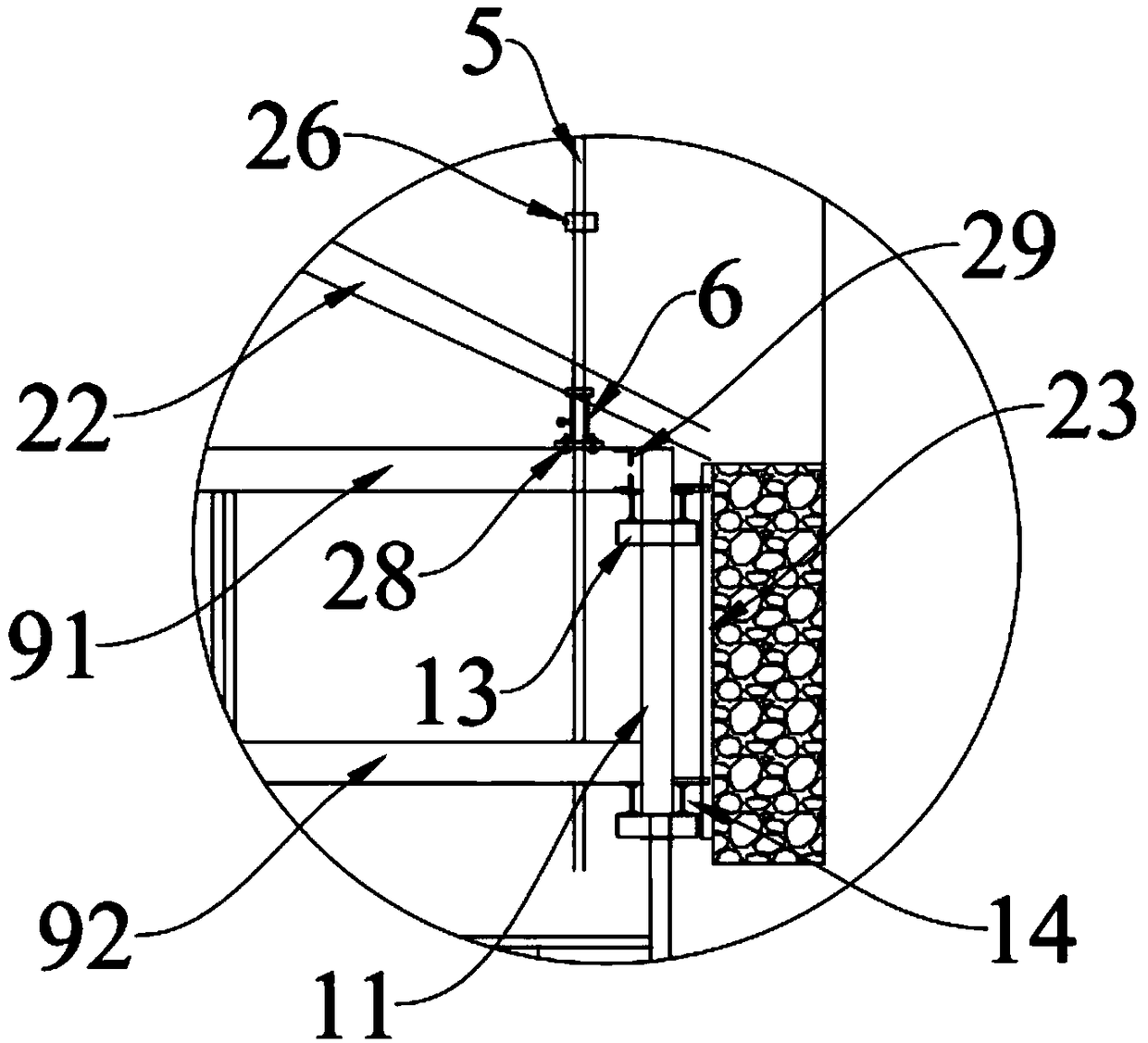

Fabricated compound wall

The invention provides a fabricated compound wall. The fabricated compound wall has a light steel structure as the skeleton, and the inner side and the outer side of the fabricated compound wall are nailed with fabricated slabs and can be poured with light insulating cement-based materials. Therefore, the fabricated compound wall is light in construction and installation as the steel structure andmeanwhile solves the problems of poor fireproof and antiseptic performance and small structural rigidity of steel structures; besides, plant fabrication of the prefabricated slabs can save field manual labors, the prefabricated slabs serving as a mouldless and support-free system can accelerate field pouring of the light insulating cement-based materials, avoid transportation of large fabricatedconcrete components, save engineering costs and meet the economic conditions in rural areas.

Owner:HEZHOU UNIV +1

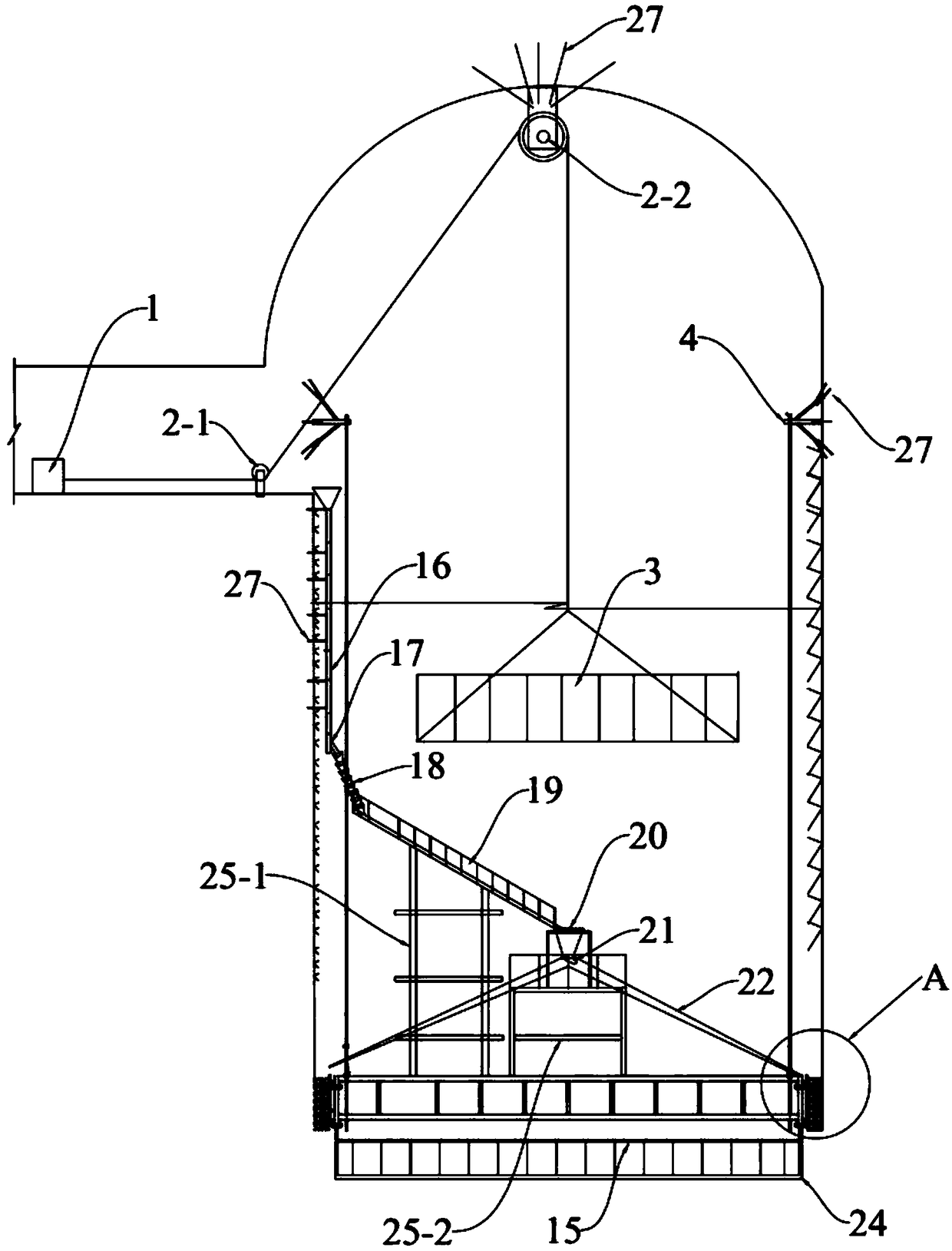

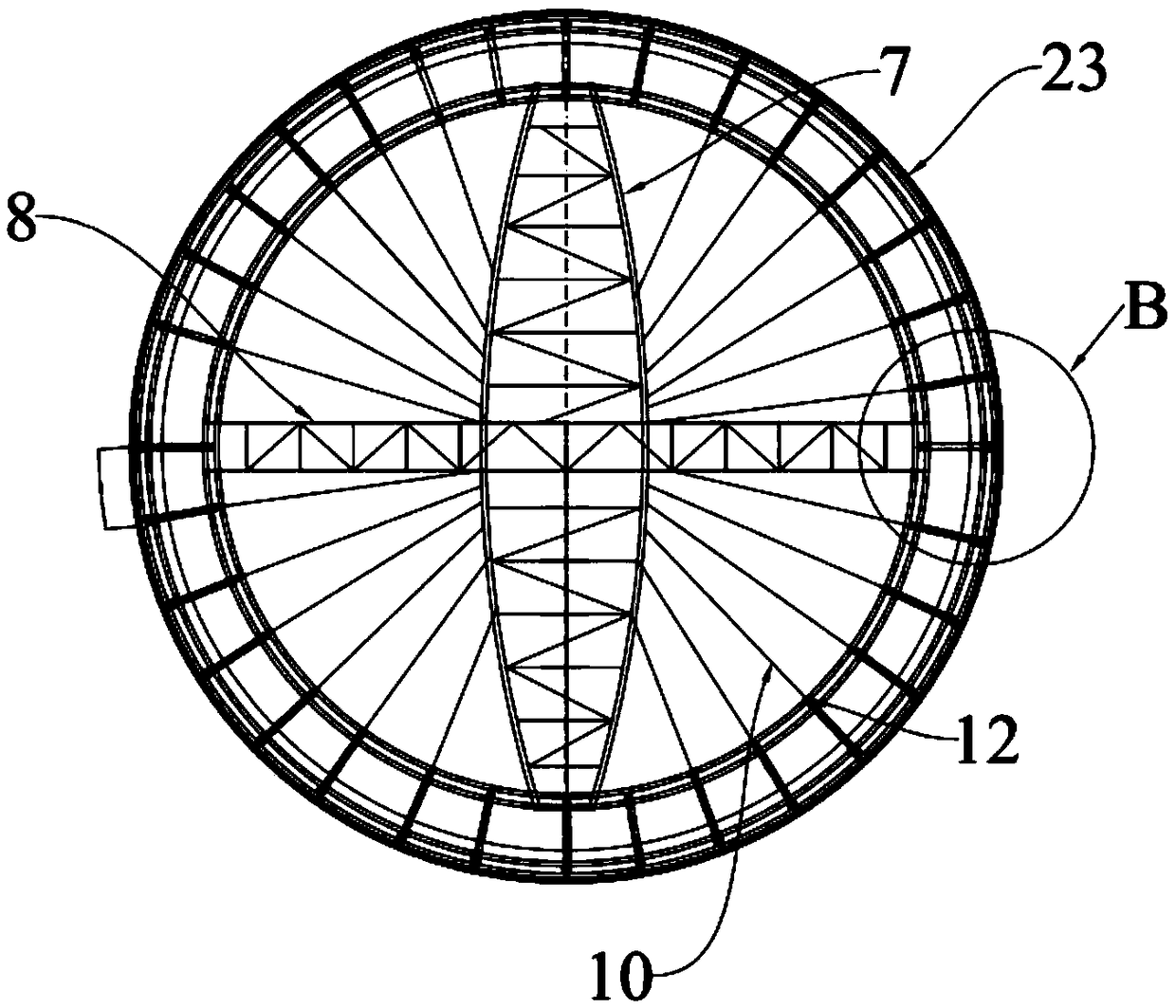

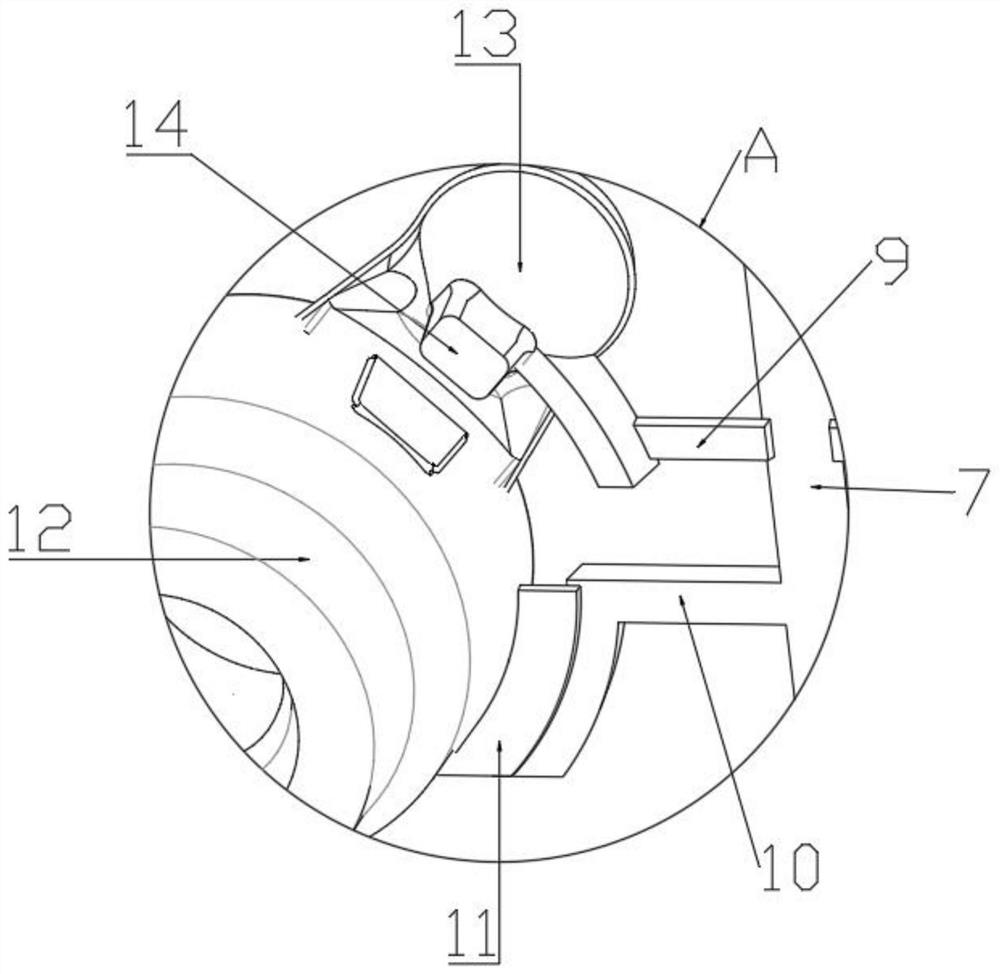

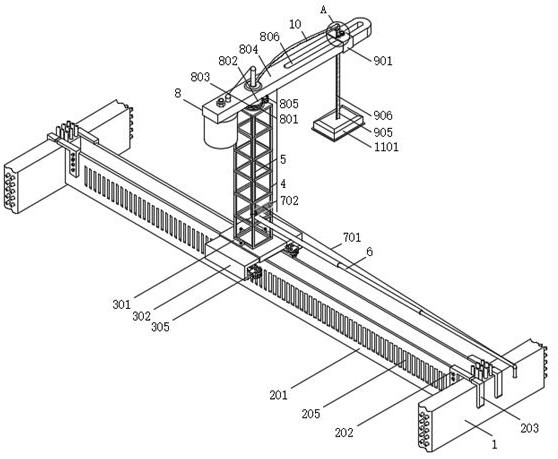

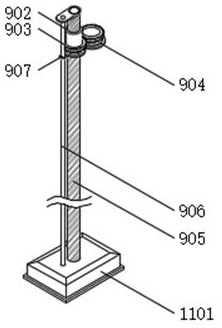

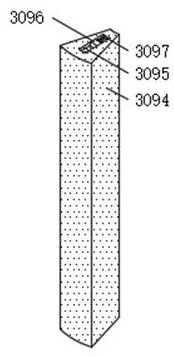

Slip form system for shaft concrete pouring and rock mass grouting

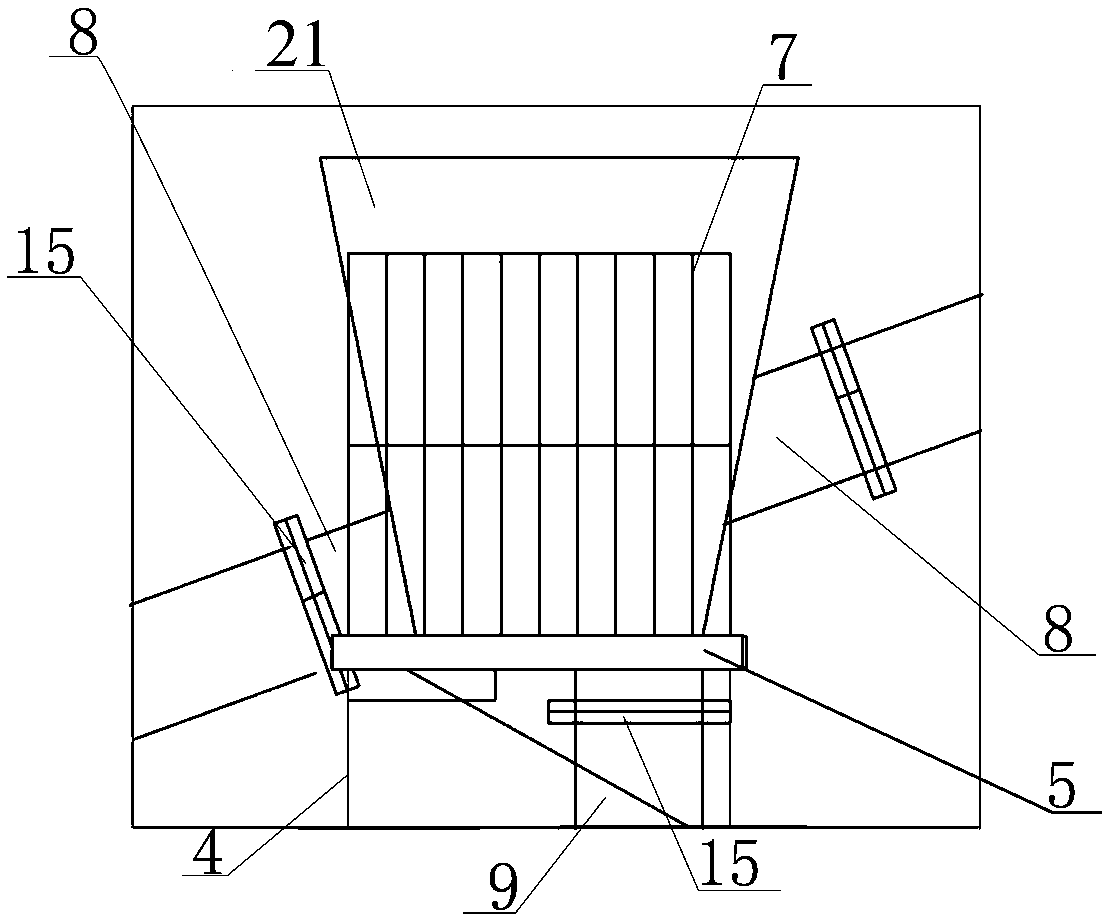

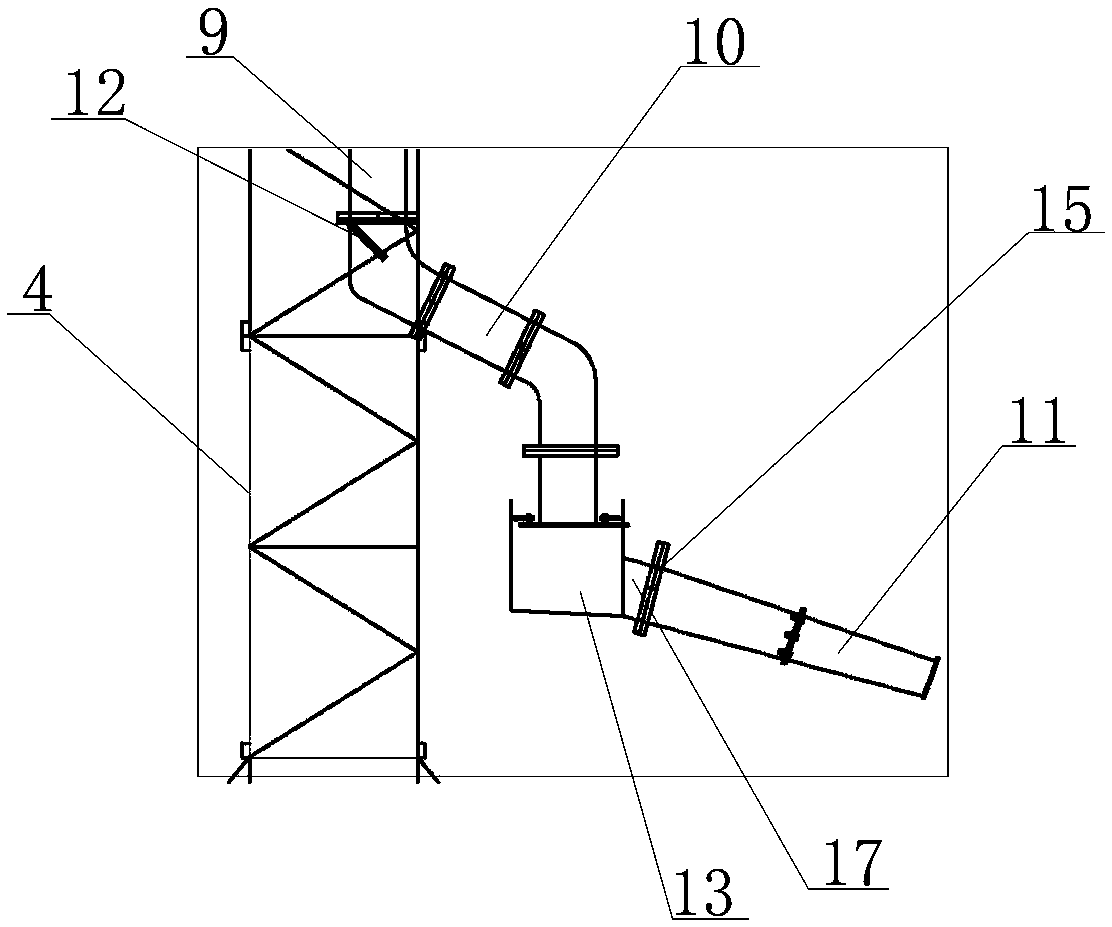

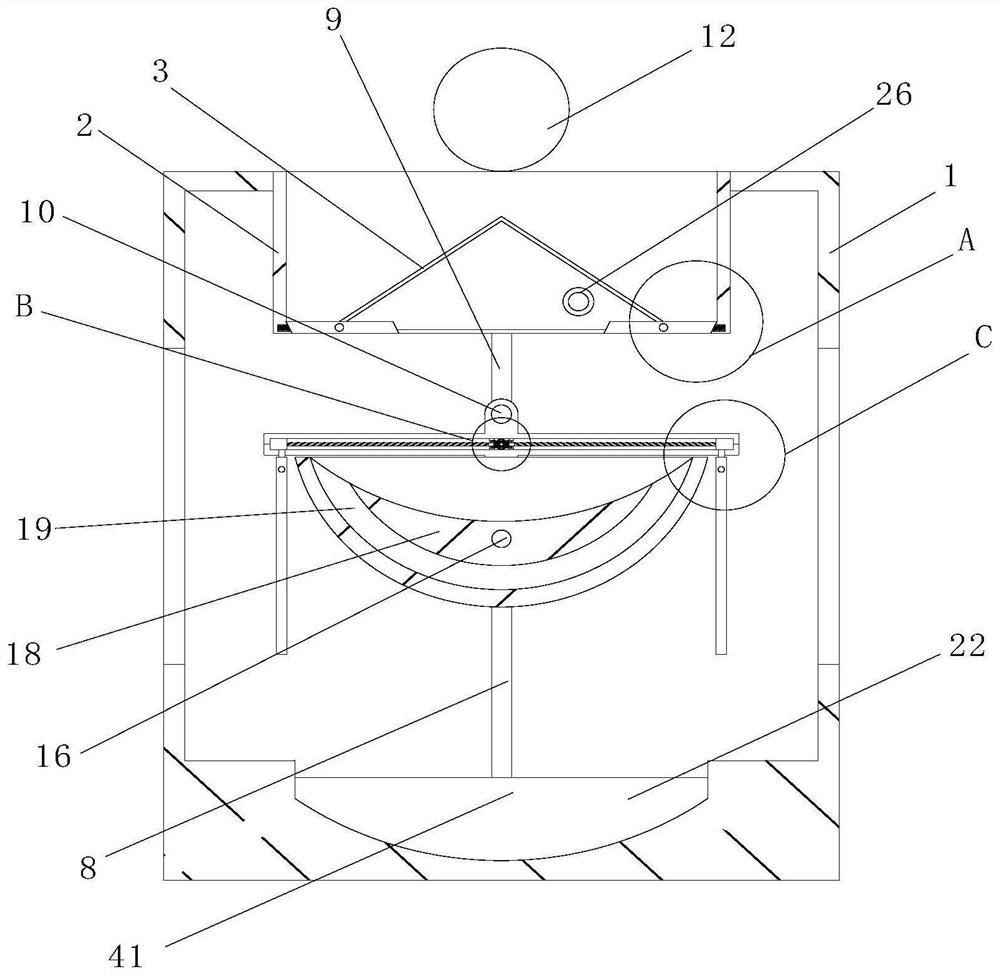

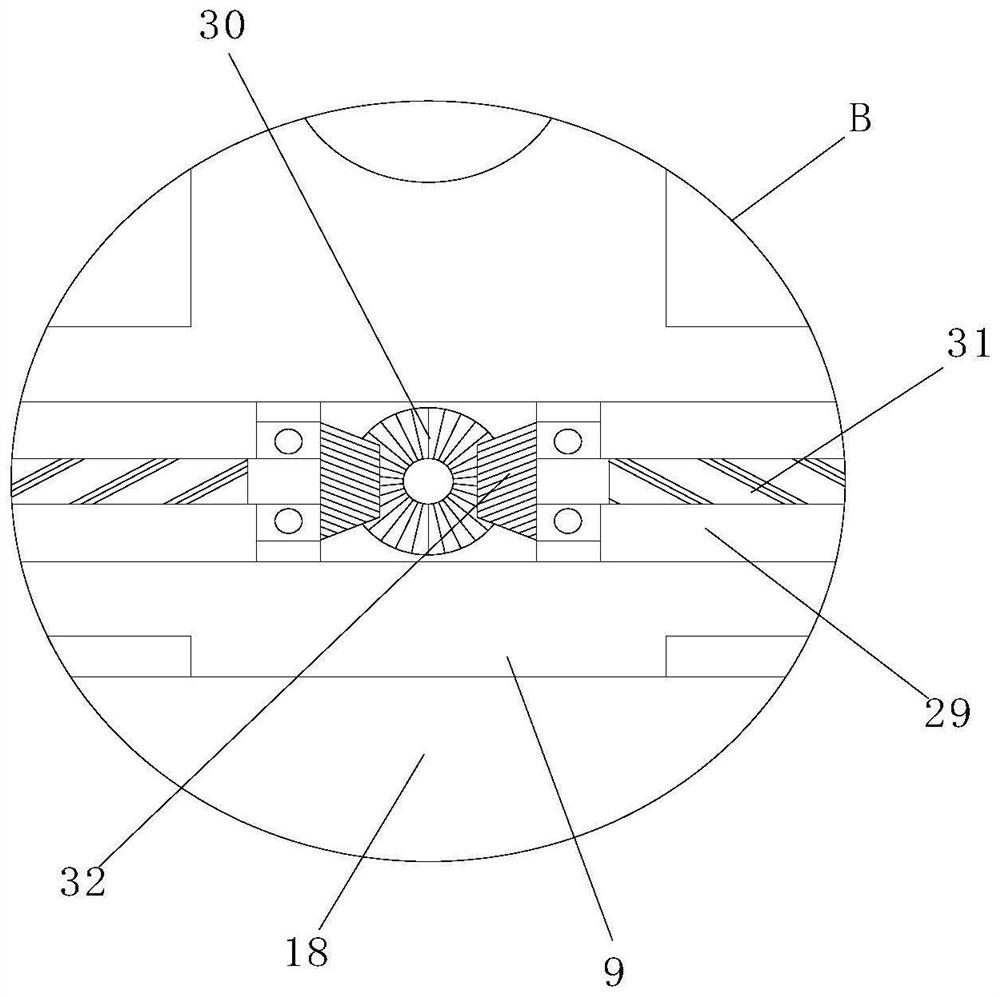

PendingCN108756890AReduce weightAvoid close-range cross-interferenceShaft liningStructural systemRebar

