Sorting device realizing concentrated treatment of dismantling and draining for dry powder can

A centralized treatment and sorting device technology, which is applied to the surface coating liquid device, special surface, solid waste removal, etc., can solve the problems of long drainage process, affecting work efficiency, high work intensity, etc., and achieve faster pouring Speed, improve work efficiency, and handle high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

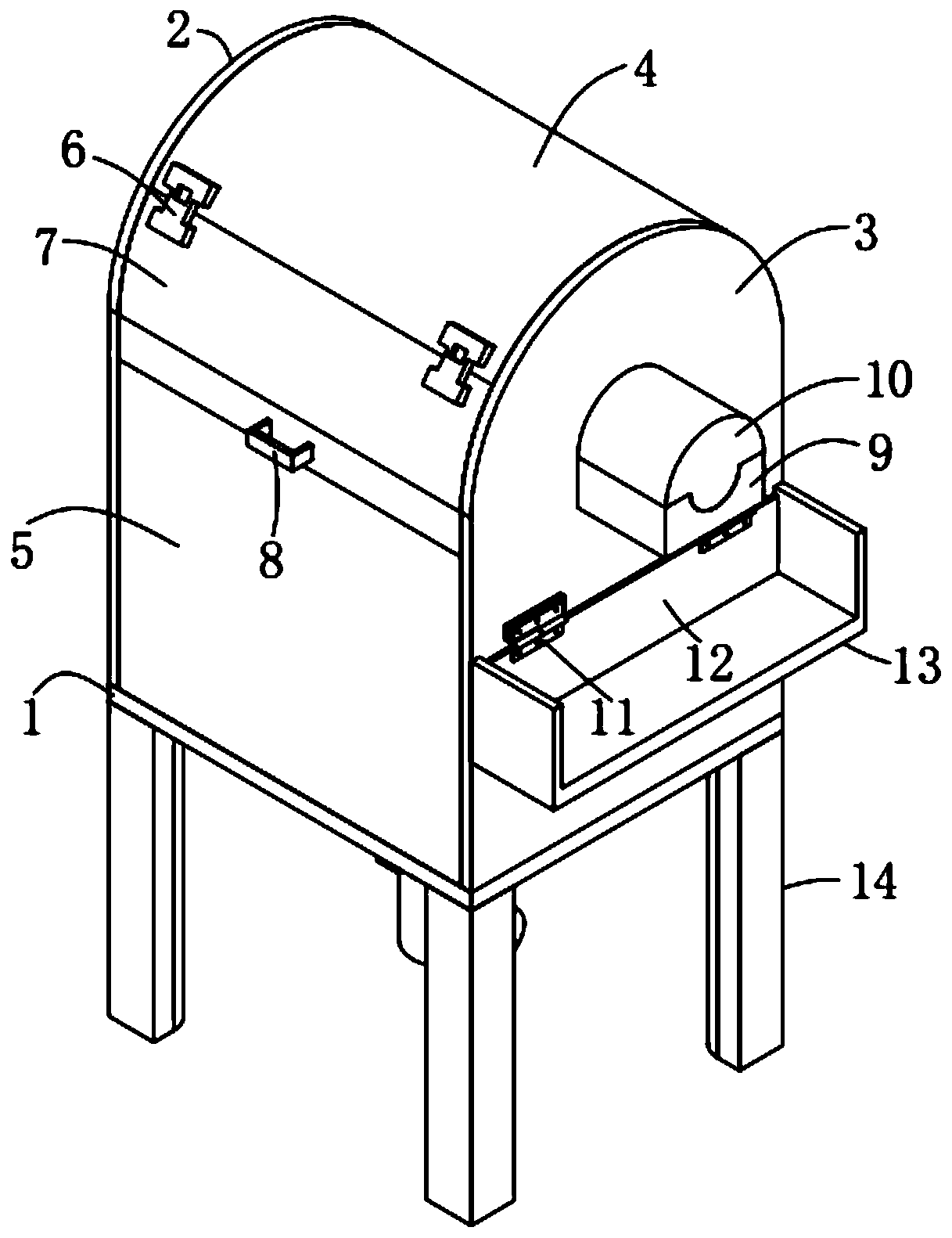

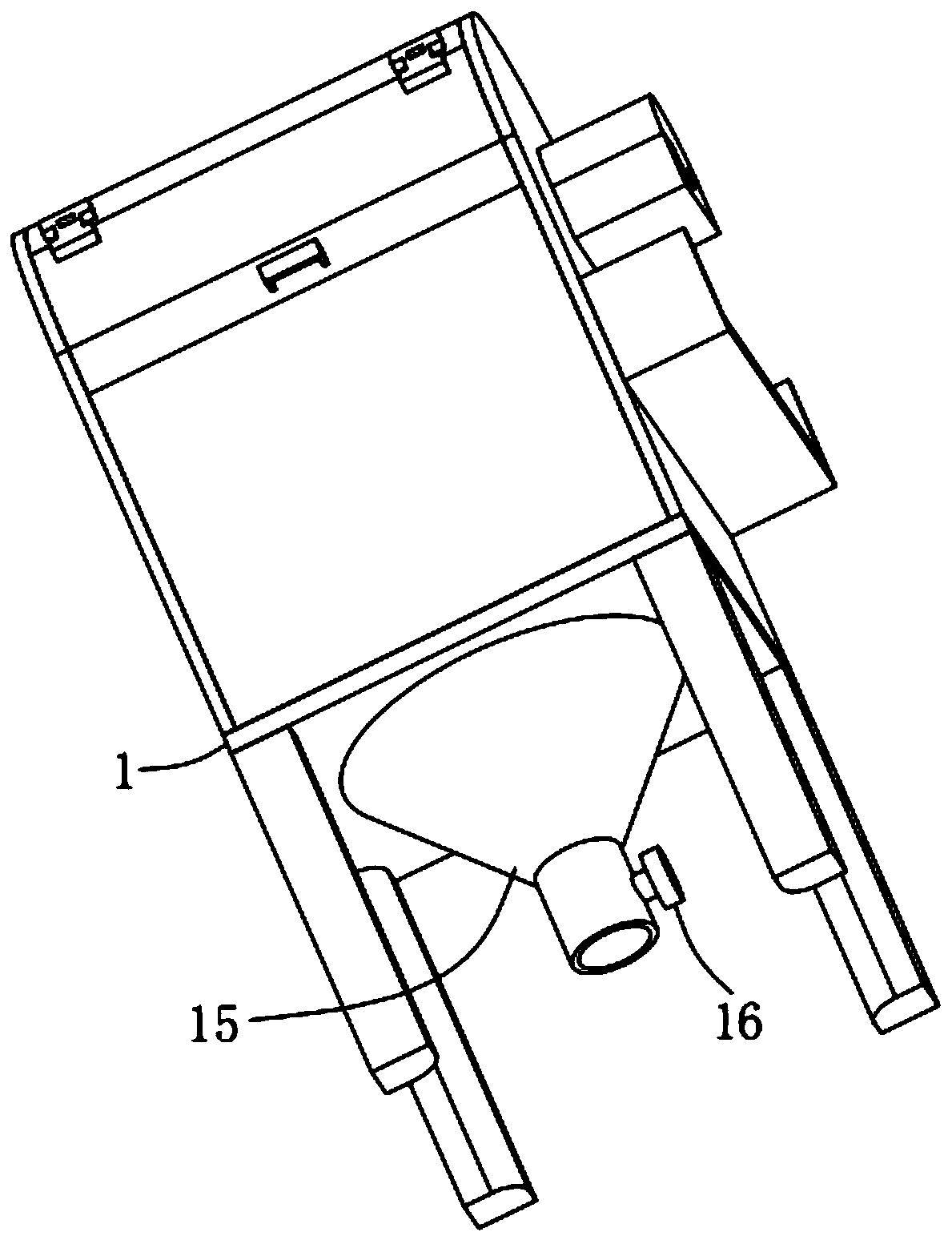

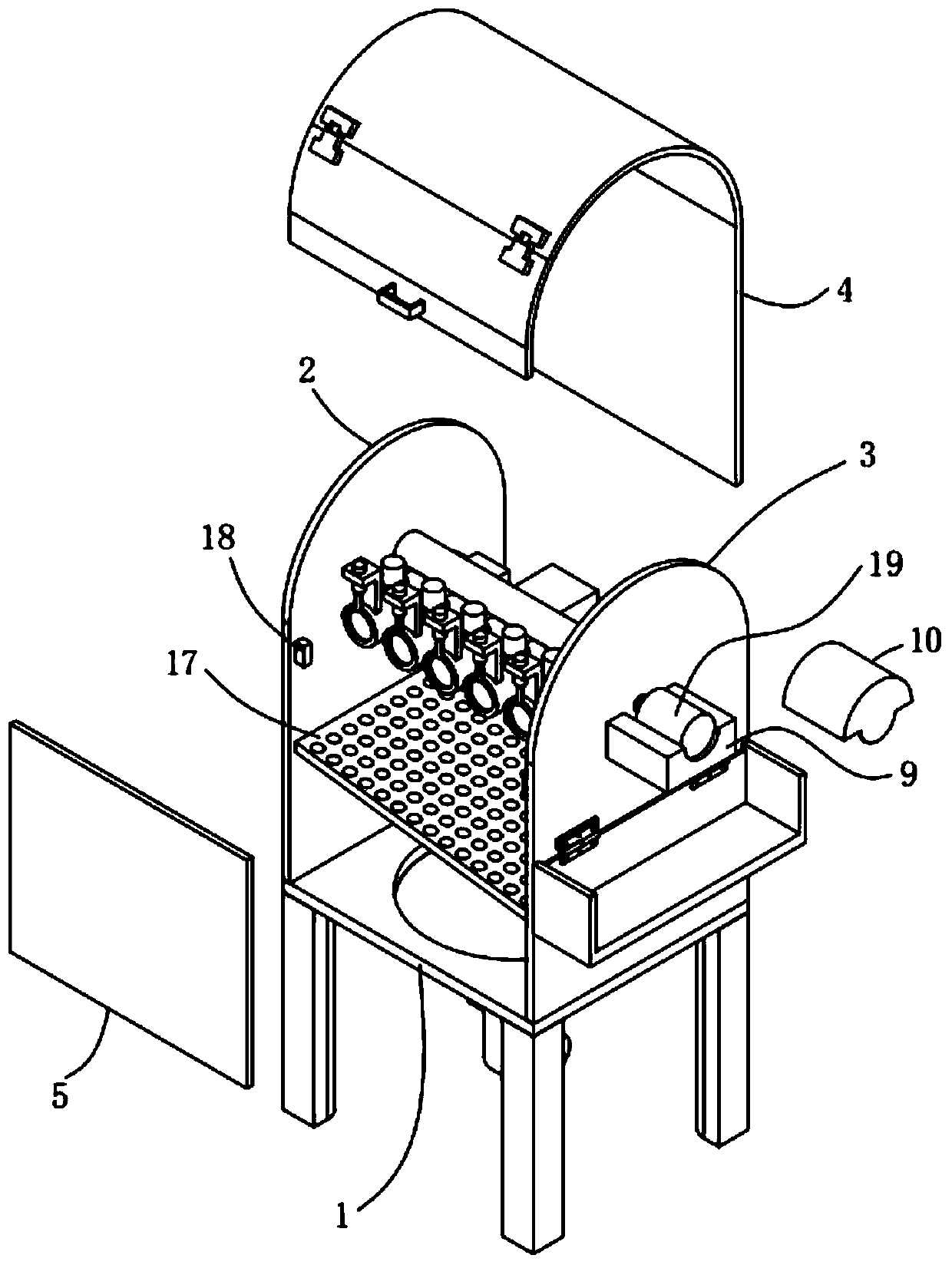

[0053] A sorting device for centralized processing of dry powder tanks, demolished and drained liquids, such as Figure 1-5 As shown, it includes a base plate 1, four legs 14, a first side plate 2, a second side plate 3, a front cover plate 5, a rear cover plate 4, a drive turning unit 37, a demolition liquid drainage unit 24, and a separation plate 17 And collecting bucket 15, described base plate 1 is a square base plate, and four described supporting legs 14 are all fixed and symmetrically installed on the bottom four corners of described base plate 1, and described