Patents

Literature

38results about How to "Reduce on-site labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integral assembling type building system and installing method

InactiveCN105649360AImprove quality controlEasy to installBuilding material handlingDwelling buildingTime of usePrecast concrete

The invention belongs to the technical field of building engineering and particularly relates to an integral assembling type building system and an installing method. The integral assembling type building system is characterized by comprising prefabricated steel reinforced concrete combination columns, prefabricated steel reinforced concrete combination beams, prefabricated reinforced concrete slabs, a prefabricated light integral inner wall and a prefabricated concrete heat preservation outer wall which are assembled together. The building system has the beneficial effects that all the members are prefabricated in a factory, quality is controlled conveniently, and the construction difficulty caused by outdoor weather changes can be reduced. Moreover, splicing is carried out on site, and installing is safe, fast and convenient. The recycle rate of formworks is high, work for the formworks and frame pipes on site is avoided, the number of times of use and consumption of the formworks and frame pipes are reduced, on-site labor is saved, the on-site dust raise phenomenon is improved substantially, the influence on the environment is small, and environmental pollution is reduced.

Owner:SHANDONG YUANBO BUILDING TECH CO LTD

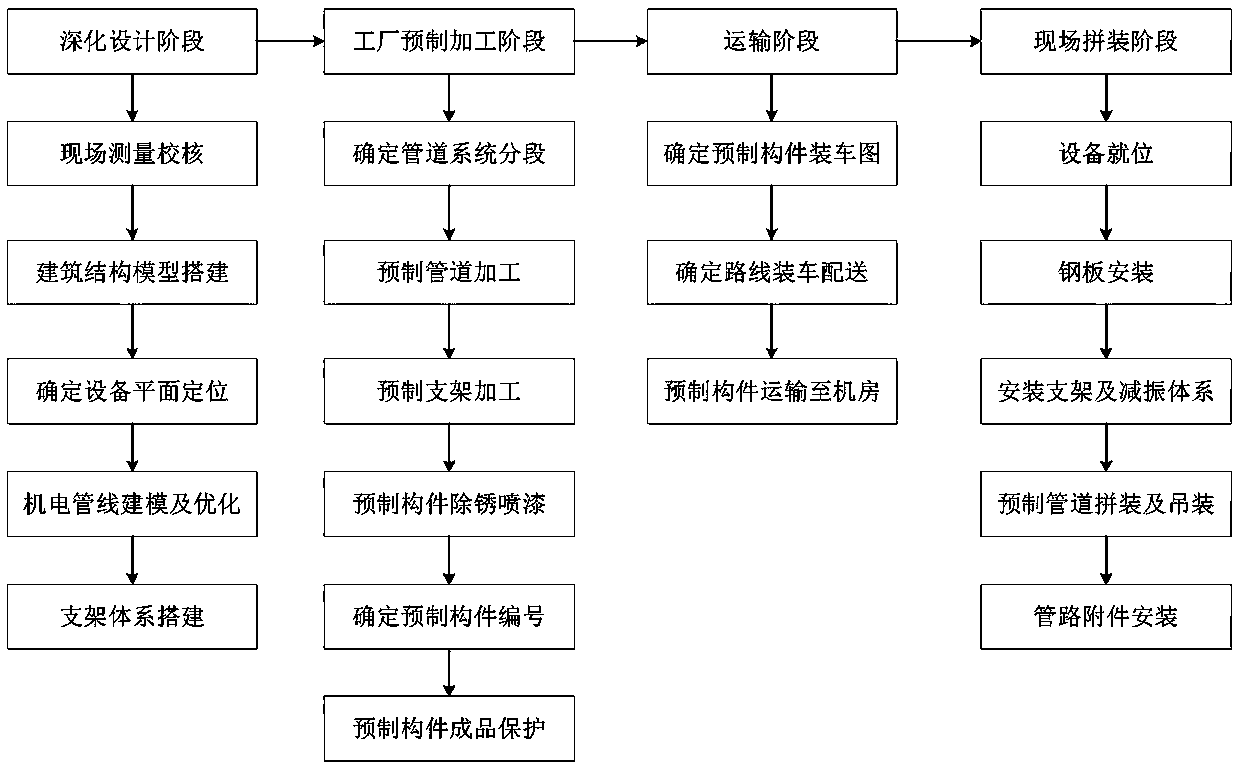

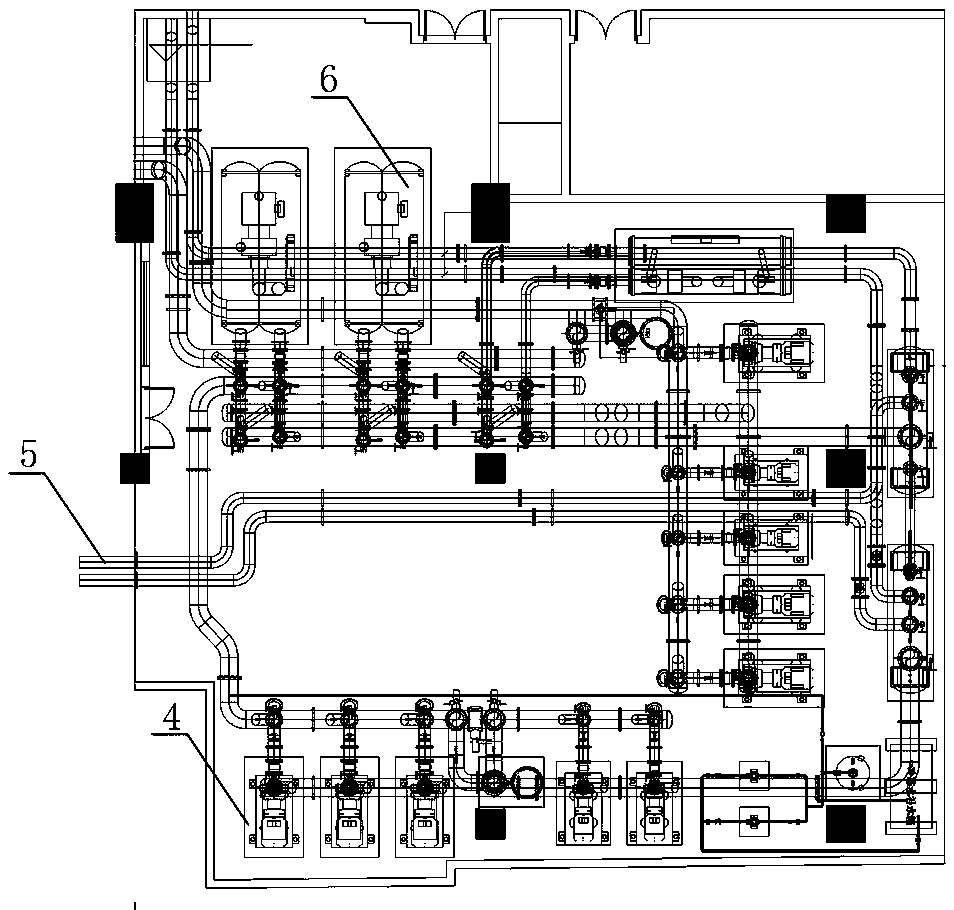

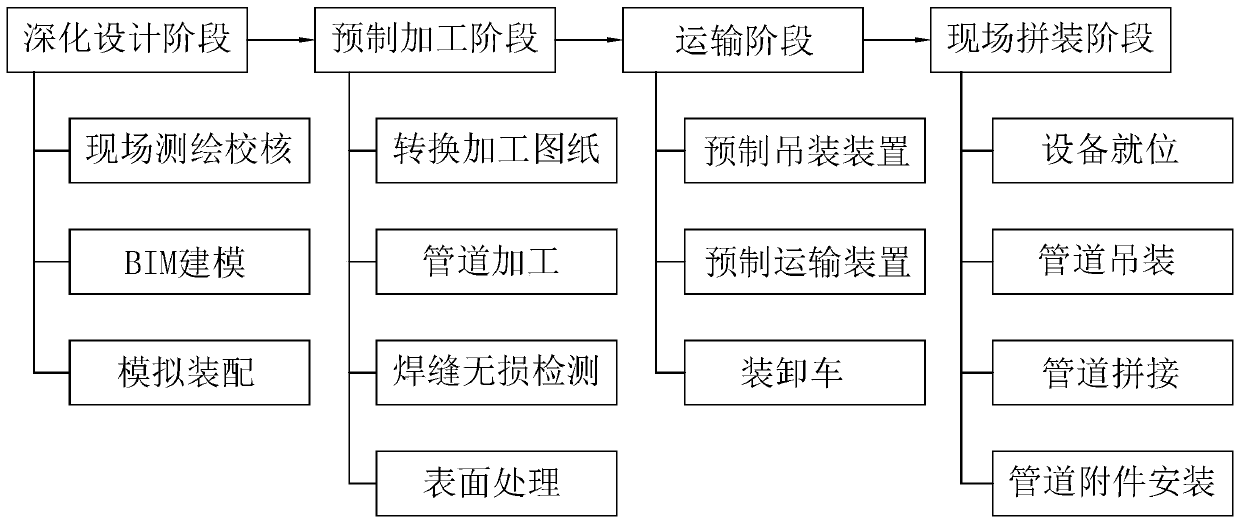

Refrigerating machine room assembly type construction method based on a BIM technology

ActiveCN109614719AEase of industrial productionEasy to transportGeometric CADDesign optimisation/simulationSystem maintenanceMachine

A refrigerating machine room assembly type construction method based on a BIM technology comprises four stages, namely a deepening design stage, a prefabrication machining stage, a transportation stage and a field assembly stage. According to the method, a designed construction drawing is combined with a construction site, electromechanical professions are comprehensively planned, civil engineering, curtain walls, decoration and other acceptance units are connected, and the problem of serious difficulty in construction and key areas are pre-judged. The method has the advantages that on-site construction is guided, engineering quality is improved, guarantee is provided for engineering progress, project cost is saved, completion data is input into the building information model finally, system maintenance and use during project operation are facilitated, and expected functions of buildings are achieved finally and added value is increased. Compared with a traditional refrigerator room construction method, the construction method adopting the prefabricated assembly refrigerator room has remarkable advancement and advantages in the aspects of construction period, quality, safety, manufacturing cost and other technical and economic effects.