The invention discloses a slip form system for shaft concrete pouring and rock mass grouting. The slip form system comprises a pouring grouting conveying system, a formwork system and a formwork moving system. The slip form system adopts externally-climbing hydraulic slip forms to solve the problem that the speed of construction is affected by the close-distance cross interference between the steel bar installation and the concrete construction in conventional shaft concrete slip form construction. Steel bars of the slip form system can be installed in advance of the working face of concrete construction more than 6.0 m to avoid the close-distance cross interference between concrete and steel bar construction, so that the slipping rising speed is high. The slip form system adopts climbingrod external suspension, form bodies can be lowered and used repeatedly after slipping rising, recycling is achieved, so that the using number of climbing rods can be saved, a basket does not need tobe manufactured and installed during application, the slip form system is composed of synchronously-driven balanced moving formwork systems of hydraulic jacks, and dismountable limiters located on thesame horizontal plane are arranged on the climbing rods to ensure the balanced, stable and safe movement of formworks and control the formworks more accurately.

Owner:SINOHYDRO BUREAU 7 CO LTD

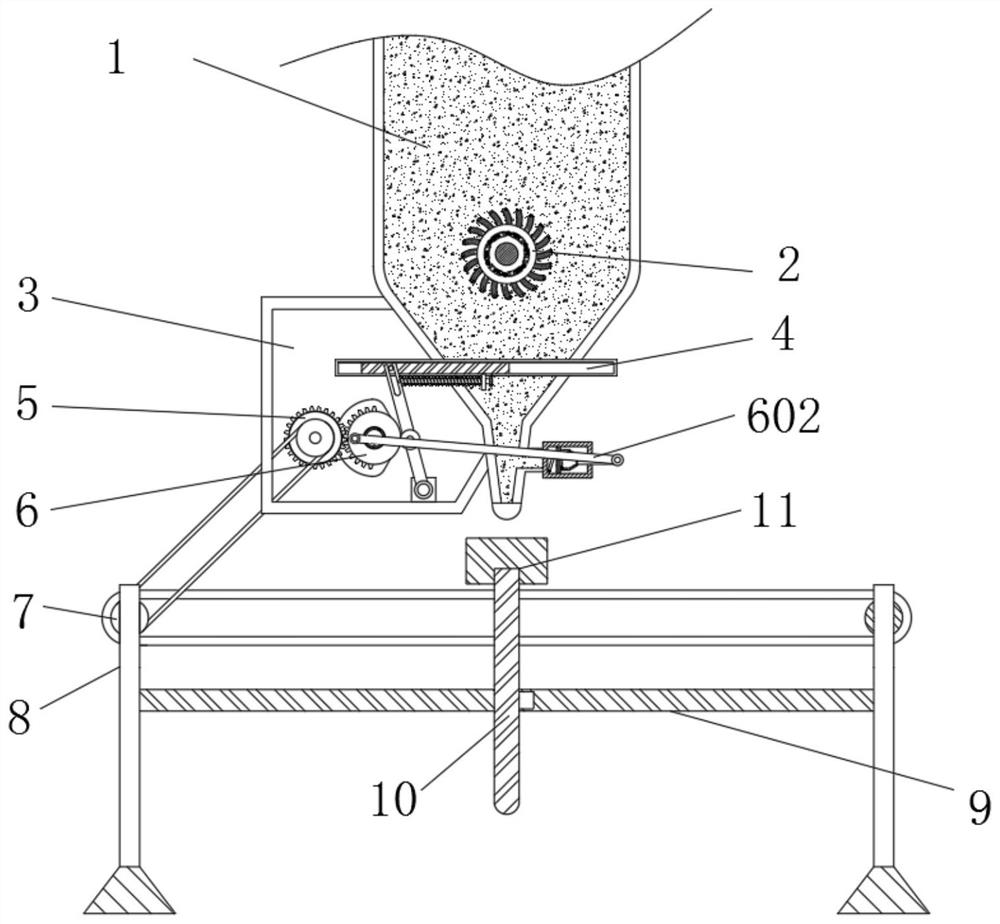

Cement loading device for loosening cement by collecting air through gravity

InactiveCN110817152AFree up storage spaceBig spaceLarge containersStructural engineeringMechanical engineering

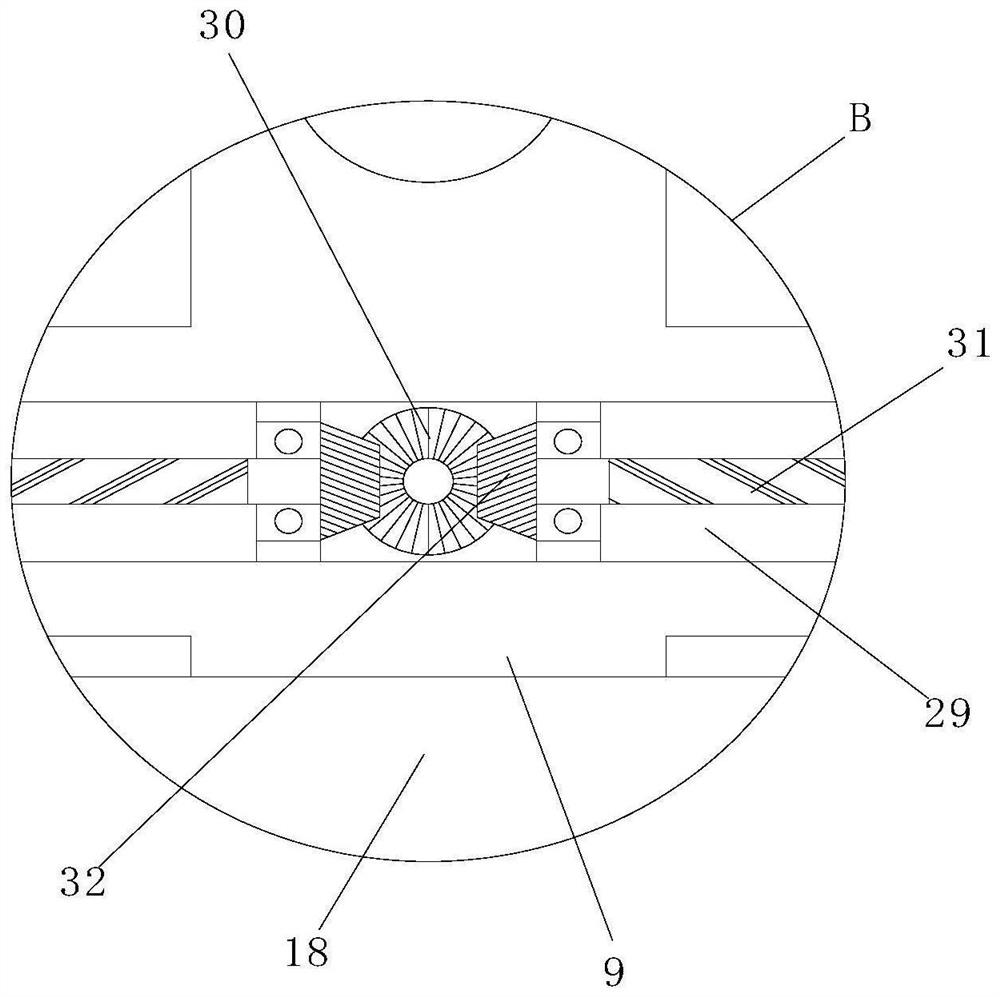

The invention relates to the technical field of cement loading equipment, and discloses a cement loading device for loosening cement by collecting air through gravity. An inner end of a rotating shaftis fixedly connected to the right end of a bearing plate; the left end of the bearing plate is fixedly connected to the outer side walls of sector plates; the inner parts of the sector plates penetrate through the right end of a hose; and the left end of the hose extends to and penetrates through the bottom end of a movable rod to be fixedly connected with an end opening of a through pipe. Scraping nails are attracted by the outer side walls of the sector plates, and the inner parts of the sector plates are adsorbed together, so that the air inside the sector plates is collected by the air inthe squeezed hose; the air returns to the inner part of the through pipe and leads to an air bag inside an inlet bin, an inner sleeved bin is squeezed upwards when the air bag bulges upwards, and a protruding block is squeezed by the inner air to stretch outwards to touch an extending rod, so that the cement compacted inside is loosened; and the cement pouring speed is increased, and the workingefficiency is improved.