first side plate 2 and described second side plate 3 fixedly installed on both sides of the upper part of the base plate 1 respectively, and the first side plate 2 and the second side plate 3 are arranged symmetrically, the front cover plate 5 is fixedly installed on the upper front part of the base plate 1, And the two sides of the front cover 5 are respectively fixedly connected with the first side plate 2 and...

Embodiment 2

[0076] The difference from Example 1 is that the inner surface of the collection bucket 15 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0077] Take the following raw materials and weigh them by weight: 20 parts of epoxy resin, 12 parts of calcium carbonate powder, 13 parts of copper oxide powder, 17 parts of polytetrafluoroethylene, 8 parts of talcum powder, 10 parts of graphite, 8 parts of acrylic emulsion, alcohol ester 2 parts of twelve, 2 parts of triethanolamine, 1 part of emulsified silicone oil and 30 parts of water;

[0078] S1. Add the weighed acrylic emulsion, alcohol ester dodecane, triethanolamine, emulsified silicone oil and water into the mixer and stir for 20 minutes at a stirring speed of 600r / min to prepare a mixed solution;

[0079] S2, adding epoxy resin, calcium carbonate powder, copper oxide powder, polytetrafluoroethylene, talc powder and graphite into the pulverizer and pulverizing until the pa...

Embodiment 3

[0085] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0086] Take the following raw materials and weigh them by weight: 24 parts of epoxy resin, 13 parts of calcium carbonate powder, 13 parts of copper oxide powder, 19 parts of polytetrafluoroethylene, 9 parts of talcum powder, 11 parts of graphite, 9 parts of acrylic emulsion, alcohol ester 3 parts of twelve, 3 parts of triethanolamine, 2 parts of emulsified silicone oil and 35 parts of water;

[0087] S1. Add the weighed acrylic emulsion, alcohol ester dodecane, triethanolamine, emulsified silicone oil and water into the mixer and stir for 25 minutes at a stirring speed of 650r / min to prepare a mixed solution;

[0088] S2, adding epoxy resin, calcium carbonate powder, copper oxide powder, polytetrafluoroethylene, talc powder and graphite into the pulverizer and pulverizing until the particle diameter of the material is not greater than 100nm, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com