Owner:THE FIRST CONSTR ENG COMPANY LTD OF CHINA CONSTR SECOND ENG BUREAU

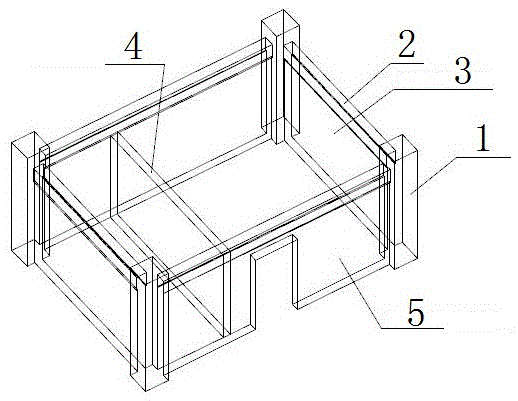

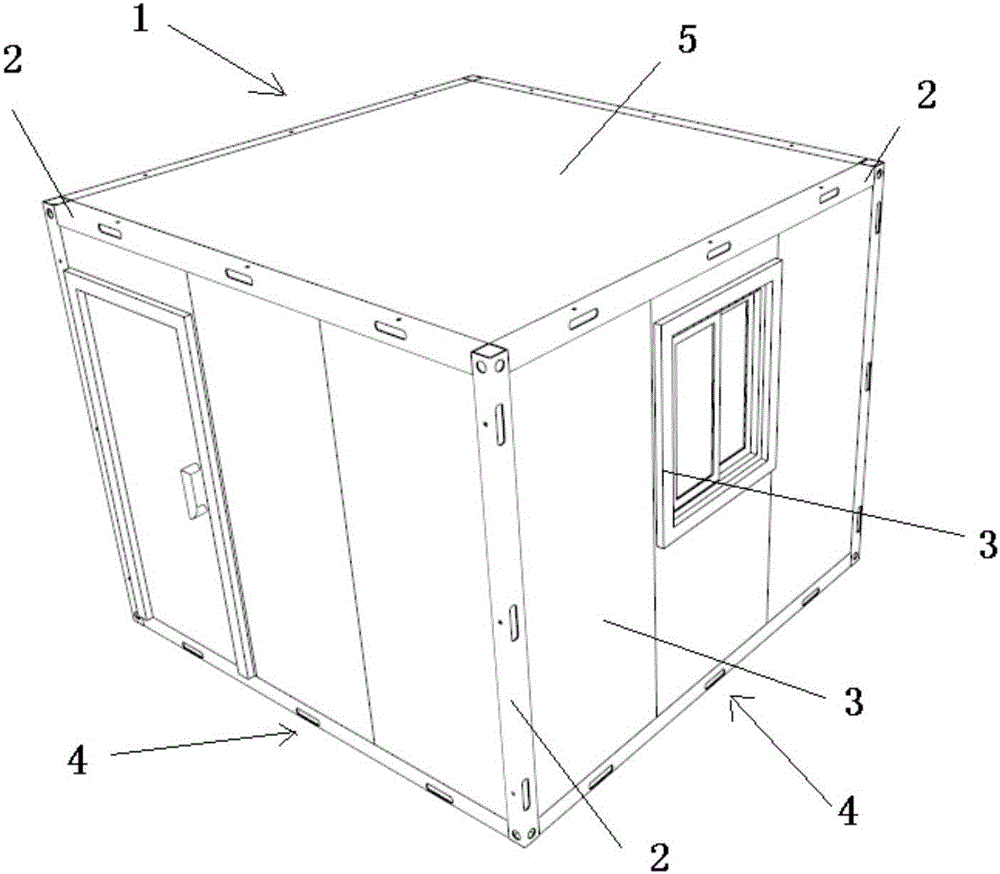

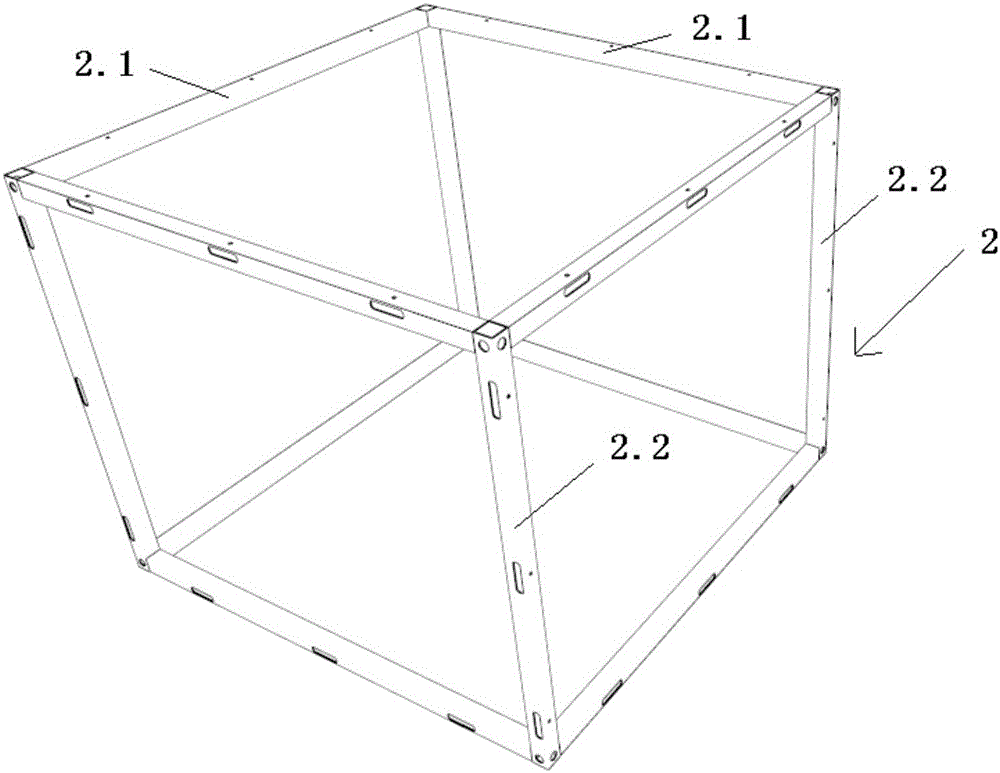

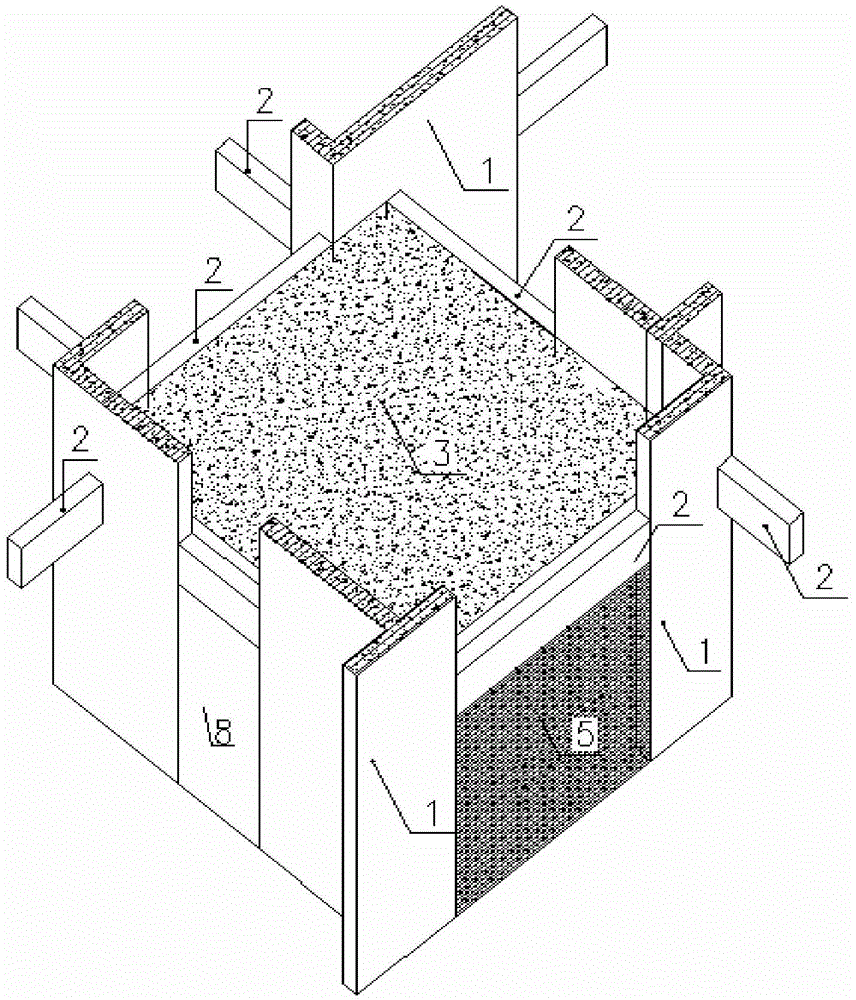

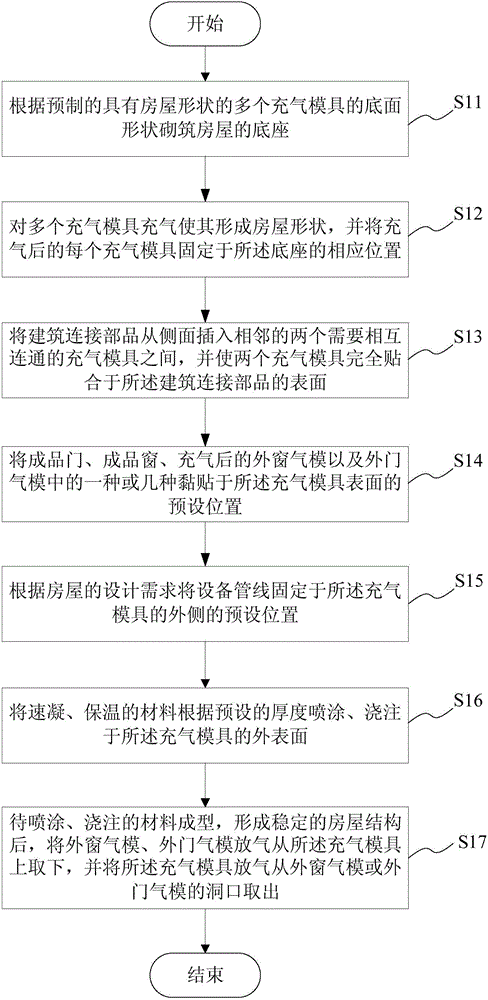

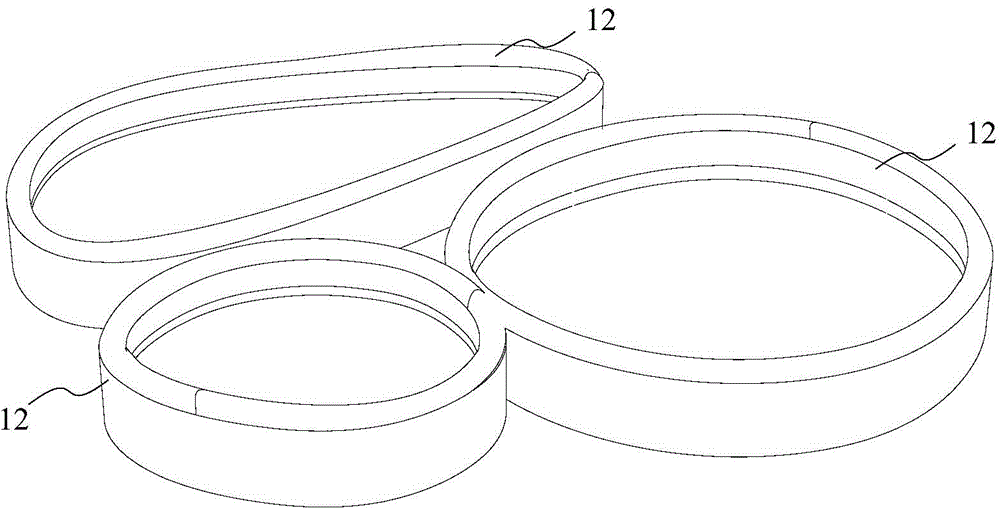

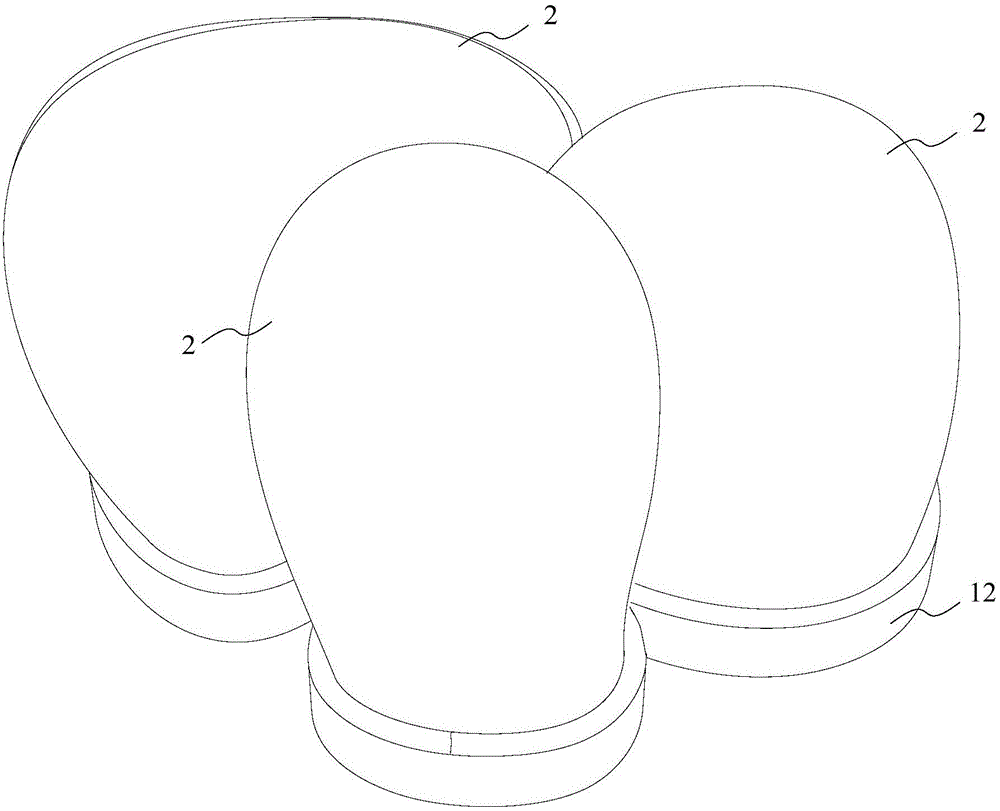

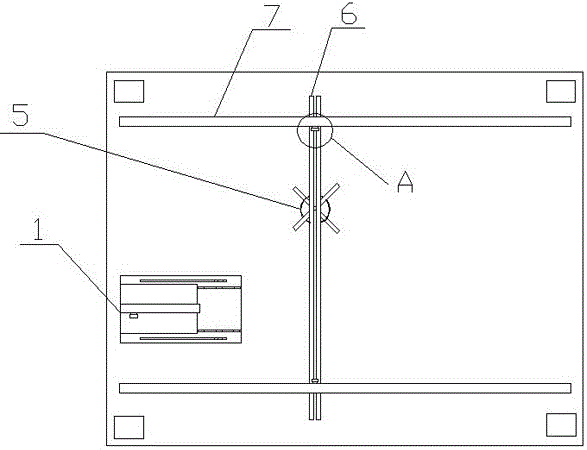

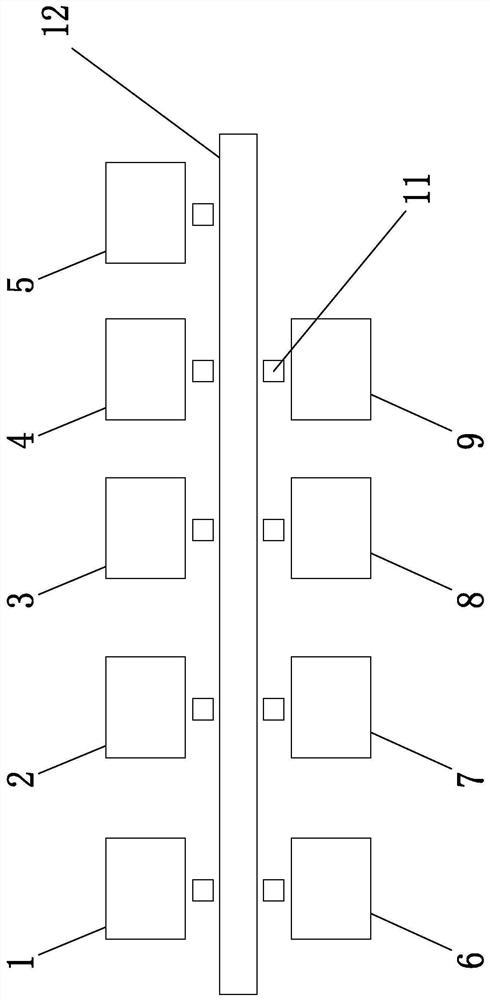

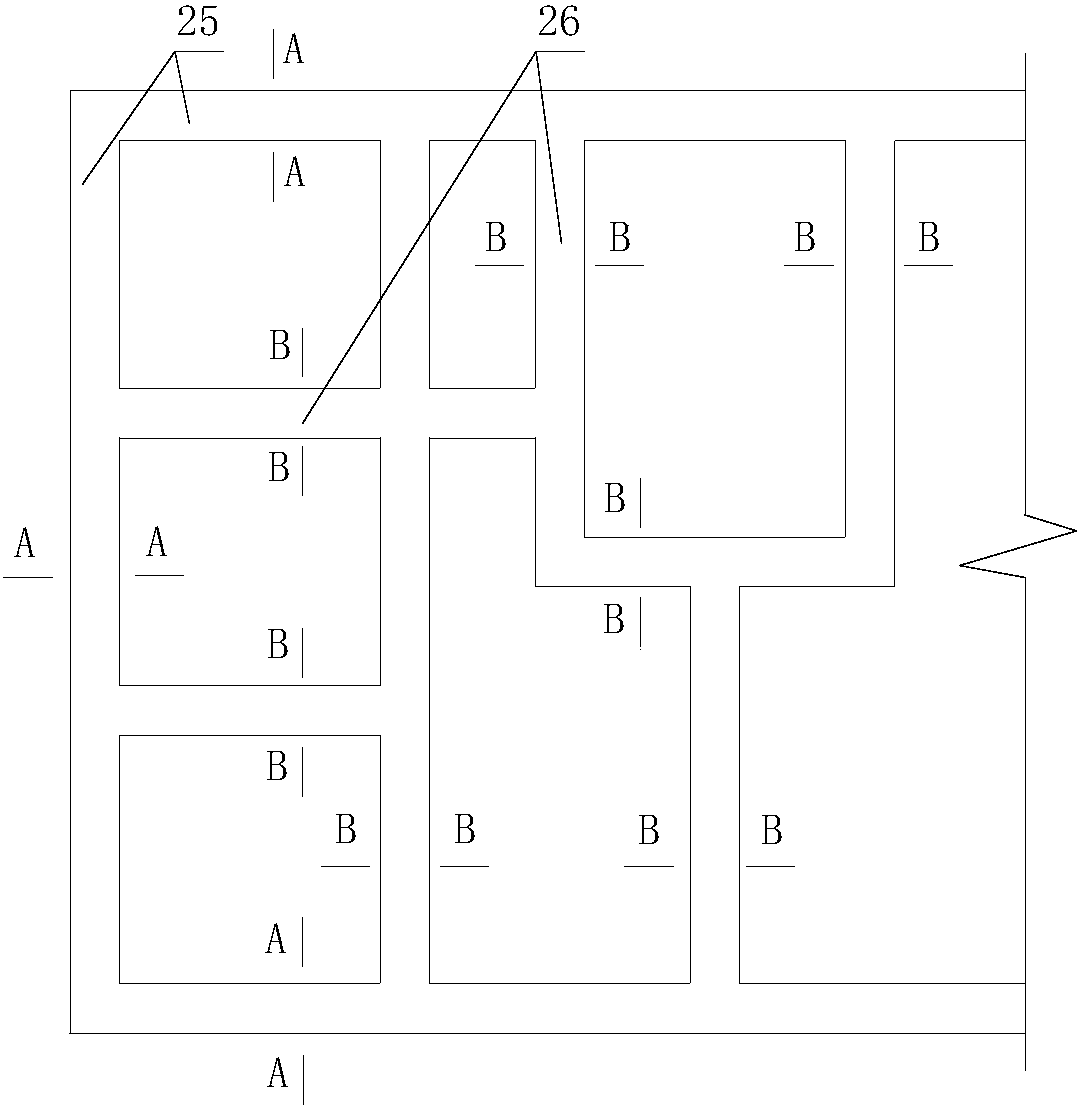

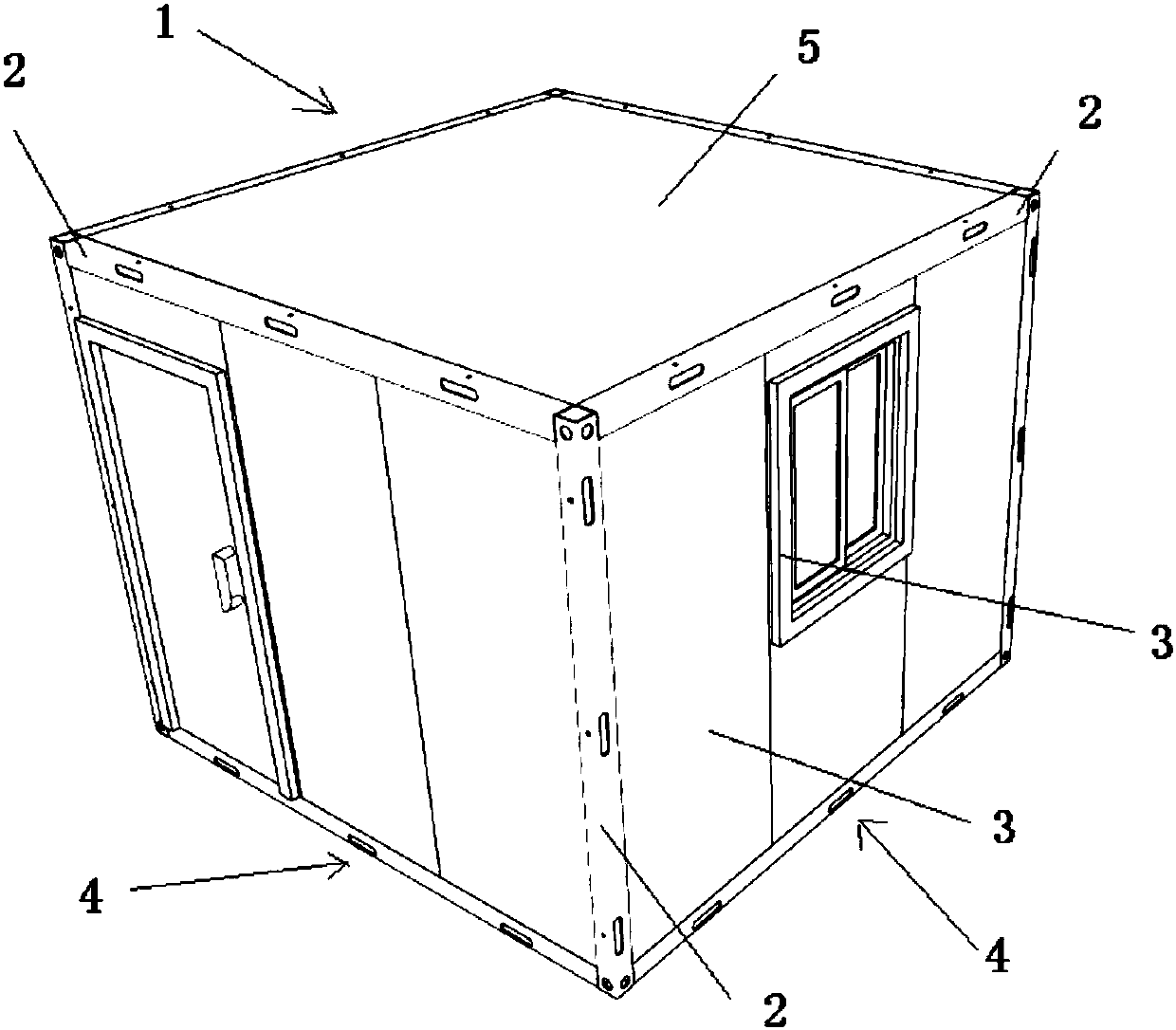

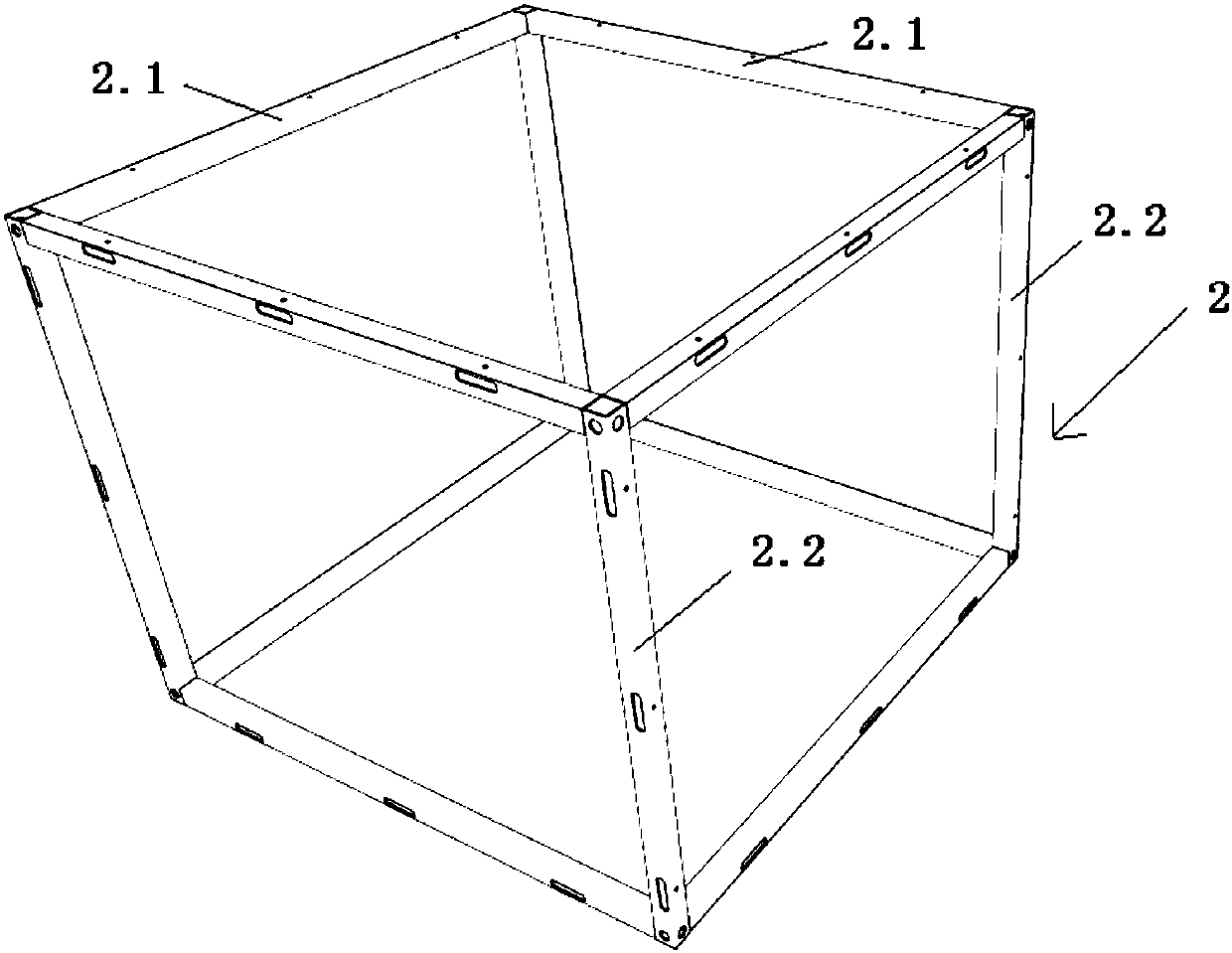

Modularized-assembly house system

The invention discloses a modularized-assembly house system. The modularized-assembly house system is characterized in that the modularized-assembly house system comprises one or more houses (1) formed by modularized production; the houses (1) within two layers extend horizontally infinitely; each house (1) comprises a steel-structure frame (2), thin-walled cold-formed steel system wallboards (3), a thin-walled cold-formed steel system floor slab (4) and a thin-walled cold-formed steel system roof (5); the steel-structure frame (2) comprises cross beams (2.1) and stand columns (2.2), the upper cross beams (2.1) are parallel to the lower cross beams (2.1), and the stand columns (2.2) are connected vertically with the cross beams (2.1); eight corners formed by encircling of the cross beams (2.1) and the stand columns (2.2) are connected through connectors (7). The modularized-assembly house system has the advantages that the defects of inconvenience in assembly and disassembly, poor combination and unsuitability for complex environments in the prior art are overcome, and disassembly, interchange and addition or reduction are achieved.

Owner:武汉迈特绿色建筑科技股份有限公司

Electric transmission line project foundation prefabricated construction method

ActiveCN108149703AReduce field construction proceduresReduce the amount of field construction workCeramic shaping apparatusFoundation engineeringTerrainMovable type

The invention provides an electric transmission line project foundation prefabricated construction method. The electric transmission line project foundation prefabricated construction method comprisesthe steps of a construction preparation stage, foundation prefabricated construction, prefabricated foundation transporting, excavation of a foundation pit and construction of an under layer, foundation hoisting in position, foundation backfilling and the like. The construction preparation stage comprises the steps of field selection, manufacturing of a movable type construction platform, manufacturing of a template, manufacturing of a suspension center pre-buried piece, hoisting of a steel wire rope and the like. The foundation prefabricated construction comprises the steps of preparation, mounting of inserting angle iron, rib braiding and template erecting, pouring, foundation identification, transferring and maintenance of the prefabricated foundation, quality detection of raw materials and concrete and the like. The prefabricated field in the construction method is fixed, the reshipment quantity of the construction raw materials, equipment and instruments are reduced, wear and loss in the reshipment process of the materials and the instruments are reduced, interference of outside factors is eliminated, resource investment is reduced, the influence of terrain to construction iseliminated, the operation frequency and time in the foundation pit are decreased, construction potential safety hazards are lowered, and the labor condition is improved.