Owner:杭州芯意智能科技有限公司

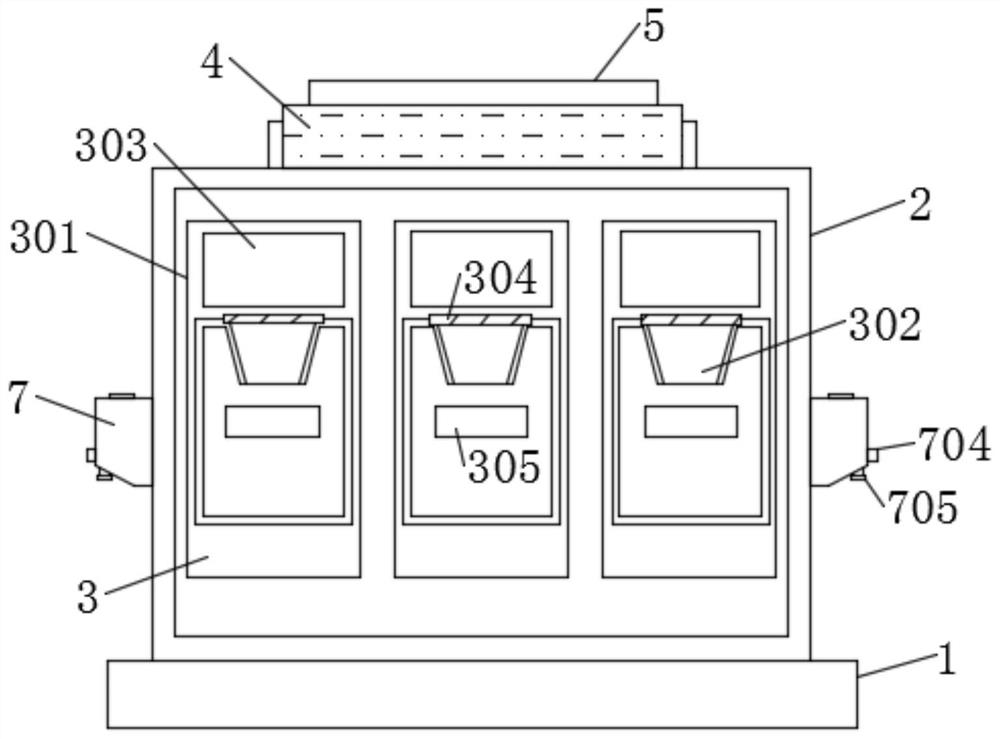

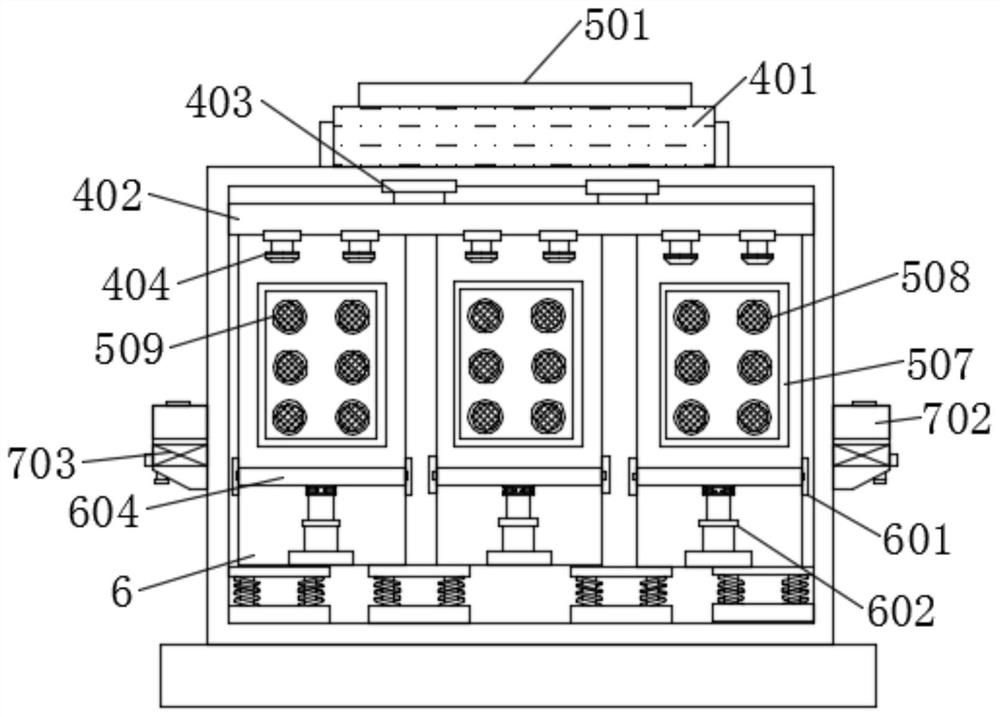

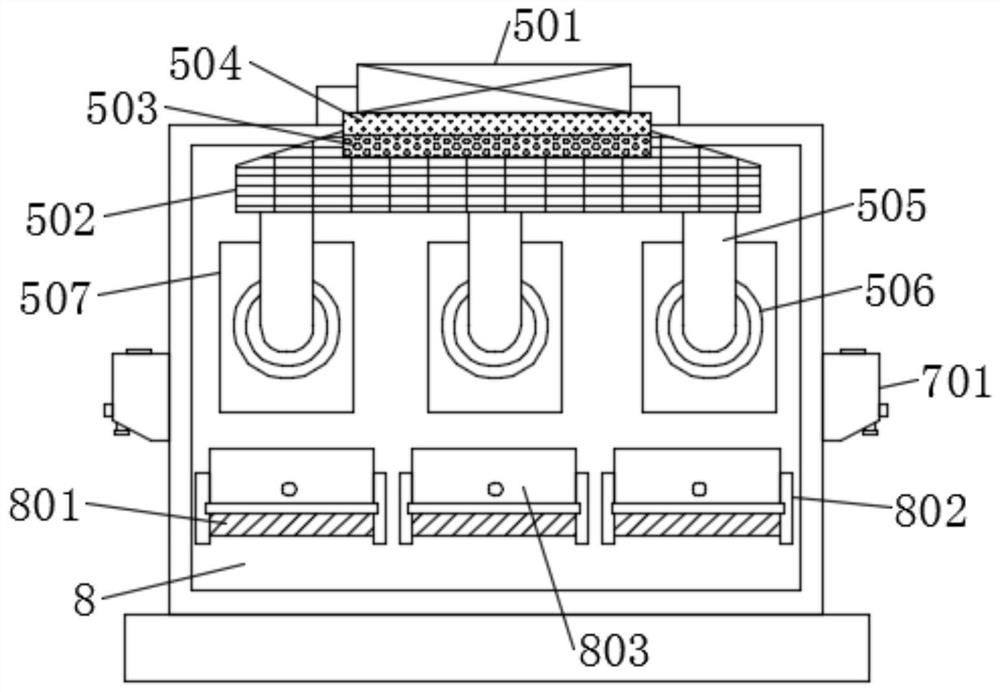

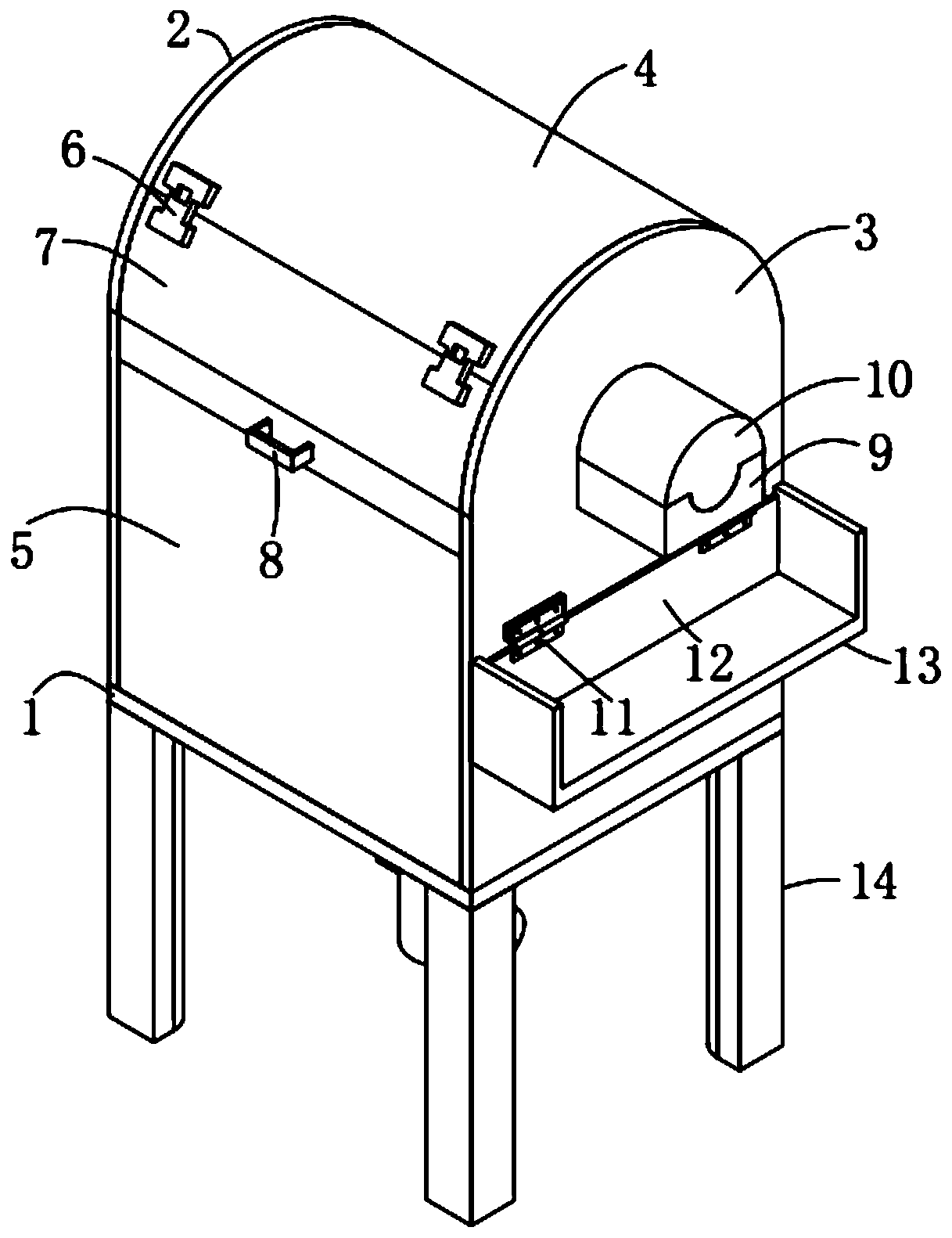

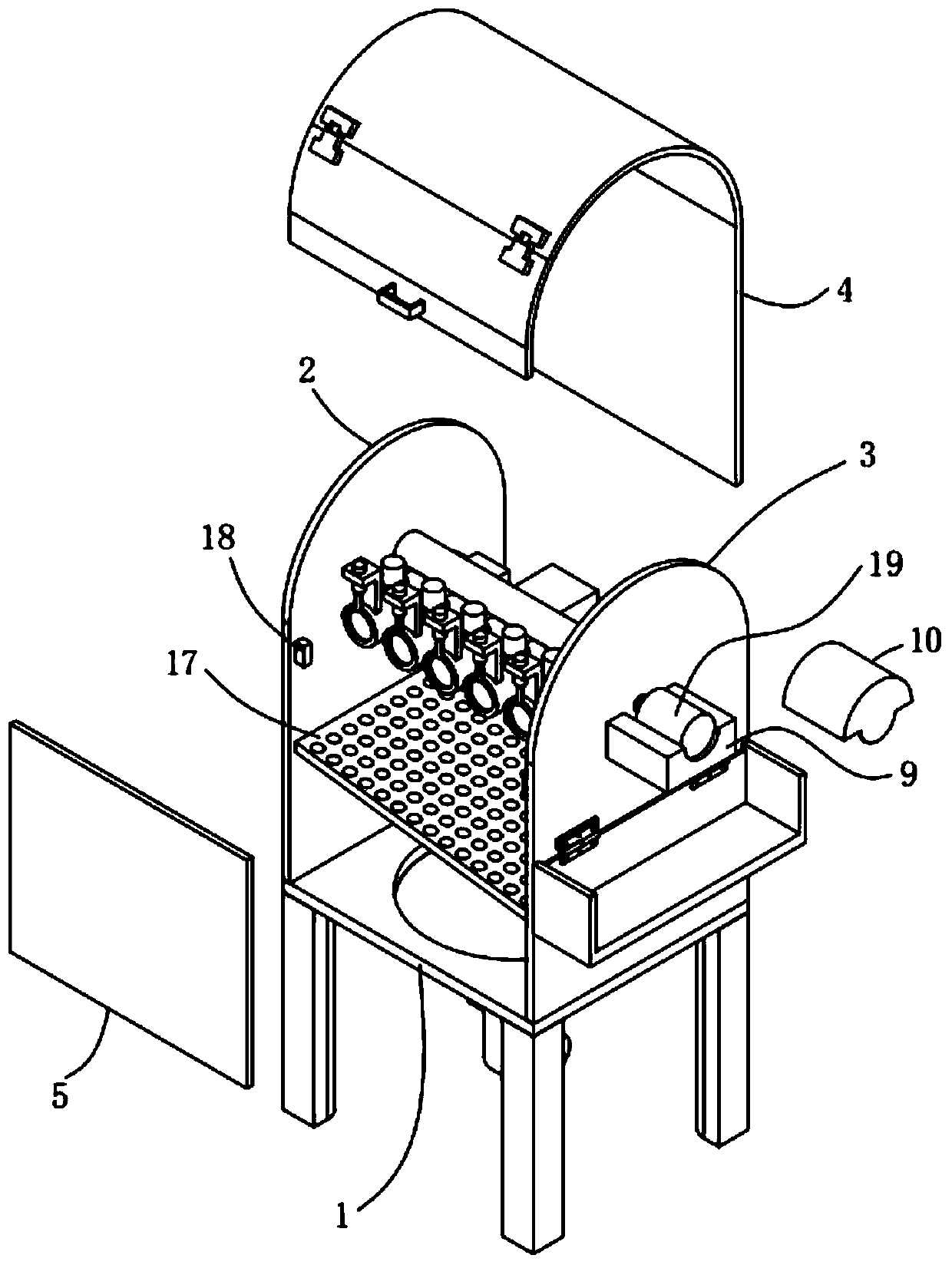

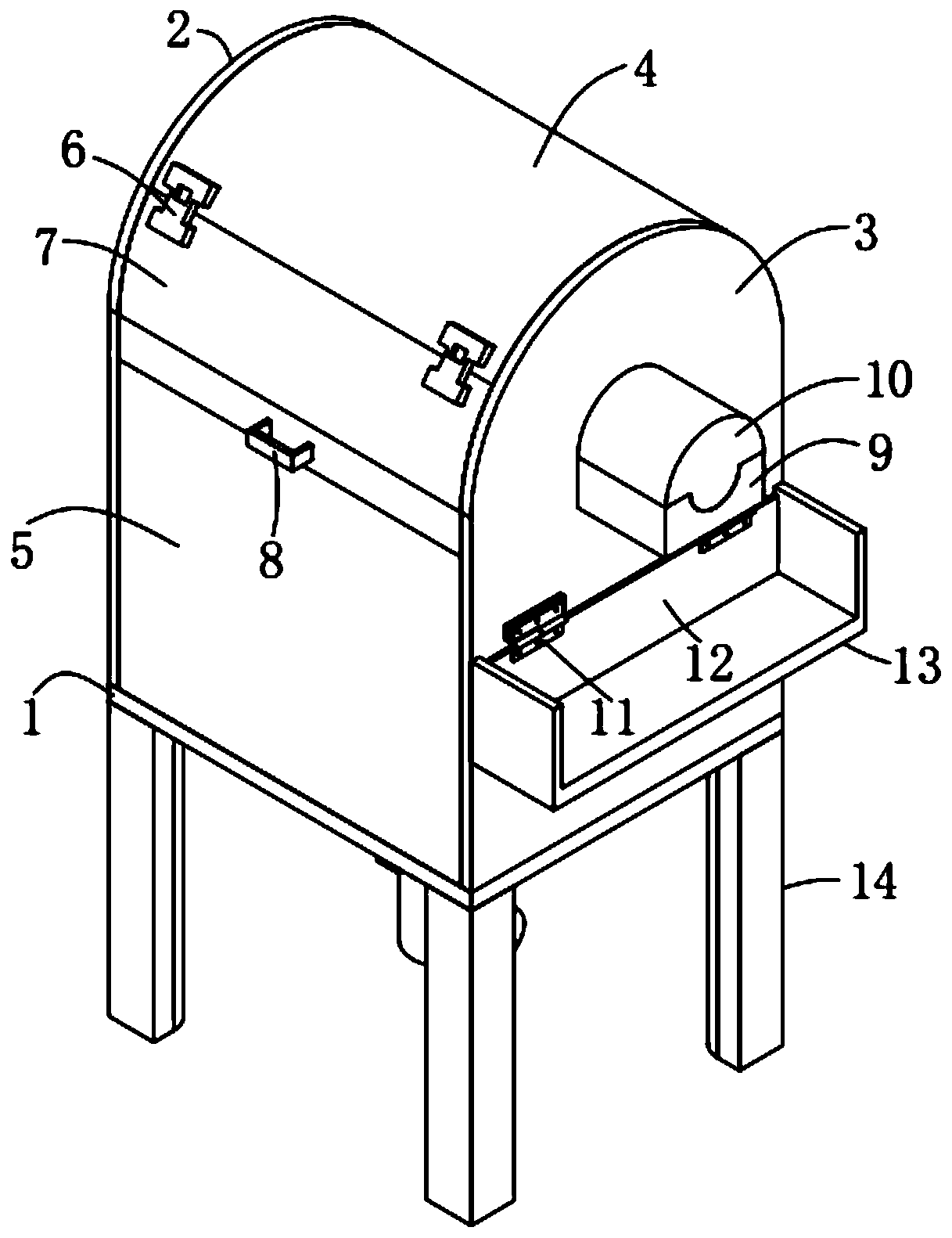

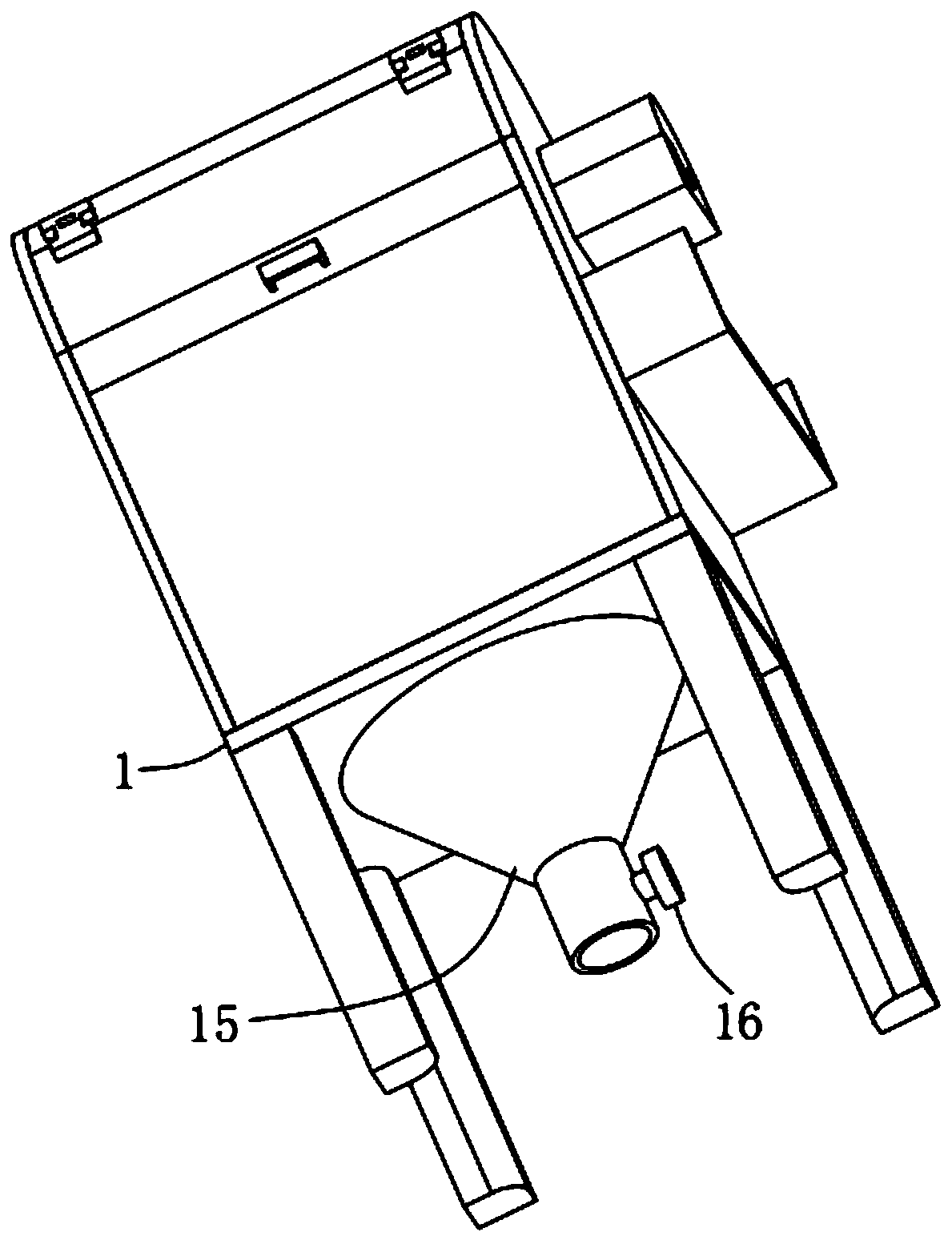

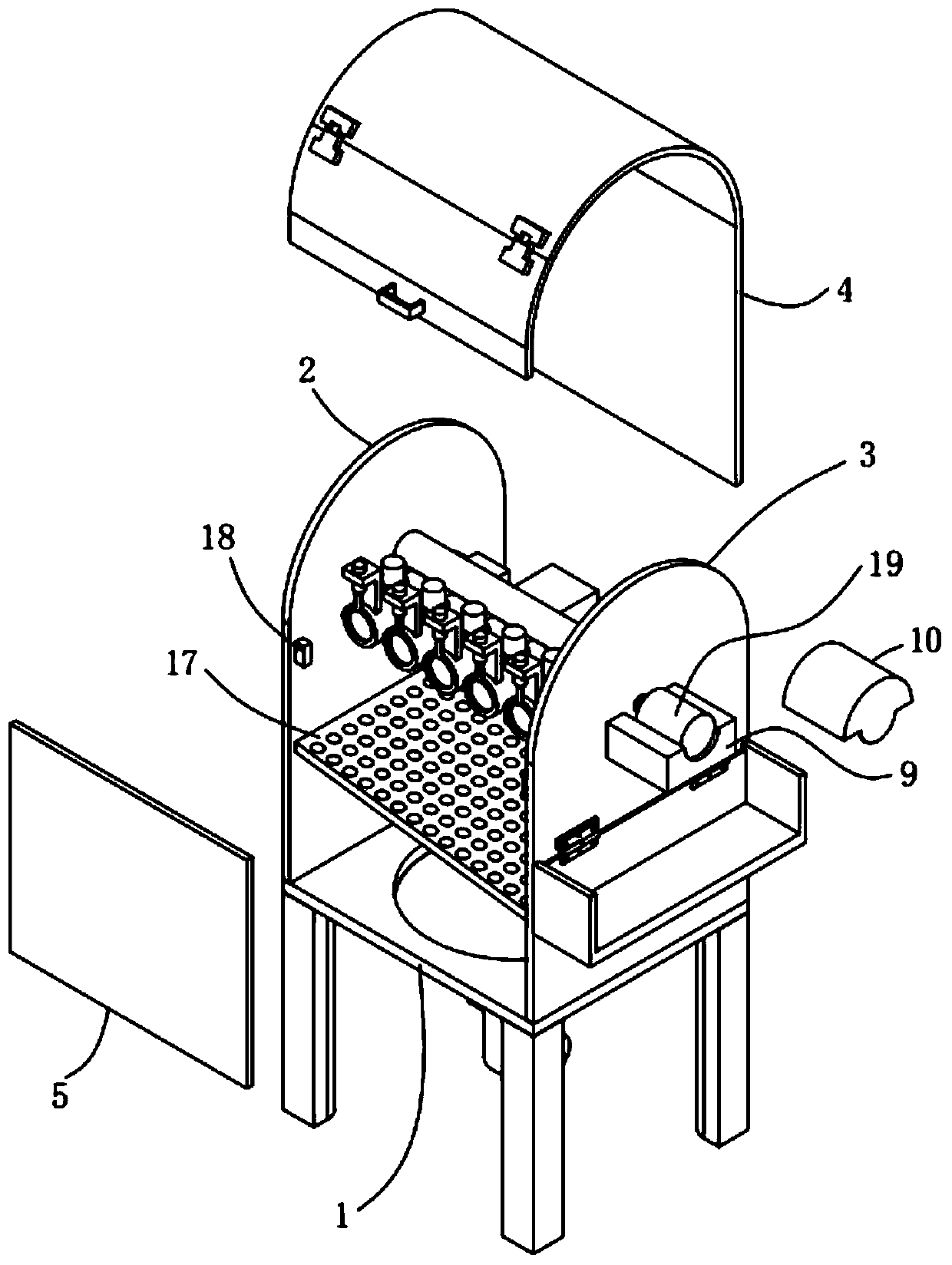

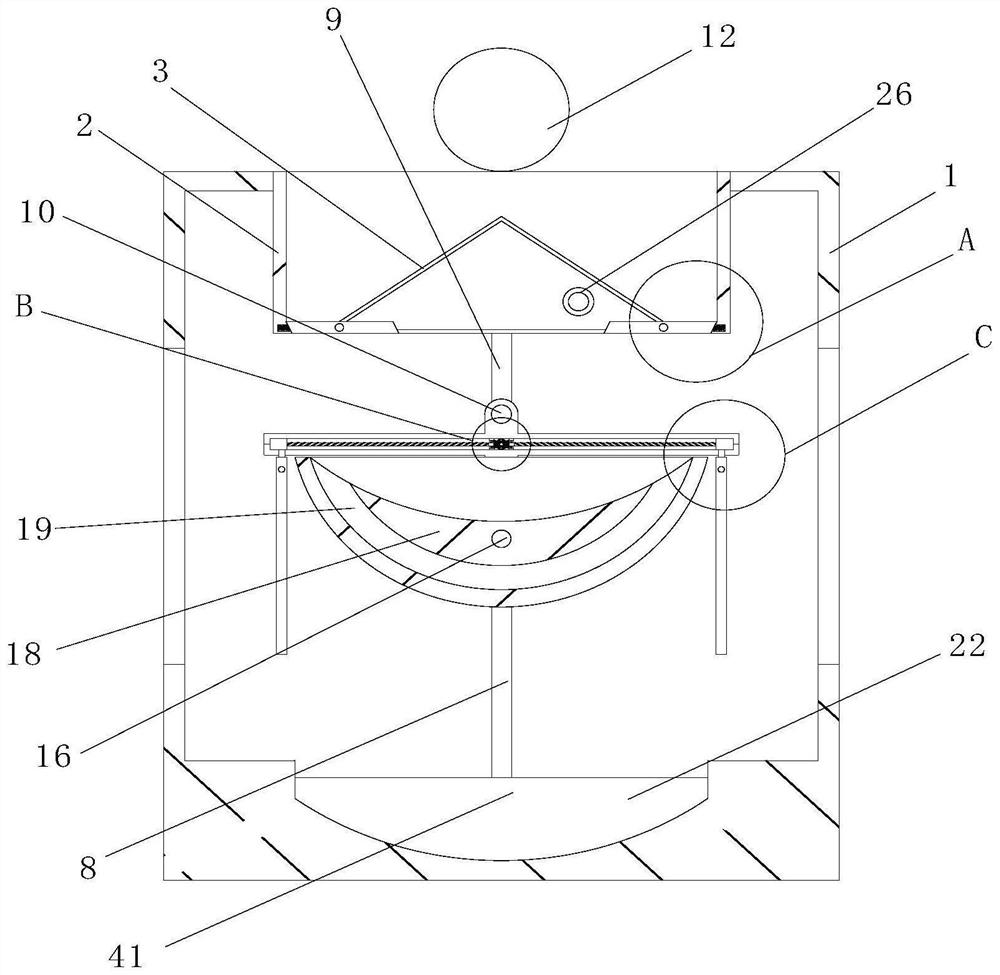

Full-automatic deodorization equipment for garbage classification throwing point deodorization

InactiveCN112678372APrevent odor dischargeSpeed up pouringDispersed particle filtrationRefuse receptaclesProcess engineeringRefuse Disposals

The invention discloses full-automatic deodorization equipment for garbage classification throwing point deodorization. The equipment comprises a base, a shell is arranged above the base, three garbage treatment cabins are arranged in the shell at equal intervals, an atomization disinfection device communicated with the three garbage treatment cabins is arranged above the shell, a deodorization device communicated with the three garbage treatment cabins is installed on the back of the shell, three discharging devices communicated with the garbage treatment cabins are further installed below the back of the shell, and a material guide device used in cooperation with the corresponding discharging device is further installed in each garbage treatment cabin. The outer portions of the left side and the right side of the shell are each provided with a hand disinfection device. According to the equipment, sterilization and deodorization treatment can be conducted on the interiors of the garbage treatment cabins, peculiar smell discharging and bacterium breeding of garbage are prevented, the surrounding environment is effectively protected, meanwhile, the internal material guide devices are matched with the discharging devices, the garbage pouring-out speed can be further increased, the garbage treatment efficiency is improved, and the labor burden is reduced.

Owner:SHANGHAI LAITAI BIOTECH

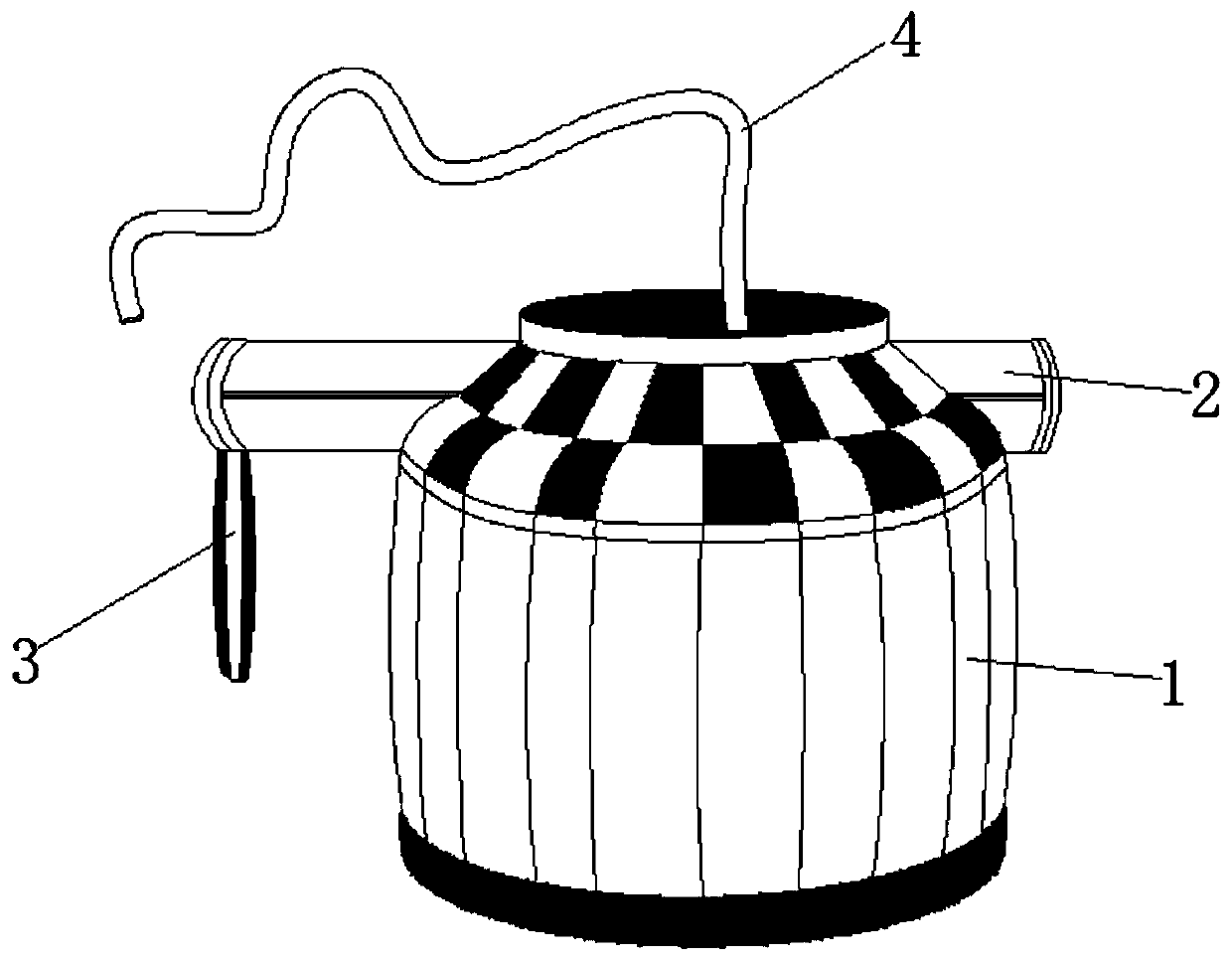

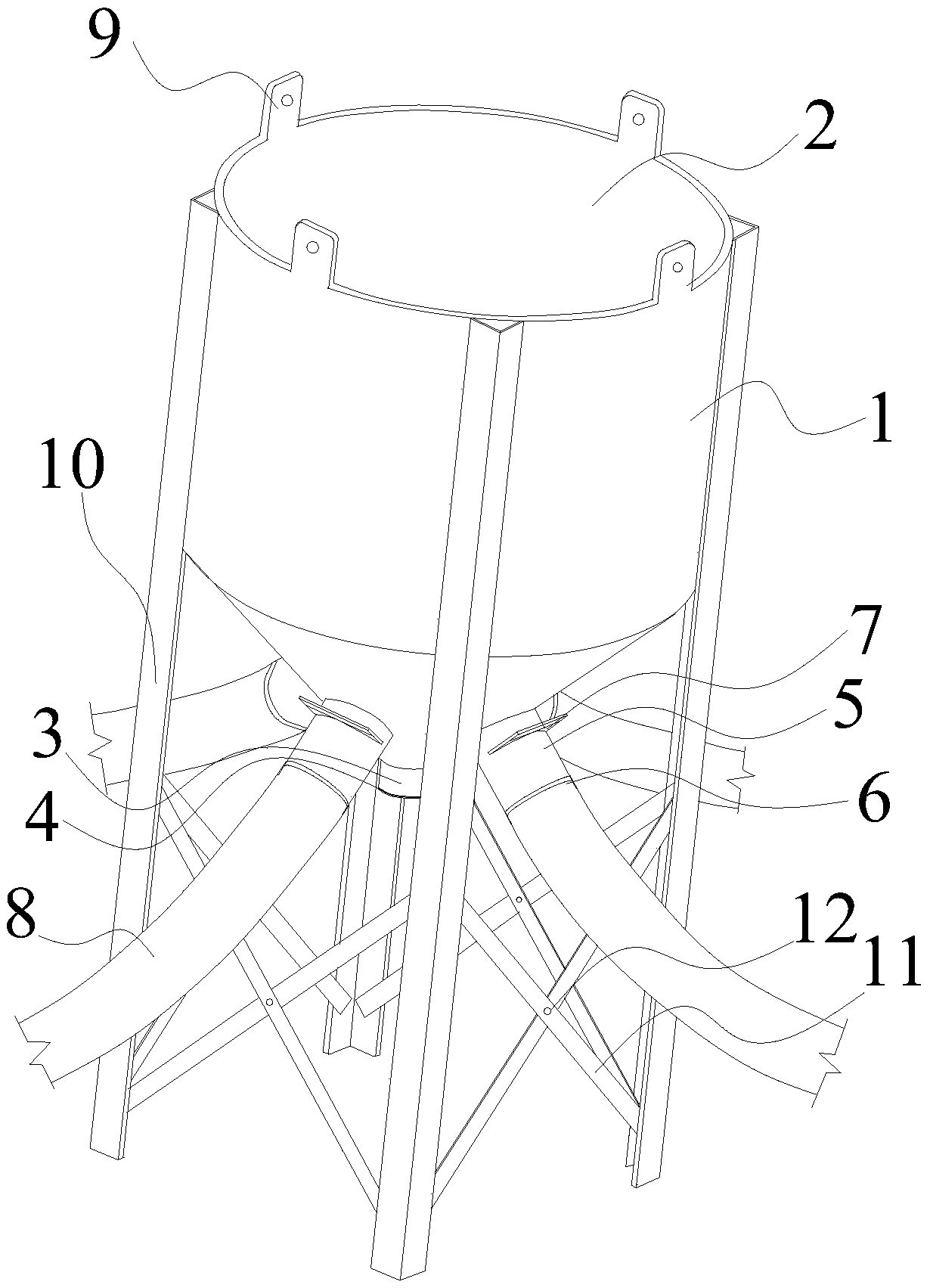

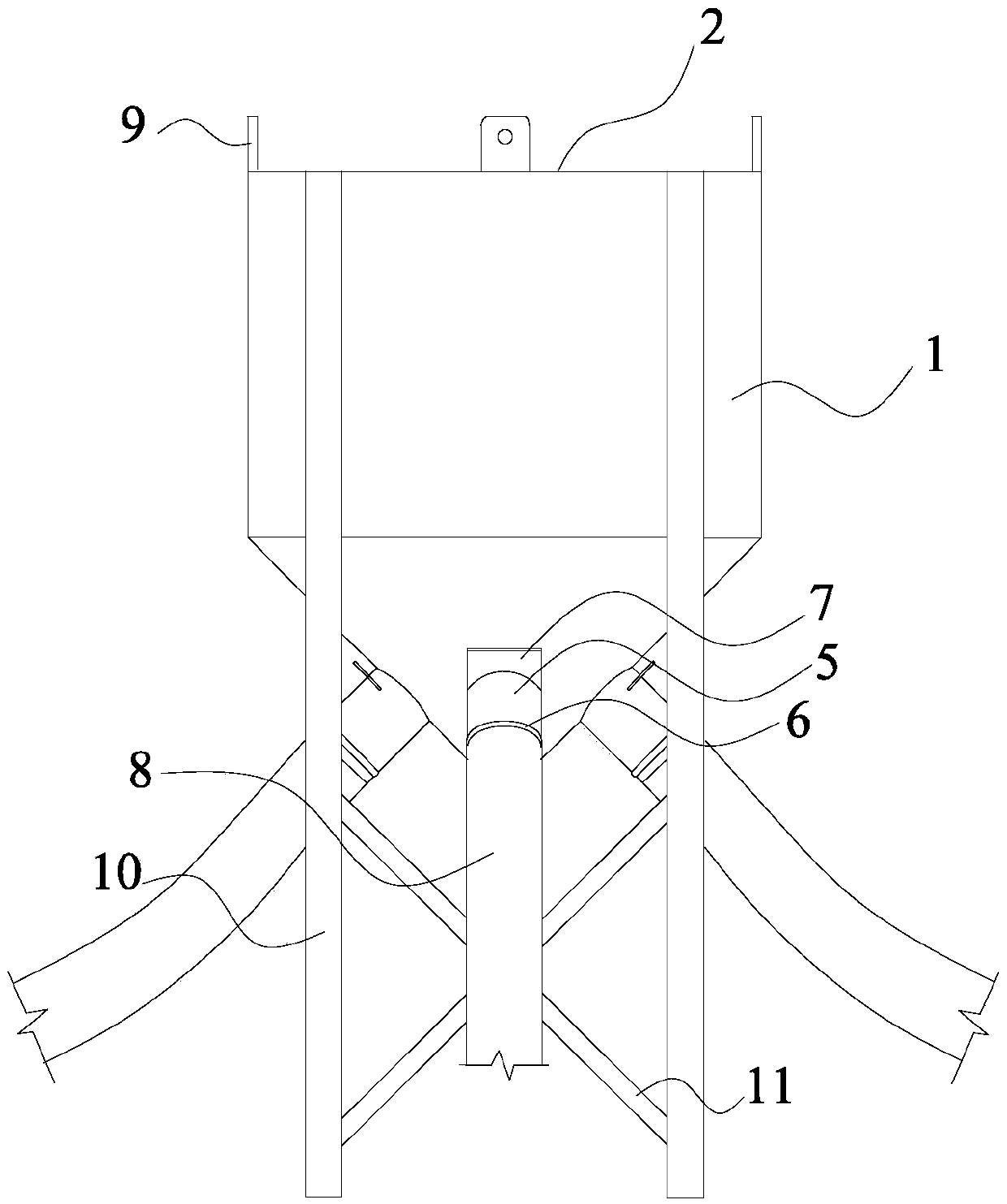

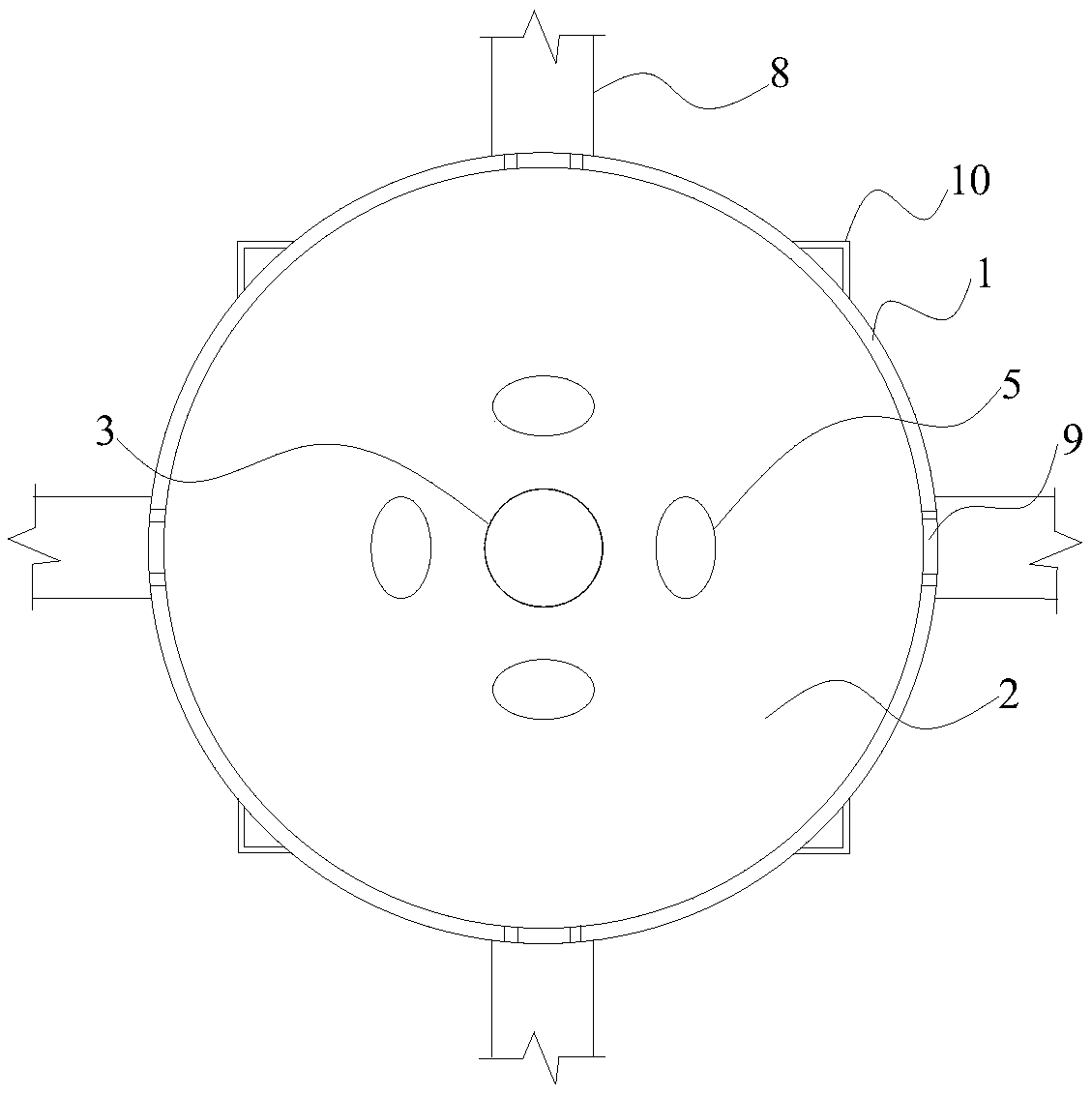

Multifunctional fast concrete pouring device

InactiveCN105507593ASpeed up pouringAccelerate gravityBuilding material handlingEngineeringBuilding construction

The invention belongs to the field of concrete application, and particularly relates to a multifunctional fast concrete pouring device. The multifunctional fast concrete pouring device comprises a discharge hopper with the upper portion of a cylindrical structure and the lower portion being of a conical structure, an open concrete feed inlet is arranged at the top end of the discharge hopper, the lower cone of the discharge hopper extends to form discharge outlets communicated with the discharge hopper, the upper portion of each discharge outlet is provided with a drawable baffle switch, the outer wall of the lower portion of each discharge outlet is provided with a bayonet, and each discharge outlet is connected with a hose used for leading concrete into a template through the corresponding bayonet. The multifunctional fast concrete pouring device is simple in structure and convenient to produce and transport, the requirement for fast concreting construction in a frame structure is met, and fast concrete construction is realized.

Owner:GUANGZHOU FOURTH CONSTR

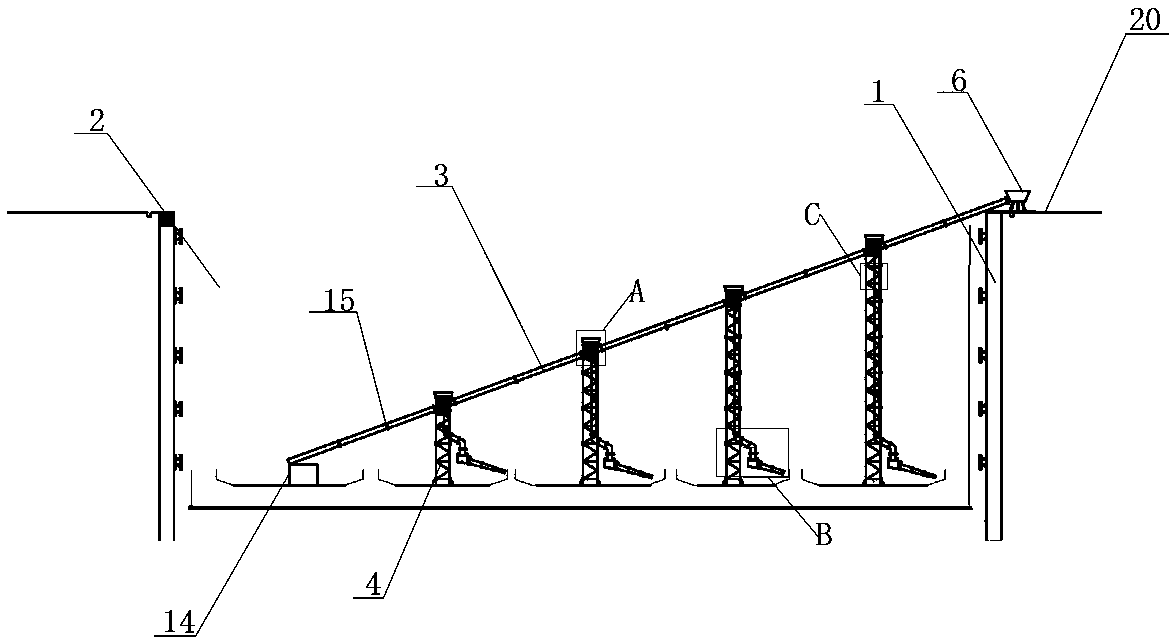

Large-volume concrete conveying device with rotatable deep foundation pit, and application method thereof

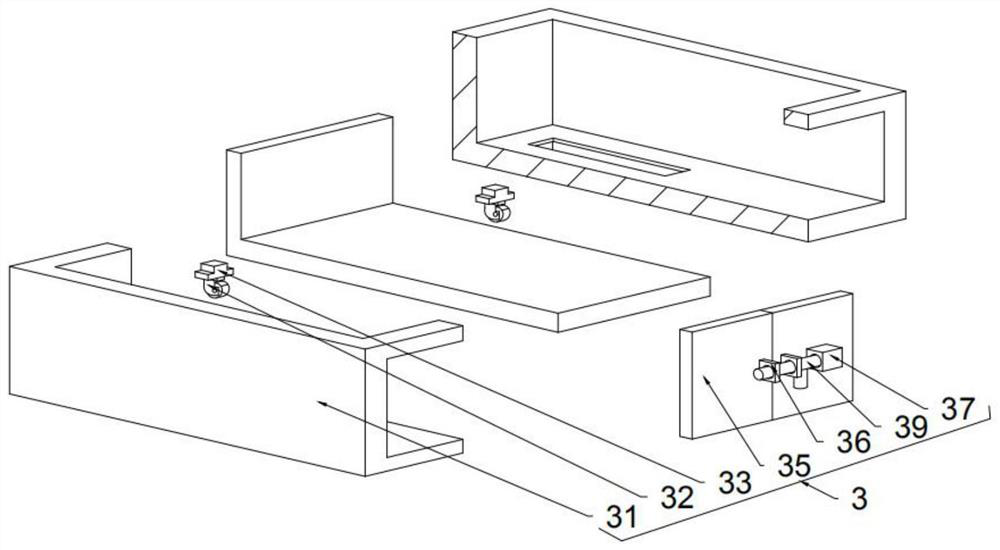

PendingCN108301416AReduce impactEasy to install and disassembleFoundation engineeringSupporting systemArchitectural engineering

The invention relates to a large-volume concrete conveying device with a rotatable deep foundation pit, and an application method thereof. The large-volume concrete conveying device with the rotatabledeep foundation pit comprises a feeding hopper, a conveying system, a supporting system and a casting system, wherein the feeding hopper is arranged on the ground outside of a side wall of the foundation pit and is in soft communication with the conveying system through a hose pipe; the conveying system is arranged inclinedly from the top surface of the side wall of the foundation pit to the bottom surface of the foundation pit, and comprises a plurality of conveying pipelines arranged at intervals and divided hoppers arranged between the adjacent conveying pipelines; the divided hoppers arearranged on the supporting system and are in soft communication with the conveying pipelines through hose pipes; the supporting system comprises a plurality of support frames horizontally arranged onthe bottom part of the conveying pipelines at intervals; and the casting system comprises a vertical pipeline, an outward bending pipeline and a grouting pipe sequentially arranged from top to bottom.The large-volume concrete conveying device with the rotatable deep foundation pit provided by the invention has the characteristics of safety and applicability, has better promotional and practical values, and can produce a favorable economic benefit after being widely popularized and applied.