Owner:POWER CHINA HENAN ENG CO LTD

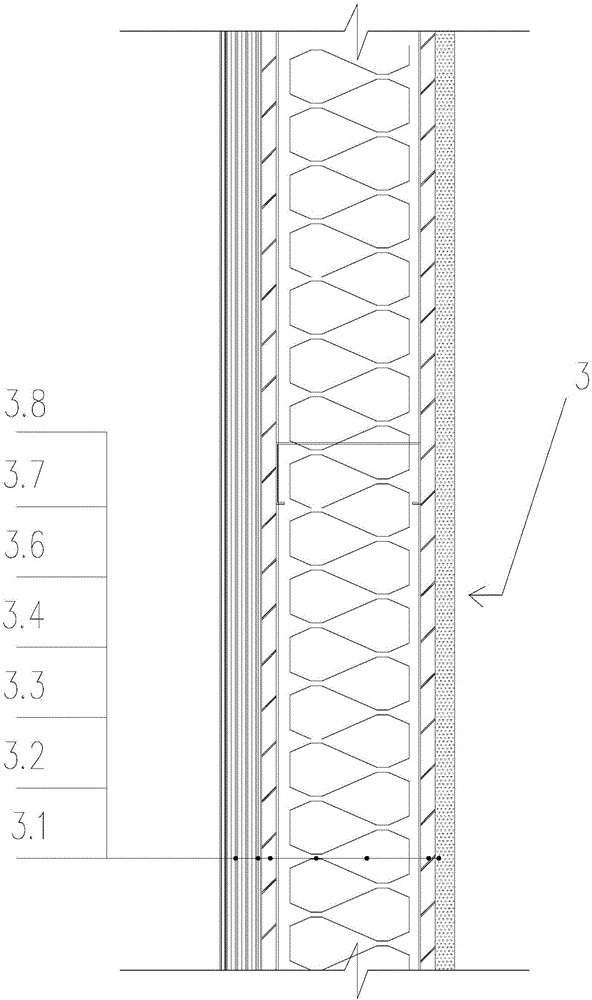

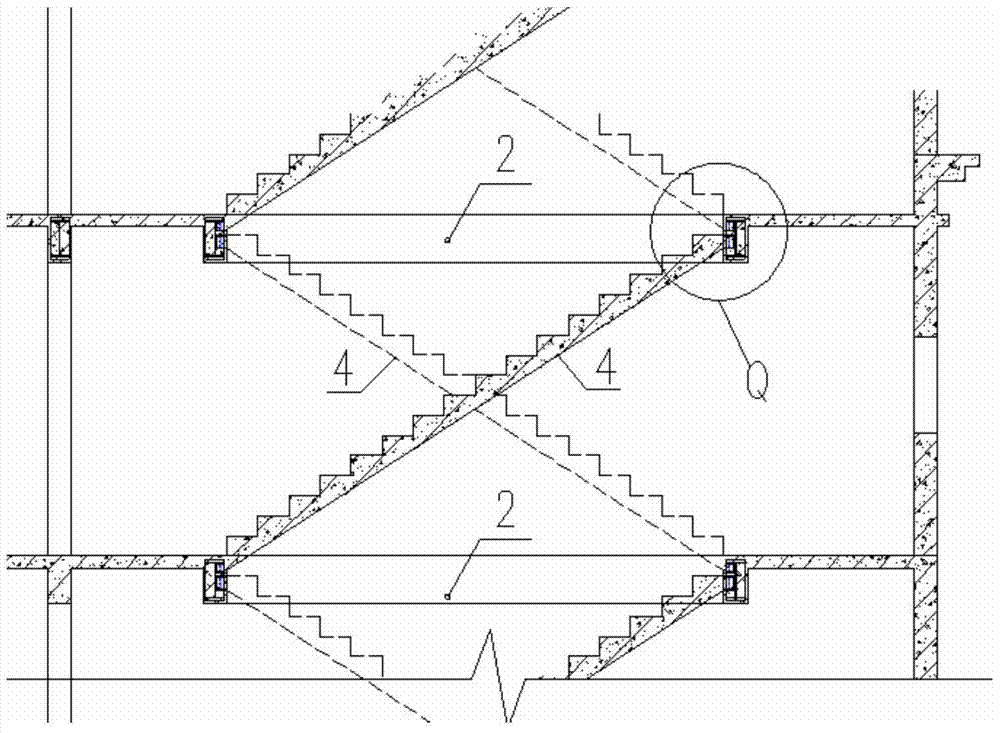

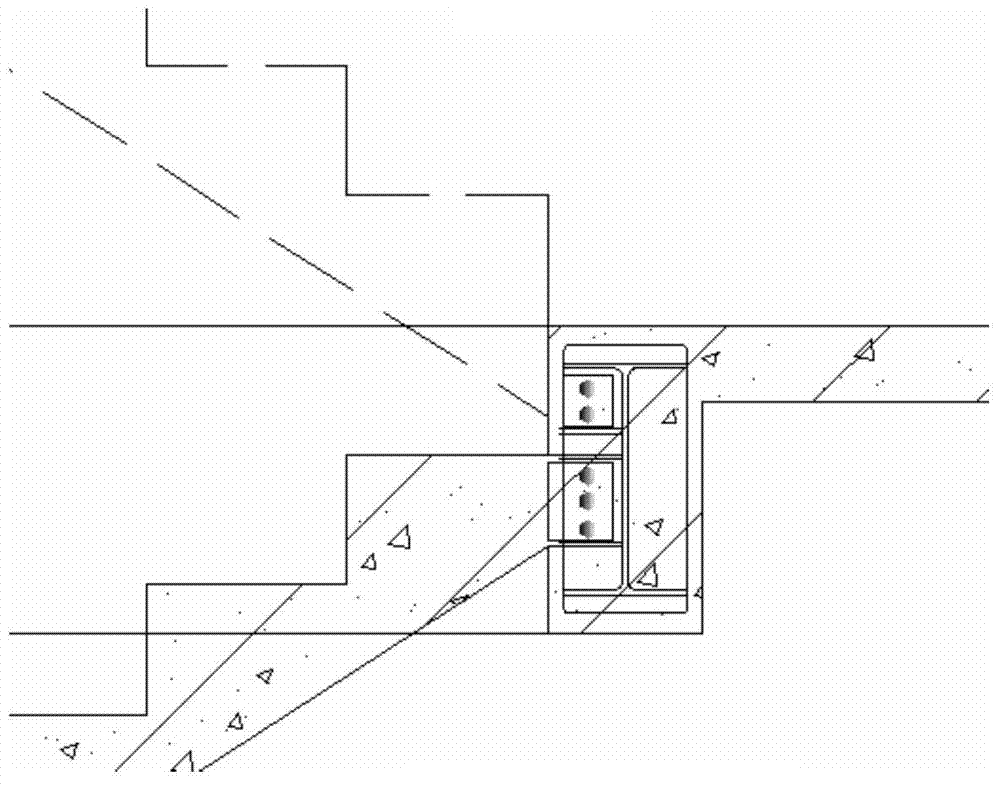

Fabricated building of pre-assembling structure of prefabricated section steel concrete shear wall

ActiveCN105089178AImprove quality controlEasy to installWallsBuilding material handlingFoam concreteConcrete beams

The invention provides a fabricated building of a pre-assembling structure of a prefabricated section steel concrete shear wall. The building is provided with a structure preformed in a factory, and the preformed structure comprises section steel concrete shear walls, prefabricated section steel concrete beams, steel bar truss concrete slabs, prefabricated reinforced concrete stairs, light masonry partition walls, and prefabricated foam-concrete outer walls. The invention further provides a mounting method of the fabricated building of the pre-assembling structure of the prefabricated section steel concrete shear wall. The fabricated building disclosed by the invention is characterized in that all components are prefabricated in the factory, so that the quality of the components is convenient to control, and construction difficulties caused by the change of outdoor weather can be reduced. The fabricated building is assembled on site, and safe, rapid and convenient to mount; the recycling rate of templates is high, work about templates and tube frames is omitted on side, the use and the consumption of the templates and the tube frames are reduced, on-site workers are saved, and the phenomenon of on-site raise dust is greatly improved, so that the influence on environment is small, and the environmental pollution is reduced. The fabricated building disclosed by the invention is suitable for various houses and buildings, such as high-rises, small high-rises, garden houses and villas.

Owner:重庆欧冠钢结构有限公司

Fabricated construction method of air-conditioning plant room

InactiveCN110469147AEase of industrial productionKeep clean and tidySpecial buildingBuilding material handlingNon destructiveEngineering

The invention discloses a fabricated construction method of an air-conditioning plant room. The fabricated construction method includes a design deepening phase, a prefabrication processing phase, a transportation phase and an on-site assembly phase. The design deepening phase includes the steps that on-site surveying and mapping are performed, and a plant room drawing is checked; BIM is performedbased on the plant room drawing; and a model is decomposed, and simulation assembly is performed. The prefabrication processing phase includes the following processes that a pipeline segment design drawing is converted into pipeline processing drawings, and the pipeline processing drawings are divided according to technological processes of cutting, grouping and welding; the pipeline processing drawings are imported into processing equipment, cutting, grouping and welding treatment is performed on pipelines, and the pipelines are assembled in sequence; non-destructive inspection of pipeline weld seams is performed; and surface treatment is performed on the pipelines. The fabricated construction method of the air-conditioning plant room can solve the problems that one-time installation inplace of complex pipelines construction is difficult, the construction efficiency is low, and the construction accuracy is poor.

Owner:北京方能机电有限公司

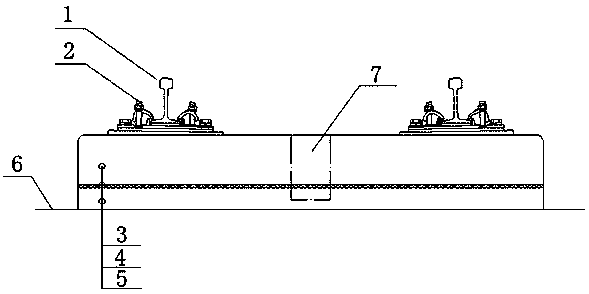

3D (three-dimensional) printing stack forming ballast bed elevation adjusting method

InactiveCN107938440AReduce on-site workloadReduce on-site laborBallastwayRailway track constructionNumerical controlMathematical model

The invention discloses a 3D printing stack forming ballast bed elevation adjusting method. The 3D printing stack forming ballast bed elevation adjusting method comprises, according to a base poured according to a gradient and line adjusting drawing and a track construction drawing, which are designed according to line through measurement and tunnel section output, and a prefabricated part arrangement plan, sectionally performing base surface elevation measurement to establish a base surface elevation three-dimensional map mathematical model; measuring the flatness of the lower surface of every prefabricated part, and establishing a lower surface flatness three-dimensional mathematical model of every prefabricated part; based on design and practical mathematical models, producing 3D printing input files, and layer-by-layer printing materials onto the surface of the base or the prefabricated parts through numerical control 3D printing equipment. Between a base assembling layer and the prefabricated parts, elastic buffer layers different in thickness are arranged to adjust the elevation of a ballast bed to meet the requirements of tracks on directional, horizontal and height smoothness and meanwhile a prefabricated part adjusting surface can meet the requirement that the prefabricated parts can be directly assembled on the base. The 3D printing stack forming ballast bed elevationadjusting method is rapid in construction speed and high in precision and is a key technical breakthrough of green track manufacturing.

Owner:GUANGXI SANWEI RAIL MANUFACTURING CO LTD

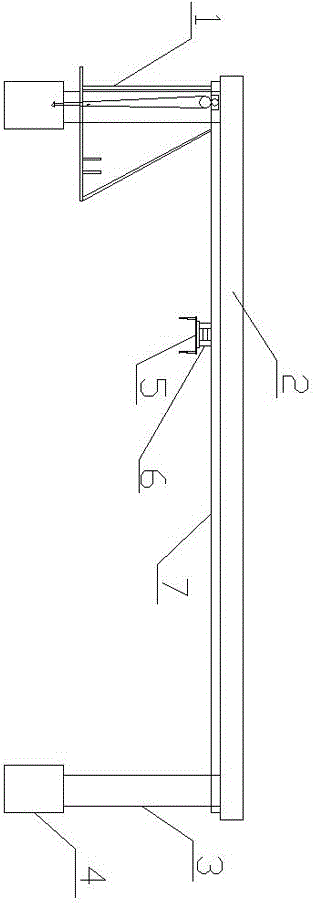

Assembling type automatic assembling platform for building

ActiveCN106245919AReduce generationReduce pollutionBuilding material handlingCranesSteel frameEnergy consumption

The invention provides an assembling type automatic assembling platform for a building. The assembling type automatic assembling platform for the building comprises a steel frame, supporting columns and a hydraulic lifting device; the steel frame is of a rectangular shape; the supporting columns are installed on the hydraulic lifting device, and the four supporting columns are installed at the four corners of the steel frame; two fixing trusses are installed on the lower side of the steel frame; the fixing trusses are of an I-shaped steel structure, and the two fixing trusses are in parallel; two horizontal transporting trusses are installed under the two fixing trusses; a short truss is further installed below the steel frame; and a vertical transporting device is installed below the short truss and fixed to the steel frame through four connecting rods. The assembling type automatic assembling platform for the building has the beneficial effects that the hoisting work of assembling type prefabricated parts for the building can be efficiently and precisely completed, and the problems that a traditional hoisting construction method is low in efficiency and high in energy consumption in the construction process are solved.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