Owner:BEIJING URBAN CONSTR GROUP

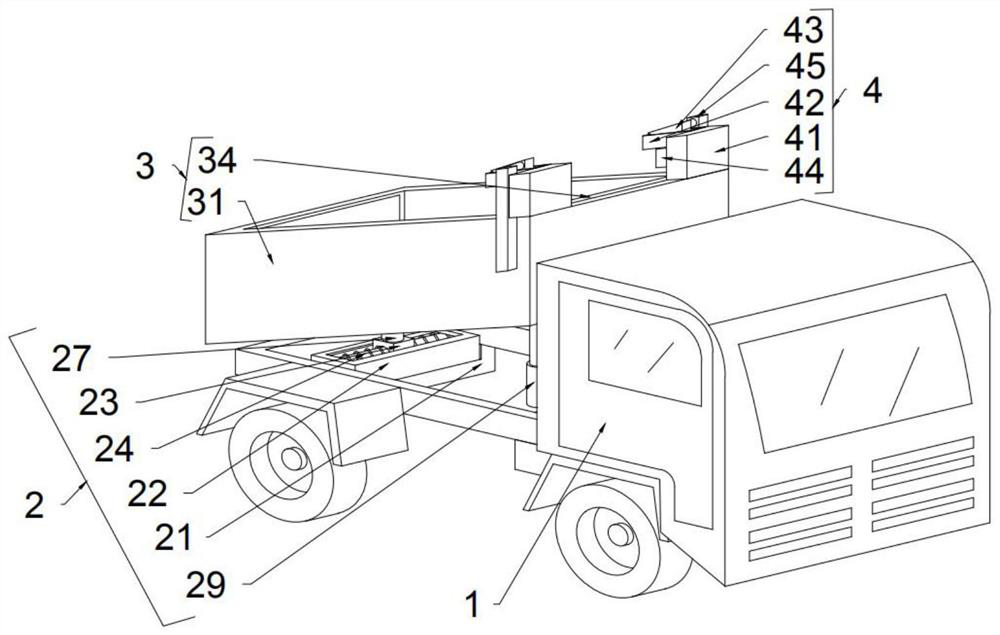

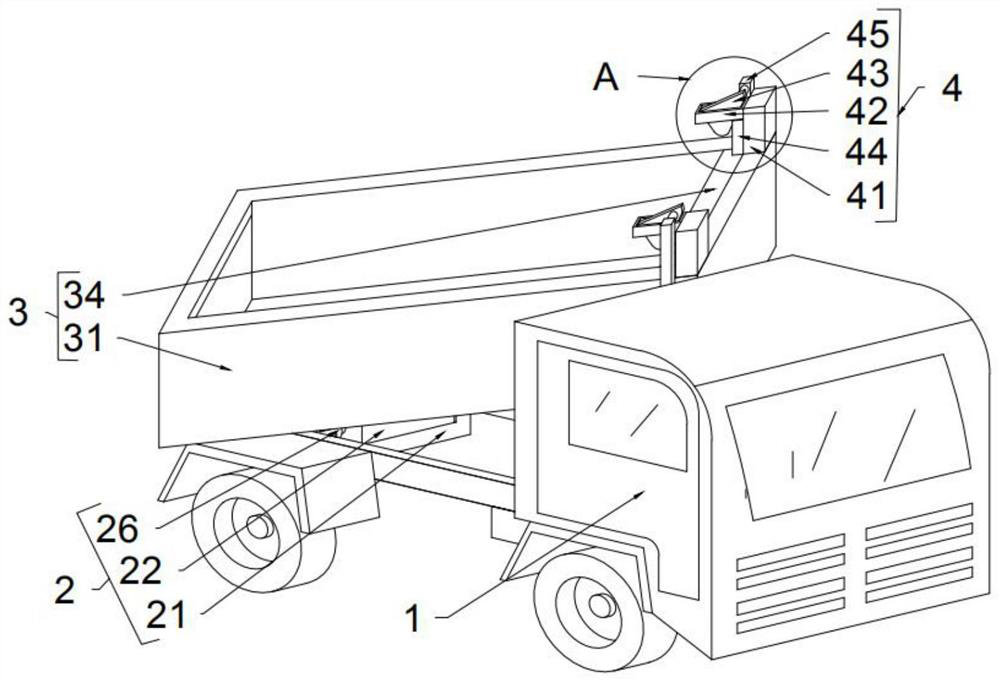

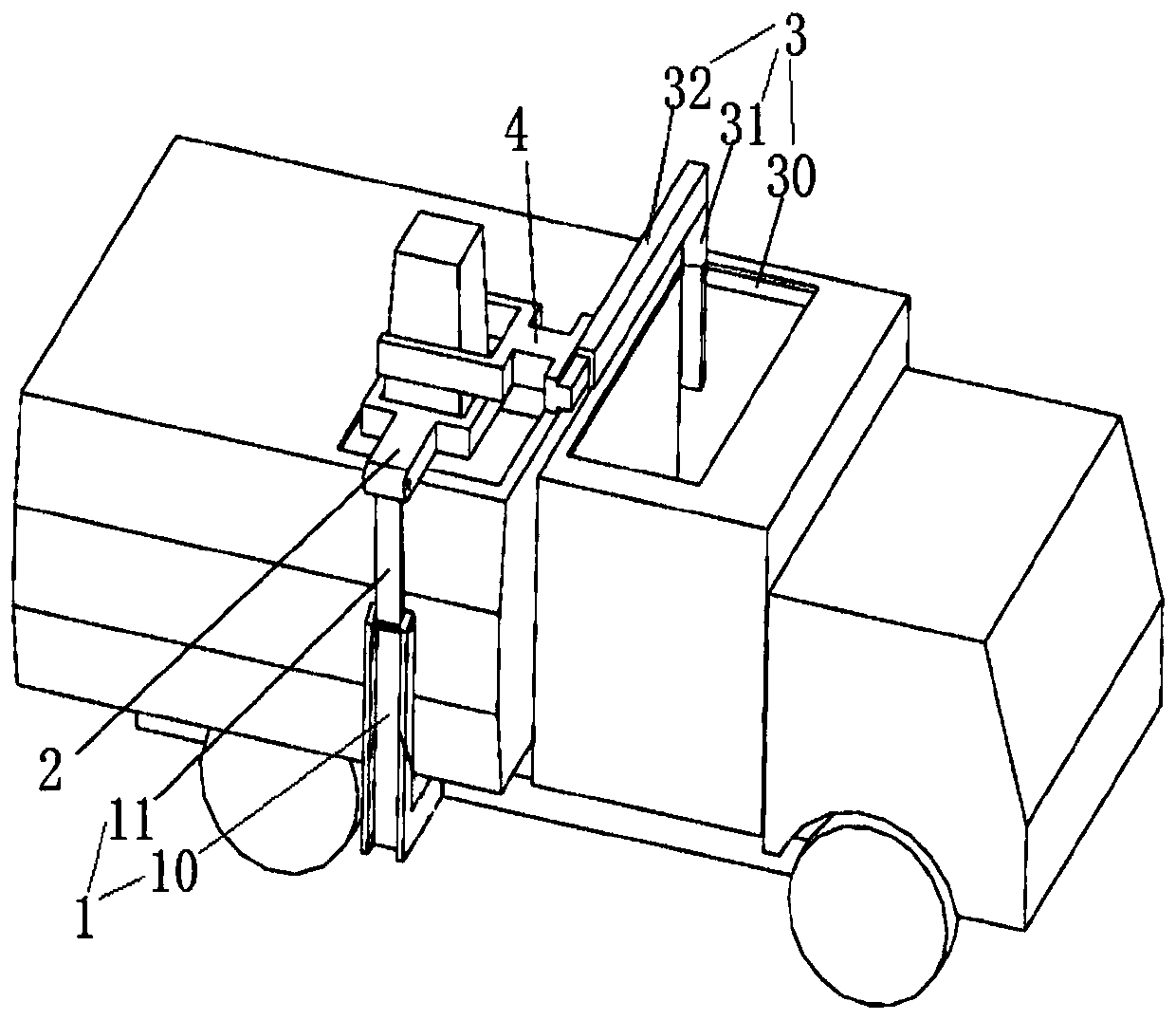

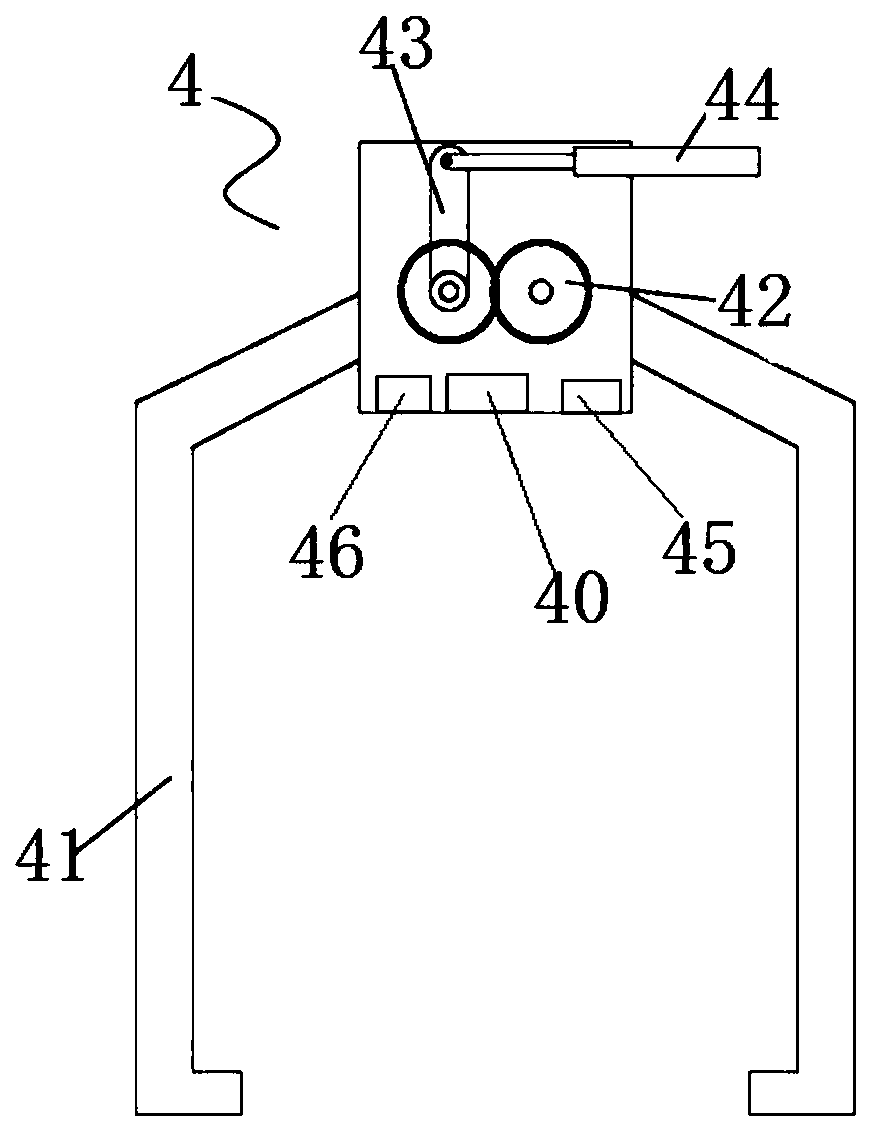

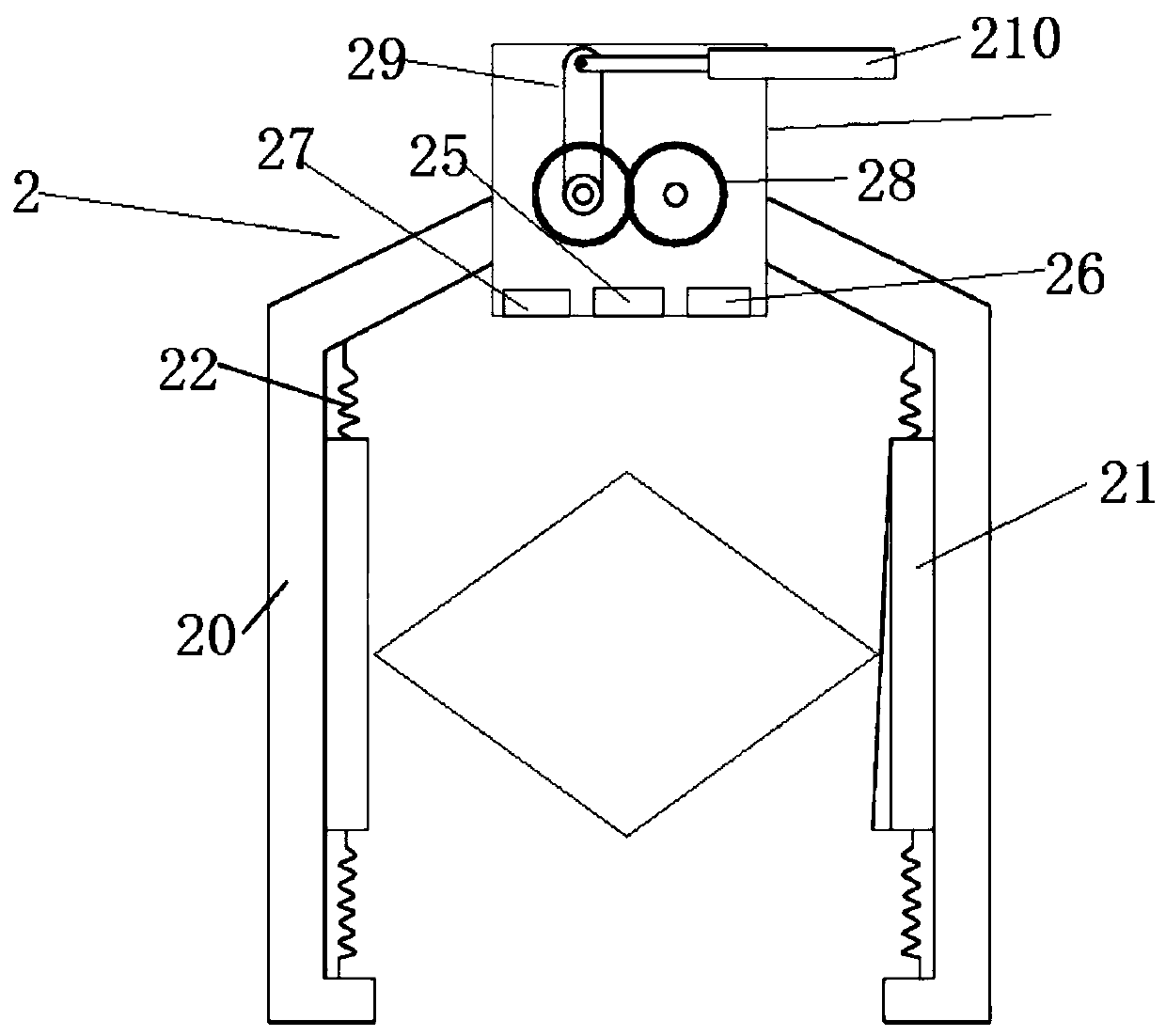

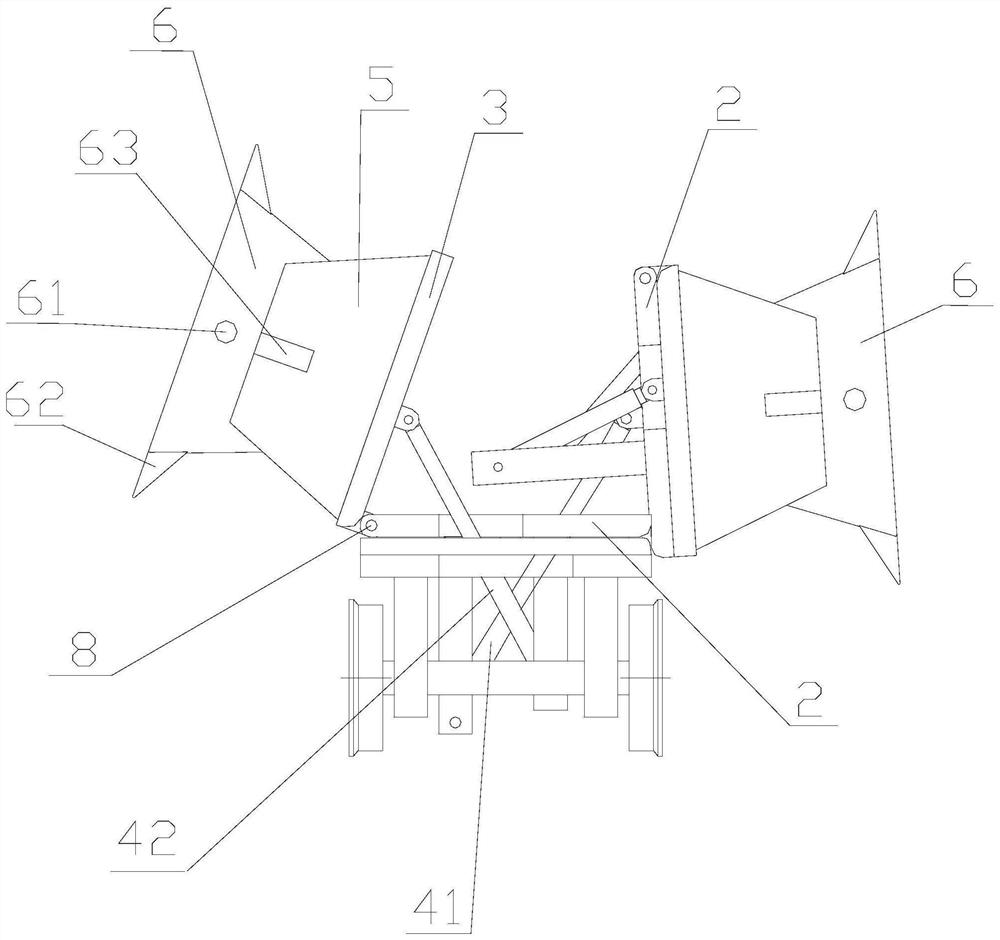

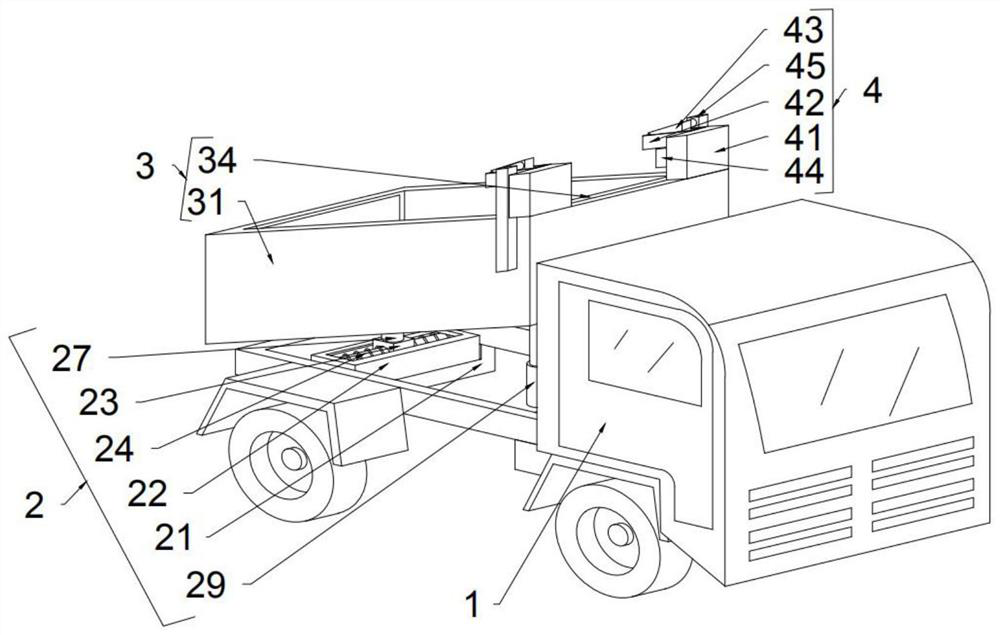

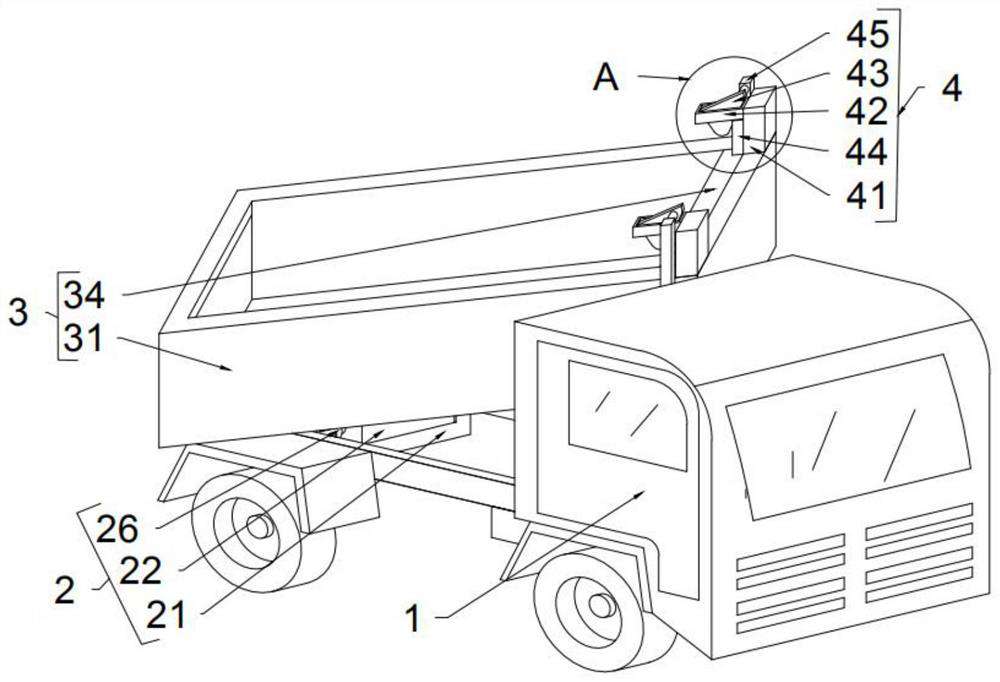

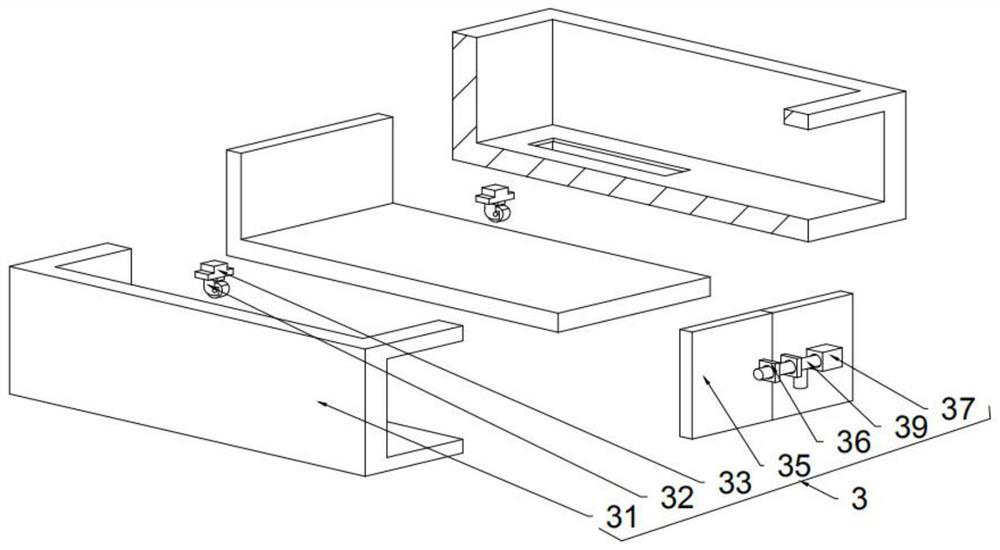

Garbage transfer vehicle with adjustable turnover angle

ActiveCN112320171ASpeed up pouringIncrease pouring speedRefuse vehiclesControl theoryMechanical engineering

The invention discloses a garbage transfer vehicle with an adjustable turnover angle. The garbage transfer vehicle comprises a vehicle body, a supporting structure fixedly arranged on the vehicle body, a dumping structure fixedly arranged on the supporting structure, and a clamping and locking structure fixedly arranged on the dumping structure, wherein the rear side of a car hopper is rotated leftwards and rightwards by a certain angle through the supporting structure, the garbage dumping angle of the car hopper can be adjusted conveniently when garbage dumping is inconvenient under normal conditions, and the garbage dumping position does not need to be changed through vehicle movement; through the dumping structure, dumping of garbage in the vehicle is accelerated, the garbage dumping isaccelerated, garbage residues in the car hopper are reduced, and the car hopper and a sliding plate can be fixed through cooperation of the clamping and locking structure; and the design is differentfrom other garbage vehicles, when the normal garbage damping is inconvenient, the garbage dumping position can be changed by adjusting the angle of the rear side of the car hopper, the situation thatthe dumping speed is affected due to too high garbage accumulation is prevented, the garbage dumping is accelerated through sliding-out of the sliding plate, and the garbage residues in the car hopper are reduced.

Owner:浙江金实乐环境工程有限公司

Aluminum alloy recycling and cleaning equipment

The invention relates to the technical field of aluminum alloy, and discloses aluminum alloy recycling and cleaning equipment which comprises a box body, a sliding hole is formed in the back side faceof the box body, a rotating shaft A is connected to the inner wall of the sliding hole in a sleeving manner, a sliding plate is fixedly connected to the end, located in the box body, of the rotatingshaft A, a hole is formed in the front face of the sliding plate and located below the rotating shaft A, a rotating shaft B is connected into the hole in a sleeving manner, one end, located on the back face of the box body, of the rotating shaft B is fixedly connected with a ratchet wheel, the ratchet wheel and a straight gear A are distributed front and back, and one end, located in the box body,of the rotating shaft B is fixedly connected with a cleaning barrel. Quantitative aluminium alloy and cleaning fluid are obtained in a sector-shaped groove of the cleaning barrel, so that the amountof the cleaning fluid is enough to disinfect and clean the aluminium alloy, the disinfecting and cleaning effect of the aluminium alloy is enhanced, the aluminium alloy is extruded by using the increased weight after the cleaning barrel accommodates the aluminium alloy and the cleaning fluid, and the automatic cleaning, disinfecting and extruding of the aluminium alloy is realized under the condition that an extra extruding mechanism is not required through the arrangement of a structure such as a toothed plate A.

Owner:江苏宏元达光伏新材料有限公司

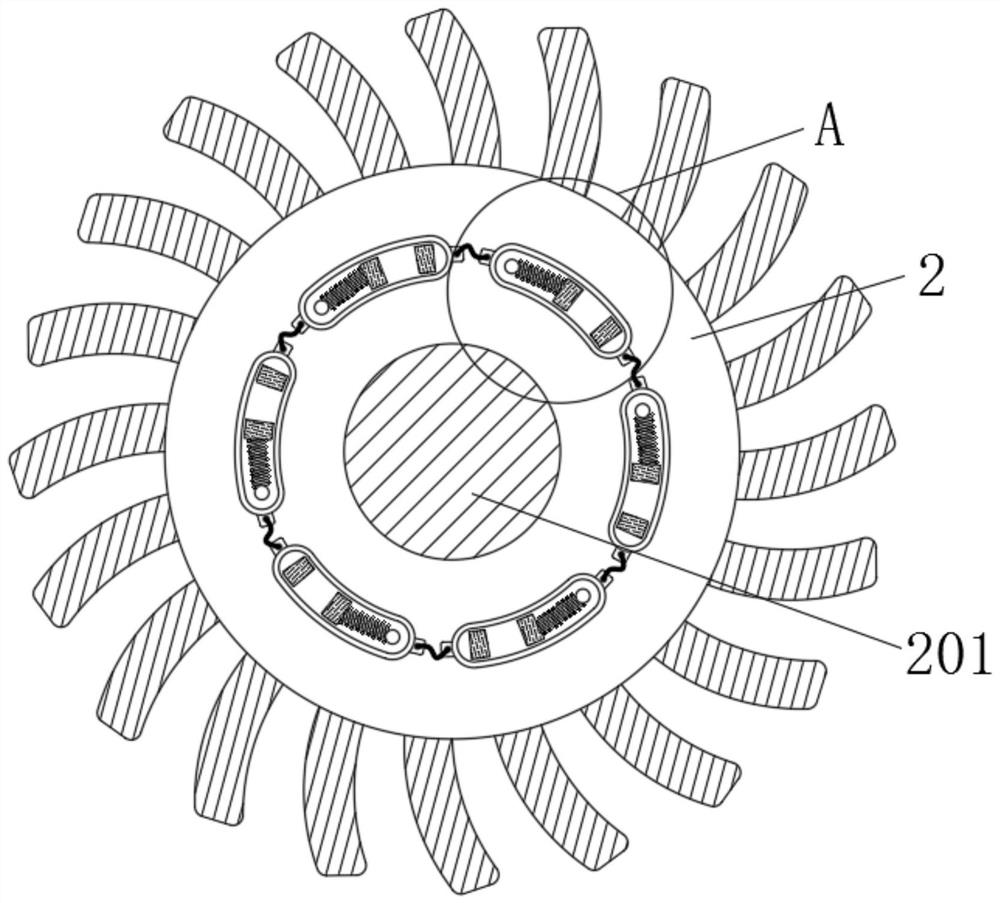

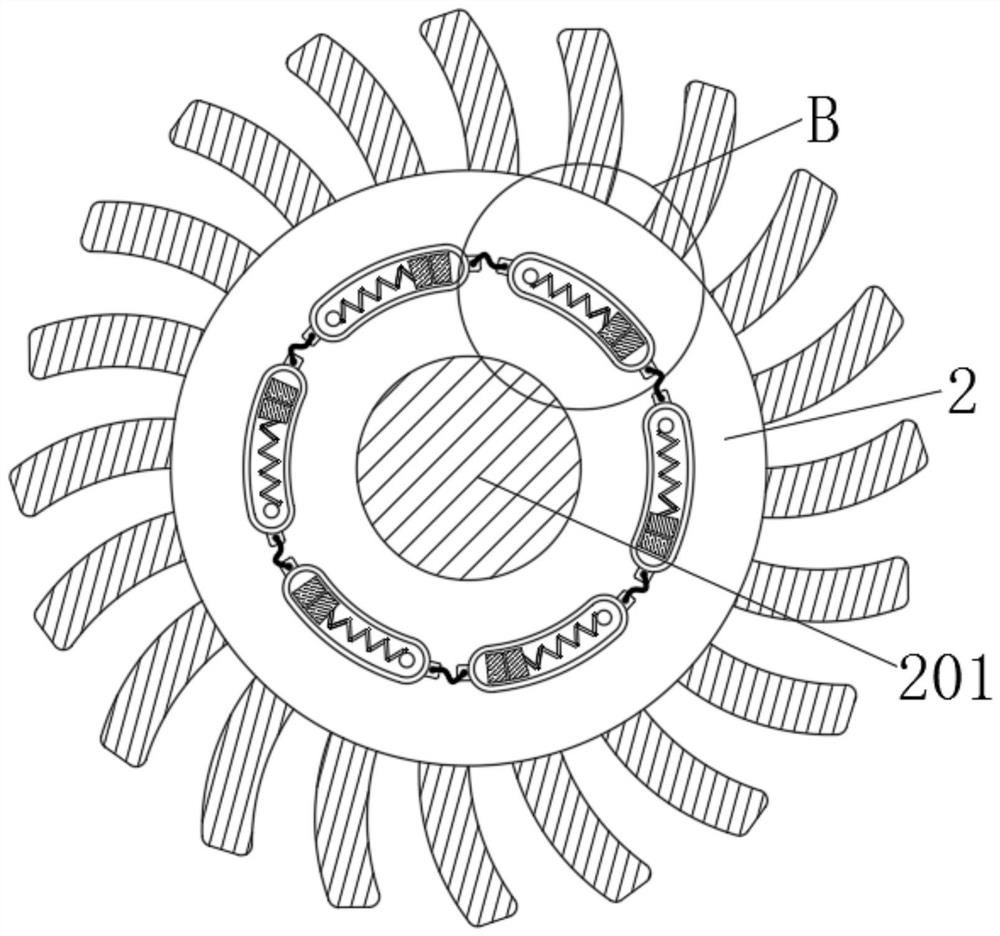

Edible oil anti-dripping and anti-toppling filling device

InactiveCN112573468AReduce labor costsSpeed up pouringLiquid bottlingStructural engineeringFan blade

The invention relates to the technical field of edible oil filling, and discloses an edible oil anti-dripping and anti-toppling filling device. The filling device comprises an oil tank, a first fan blade box is arranged in the oil tank, a fourth connecting rod is rotatably connected to the rear side of a third connecting rod, a connecting frame is fixedly connected to the left side of the fourth connecting rod, a fourth movement chamber is arranged on the outer side of the connecting frame, the inner side of the connecting frame is rotationally connected with a first movement cover, the left side of the connecting frame is fixedly connected with a piston, and the inner side of the fourth movement chamber is rotationally connected with a second movement cover. According to the edible oil anti-dripping and anti-toppling filling device, the third connecting rod drives the fourth connecting rod to move rightwards, the fourth connecting rod drives the piston to move rightwards, at the moment, due to the action of air pressure, the first movement cover is tightly attached to the piston, the second movement cover rotates, and therefore air suction work is conducted, oil left in the oil tank on the lower side of a first baffle is sucked into the fourth movement chamber, and therefore the effects of preventing dripping and reducing the labor cost are achieved.

Owner:陈正通

Dynamic gangue concrete used for filling beside gob-side entry retaining

InactiveCN102276221AReduce shrinkage and crackingImprove ultimate compressive strengthSolid waste managementPulverised fuel ashMaterials science

The invention discloses a dynamic gangue concrete for filling beside gob-side entry retention, which is composed of 1000 parts of gangue with a particle size of less than 1.5 cm, 200 parts of ordinary Portland cement, 100 parts of fly ash from a power plant, and 3 hydration agents. part, 2 parts of internal curing agent, 50 parts of non-alkali liquid quick-setting agent and 500 parts of water are uniformly stirred and mixed; the above-mentioned parts all refer to parts by weight; The compressive strength is 6-9Mpa, and the uniaxial compressive strength at 28-day age is 16-24Mpa, which can fully meet the support requirements of gob-side entry retaining.

Owner:XINWEN MINING GROUP

Trash can cleaning transition position changing structure

InactiveCN110817208AEasy to holdAvoid the problem of unstable clampingProgramme-controlled manipulatorRefuse receptaclesStructural engineeringTruck

The invention provides a trash can cleaning transition position changing structure. The structure comprises a first mechanical arm mounted on one side of a garbage truck body, a first gripper arm mounted on the tail end of the first mechanical arm, a second mechanical arm mounted in a garbage truck cleaning box and a second gripper arm mounted on the tail end of the second mechanical arm, the second gripper arm comprises a second gripper arm base and second clamping rods hinged to the two sides of the second gripper arm base, and a second induction device used for identifying an identifying label for calibrating the height position of a trash can body is mounted on the second gripper arm base. A processor is used for controlling the second mechanical arm and the second gripper arm to move,through the second induction device, and the identifying label on the garbage can body, the height position of the garbage can body can be identified, the second gripper arm is controlled to clamp the lower middle portion of the garbage can body, and the trash can can be rapidly and conveniently clamped into a cleaning box of a garbage truck.

Owner:FOSHAN UNIVERSITY

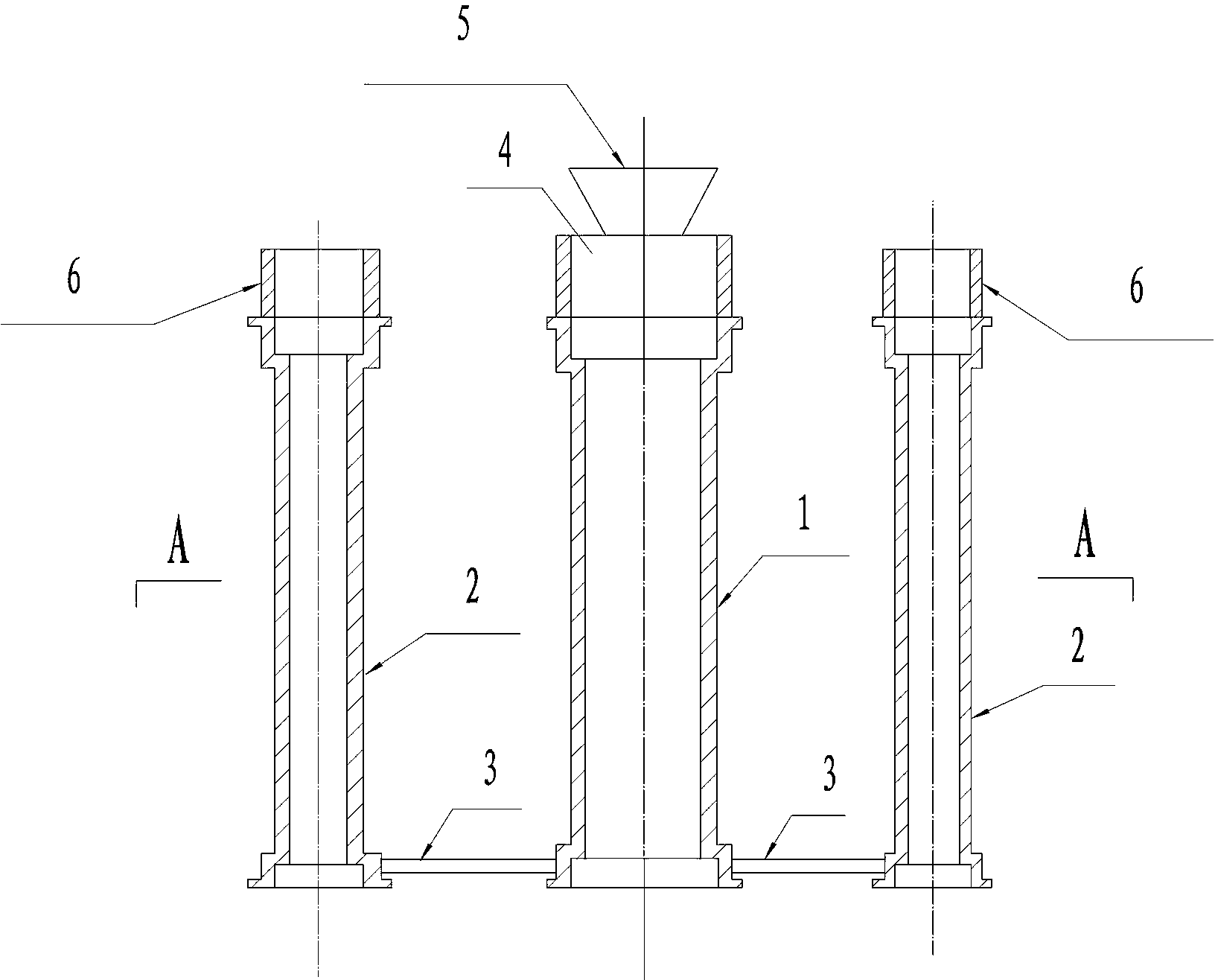

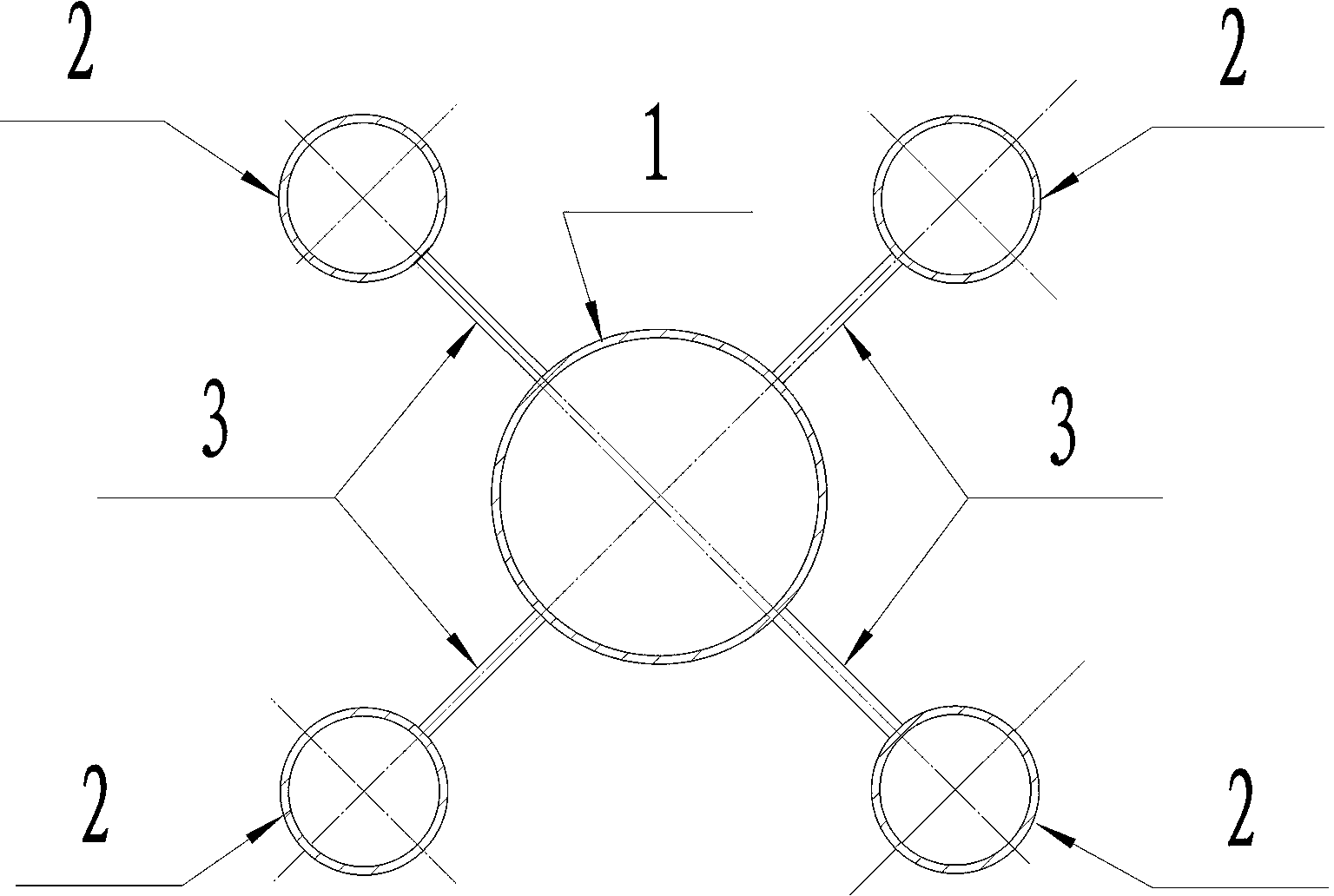

Combined model structure for improving product yield of evaporative pattern casting process for cast iron pipe fittings

The invention relates to the field of evaporative pattern casting and in particular relates to a combined model structure for improving product yield of an evaporative pattern casting process for cast iron pipe fittings. The combined model structure comprises a central pipe fitting model and a plurality of peripheral pipe fitting models, wherein the peripheral pipe fitting models are arranged at the periphery of the central pipe fitting model by taking the central pipe fitting model as a center; inner runner models are arranged between the bottom of the central pipe fitting model and the bottoms of the peripheral pipe fitting models and used for connecting two pipe fitting models; a sprue cup is arranged at the top of the central pipe fitting model; a connection runner model is arranged between the top of the central pipe fitting model and the spure cup; dead head models are arranged at the tops of the peripheral pipe fitting models. The models are foam plastic models applied to the evaporative pattern casting process. The combined model structure is simple and reasonable in structure, capable of reducing the use amount of iron liquid in the evaporative pattern casting of the cast iron pipe fittings, reducing the production cost and improving the product yield of an evaporative pattern casting process for cast iron pipe fittings and applicable to the evaporative pattern casting of same types of products made of different materials.

Owner:阳城县华王通用离心铸管厂 +1

Lifting device for a grain dryer

ActiveCN111703811BReduce wasteIncrease tightnessConveyorsSeed preservation by dryingElectric machineControl theory

The present invention relates to the technical field of grain dryers, and more specifically relates to a lifting device for grain dryers, including a lifting motor, a driving runner, a driven runner, a lifting bucket and a feed gate, and a lifting bucket The positioning pin is fixedly connected with the conveyor belt. The top of the lifting bucket is fixedly connected with an extension plate. The feed gate includes an inclined channel, a switch plate, a No. 1 electric telescopic rod and an exhaust fan. The switch plate is slidingly connected with the inclined channel. There is a pressure sensor on the top, the pressure sensor is electrically connected to the No. 1 electric telescopic rod, and the No. 1 electric telescopic rod is fixedly connected to the bottom surface of the switch plate; the invention improves the tightness of the connection between the inclined channel, the switch plate and the conveyor belt, and effectively prevents grain Falling into the space below the inclined channel, it is crushed and stuck between the conveyor belt and the runner, effectively reducing the waste of grain, avoiding negative impact on the operation of the conveyor belt and runner, and improving the cleaning efficiency of the grain.

Owner:合肥麦稻之星机械有限公司

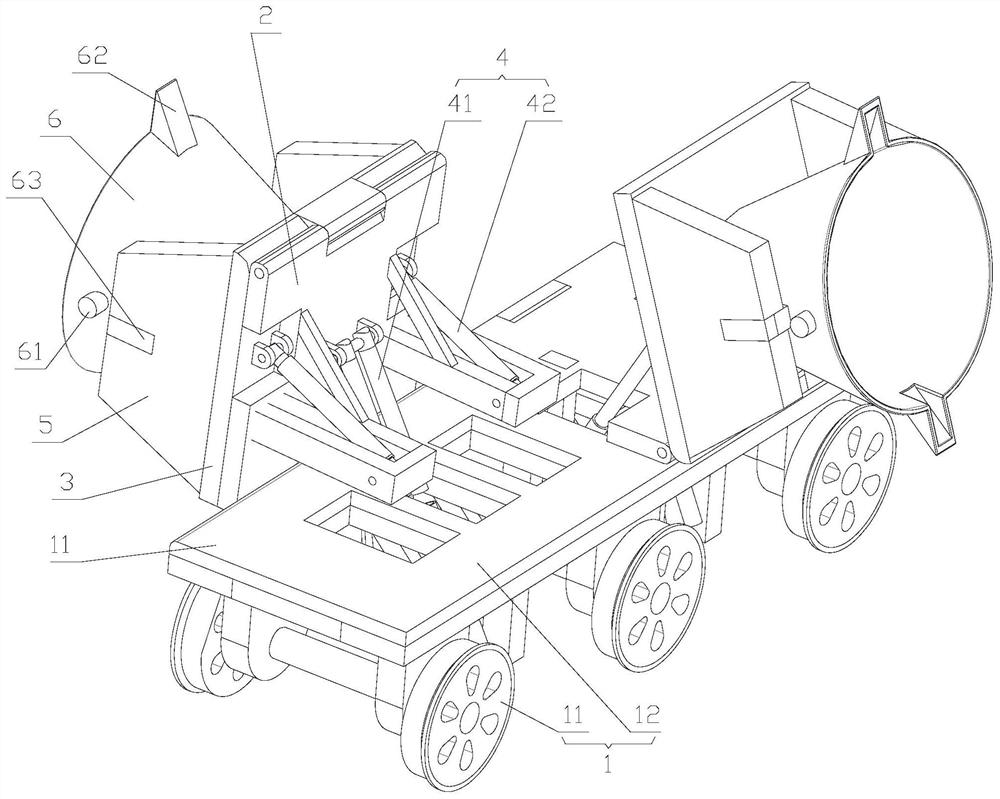

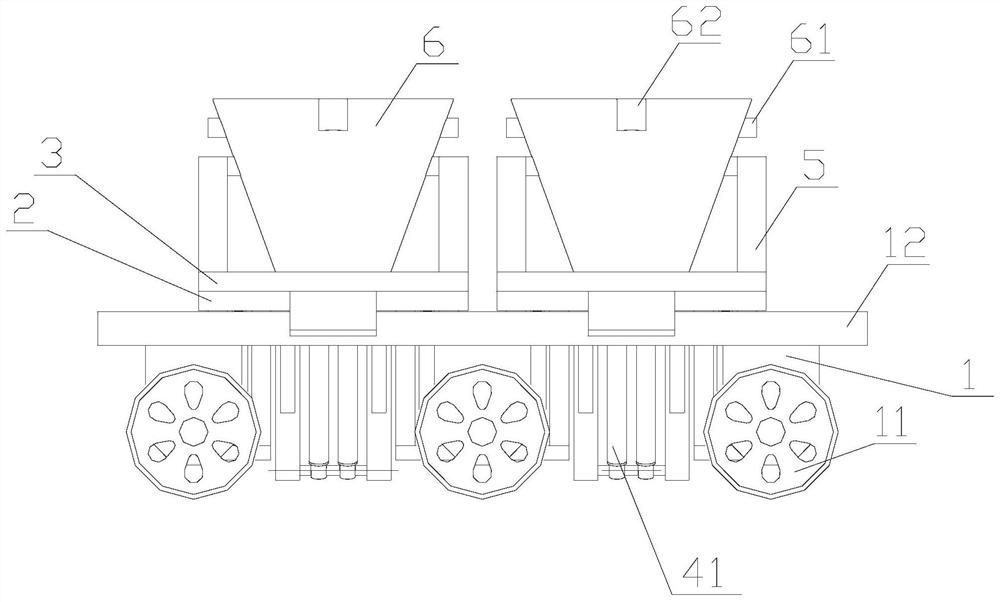

Double-station bidirectional tipping steel slag carrier loader

ActiveCN113699290AImprove transportationSpeed up pouringRecycling and recovery technologiesSlagStructural engineering

The invention discloses a double-station bidirectional tipping steel slag carrier loader which comprises a loader body and two sets of independent tipping devices. Each set of tipping device comprises a large turning plate, a small turning plate, a lifting mechanism, a slag pot support and a slag pot; and the power of rotation of the large turning plates around the loader body and the power of rotation of the small turning plates around the large turning plates are provided by the lifting mechanisms. According to the double-station bidirectional tipping steel slag carrier loader, by arranging the two sets of bidirectional tipping devices, the double-station bidirectional tipping function is achieved, the turning frequency of the loader body is reduced, and the tipping efficiency is improved. The invention provides the double-station bidirectional tipping steel slag carrier loader, the two requirements of double stations and two-way tipping are met, the tipping actions of the two stations are independently operated, the operability is flexible, the steel slag transportation, dumping and air quenching efficiency is remarkably improved, the structure is simple, continuous air quenching of the whole furnace of steel slag is facilitated, and the automation level of a steel mill is improved.

Owner:WUHAN UNIV OF SCI & TECH

Sorting device realizing concentrated treatment of dismantling and draining for dry powder can

ActiveCN110624942ARealize classified collectionFacilitate subsequent unified processingSolid waste disposalCoatingsEngineeringTherapeutic effect

The invention discloses a sorting device realizing concentrated treatment of dismantling and draining for a dry powder can. The device comprises a bottom plate, four supporting legs, a first side plate, a second side plate, a front cover plate, a rear cover plate, a driving turnover unit, a dismantling and draining unit, a separating plate and a collecting hopper, wherein the four supporting legsare fixedly mounted at four corners of the bottom of the bottom plate in a symmetrically mode, and the first side plate and the second side plate are fixedly mounted on the two sides of the upper portion of the bottom plate correspondingly. According to the sorting device, the used dry power can can be treated without using manual operation, the working efficiency is effectively improved, and thethe working intensity is effectively reduced; the dismantled dry power can, dry power and water can be classified and collected for facilitating subsequent unified treatment; the residual quantity ofthe dry powder and water on the inner wall of the dry powder can can be effectively reduced, and the good treatment effect for the used dry power is achieved; and meanwhile, a prepared protective layer can prevent a large amount of residual dry powder and water being adhered to the inner surface of the collecting hopper, so that internal cleaning of the dry powder can is convenient, and cleaning can be carried out only by flushing with water.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

A garbage transfer vehicle with adjustable turning angle

ActiveCN112320171BSpeed up pouringIncrease pouring speedRefuse vehiclesMarine engineeringStructural engineering

The invention discloses a garbage transfer vehicle with an adjustable turning angle, which comprises: a vehicle body; a support structure, which is fixedly arranged on the vehicle body; a dumping structure, which is fixedly arranged on the support structure; and a locking structure, which is fixedly arranged on the On the dumping structure; the rear side of the bucket can be rotated left and right by a certain angle through the support structure, which is convenient to adjust the angle of dumping garbage in the bucket when it is inconvenient to dump garbage under normal conditions, without changing the position of dumping garbage through the movement of the vehicle; through the dumping structure, it is convenient to speed up the vehicle The dumping of the garbage inside can speed up the dumping of the garbage and reduce the garbage residue in the vehicle body, and the body and the slide plate can be fixed through the lock structure; this design is different from other garbage vehicles. When it is inconvenient to dump the garbage normally, it can be adjusted The angle of the rear side of the vehicle body changes the dumping position of the garbage, preventing excessive accumulation of garbage from affecting the dumping speed, and speeding up the dumping of garbage through sliding out of the skateboard, reducing the residue of garbage in the vehicle bucket.