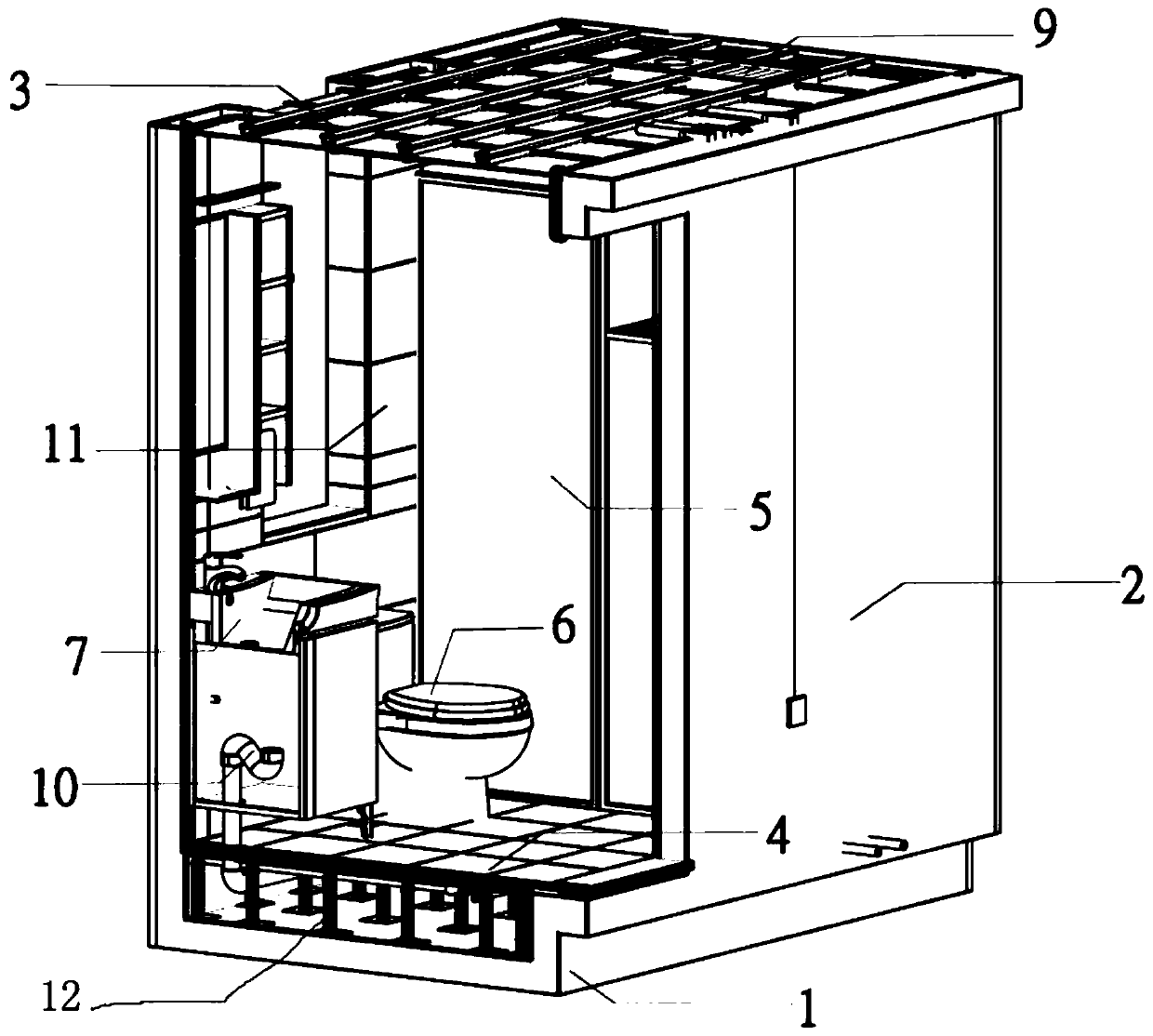

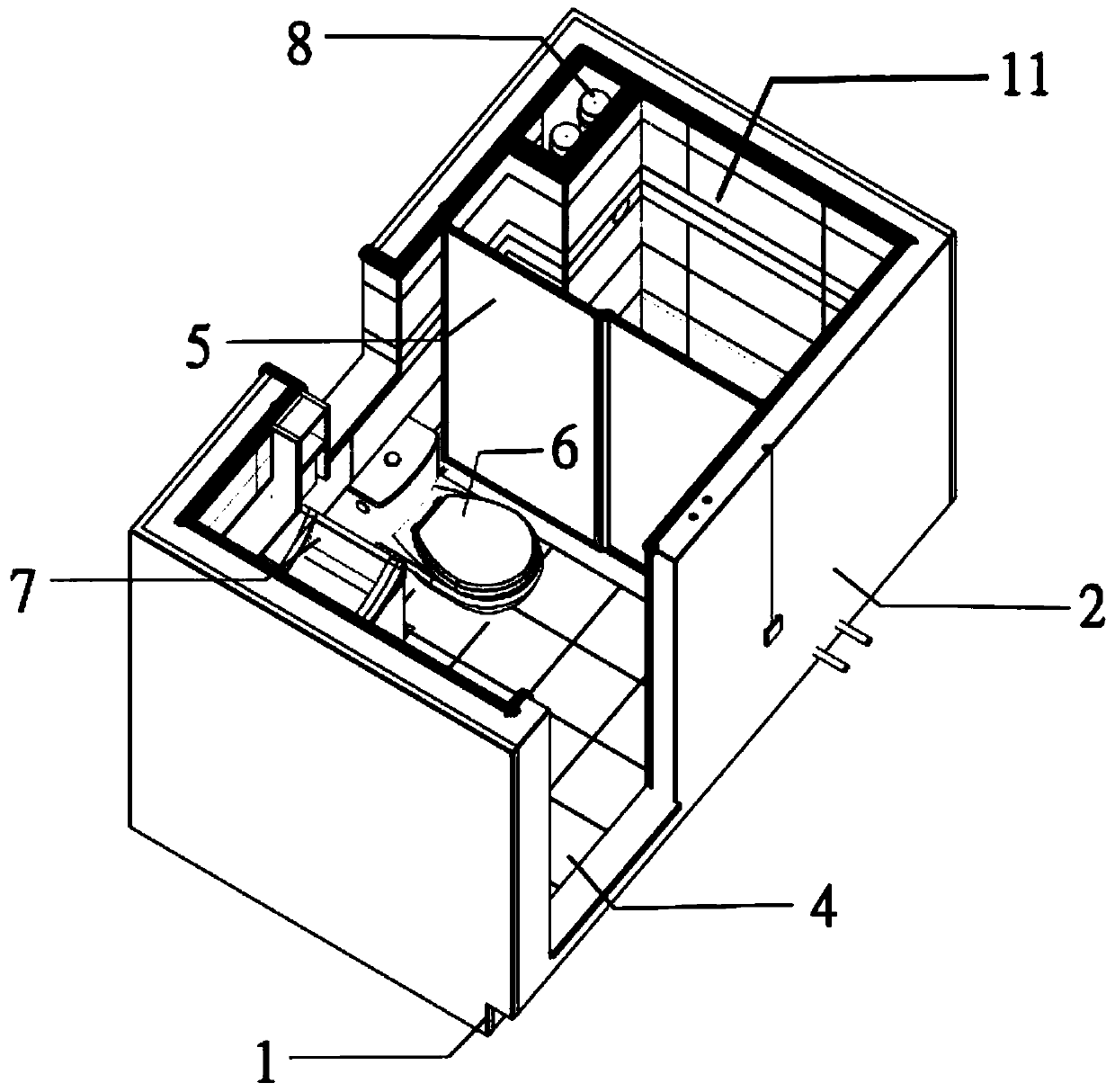

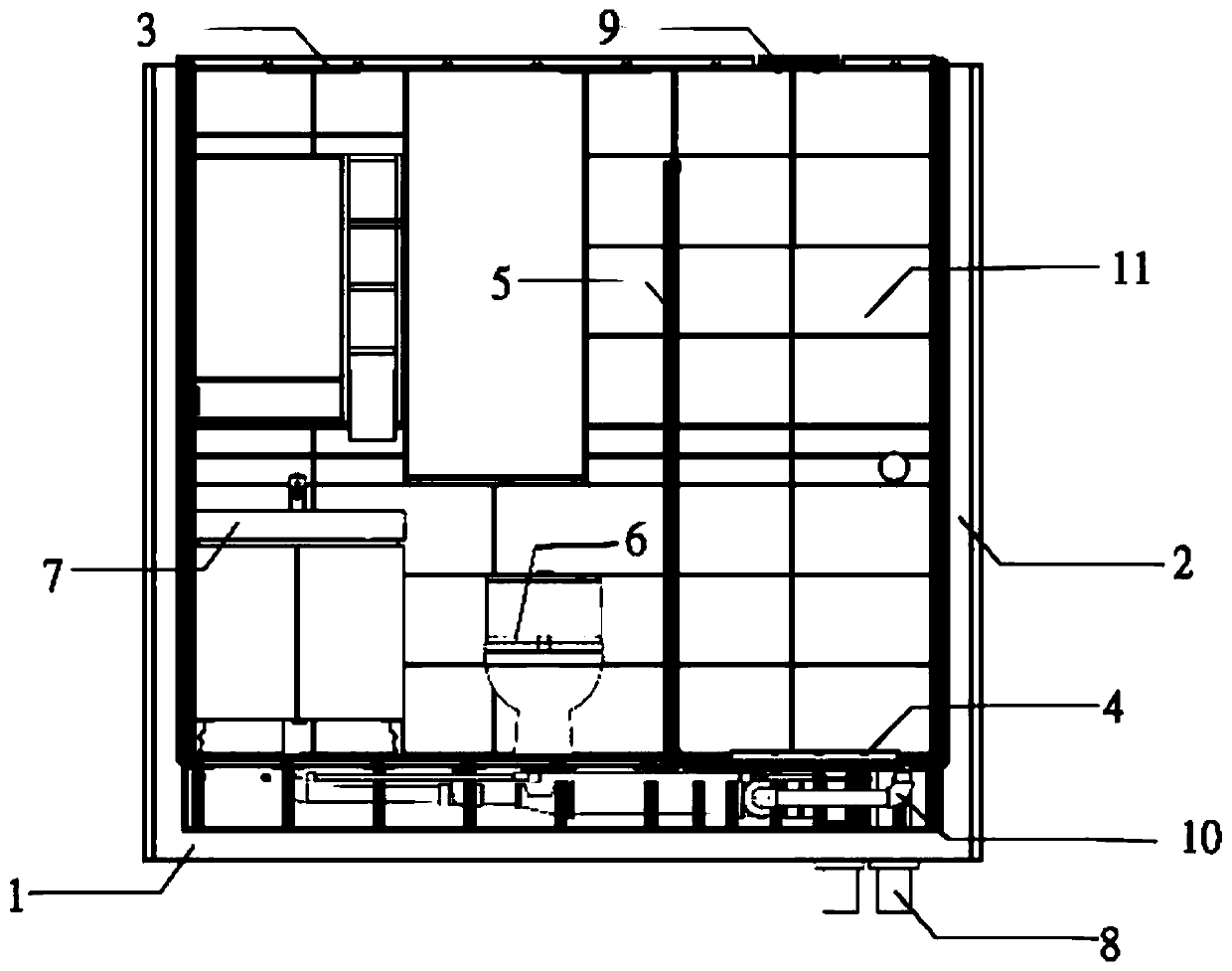

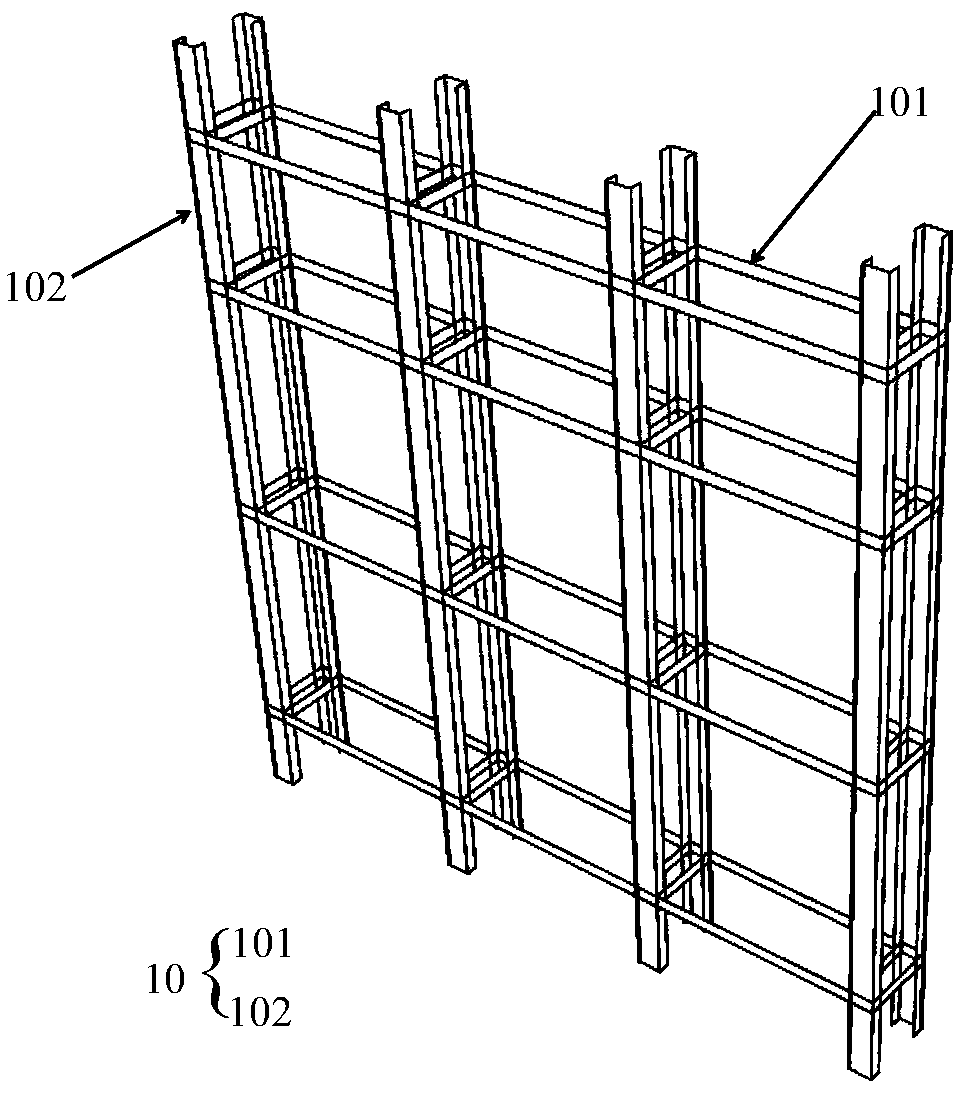

Structure, pipeline, heat preservation and decoration integrated assembly type toilet

PendingCN110159006AImprove integrityHigh strengthDomestic plumbingSpecial buildingBathroom EquipmentSteel bar

The invention discloses a structure, pipeline, heat preservation and decoration integrated assembly type toilet. The integrated assembly type toilet comprises a toilet body, wherein the toilet body isof an integrated structure formed by light-weight aggregate concrete and reinforcing steel bars in a pre-casting manner, a waterproof chassis is arranged in a cavity of the toilet body, and the waterproof chassis divides the toilet body into a wall body and a caisson located at the lower end of the wall body. The inner wall of the wall body is paved with shingles, a top cover is arranged at the top of the wall body, and water supply pipes and wire pipes are pre-embedded in the wall body; bathroom equipment which communicate with the water supply pipes is installed on the waterproof chassis and / or the shingles, and a sewer pipe which communicates with the bathroom equipment and a drainage pipe which communicates with the sewer pipe are arranged in a cavity between the bottom of the caissonand the waterproof chassis; and the lower end of the top cover is provided with a bathroom appliance which is connected with wires in the wire pipes. According to the structure, pipeline, heat preservation and decoration integrated assembly type toilet, the problems that for the structure, pipelines, heat preservation and decoration of a traditional toilet, the workload of field operation is large, the quality is difficult to guarantee, and the work efficiency is low can be solved, and the assembly rate of buildings is improved.

Owner:HUNAN CONSTR ENG GRP COR +1

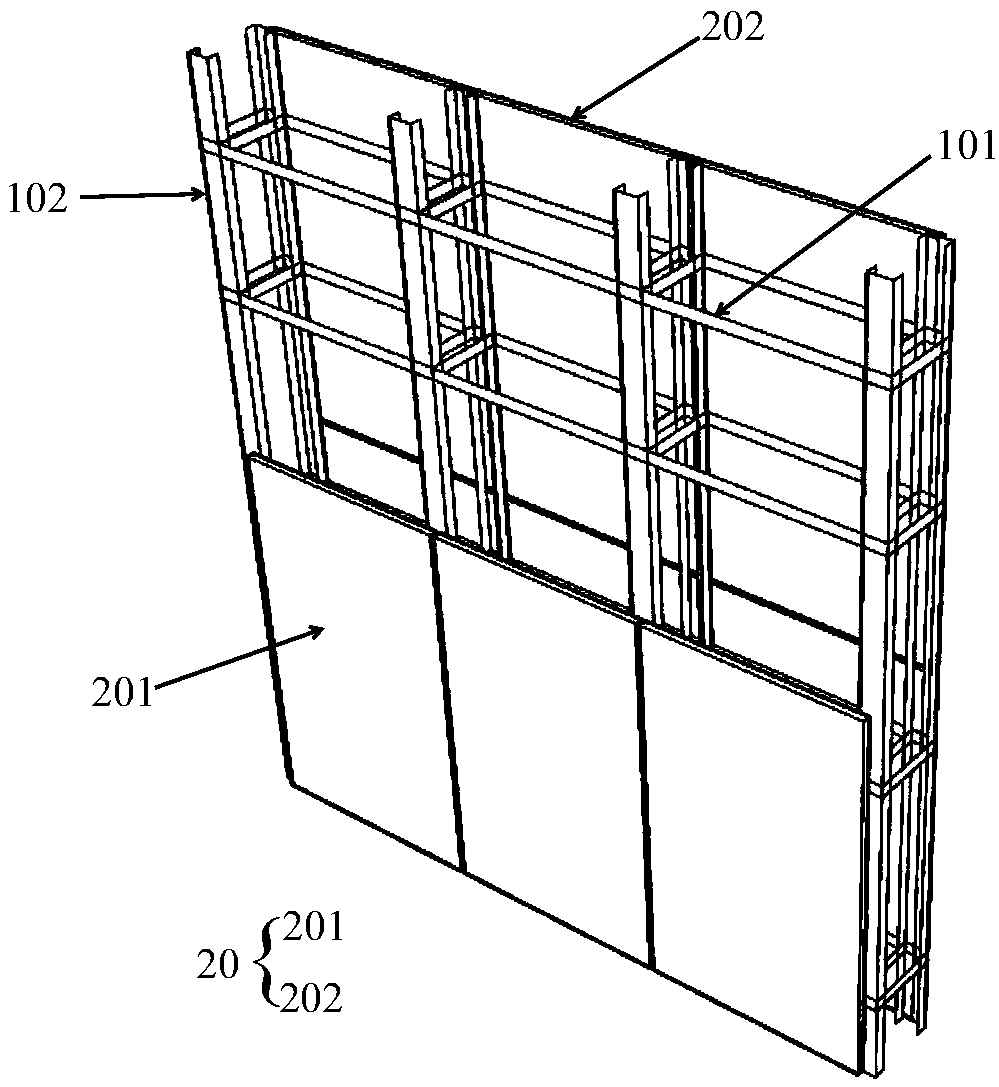

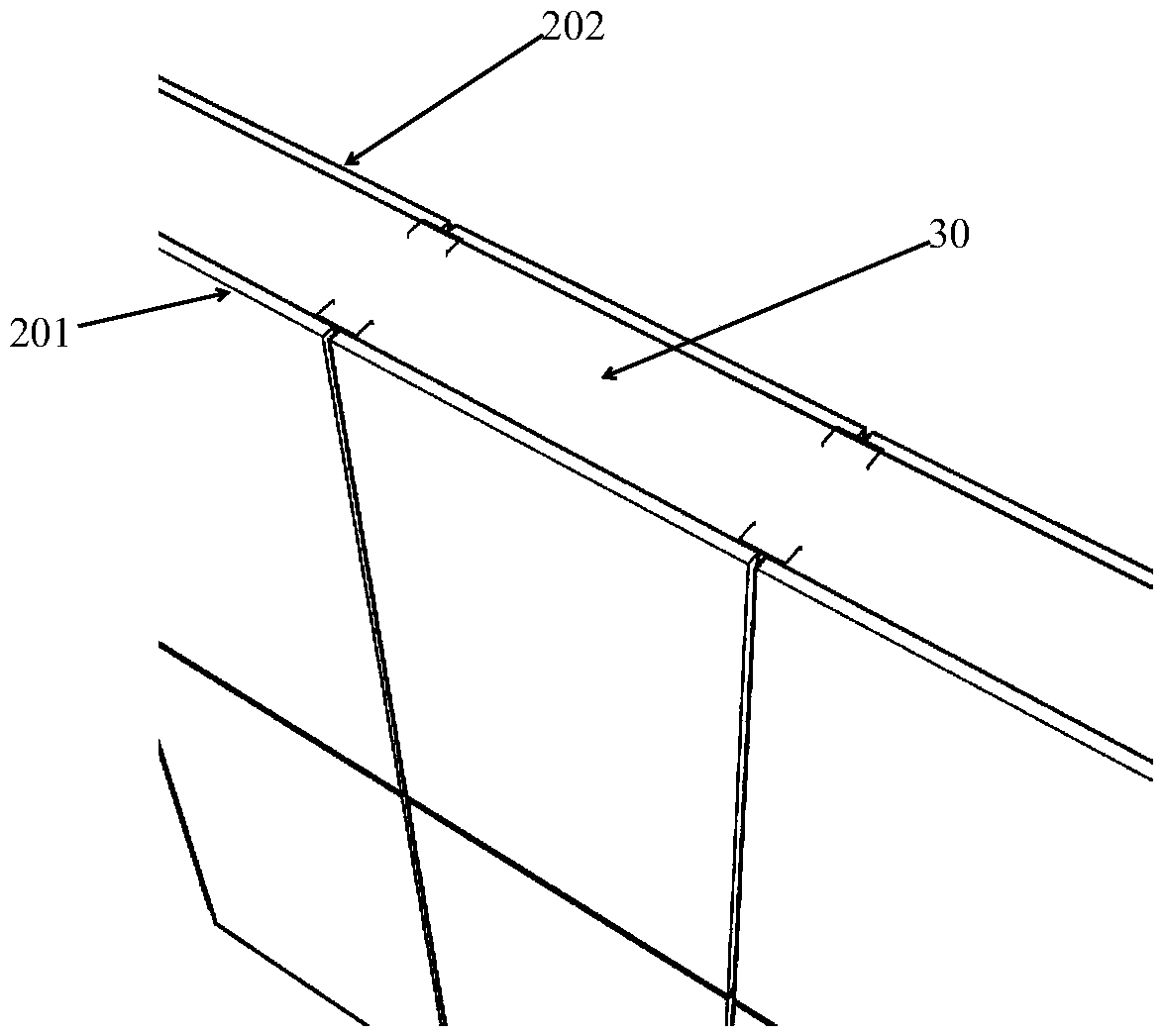

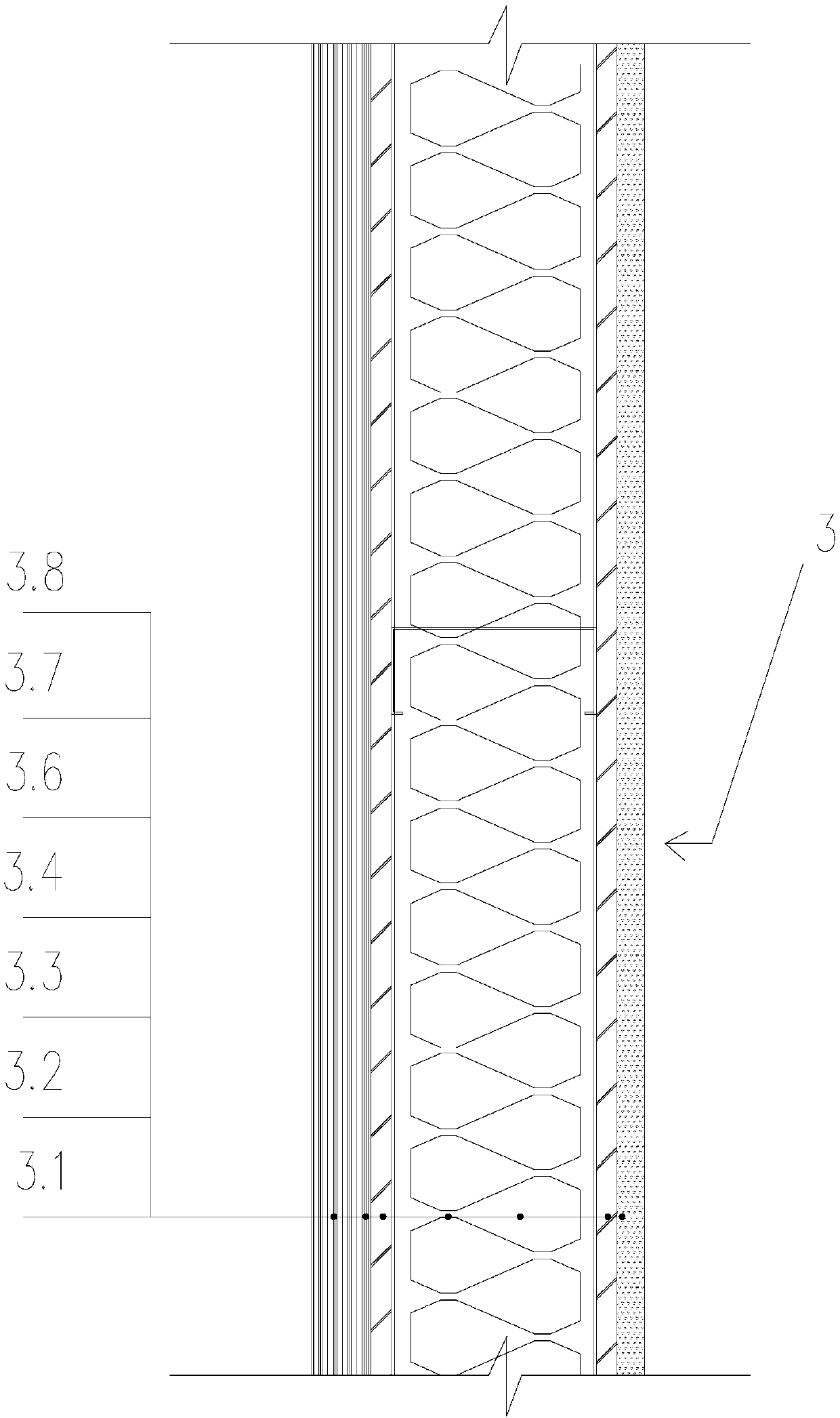

Fabricated compound wall

The invention provides a fabricated compound wall. The fabricated compound wall has a light steel structure as the skeleton, and the inner side and the outer side of the fabricated compound wall are nailed with fabricated slabs and can be poured with light insulating cement-based materials. Therefore, the fabricated compound wall is light in construction and installation as the steel structure andmeanwhile solves the problems of poor fireproof and antiseptic performance and small structural rigidity of steel structures; besides, plant fabrication of the prefabricated slabs can save field manual labors, the prefabricated slabs serving as a mouldless and support-free system can accelerate field pouring of the light insulating cement-based materials, avoid transportation of large fabricatedconcrete components, save engineering costs and meet the economic conditions in rural areas.

Owner:HEZHOU UNIV +1

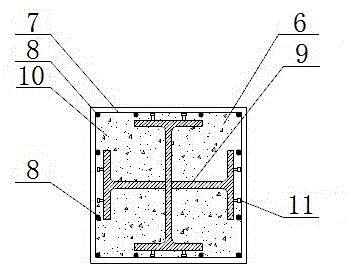

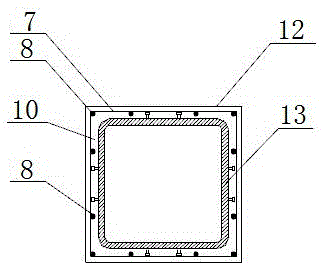

Assembly type concrete air duct for underground engineering and construction method thereof

InactiveCN106836286APositive and beneficial technical effectsAvoid hard-to-fix problemsArtificial islandsUnderwater structuresEngineeringPrecast concrete

The invention discloses an assembly type concrete air duct for underground engineering. The assembled concrete air duct for underground engineering comprises an air duct base plate, an air duct side wall and an air duct roof plate, wherein the air duct bottom plate consists of a plurality of precast concrete air duct base plates which are assembled along the air duct direction. The air duct bottom plate consists of a plurality of precast concrete air duct bottom plates which are assembled along the air duct direction; the air duct side wall and the air duct roof plate are poured into shape by concrete pouring; the two ends of the air duct base plate are provided with upper hooks and the inner side of the side wall of the air channel is provided with lower hooks matched with the hooks on the bottom board of the wind channel. The invention also discloses a construction method of the assembly type concrete air duct for underground engineering. The construction method comprises the following steps of manufacturing precast concrete air duct base plate; manufacturing and constructing of the air duct side wall and air duct roof plate; installing the bottom plate of precast concrete duct; completing assembling of air duct bottom plate; carrying out sealing treatment on the assembly type concrete air duct. The assembly type concrete air duct for underground engineering and the construction method thereof improve the prefabricated assembly rate of the concrete, reduce the labor consumption and template consumption, and speed up the progress of construction projects.