Owner:浙江金实乐环境工程有限公司

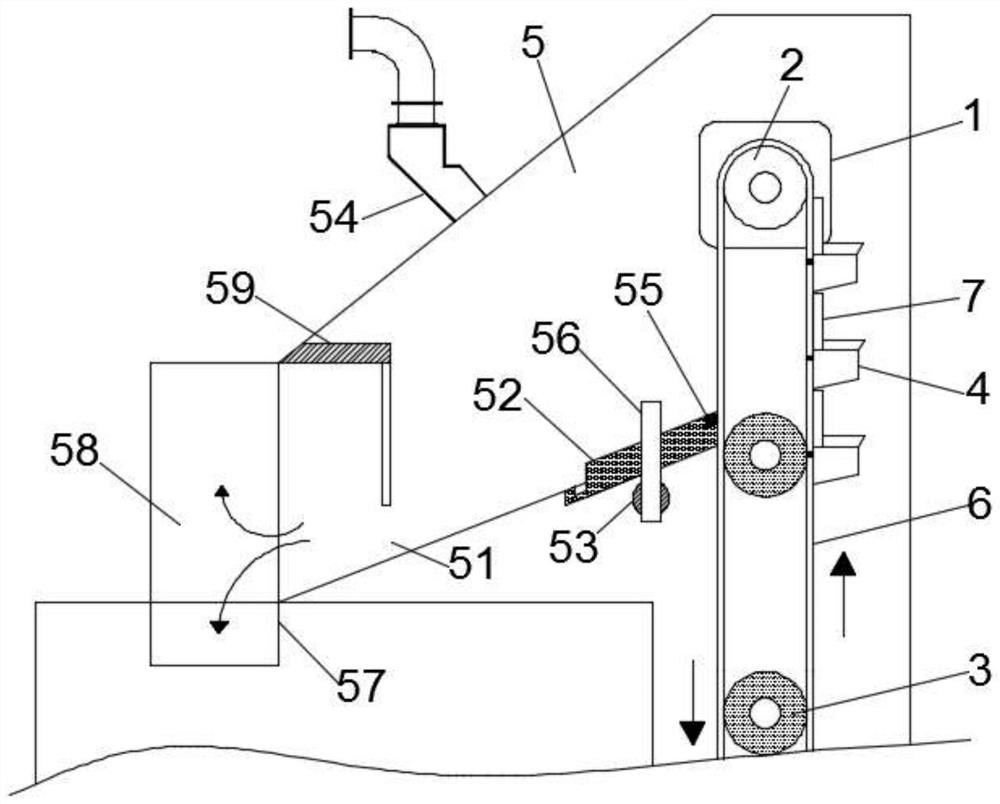

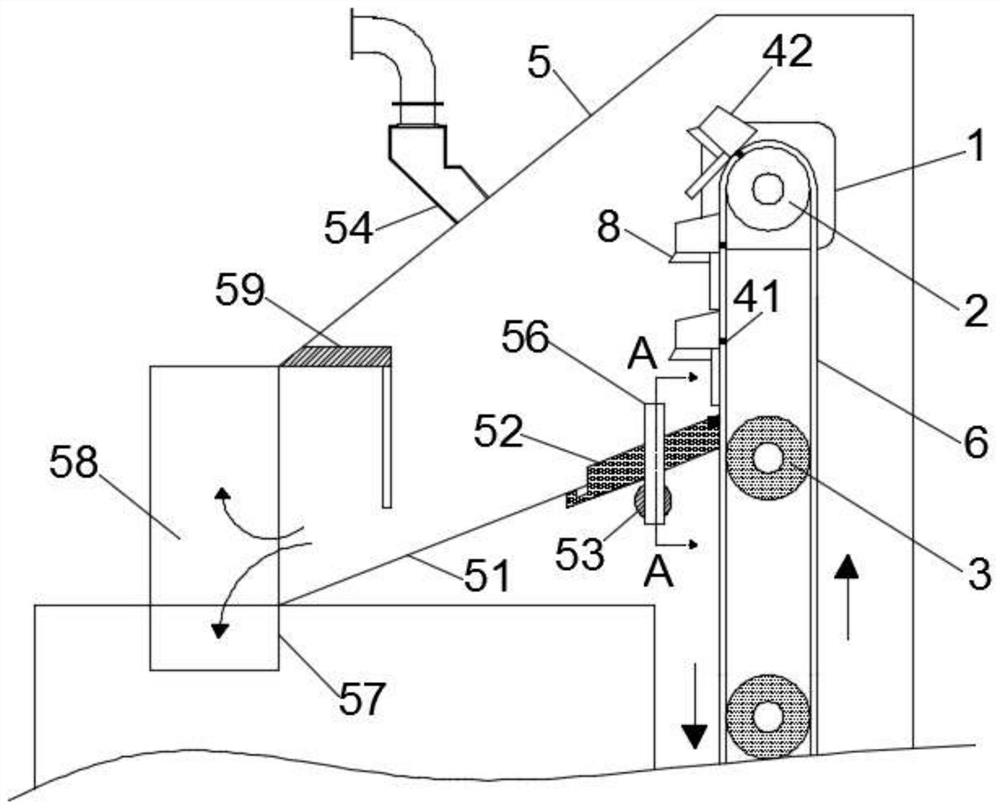

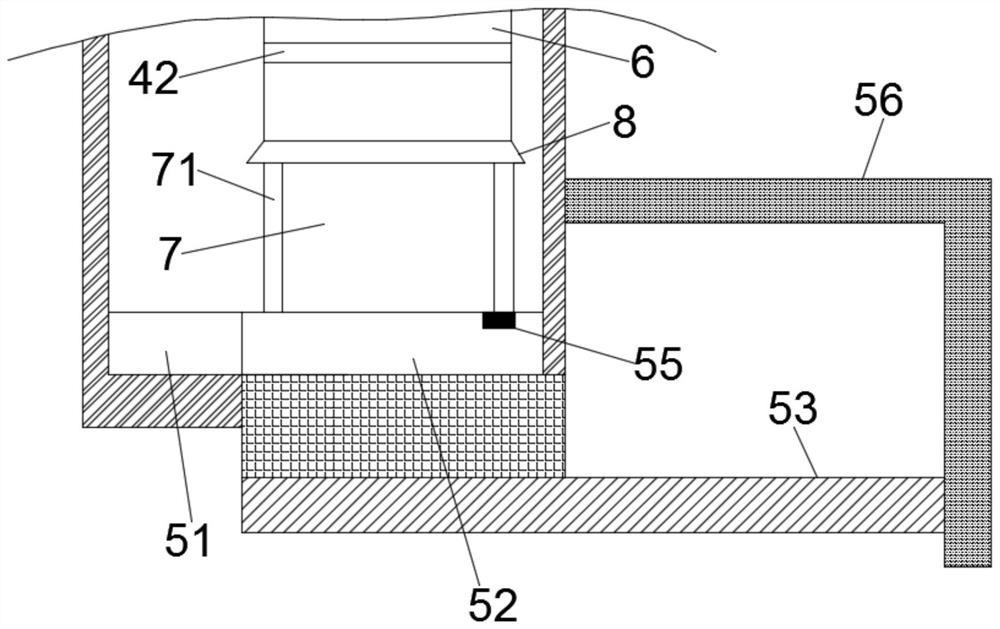

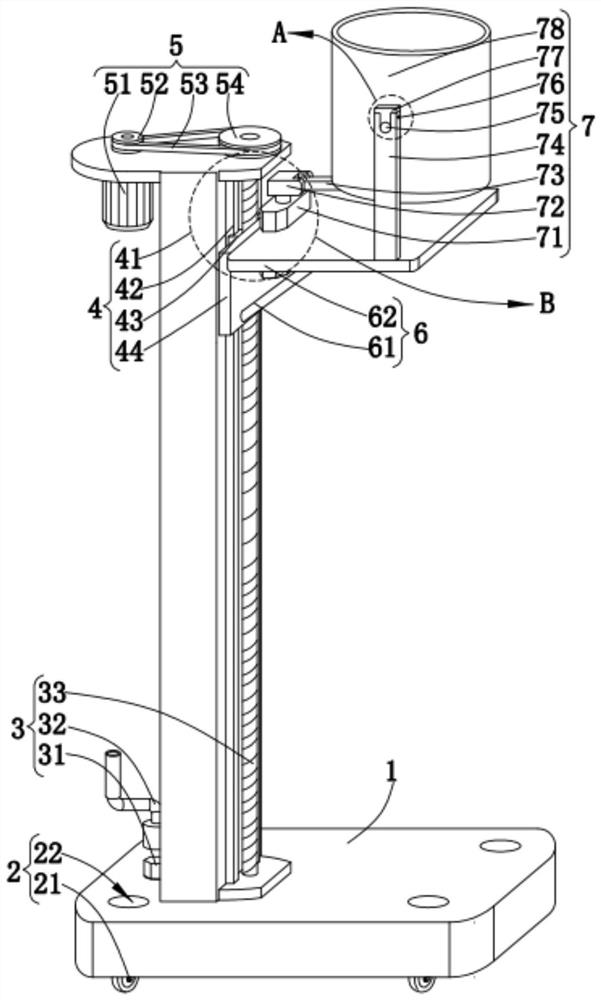

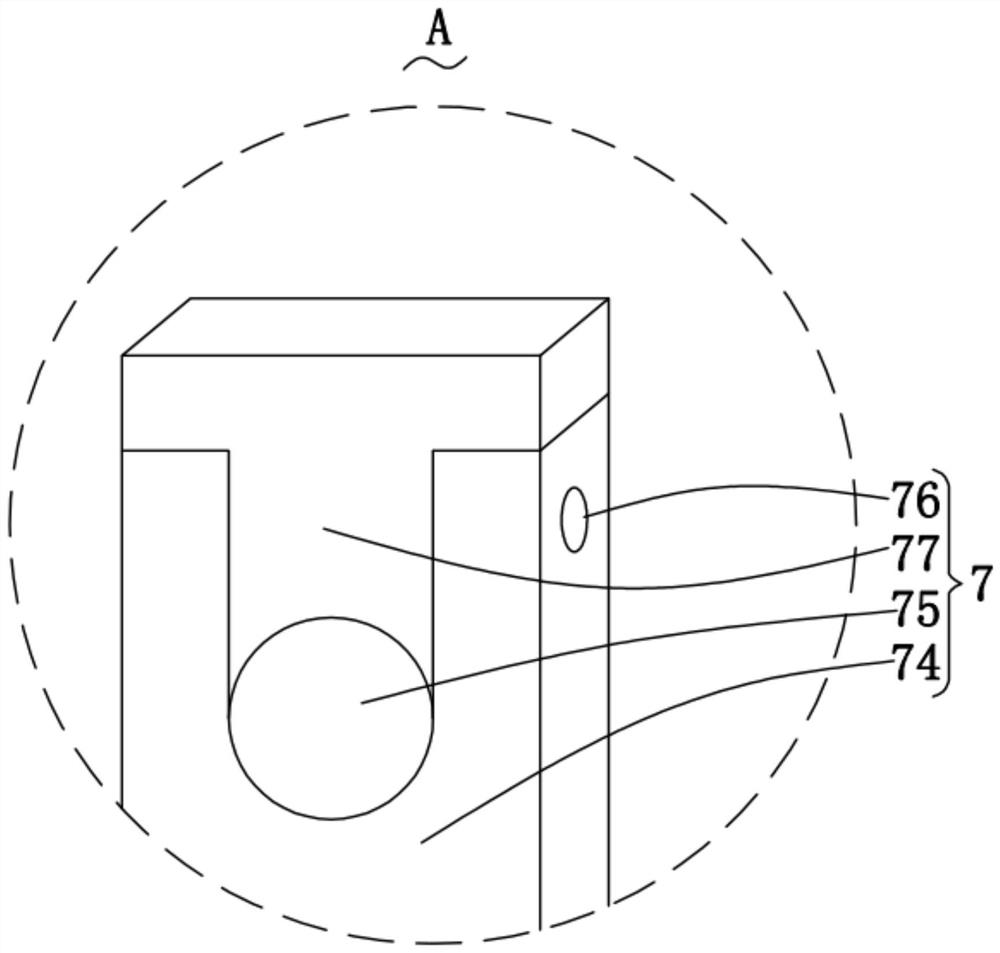

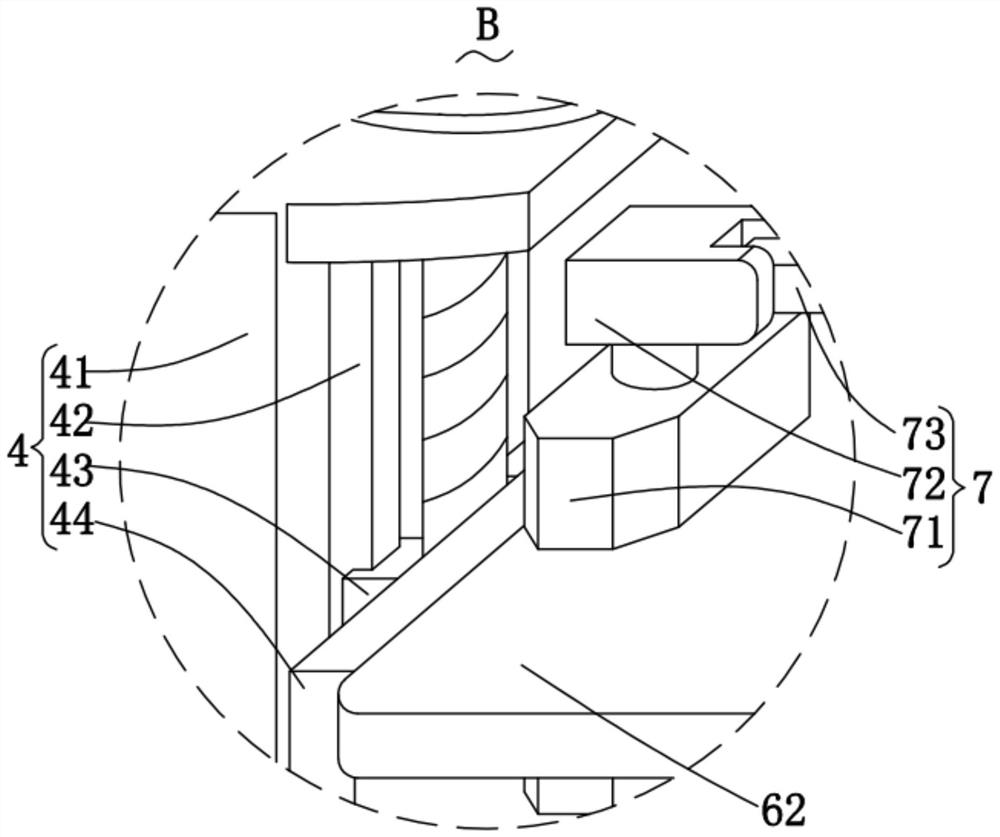

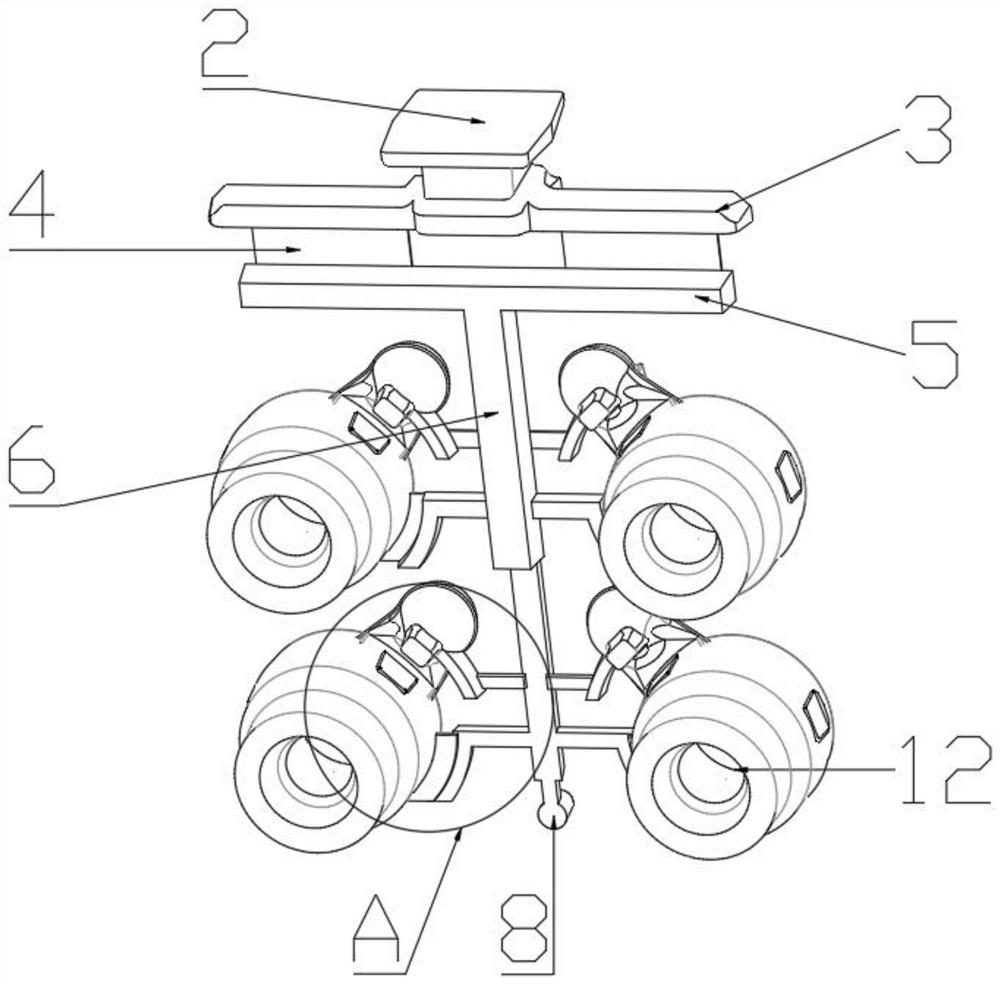

High slope pouring lifting device

InactiveCN113502821AConvenience pouring fillingEasy to disassembleLifting framesExcavationsStructural engineeringMechanical engineering

Owner:SINOHYDRO BUREAU 12 CO LTD

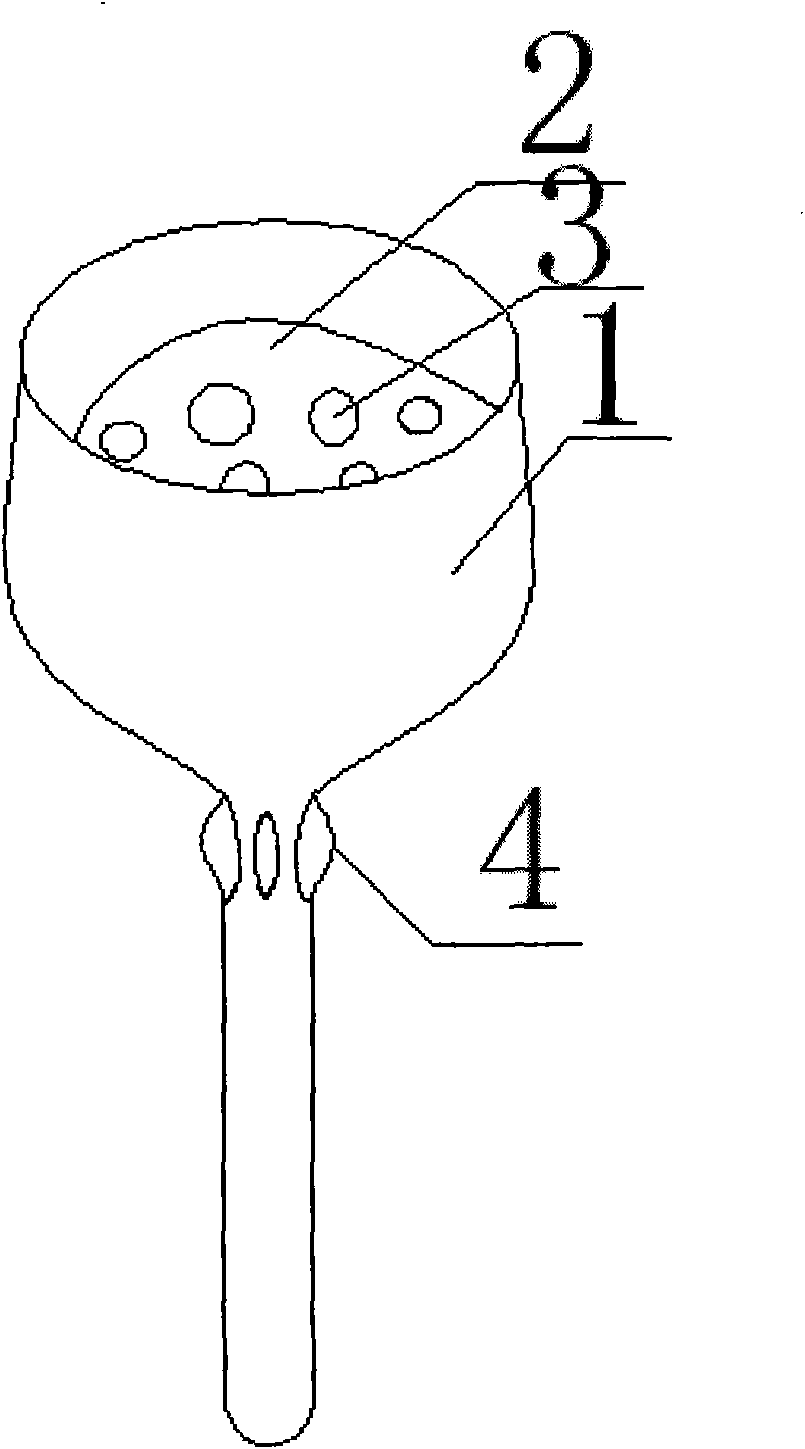

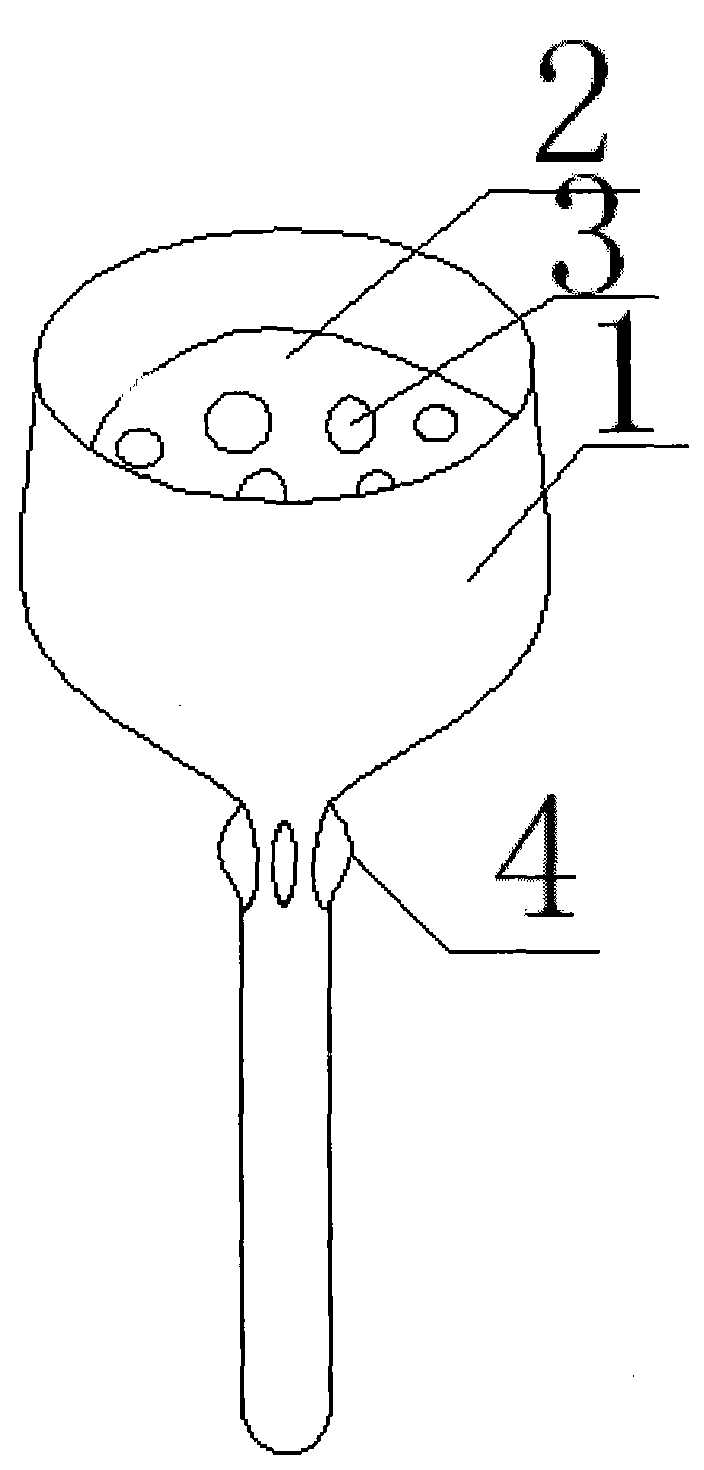

Novel hopper

The invention relates to an auxiliary tool for pouring water from a container, in particular relates to a novel hopper. The novel hopper comprises a funnel and is characterized in that an interlayer for separating the upper part and the lower part of the funnel is arranged at the middle of the funnel, dispersed small holes are arranged on the surface of the interlayer, and dispersed small bulges are arranged on the outer surface of the upper section of a stream tube at the bottom of the funnel. Therefore, the novel hopper has a simple structure and is convenient to use.

Owner:吕高晋

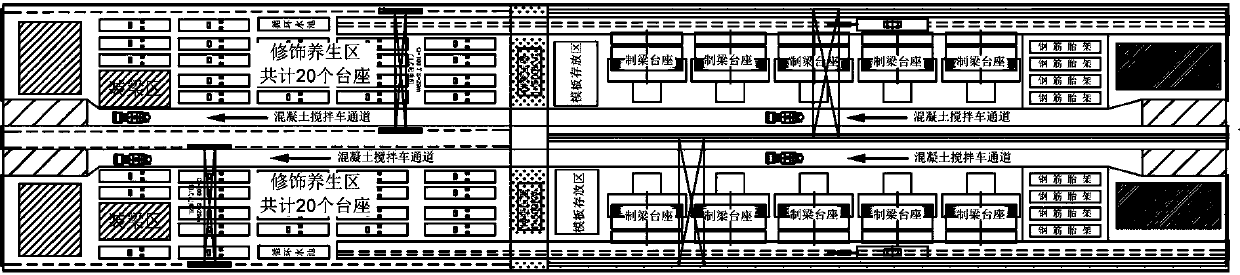

A buffer zone of a bridge segment prefabrication plant

ActiveCN109138543BReduce the temperatureSmooth trafficMechanical controlsIndustrial buildingsCold airAgricultural engineering

The invention, which belongs to the technical field of a bridge segment prefabricated plant, relates to a buffer zone in a bridge segment prefabricated plant. With an isolation zone with the double-layer partition and a sensing zone for sensing entrance and exit of vehicles, the vehicle passing efficiency is ensured and the external cold air is prevented from entering the prefabricated plant, so that the concrete pouring and maintaining effects in the prefabricated plant can be improved. The prefabrication of the bridge segments in the prefabrication plant does not change with seasons and thusthe construction progress is not affected; and the normal prefabrication of the bridge segments can be guaranteed even in winter.

Owner:瀚阳国际工程咨询有限公司

A sorting device for centralized treatment of dry powder tanks, demolition and discharge liquid

ActiveCN110624942BRealize classified collectionFacilitate subsequent unified processingSolid waste disposalSpecial surfacesStructural engineeringProcess engineering

The invention discloses a sorting device realizing concentrated treatment of dismantling and draining for a dry powder can. The device comprises a bottom plate, four supporting legs, a first side plate, a second side plate, a front cover plate, a rear cover plate, a driving turnover unit, a dismantling and draining unit, a separating plate and a collecting hopper, wherein the four supporting legsare fixedly mounted at four corners of the bottom of the bottom plate in a symmetrically mode, and the first side plate and the second side plate are fixedly mounted on the two sides of the upper portion of the bottom plate correspondingly. According to the sorting device, the used dry power can can be treated without using manual operation, the working efficiency is effectively improved, and thethe working intensity is effectively reduced; the dismantled dry power can, dry power and water can be classified and collected for facilitating subsequent unified treatment; the residual quantity ofthe dry powder and water on the inner wall of the dry powder can can be effectively reduced, and the good treatment effect for the used dry power is achieved; and meanwhile, a prepared protective layer can prevent a large amount of residual dry powder and water being adhered to the inner surface of the collecting hopper, so that internal cleaning of the dry powder can is convenient, and cleaning can be carried out only by flushing with water.

Owner:THE FIRST PEOPLES HOSPITAL OF CHANGZHOU

A kind of aluminum alloy recovery and cleaning equipment

Owner:江苏宏元达光伏新材料有限公司

Concrete dense column gypsum composite wallboard deployed small high-rise residential hybrid structure system

ActiveCN102182328BNo idle functionIncrease stressBuilding constructionsDwelling buildingReinforced concreteResidence

The invention relates to a concrete dense column gypsum composite wallboard deployed small high-rise residential hybrid structure system. Longitudinal and transverse concrete dense column gypsum composite inner and outer wallboards of the system are previously supported, ribs are deployed in a board cavity, and concrete in the cavity, a reinforced concrete cylindrical transport core, a concrete floor and concrete built-in surrounding beams are cast together to form a hybrid structure, namely the small high-rise residential load stress system; the gypsum walls of the concrete dense column gypsum composite inner and outer wallboards and the reinforced concrete dense columns in the board cavity participate in structural stress calculation; and the cavities of the concrete dense columns of the wallboards of each layer are vertically communicated, and the longitudinal ribs in the cavity pass through the floor of each layer or the concrete built-in surrounding beams. The system has the advantages of energy conservation, low consumption, environment friendliness, economical efficiency, practicability, factory production and integrated installation; the hybrid structural form improves theintegrated stress performance of the building; and the gypsum walls and the concrete dense columns participate in structural stress together, so safety is ensured, no functional waste is caused and the integrated modern level of the residence industry is improved.

Owner:天津开发区福林发展有限公司

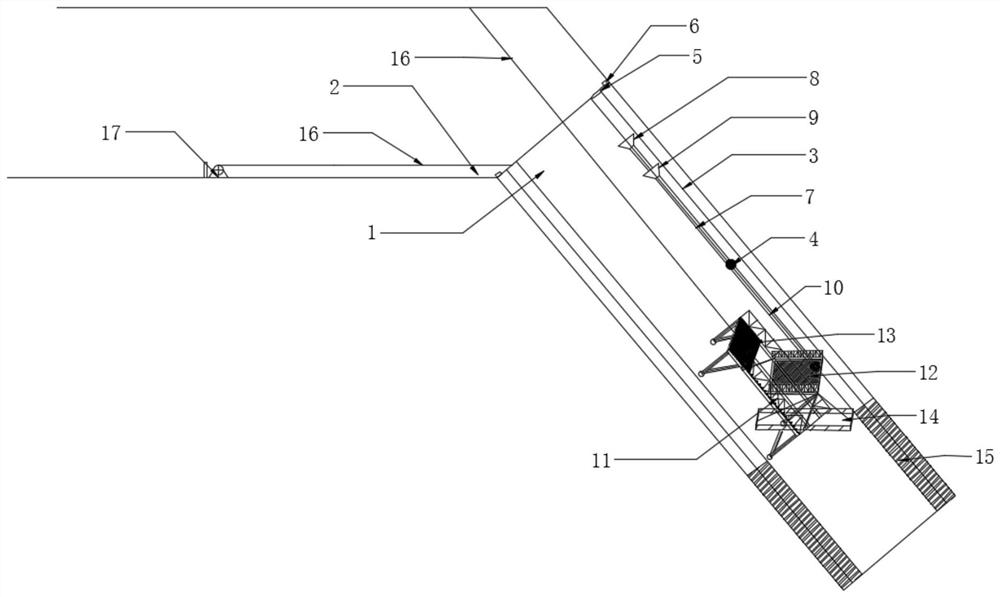

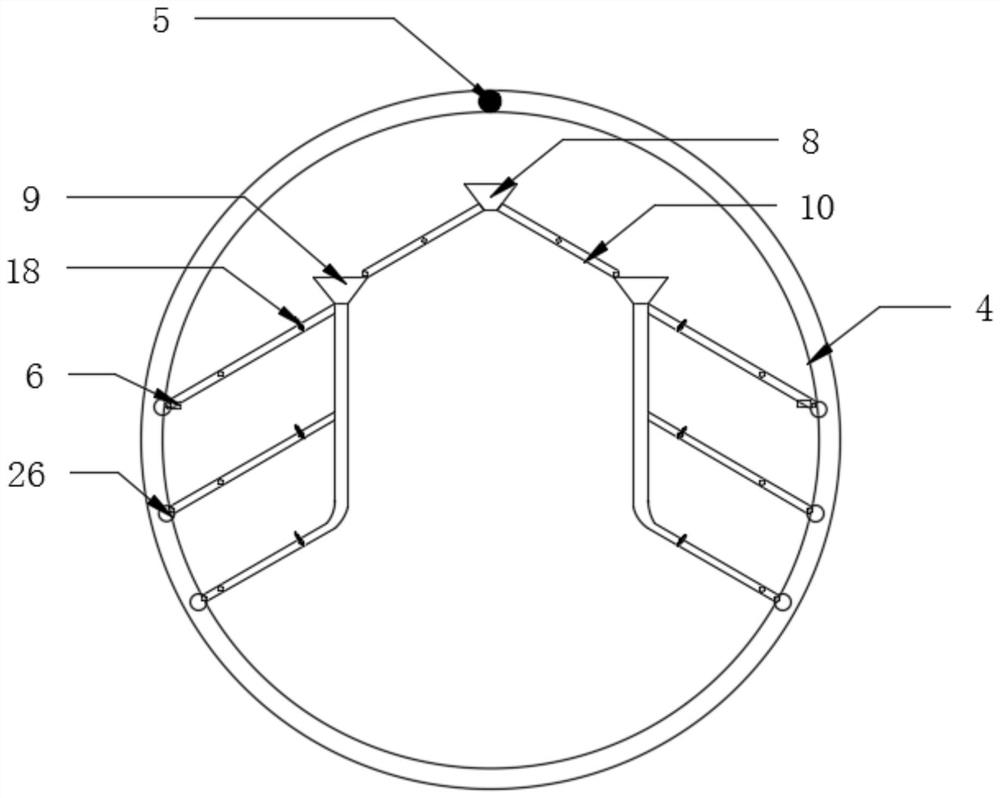

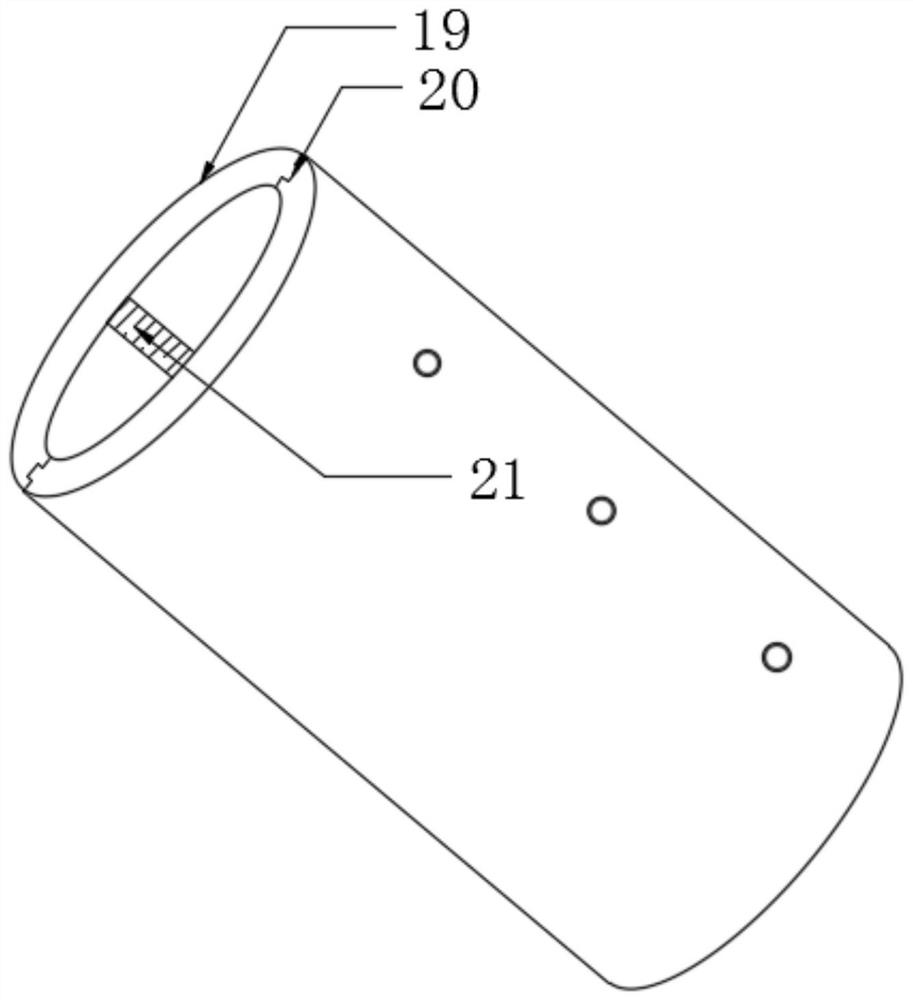

Steep inclined shaft slip form system and cast-in-place concrete lining construction method

InactiveCN112282795AImprove pouring efficiencyImprove pouring qualityUnderground chambersDrainageArchitectural engineeringRabbet

The invention discloses a steep inclined shaft slip form system and a cast-in-place concrete lining construction method, and belongs to the technical field of steep inclined shaft concrete construction. The construction method comprises the steps that construction preparation is carried out, and specifically, a winch, a prefabricated separation type steel form, and a lifting vehicle which are needed by construction are prepared; form body mounting is carried out, specifically, the separation type steel form is aligned and folded according to a rabbet and then is lowered to an inclined shaft, and the lifting vehicle is adjusted and placed in the separation type steel form to be adjusted; chute mounting is carried out, and specifically, a chute at the customized pouring device communicates with a chute pouring window preset on the separated steel form; and concrete pouring is carried out, and specifically, concrete is poured into the concrete pump pouring window by using a concrete pumpto fill a gap between the separation type steel form and the inclined shaft; and chute pouring is carried out while concrete pouring is carried out, and a lifting trolley is lifted through a winch toconvey workers to conduct quality inspection on a poured section. Inner wall pouring of the steep inclined shaft is completed through the above steps, maintenance is carried out through a spraying device, and the service life of the inclined shaft is prolonged.