Owner:ZHENGZHOU MUNICIPAL ENG CORP +1

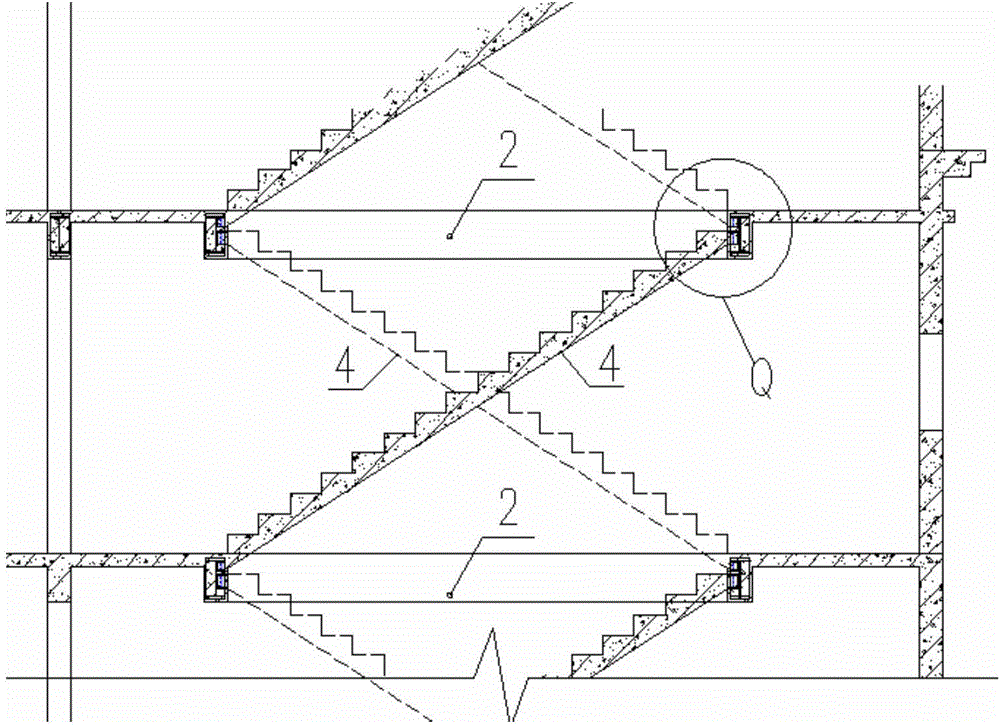

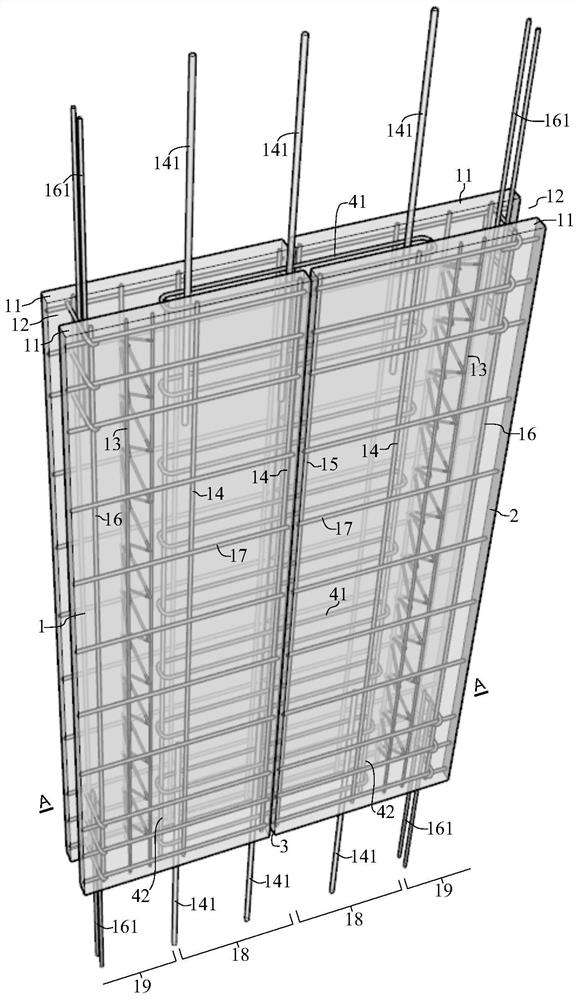

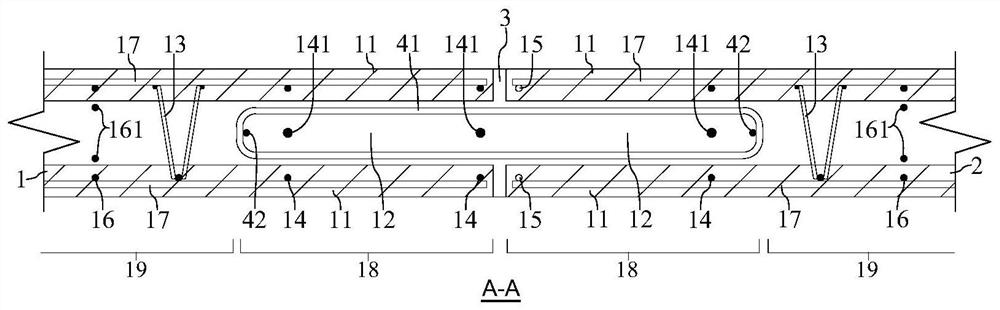

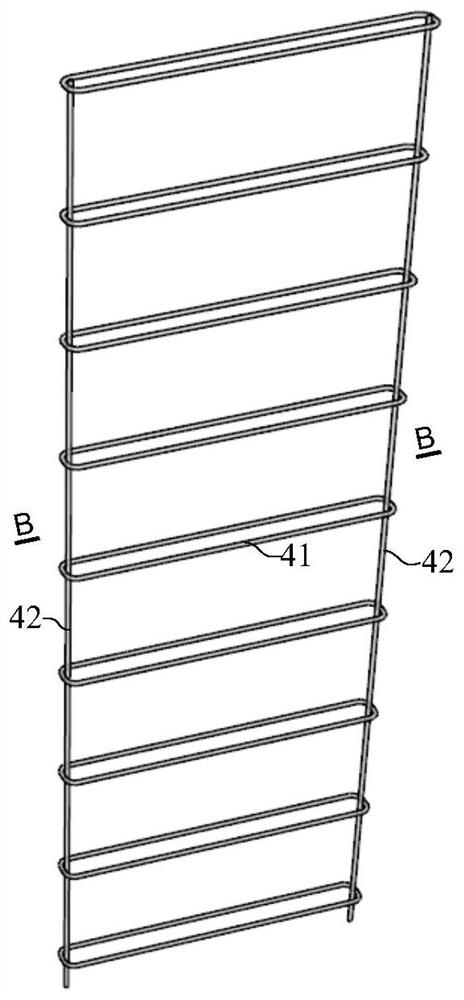

Laminated shear wall closely-spliced vertical joint structure and construction method

PendingCN111691582AReduction in formwork and reinforcement workImprove construction efficiencyWallsForms/shuttering/falseworksRebarLap joint

The invention discloses a laminated shear wall closely-spliced vertical joint structure and a construction method. Only a mounting joint with the width of about 20 mm is arranged between adjacent prefabricated walls, a specially designed vertical joint mold is adopted to improve the capacity of a cantilever section at the end part of a prefabricated concrete wallboard of the prefabricated wall forresisting the pressure of a concrete pouring side mold, the distance between a steel bar truss and the side edge of the prefabricated wall is increased, an internal large cavity is formed in the position of the closely-spliced vertical joint, and a horizontally-connected steel bar shaping steel bar cage is arranged in the cavity in a back arranged mode to achieve lap joint of horizontally-distributed steel bars of the prefabricated wall on the two sides of the vertical joint. According to the construction method, closely-spliced construction of the vertical joint of the laminated shear wall can be achieved, the vertical joint horizontal connecting steel bars are shaped steel bar cages produced industrially, the mold is a shaped universal mold, the standardized operation degree of steel bar penetrating and mold supporting in site construction of vertical joint is high, the site construction efficiency can be improved, the construction quality can be improved, meanwhile, the construction cost can be reduced through standardization and universalization.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

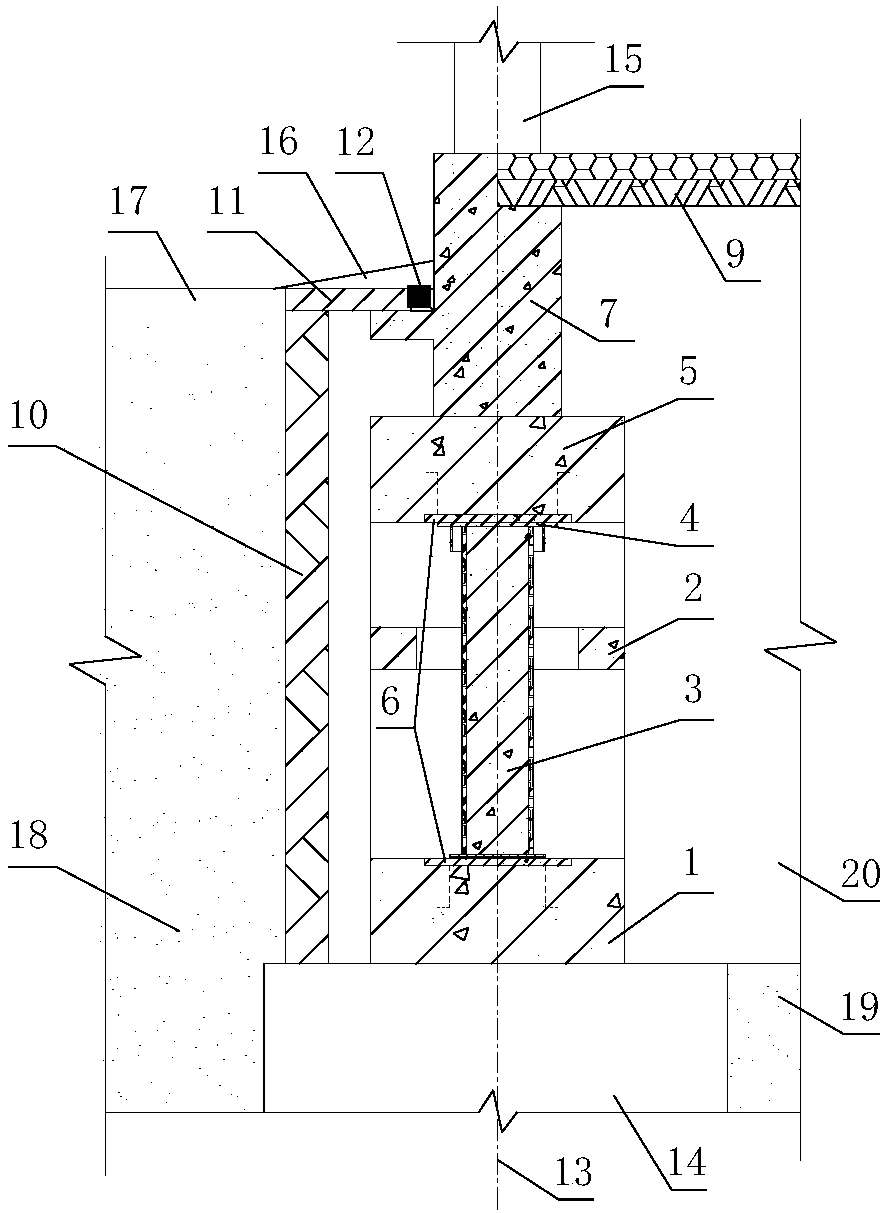

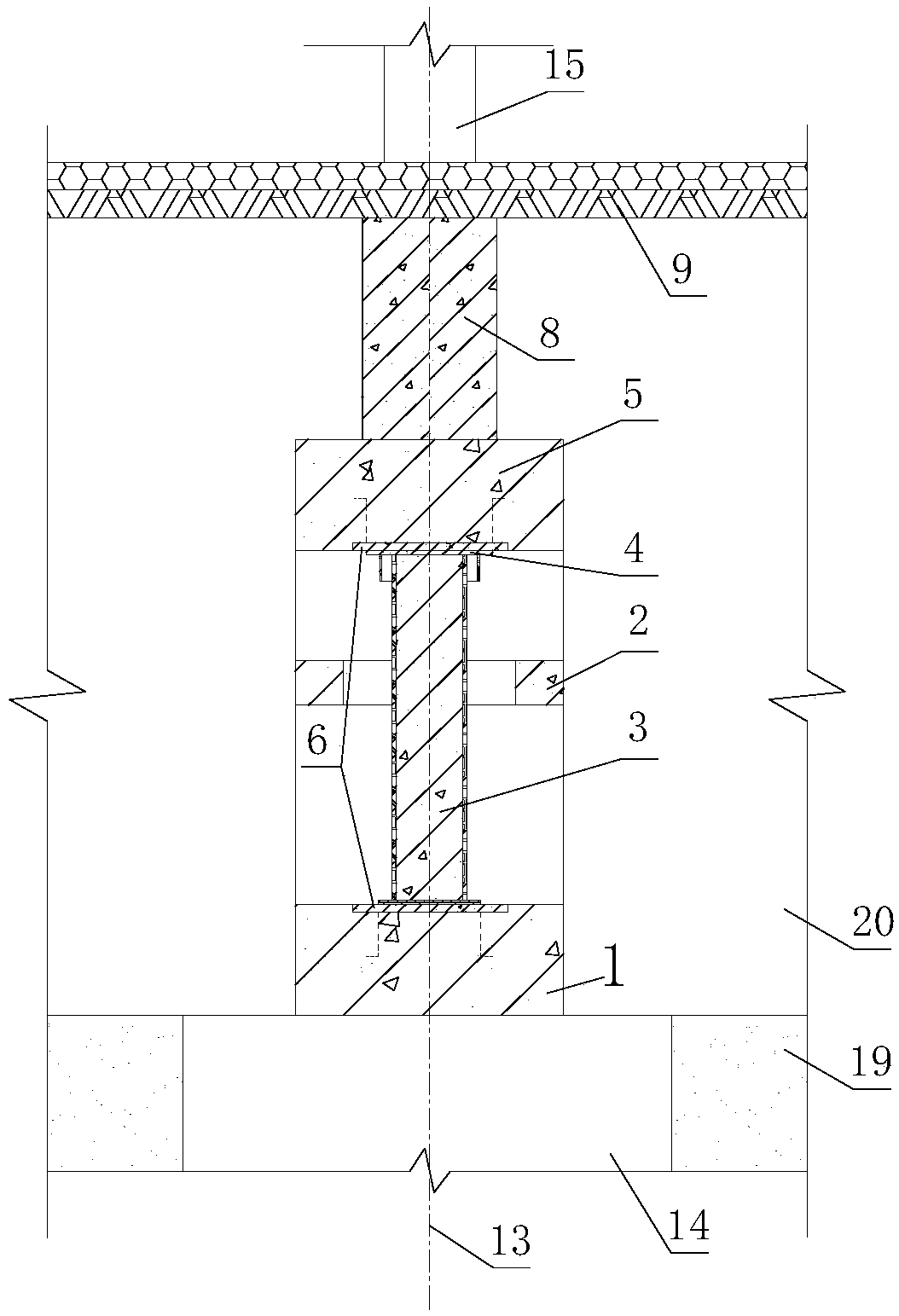

A prefabricated strip foundation and its construction technology

ActiveCN106013200BImprove quality controlEasy to installFoundation engineeringHoopingQuality control

The invention belongs to the technical field of construction engineering and particularly relates to a prefabricated assembly type strip foundation and a construction technology. The prefabricated assembly type strip foundation is characterized in that the prefabricated assembly type strip foundation comprises a longitudinal rebar; a plurality of hooping ribs are wound and fixed outside the longitudinal rebar; and the longitudinal rebar and the hooping ribs serve as a whole stress body through concrete pouring. The prefabricated assembly type strip foundation has the beneficial effects that factory prefabricated production can be achieved, quality control is convenient, construction difficulty caused by outdoor weather changes is avoided, field installation is safe, fast and convenient, energy conservation and environment protection are achieved, labor and time are saved, and the assembly efficiency is high.

Owner:SHANDONG YUANBO BUILDING TECH CO LTD

Mounting method of assembled building

The invention discloses a mounting method of an assembled building. The mounting method includes: (1), performing foundation construction, and pre-burying a connecting plate; (2), mounting a prefabricated steel reinforced concrete shear wall; (3), mounting a prefabricated steel reinforced concrete beam; (4), mounting a prefabricated lightweight masonry partition wall; (5), mounting a prefabricated steel truss reinforced concrete slab; (6), mounting a prefabricated reinforced concrete staircase; (7), mounting a prefabricated steel reinforced concrete balcony; (8), mounting a prefabricated steel reinforced concrete air conditioner plate; (9), mounting a prefabricated foam concrete heat-insulating exterior wall; (10), mounting a previous section of the prefabricated steel reinforced concrete shear wall; (11), repeating the steps (2)-(10) to complete mounting of each floor of the building; (12), after each floor of the building is mounted, mounting doors and windows of each floor of the building in a unified manner. The mounting method completely adopts prefabricated components, thereby having the advantages of environment friendliness, energy conservation and green construction.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

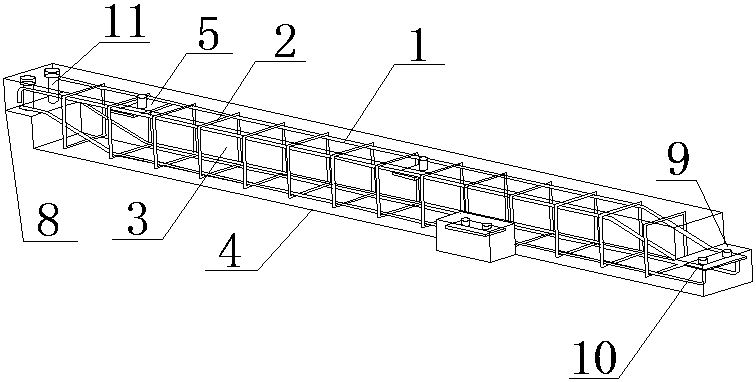

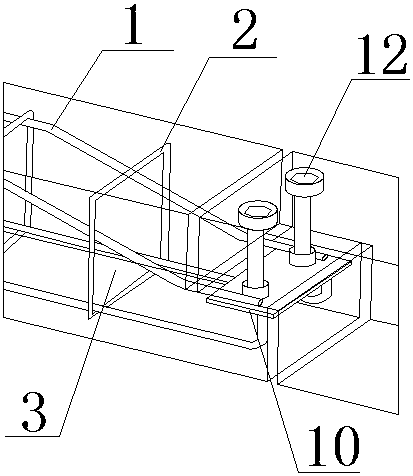

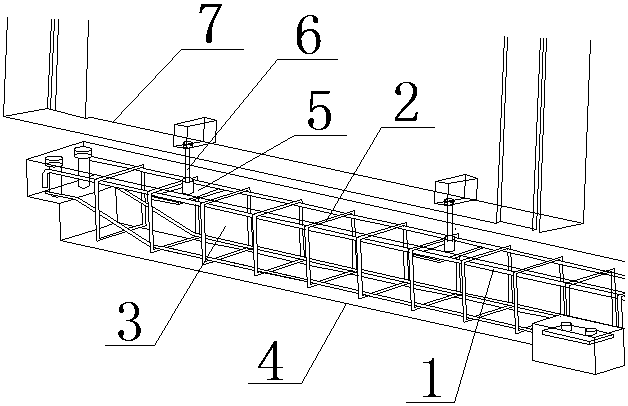

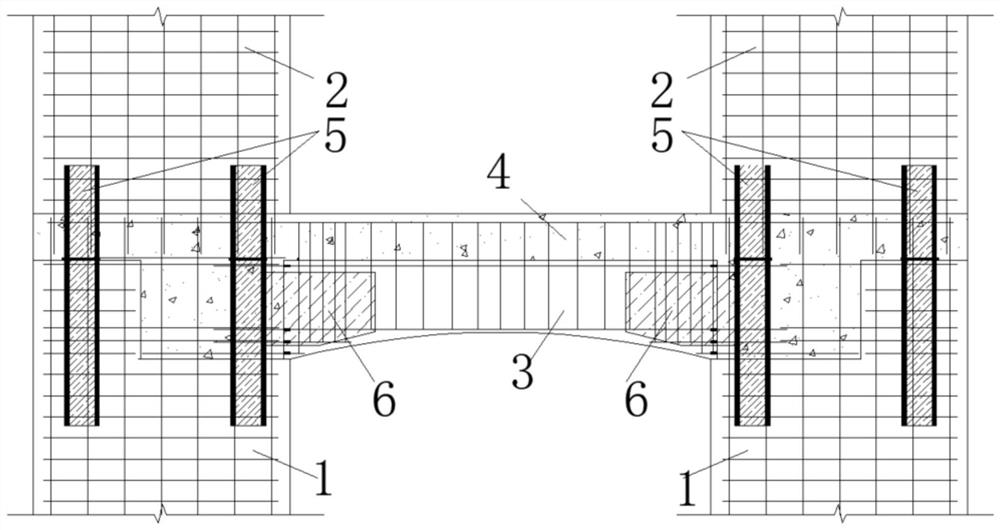

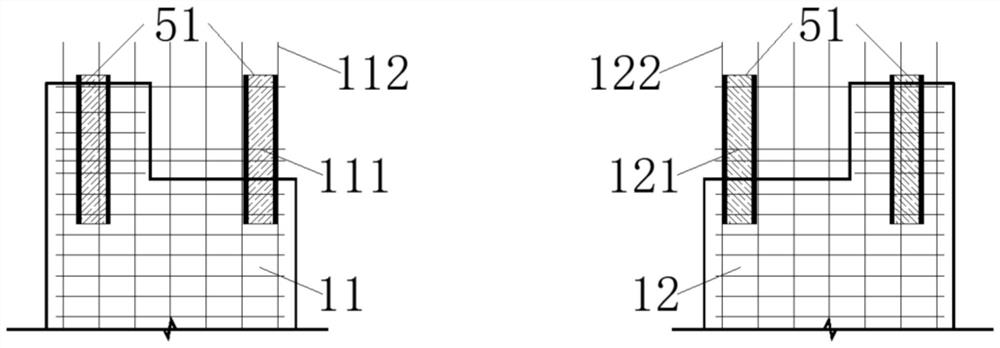

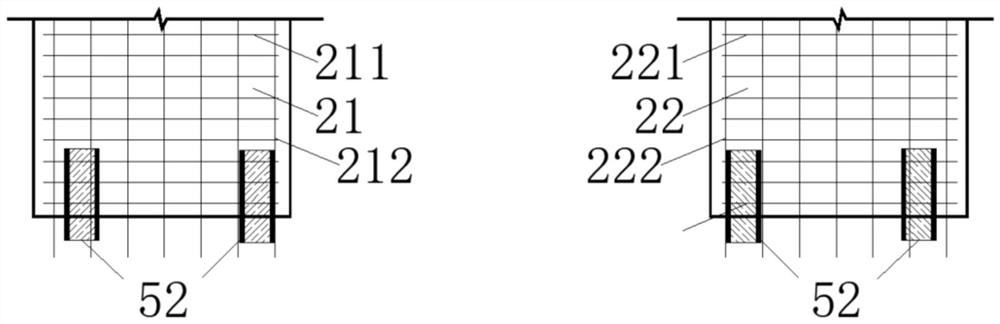

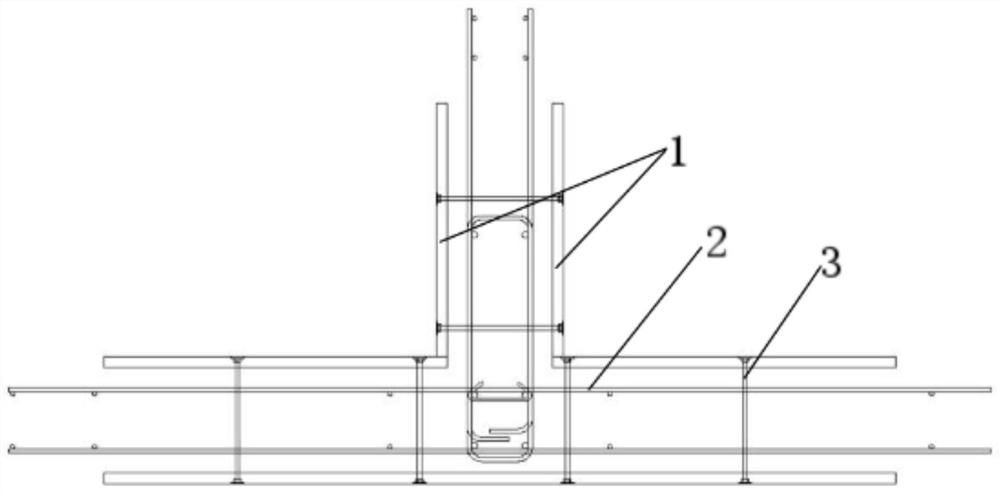

Fabricated double-limb shear wall with an inner arch type coupling beam and assembly method

The invention relates to a fabricated double-limb shear wall with an inner arch type coupling beam. The fabricated double-limb shear wall is characterized by comprising first shear wall units, secondshear wall units, the inner arch type coupling beam, laminated layers, vertical connecting components and horizontal connecting components, and the first shear wall units and the second shear wall units correspond up and down and are connected through the vertical connecting components; and the double-limb first shear wall units are connected to the inner arch type coupling beam through the horizontal connecting components, gaps are reserved between the first shear wall units and the second shear wall units, and concrete is poured into the gaps to form the laminated layers. According to the fabricated double-limb shear wall, the connecting components between the shear wall units can be prefabricated in a component processing factory, and compared with a traditional cast-in-place building structure construction method, on-site welding and mounting are convenient, operation time is saved, on-site labor force is reduced, and assembling efficiency is improved.