Owner:浙江世润建创科技发展有限公司

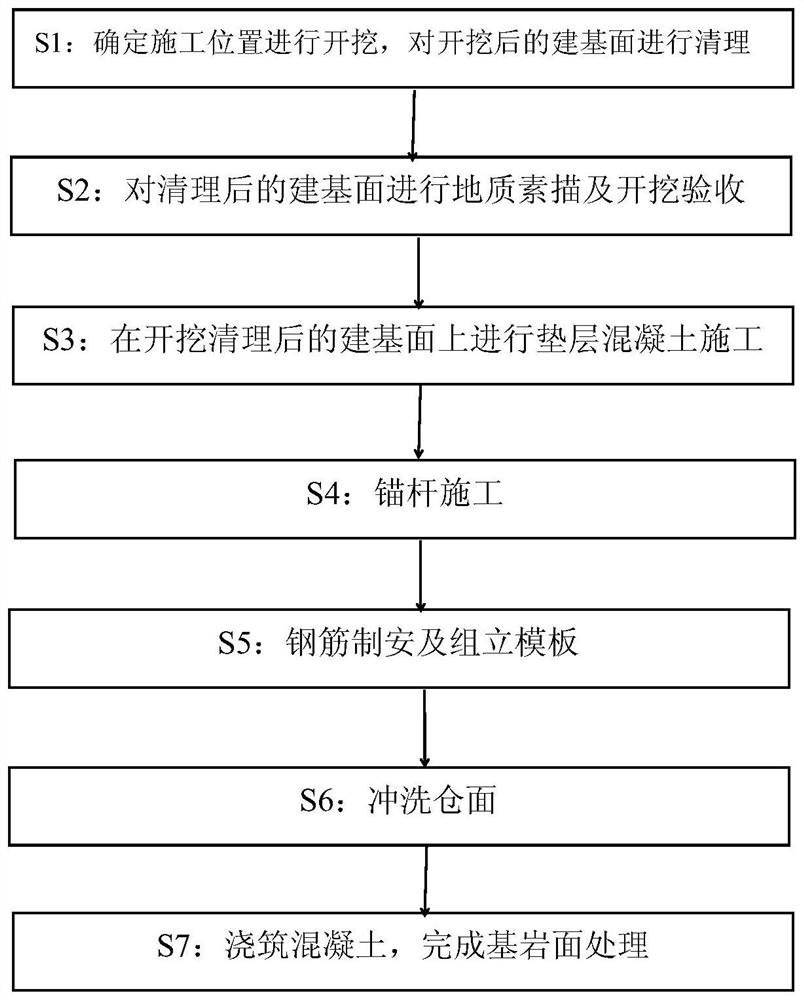

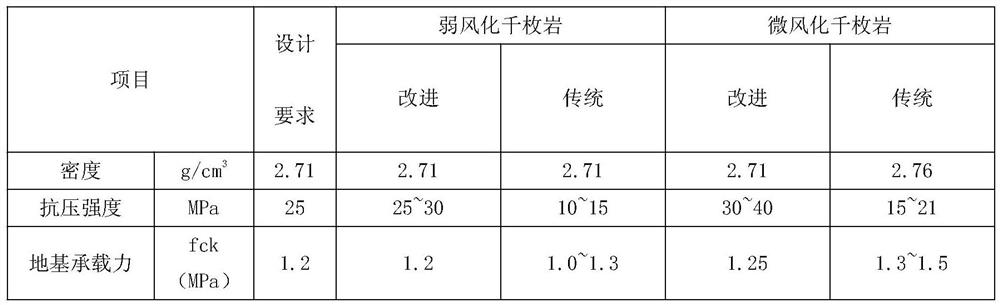

Construction method for efficiently treating phyllite base rock surface

The invention provides a construction method for efficiently treating a phyllite base rock surface, which comprises the following steps: S1, determining a construction position for excavation, and cleaning an excavated foundation surface; s2, geological sketching and excavation acceptance inspection are conducted on the cleaned foundation surface; s3, cushion layer concrete construction is carried out on the foundation surface after excavation and cleaning; s4, anchor rod construction is conducted, specifically, drilling is conducted on the solidified cushion layer concrete and phyllite through a drilling machine, and anchor rods are installed and fixed; s5, steel bars are manufactured and installed, a formwork is assembled, a water pump, a slag hopper and an air gun are used for cleaning rock debris generated during anchor rod construction, and then the formwork is assembled; s6, the bin surface is flushed, specifically, the bin surface is flushed through a water pump, and broken stones and the like generated in the construction process are flushed away; and S7, concrete is poured, and bedrock surface treatment is completed. According to the method, the mechanical indexes of the phyllite are prevented from being reduced, so that the foundation surface meets the design requirements, the manual cleaning workload is reduced, the working intensity is reduced, the construction efficiency is improved, the construction period is shortened, the labor cost is reduced, and the construction benefits are increased.

Owner:大唐陕西发电有限公司旬阳水力发电厂

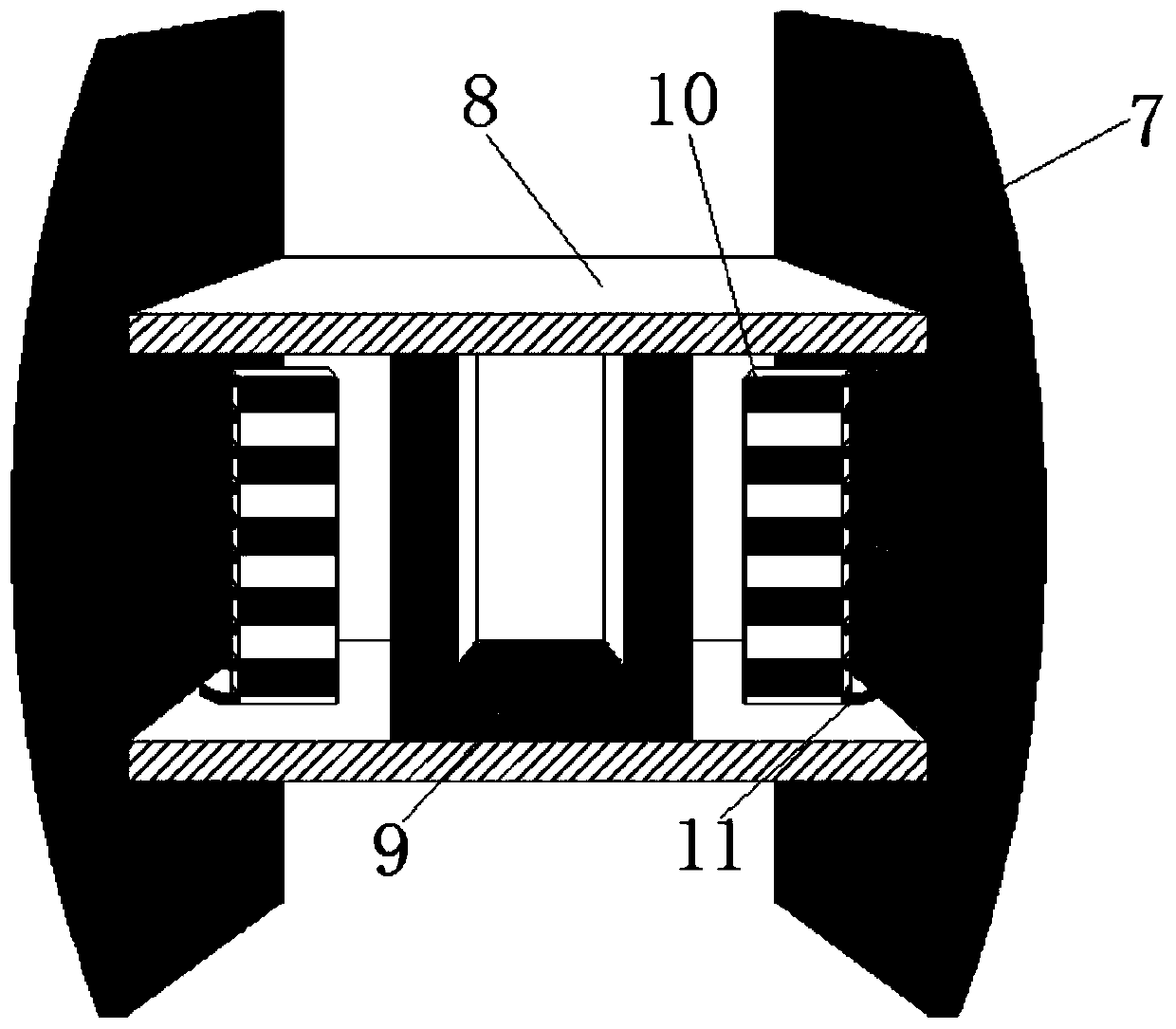

Polishing-free pouring system for one-mold four-piece sand casting of bearing sleeve

PendingCN113714463AIncrease water flow areaReduce trachomaFoundry mouldsFoundry coresMold fillingPolishing

The invention discloses a polishing-free pouring system for one-mold four-piece sand casting of a bearing sleeve, and relates to the technical field of pouring. The polishing-free pouring system comprises the following steps: carrying out mold manufacturing, specifically, manufacturing a mold, forming a pouring gate in the upper side of the mold, and sequentially forming a transverse groove set, a vertical groove set, four hot risers and four casting grooves in the mold; carrying out smelting, specifically, selecting appropriate metal materials for mixed smelting, wherein the smelting temperature is 1500-1600 DEG C; carrying out pouring, specifically, aligning molten iron with the pouring gate of the mold for slow pouring; carrying out demolding, specifically, taking castings out of the mold after the castings are naturally cooled in the mold; carrying out machining, specifically, removing residues during machining; and carrying out encasement, specifically, detecting the quality of the castings, and packing and encasing the castings after the castings are qualified. According to the polishing-free pouring system, impurities are filtered while the flow of the molten iron is guaranteed through the transverse groove set, sand holes of the castings are reduced, and the mold filling flow speed is decreased; the yield of the castings is increased through the vertical groove set and the casting grooves, and the four castings are poured at a time; and molten iron supplement is provided through the hot risers, and the probability that the upper portions of the castings collapse after the molten iron is solidified is decreased.

Owner:ANHUI HAILI PRECISION CASTING CO LTD

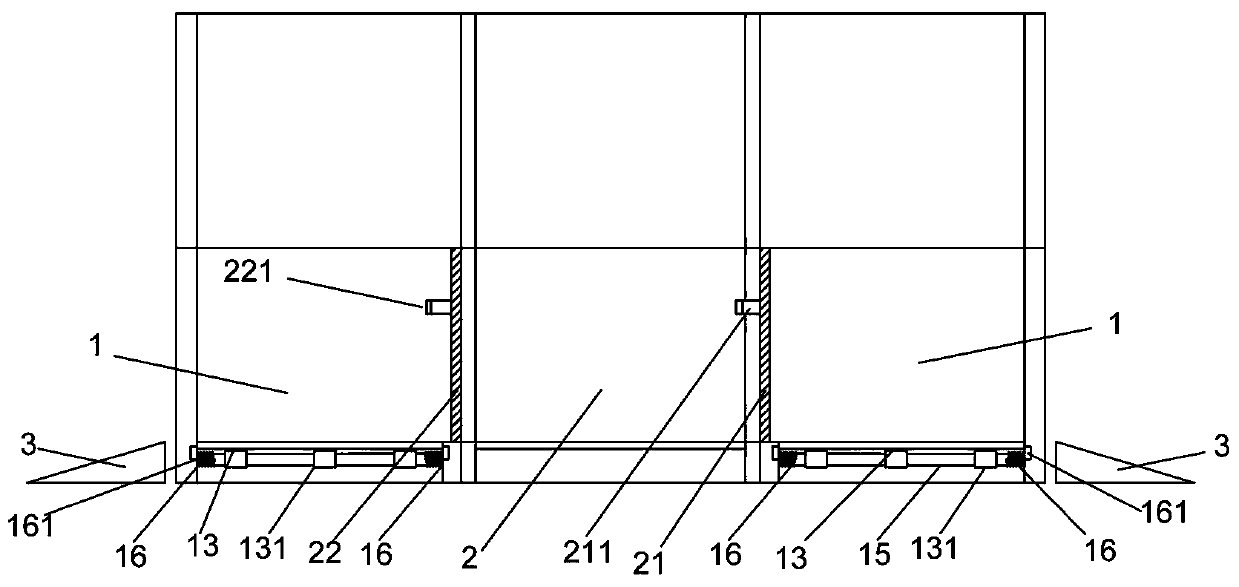

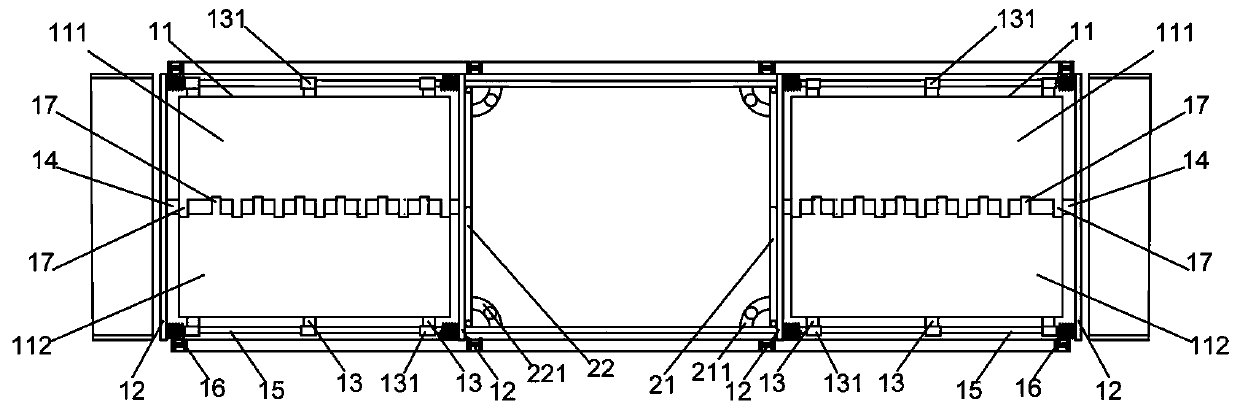

A large-area dense upper-reverse beam construction equipment

ActiveCN113482354BImprove construction efficiencyDirect control of import volumeForms/shuttering/falseworksBuilding material handlingArchitectural engineeringWorking environment

The invention discloses a large-area intensive upper-reverse beam construction equipment, comprising an outer ring beam beam body, an upper reverse beam side formwork assembly is hung on the outer ring beam beam body, and the upper reverse beam side formwork assembly is The corresponding surface is connected with a high-position walking mobile component. In the present invention, through the mutual cooperation of the designed upper reverse beam side formwork assembly, high-position walking moving assembly, working position control assembly, working position control assembly, and concrete light-receiving assembly, the concrete placing machine can be avoided. The beam and slab after pouring will have an impact, reduce the use of the tower, effectively improve the construction scope of the concrete placing machine, and improve the construction efficiency of the concrete placing machine. It is suitable for the working environment where the sky pump cannot be used on all floors, and the In the case of a large-scale lift-type placing machine, it can directly control the amount of concrete introduced in a unit time, avoid the phenomenon of too much or too little concrete introduction in the final stage, and effectively improve the efficiency of concrete pouring and light collection.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

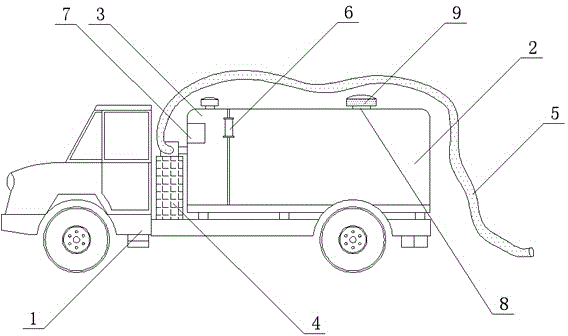

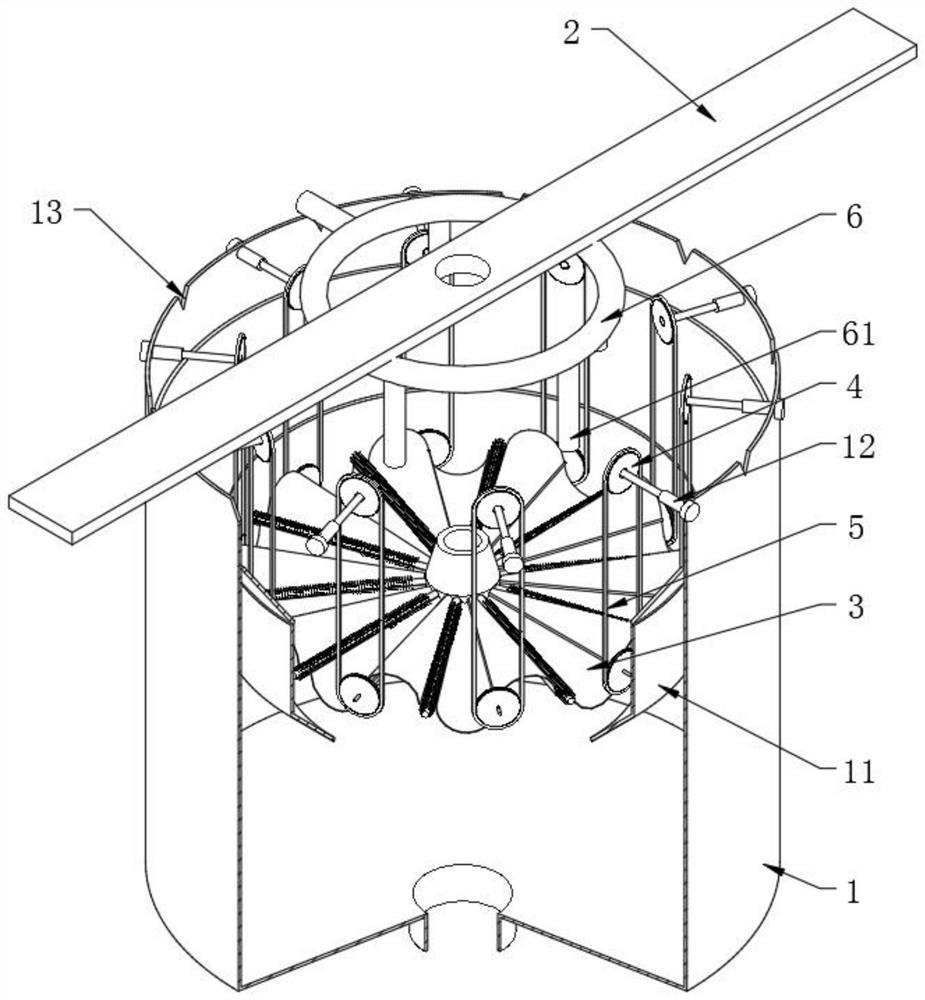

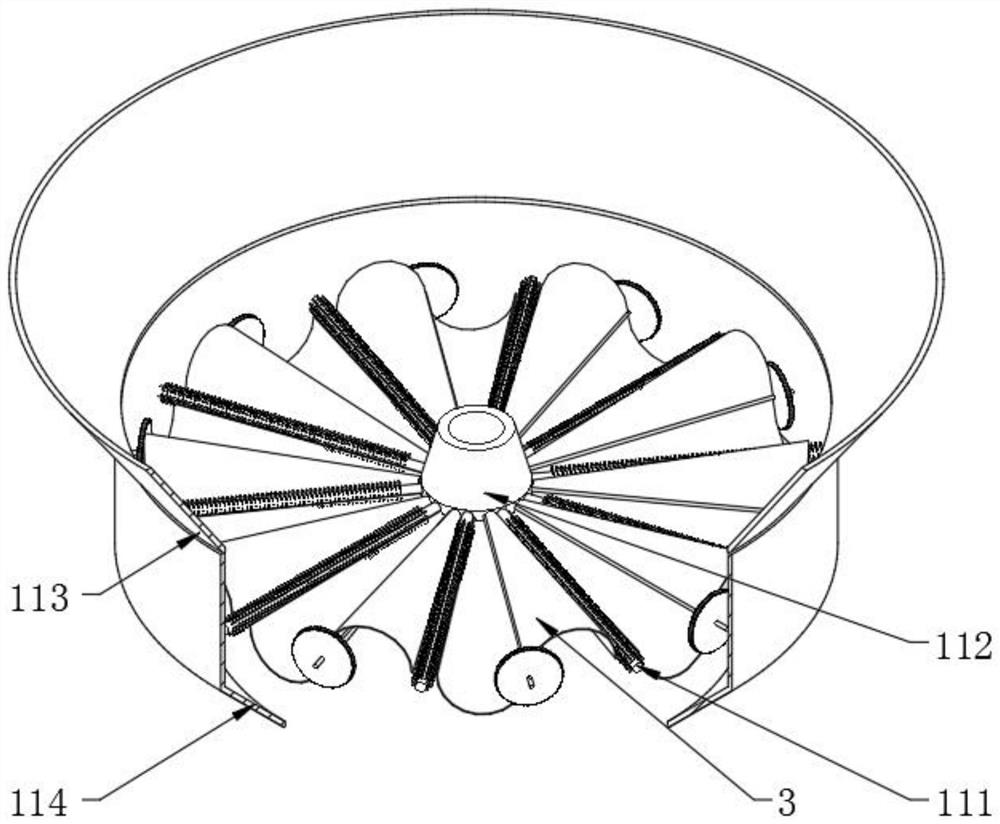

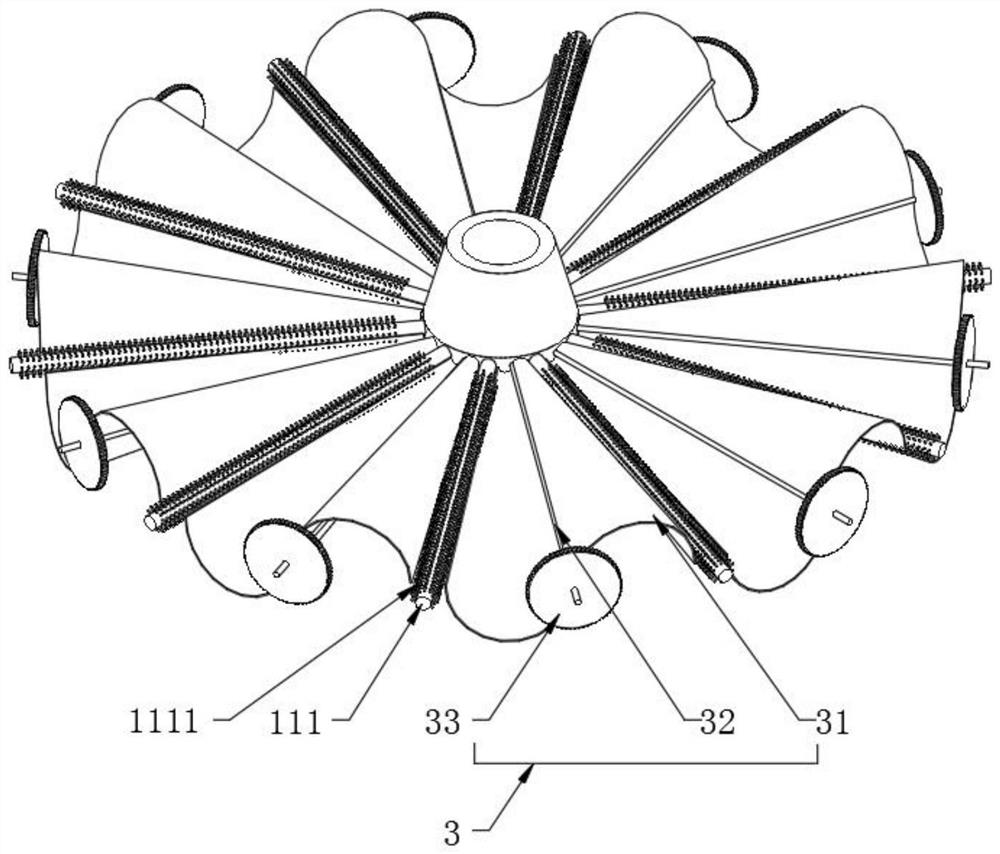

Sewer pumping drainage dredging device

A sewer pumping drainage dredging device comprises a vehicle body (1). A sewage tank (2) is fixed onto the vehicle body (1). The sewer pumping drainage dredging device is characterized in that a pressurizing bin (3) is arranged at the internal upper end of the sewage tank (2), a pressurizer (7) is mounted inside the pressurizing bin (3), a gas pressure balance port (8) is formed in the top of the sewage tank (2), a deodorization filter screen (9) is mounted at the gas pressure balance port (8), a sewage pump (4) is mounted on the outer side of the sewage tank (2) and connected with an air outlet of the pressurizing bin (3), and a suction inlet of the sewage pump (4) is connected with a pumping drainage dredging pipe (5). The pressurizing bin arranged inside the sewage tank can pressurize compressed gas of the sewage tank and the sewage pump, pouring and drainage of sewage in the sewage tank are accelerated, a sewer line can be dredged by the aid of large airflow, and the sewer pumping drainage dredging device has a compressed gas pressurizing auxiliary dredging function and has a good pumping drainage dredging effect on a long sewer.

Owner:钟名

An integrated sludge thickening tank

ActiveCN111661991BAccelerated Concentration ProcessingBlock upSludge treatmentSettling tanks feed/dischargeSludgeSewage

Owner:湖北众堃科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com