Owner:CHANGCHUN INST OF TECH

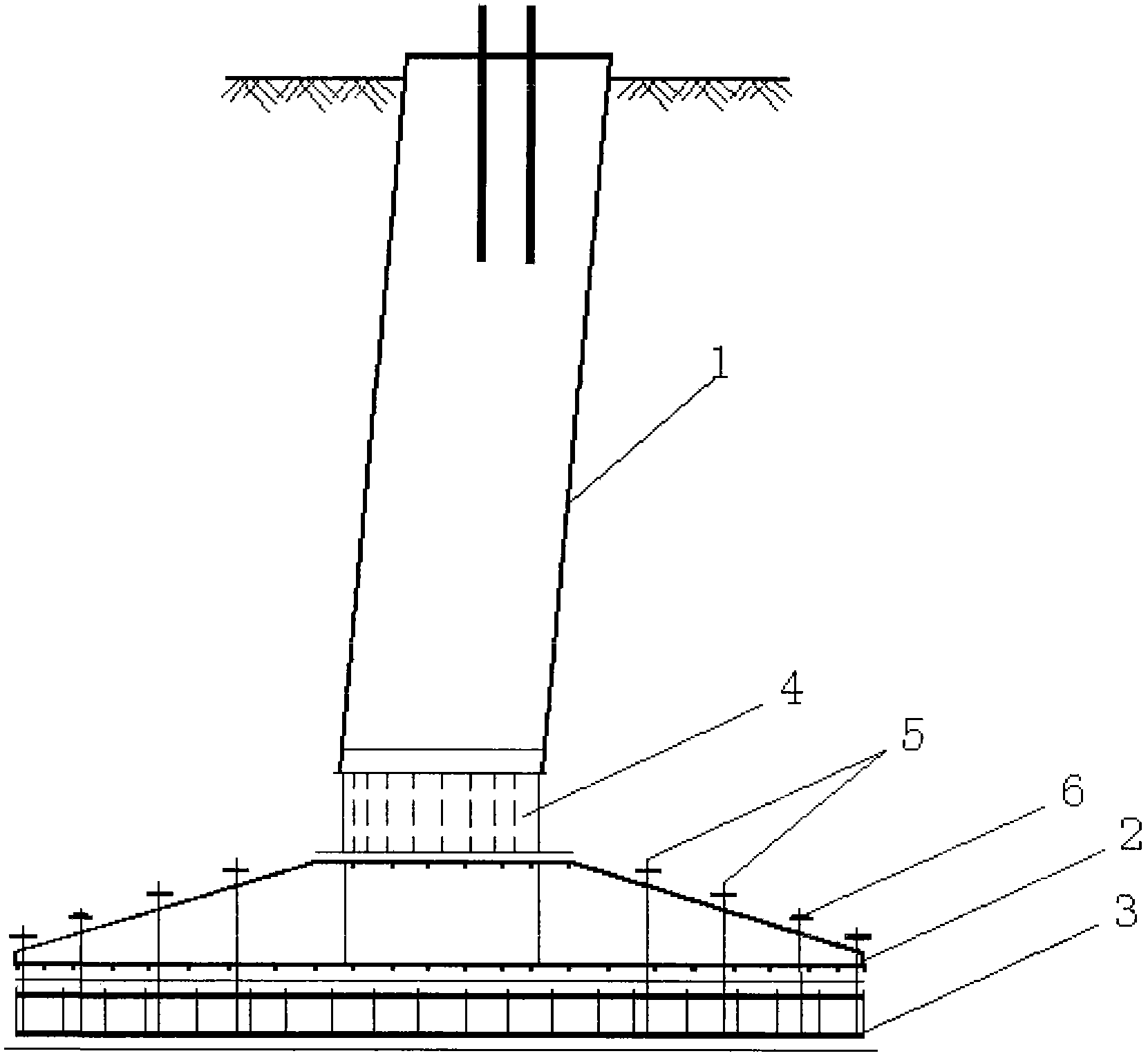

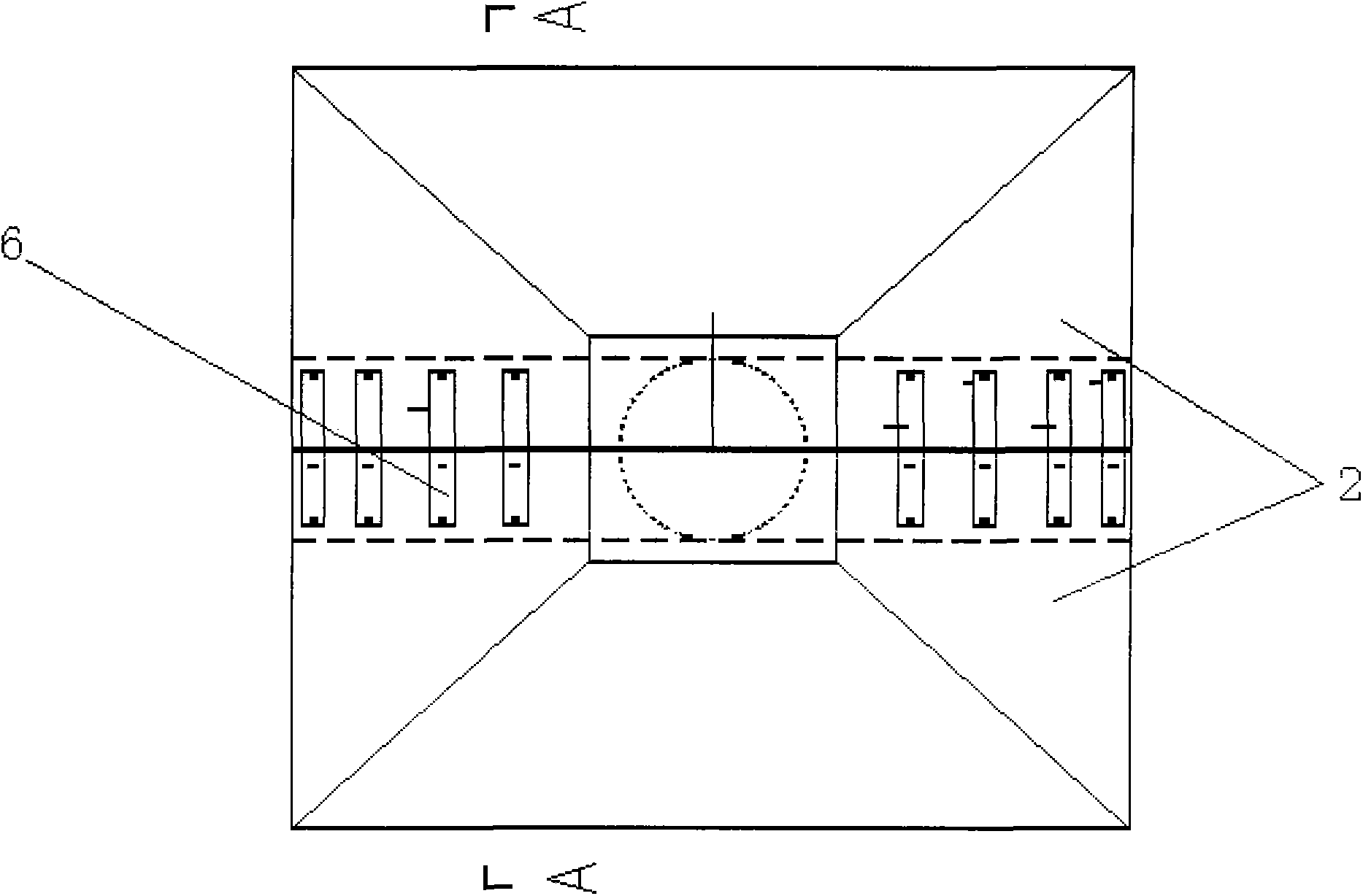

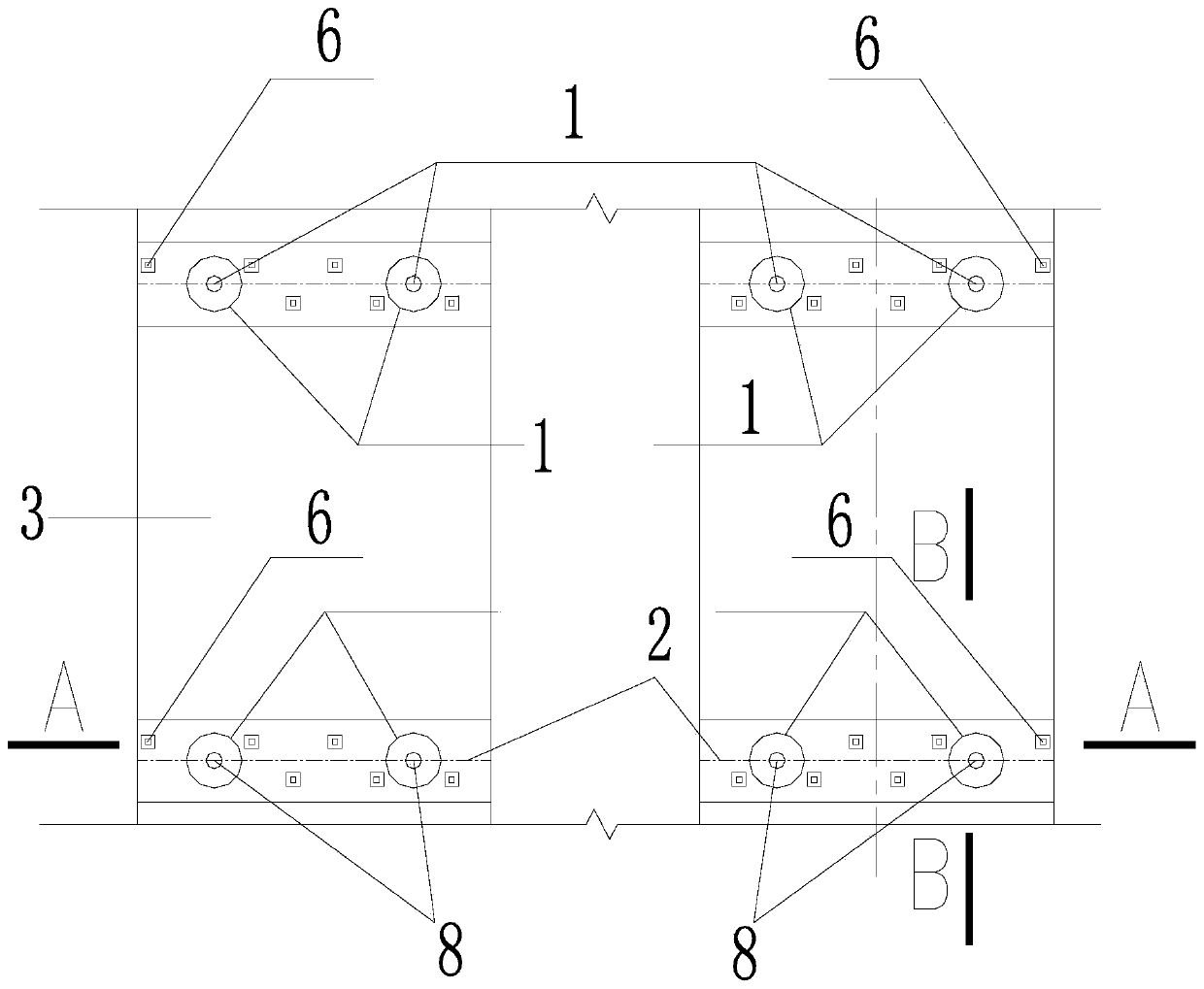

Batter post expansion plate type assembling foundation adopting weathering resistant steel for connection

InactiveCN103967035AReduce corrosionReduce horizontal forceFoundation engineeringArchitectural engineeringHigh pressure

The invention provides a batter post expansion plate type assembling foundation adopting weathering resistant steel for connection, and relates to the technical field of high-voltage transmission lines. The batter post expansion plate type assembling foundation comprises a stand column, bottom plates and a beam. The number of the bottom plates is two, the beam is arranged under the two bottom plates, anchor bolts are buried in the beam in advance, the anchor bolts penetrate through preset bolt holes in the bottom plates and then connect the beam and the bottom plates to be a whole through steel channels, a flange disc is buried in the lowest end of the stand column in advance, and the bottom plates and the stand column are connected through the flange disc to form a complete assembling foundation. The steel structure is long in service life, the batter post foundation is small in size, the construction period can be shortened by 1 / 3 to 1 / 2, labor on site can be saved by about 30% to 50%, limit of construction seasonality is overcome, material conveying amount is reduced, and efficiency of construction particularly in mountainous areas and hill sections is greatly improved.

Owner:梁东跃 +15

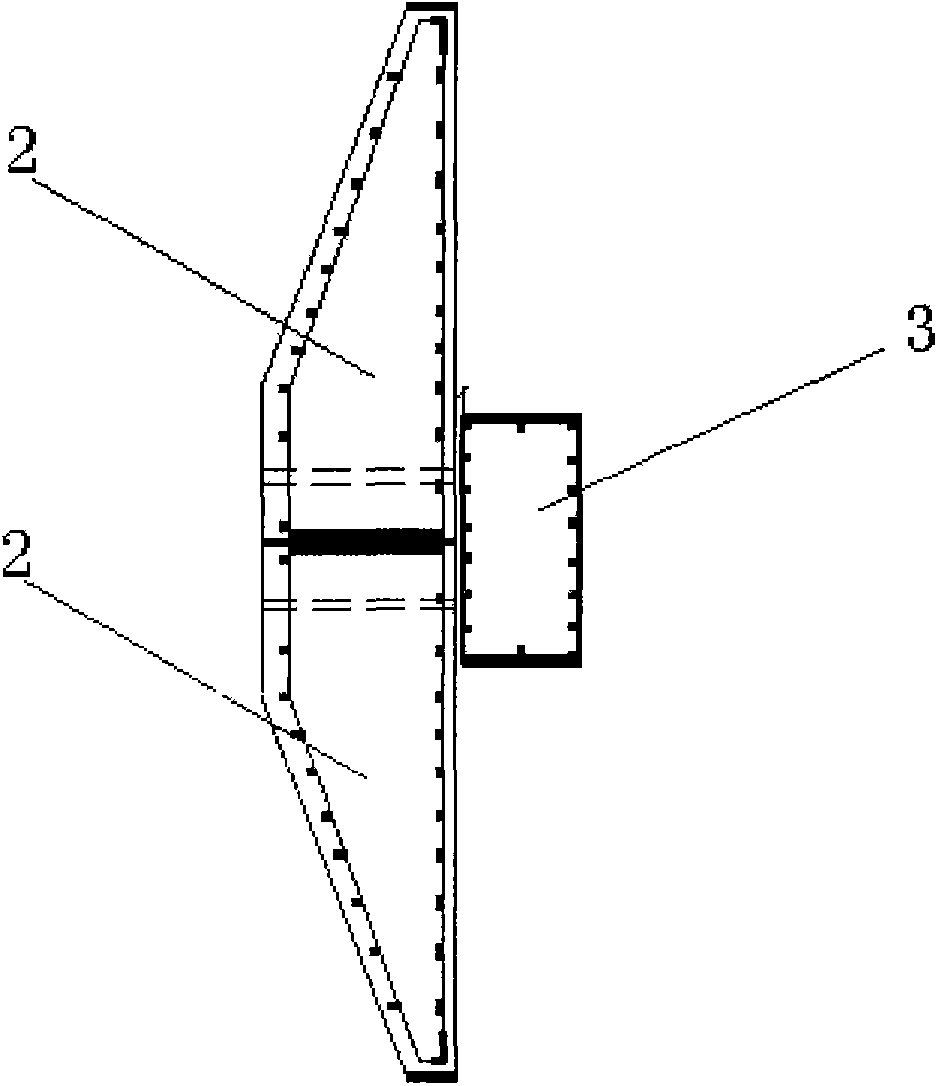

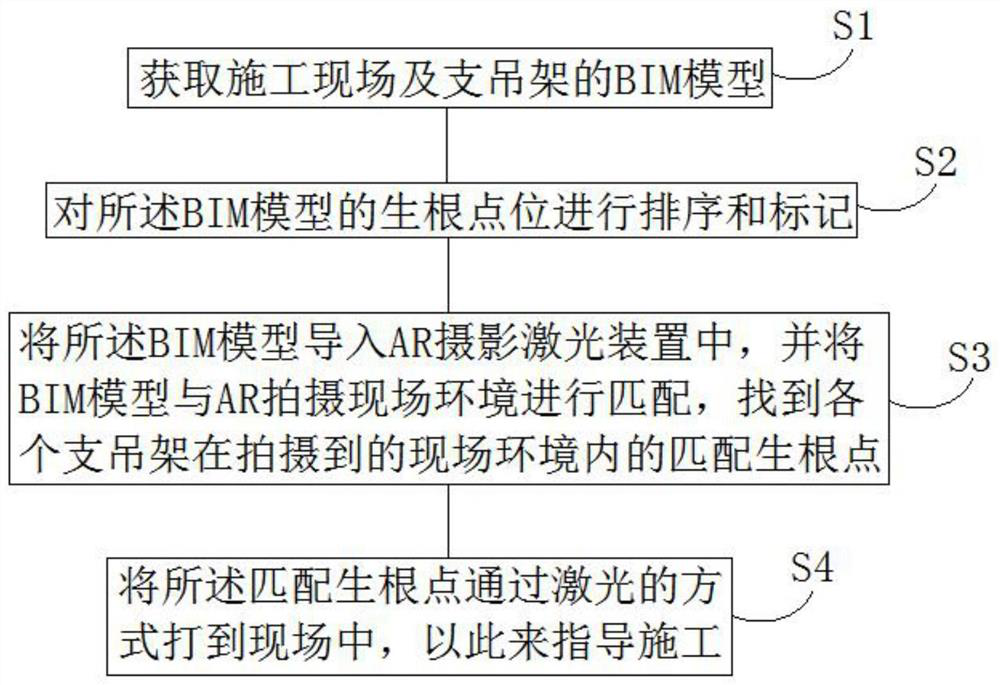

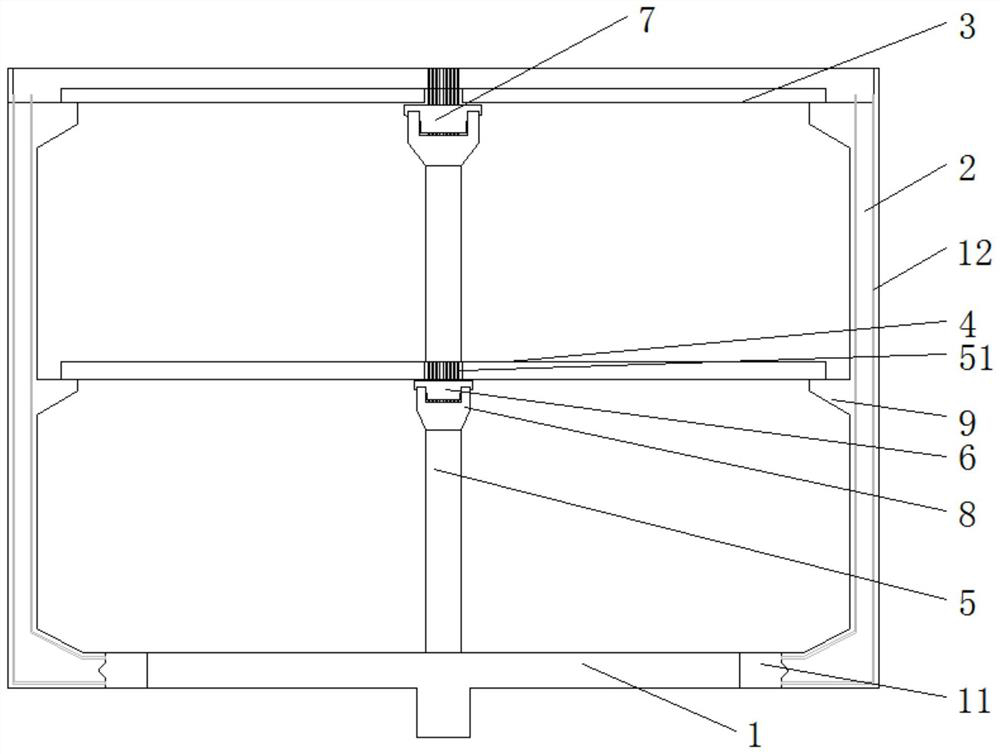

BIM-based AR lofting method and system for on-site support and hanger point location

The invention relates to the technical field of building construction, in particular to a BIM-based AR lofting method and system for on-site support and hanger point locations. The method comprises the following steps that a BIM model of a construction site and supports and hangers are obtained; rooting point positions of the BIM model are sorted and marked, the BIM model is imported into an AR photographing laser device, the BIM model is matched with an AR photographing site environment, and the matched rooting points of all the supports and hangers in the photographed site environment are found; and the matched rooting points are shot into the site in a laser mode so as to guide construction. The on-site support hanger point location positioning scheme is easy to operate, high in precision and high in speed. The content of the BIM model can be projected into a field environment through laser by utilizing an AR lofting technology so as to guide construction. The technology can be applied to support and hanger construction assistance of most construction sites only by developing the AR photography laser device which is provided with a processor and can process the BIM model at a time. On-site labor is saved, and the precision of on-site construction of the supports and hangers is improved.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Assembled integral type subway station structure

PendingCN114875965AEasy to transportImprove integrityArtificial islandsProtective foundationArchitectural engineeringSubway station

The invention discloses an assembled integral subway station structure which comprises a cast-in-place bottom plate, prefabricated side walls, a prefabricated top plate, a prefabricated middle plate, a prefabricated middle column, a middle longitudinal beam and a top longitudinal beam. The prefabricated side walls are arranged on the two sides of the cast-in-place bottom plate, and the prefabricated middle column is arranged on the middle side of the upper portion of the cast-in-place bottom plate; the top longitudinal beam and the middle longitudinal beam are arranged on the upper portion and the middle of the prefabricated middle column respectively, and the prefabricated middle column is a double-layer integrated segment column. According to the assembled integral type subway station structure, through organic combination of a prefabricated structure and cast-in-place and UHPC post-pouring at the joints, rigid connection of the joints is achieved, the structural integrity is good, safety and reliability are achieved, compared with full prefabrication, components are lighter, transportation and hoisting are convenient, the requirement for prefabrication and installation precision is low, the construction period can be shortened by 20%, and mold-free and support-free effects are basically achieved; and the on-site labor amount is reduced.

Owner:青岛中科坤泰装配建筑科技有限公司

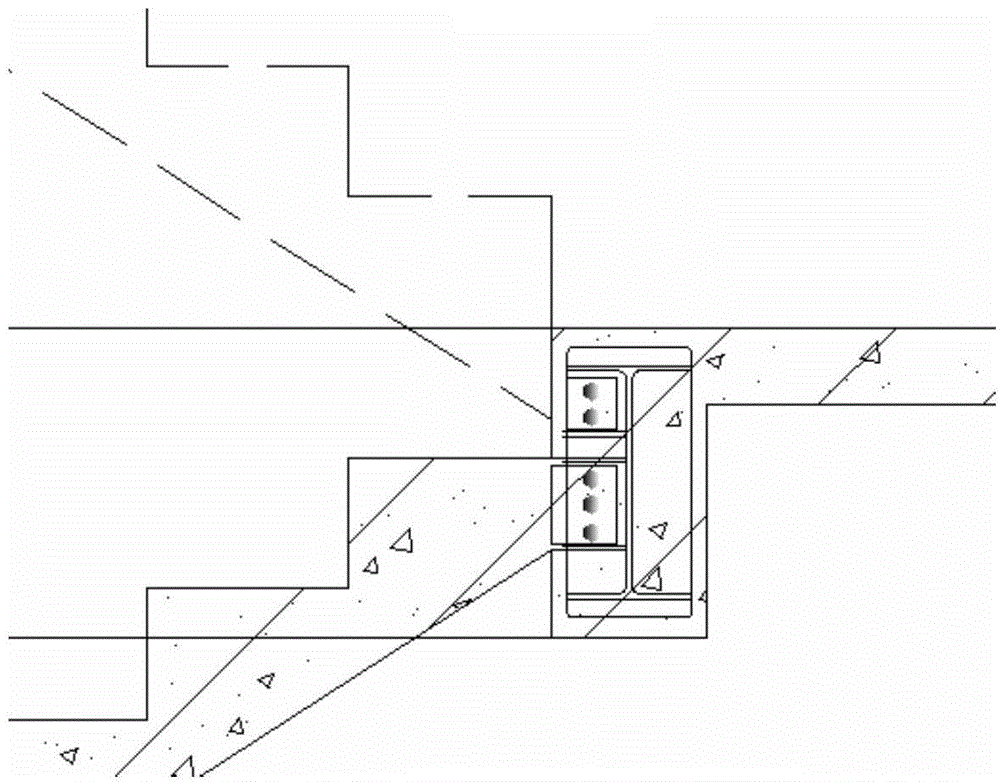

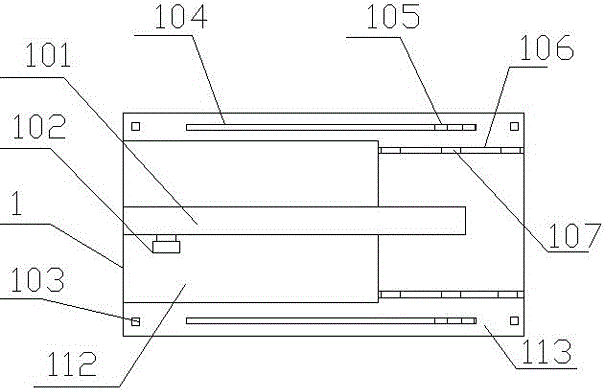

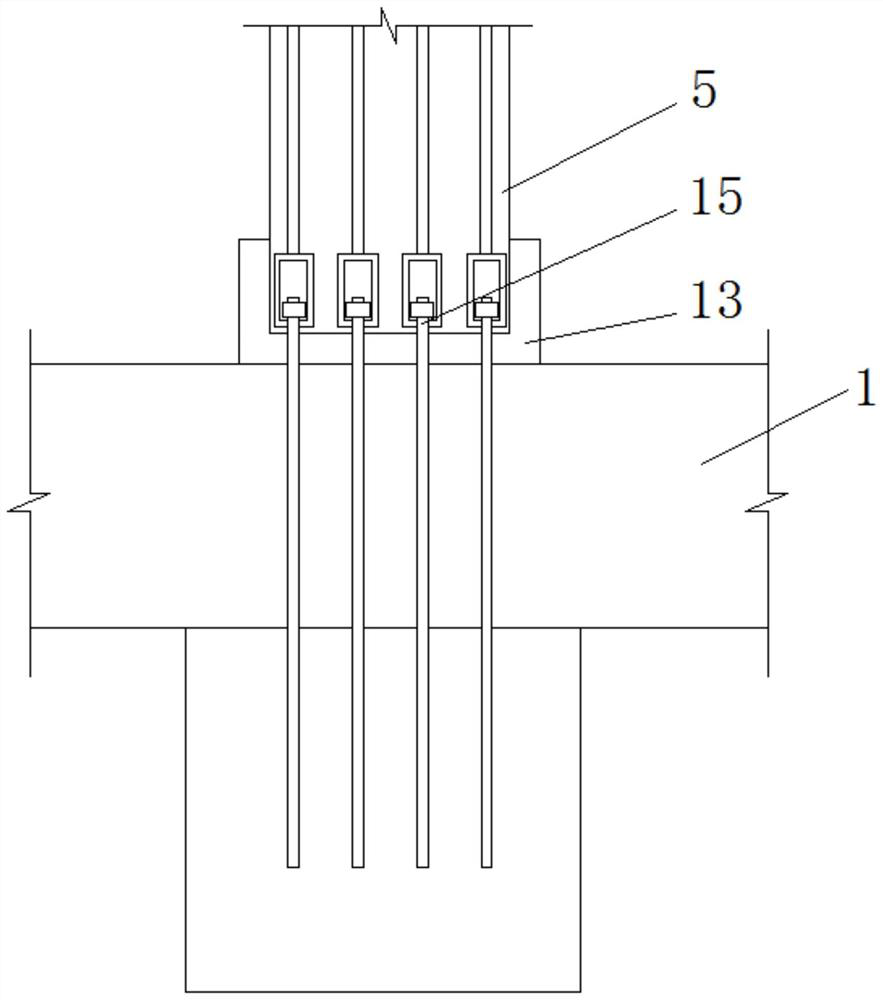

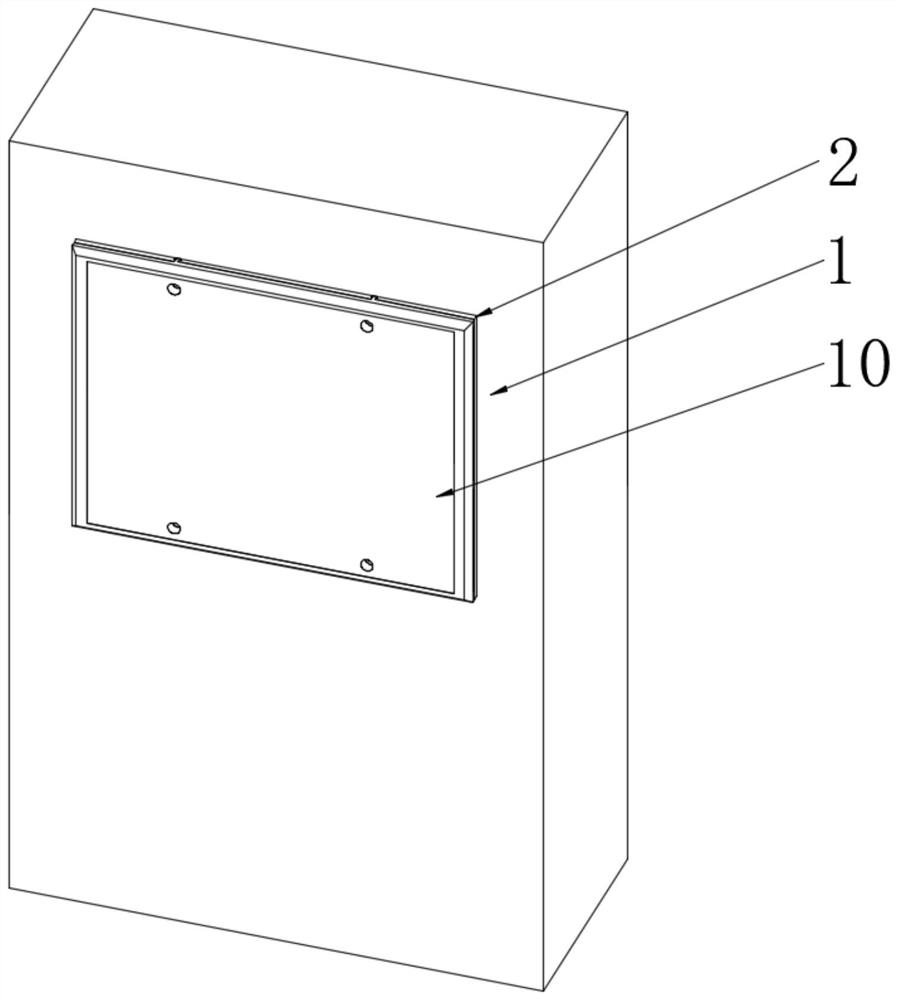

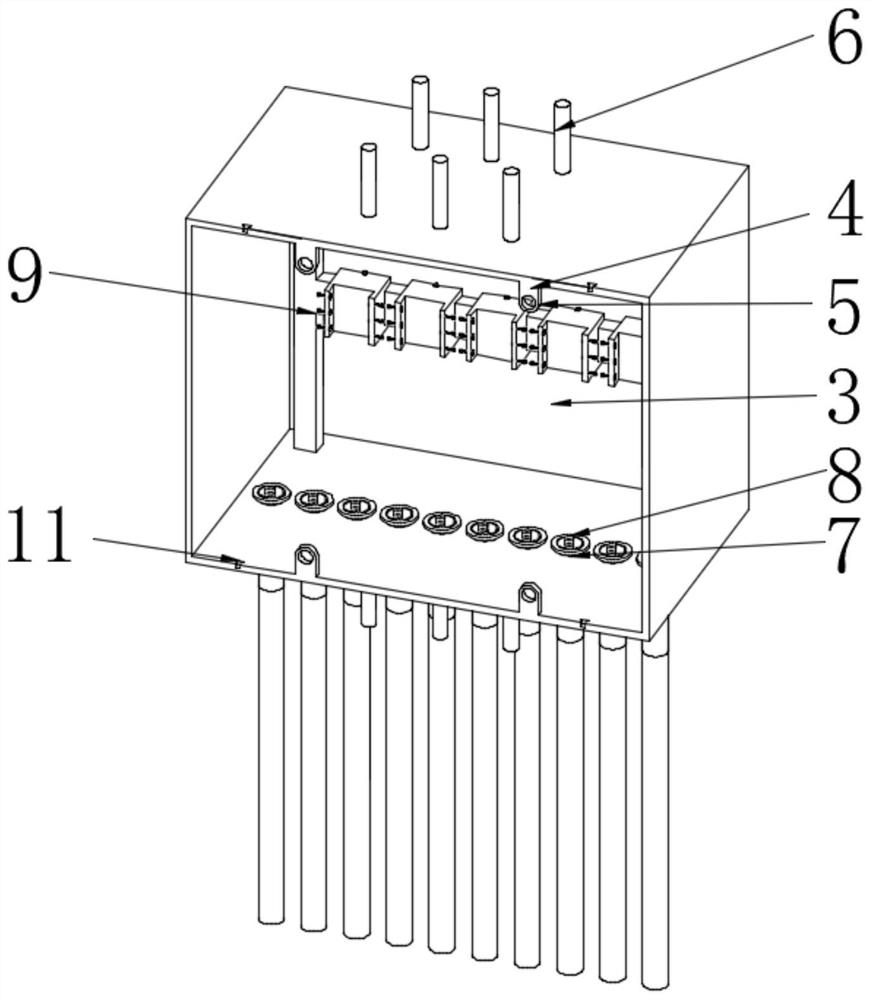

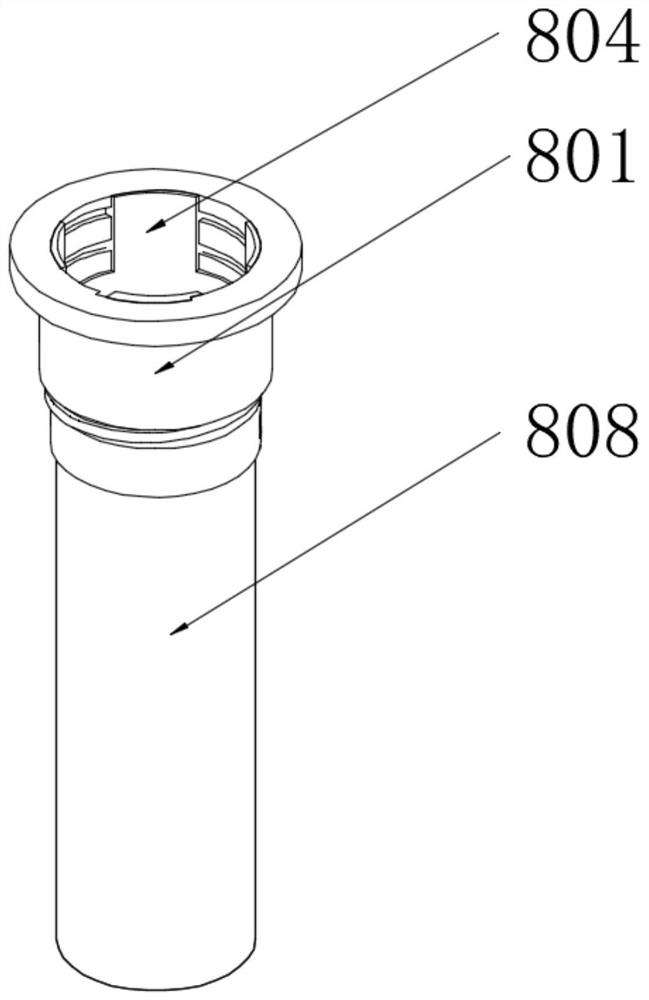

Low-position electric box body

PendingCN114039277AReduce wasteReduce on-site laborBus-bar/wiring layoutsSubstation/switching arrangement casingsStructural engineeringMechanical engineering

The invention provides a low-position electric box body, and relates to the technical field of low-position electric boxes. The low-position electric box body comprises an electric box main body, the electric box main body is fixedly installed in a concrete block through pouring, a plurality of positioning pins are fixedly installed on the upper surface and the lower surface of the electric box main body, and an electric box inner wall is arranged on the surface of one side of the electric box main body. A plurality of through holes are formed in the lower surface of the electric box main body in a penetrating mode, a flat cable pipe fixing mechanism is connected in each through hole, a plurality of fixing plates are fixedly installed on the outer sides of the upper side surface and the lower side surface of the inner wall of the electric box main body, first fixing threaded holes are formed in the fixing plates, and a positioning mechanism is installed in the electric box main body; and when the electric box main body and the concrete block are poured and fixed, resources on a construction site can be fully utilized, and the processes of pipe groove cutting, groove removing, line pipe installation, groove repairing, net hanging, plastering and the like which are added due to installation of an electromechanical professional electric box after masonry construction are saved, so that waste of on-site labor and materials is reduced, and working efficiency is improved.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

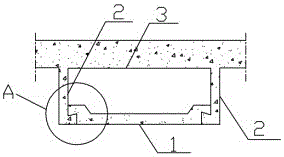

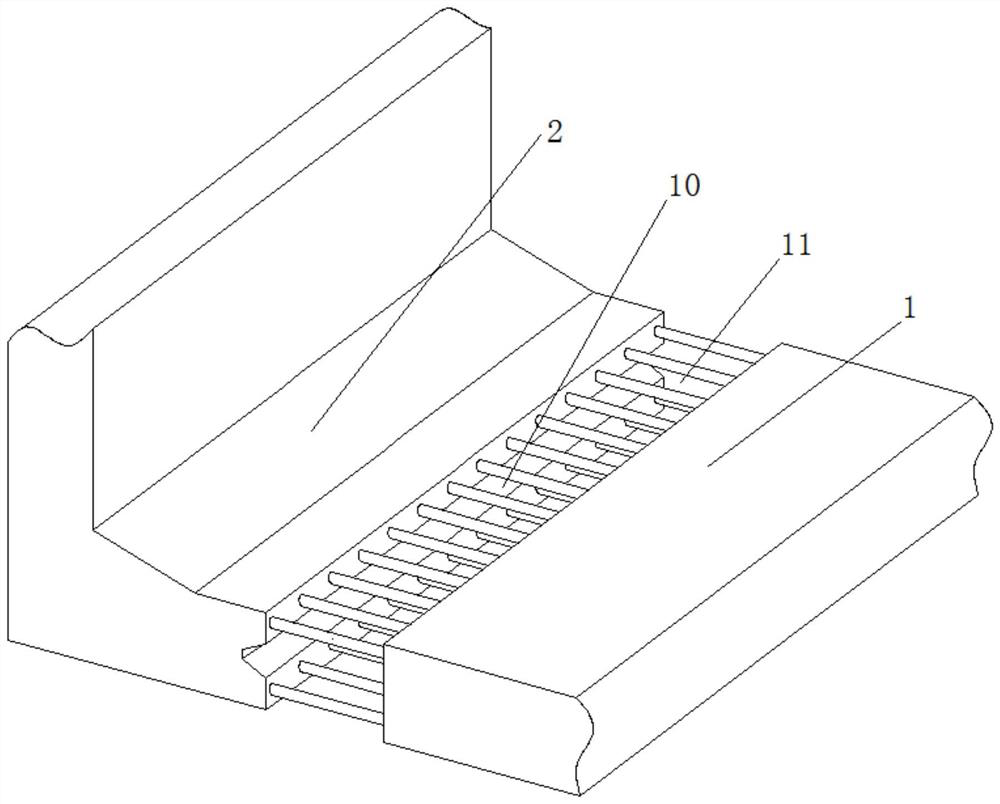

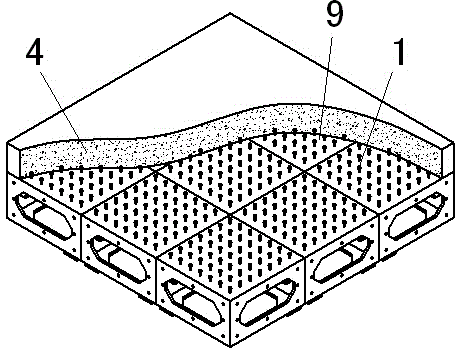

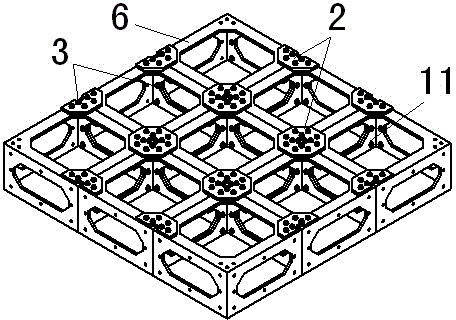

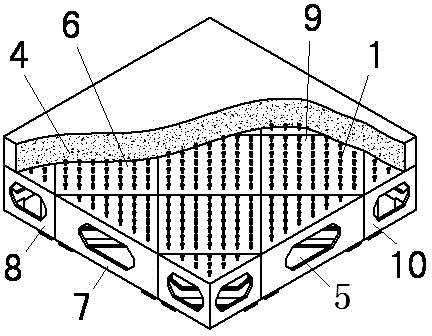

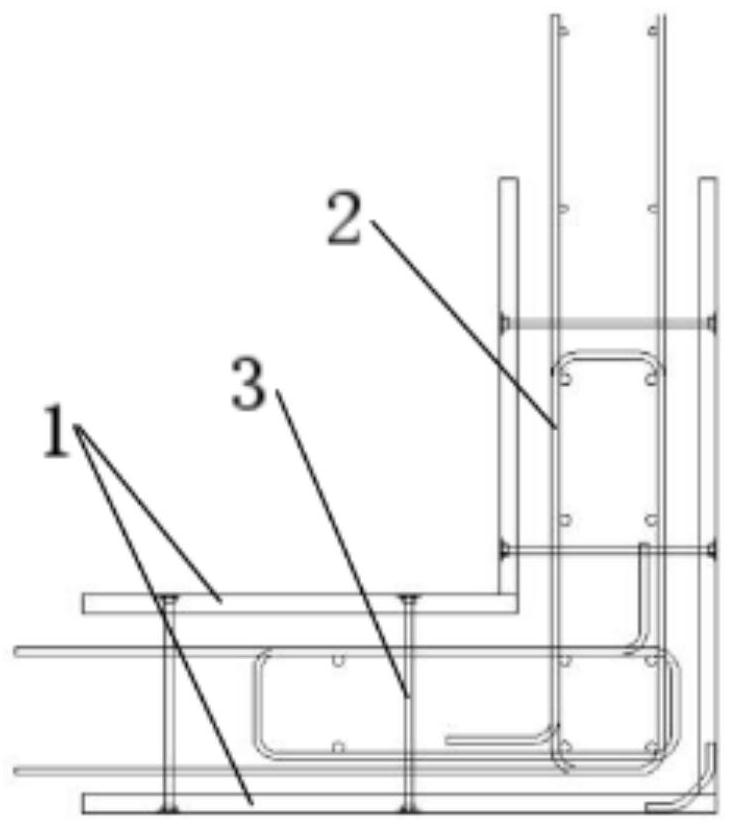

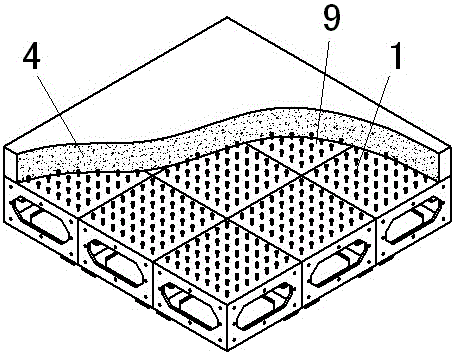

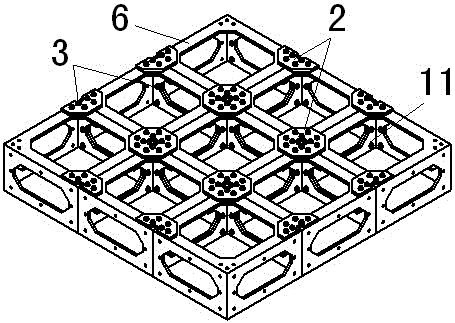

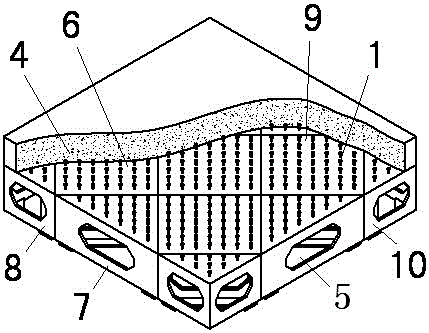

Combined long-span ribbed slab structure

InactiveCN104563354AImprove performanceTake advantage of the tensile strengthFloorsFloor slabEconomic benefits

The invention discloses a combined long-span ribbed slab structure. The ribbed slab is formed by splitting steel form shells of different shapes; the frontages of the steel form shells of the different shapes are uniformly distributed with rivets (1), the sides of the steel form shells of the different shapes are connected through bolts, and the backs of the steel form shells of the different shapes are connected to form a slab plane through connecting plates (2) and bolts (3); a reinforced bar casting concrete layer (4) is paved on the plane of the slab and is closely connected with the plane of the slab to form the combined long-span ribbed slab through the uniformly distributed rivets (1). Compared with the prior art, the combined long-span ribbed slab structure provided by the invention has a few of combined components; furthermore, the combined long-span ribbed slab is processed in batches by a professional factory, good interchangeability and convenience in field splitting can be realized, the field labor capacity can be reduced, the construction period can be reduced significantly and the economic benefit can be improved; an existing wooden form can be substituted by the plane of the slab formed by splitting the steel form shells, therefore, the compressive property can be improved and the cost saving can be realized; in addition, lightening holes are formed in side plates, therefore materials can be saved and dead weight can be reduced.

Owner:GUIZHOU UNIV

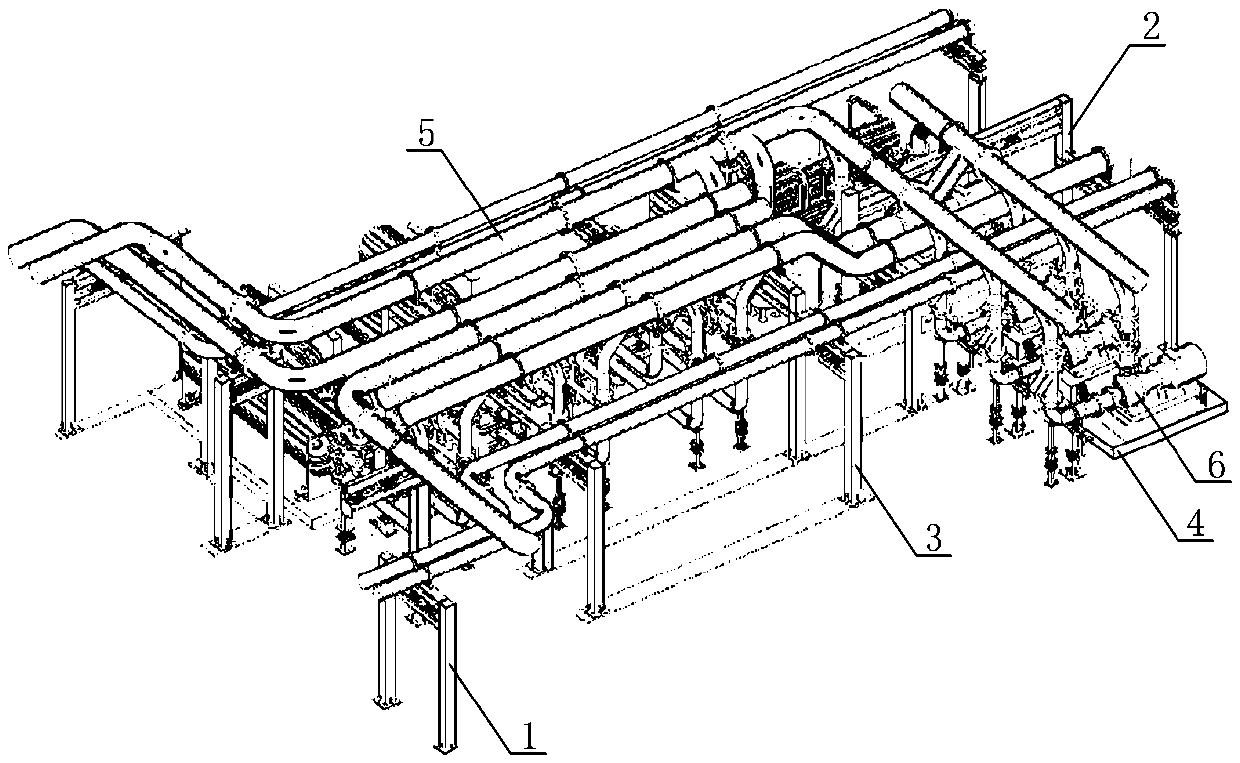

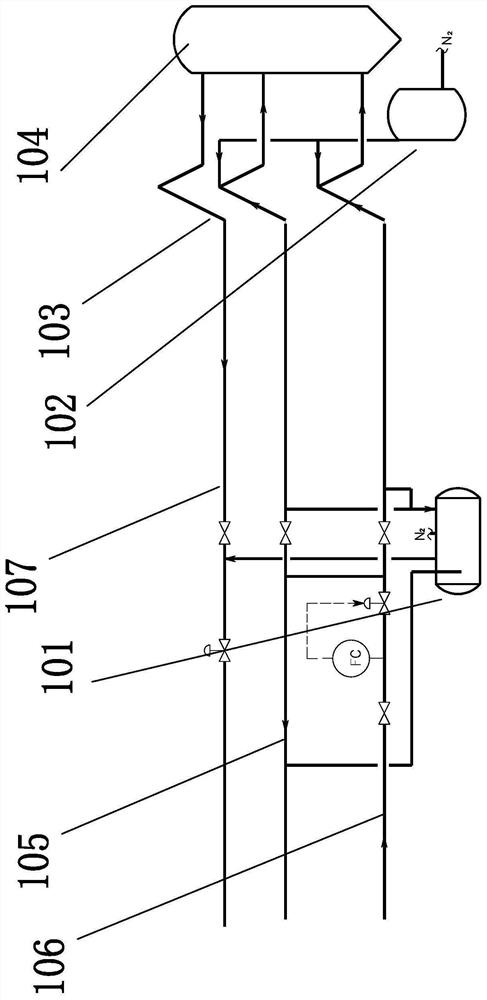

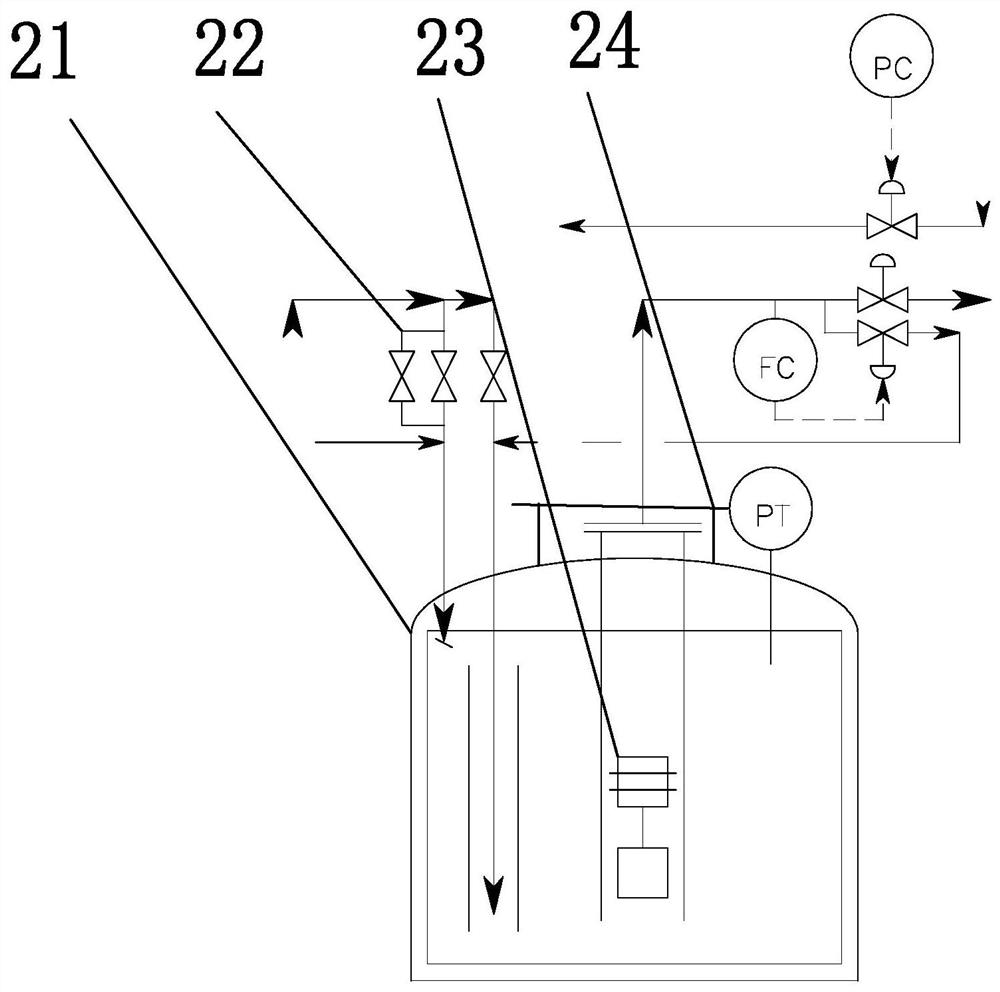

Modular structure for LNG receiving station

PendingCN111853531ALess investmentImprove functionalityGas handling/storage effectsPipeline systemsControl engineeringArchitectural engineering

The invention provides a modular structure for an LNG receiving station. The modular structure is provided with a ship loading and unloading module, a storage tank module, a high-pressure conveying module, a recondenser module, a BOG processing module, an SCV module, an ORV module, a torch module, a tank wagon loading and unloading module and a main pipe rack module. The whole device can be formedby constructing the plurality of modules and a plurality of skids like constructing Lego building blocks, and all the modules are independently skids, so that construction and installation are convenient, and meanwhile the internal modules can be independently detached or replaced during maintenance; and according to the modular structure for the LNG receiving station, the on-site construction, installation and debugging time is greatly shortened, the construction and debugging personnel are reduced, the on-site machine tool cost is saved, the large-scale, comprehensive, integrated and intelligent development trend and direction of the LNG receiving station can be adapted, the integration level of the device is improved, the equipment investment is reduced, and the occupied area of a factory is saved.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

Steel fiber common template frame and preparation method thereof

The invention discloses a steel fiber common type template frame and a preparation method thereof. The steel fiber common type template frame comprises a template, reinforcing steel bars and opposite-pull connecting pieces, and the template comprises the following materials: cement, natural sand, steel fibers, silica fume, fly ash, polycarboxylate superplasticizer powder, an antifoaming agent, rubber powder and an early strength agent. The template frame has the beneficial effects that: the thickness of the template frame is 20 mm, the template frame has higher strength, the distance between the opposite-pull connecting pieces can be set to be 40 cm, the number of the connecting pieces can be reduced to a large extent, the cost of the opposite-pull connecting pieces is reduced, the compressive strength and the breaking strength of the template material can be improved to a large extent by arranging the steel fibers, and meanwhile brittle failure of the template material can be avoided.The produced template material is high in fluidity, can be self-leveled, does not need to be vibrated during template forming, uses ordinary Portland cement, is lower in cost, adapts to the requirements of building industrialization in the aspects of saving field labor, saving turnover materials and the like, and can greatly improve the production efficiency of components.

Owner:CHINA RAILWAY CONSTR CORP LTD +1

A combined long-span dense-ribbed floor structure

InactiveCN104563354BImprove performanceTake advantage of the tensile strengthFloorsFloor slabEconomic benefits

The invention discloses a combined long-span ribbed slab structure. The ribbed slab is formed by splitting steel form shells of different shapes; the frontages of the steel form shells of the different shapes are uniformly distributed with rivets (1), the sides of the steel form shells of the different shapes are connected through bolts, and the backs of the steel form shells of the different shapes are connected to form a slab plane through connecting plates (2) and bolts (3); a reinforced bar casting concrete layer (4) is paved on the plane of the slab and is closely connected with the plane of the slab to form the combined long-span ribbed slab through the uniformly distributed rivets (1). Compared with the prior art, the combined long-span ribbed slab structure provided by the invention has a few of combined components; furthermore, the combined long-span ribbed slab is processed in batches by a professional factory, good interchangeability and convenience in field splitting can be realized, the field labor capacity can be reduced, the construction period can be reduced significantly and the economic benefit can be improved; an existing wooden form can be substituted by the plane of the slab formed by splitting the steel form shells, therefore, the compressive property can be improved and the cost saving can be realized; in addition, lightening holes are formed in side plates, therefore materials can be saved and dead weight can be reduced.

Owner:GUIZHOU UNIV

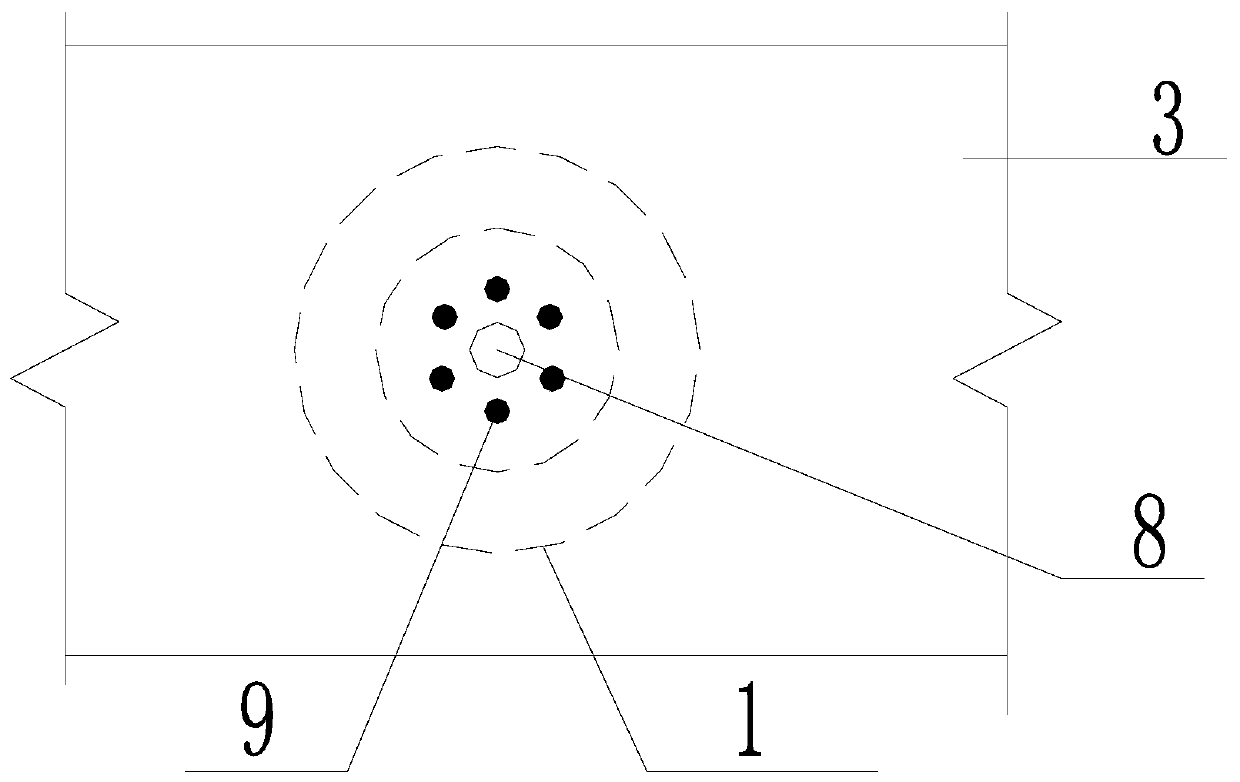

A kind of seismic isolation foundation structure and construction method of steel pipe concrete column support of masonry building

ActiveCN106436730BAdvantages of Seismic Isolation Foundation StructuresLittle impact on costProtective foundationJoistRetaining wall

The invention discloses a masonry building concrete filled steel tubular column pedestal shock isolation foundation structure and a construction method thereof. The masonry building concrete filled steel tubular column pedestal shock isolation foundation structure comprises a building peripheral outer wall shock isolation foundation and a building peripheral inner wall shock isolation foundation; the building peripheral outer wall shock isolation foundation is composed of a lower part structure, a peripheral upper supporting beam and an upperpart structure; the peripheral upper supporting beam and the upperpart structure are arranged above the lower part structure; and shock isolation devices are arranged between the peripheral upper supporting beam and the lower part structure as well as between a middle upper supporting beamand the lower part structure respectively. The construction method comprises the following steps: arranging the shock isolation devices; arranging the upper supporting beams; prefabricating a shock isolation device component; excavating earthwork; detecting the lower part structure; carrying out location and line laying of the shock isolation devices; installing the shock isolation devices; carrying out reinforcement operation on the shock isolation devices; constructing the upper supporting beams; filling sealing materials; constructing concrete composite slabs; and constructing earth-retaining walls and scattered-water concrete. The masonry building concrete filled steel tubular column pedestal shock isolation foundation structure is low in construction cost and ensures the service life when reducing the backfilling engineering quantity of an indoor foundation.

Owner:GUIZHOU KAILIN CONSTR GRP CO LTD

modular house system

ActiveCN105926981BConvenient sourceEasy to install on siteRoof improvementWallsFloor slabClassical mechanics

The invention discloses a modular assembly house system, which is characterized in that it includes one or more modular houses (1), and the houses (1) within two floors extend infinitely in the horizontal direction, Each house (1) is composed of a steel structure frame (2), a cold-formed thin-walled steel system wall panel (3), a cold-formed thin-walled steel system floor plate (4) and a cold-formed thin-walled steel system roof (5) Composition; described steel structure frame (2) comprises crossbeam (2.1) and vertically connected column (2.2) that are parallel to each other up and down, and the eight corners that described beam (2.1) and column (2.2) surround are all used The connecting piece (7) is connected; it overcomes the disadvantages of inconvenient folding and assembly in the prior art, poor combination, and unsuitability for complicated environments, and has the advantages of detachable, interchangeable, and increase-reducible.

Owner:武汉麦特建筑科技有限公司

Steel fiber quick-hardening template frame and preparation method thereof

InactiveCN112279572AHigh strengthReduce in quantityCeramic shaping apparatusCement mixing apparatusBreaking strengthSuperplasticizer

The invention discloses a steel fiber quick-hardening template frame and a preparation method thereof. The steel fiber quick-hardening template frame comprises a template, reinforcing steel bars and opposite-pull connecting pieces, and template materials comprise cement, natural sand, steel fibers, silica fume, a retarder, polycarboxylate superplasticizer powder, a defoaming agent, rubber powder and an accelerator. The frame has the beneficial effects that the thickness of the formwork is 20 mm, the formwork has higher strength, the distance between the opposite-pull connecting pieces can be set to be 40 cm, the number of the connecting pieces can be reduced to a large extent, the cost of the opposite-pull connecting pieces is reduced, the compressive strength and breaking strength of formwork materials can be improved to a large extent by arranging the steel fibers, and meanwhile brittle failure of the formwork materials can be avoided. The produced template material is high in fluidity and can be self-leveled, vibration is not needed during template forming, the requirements of building industrialization are met in the aspects of saving on-site labor, saving turnover materials and the like, and the production efficiency of components can be greatly improved.

Owner:CHINA RAILWAY CONSTR CORP LTD +1

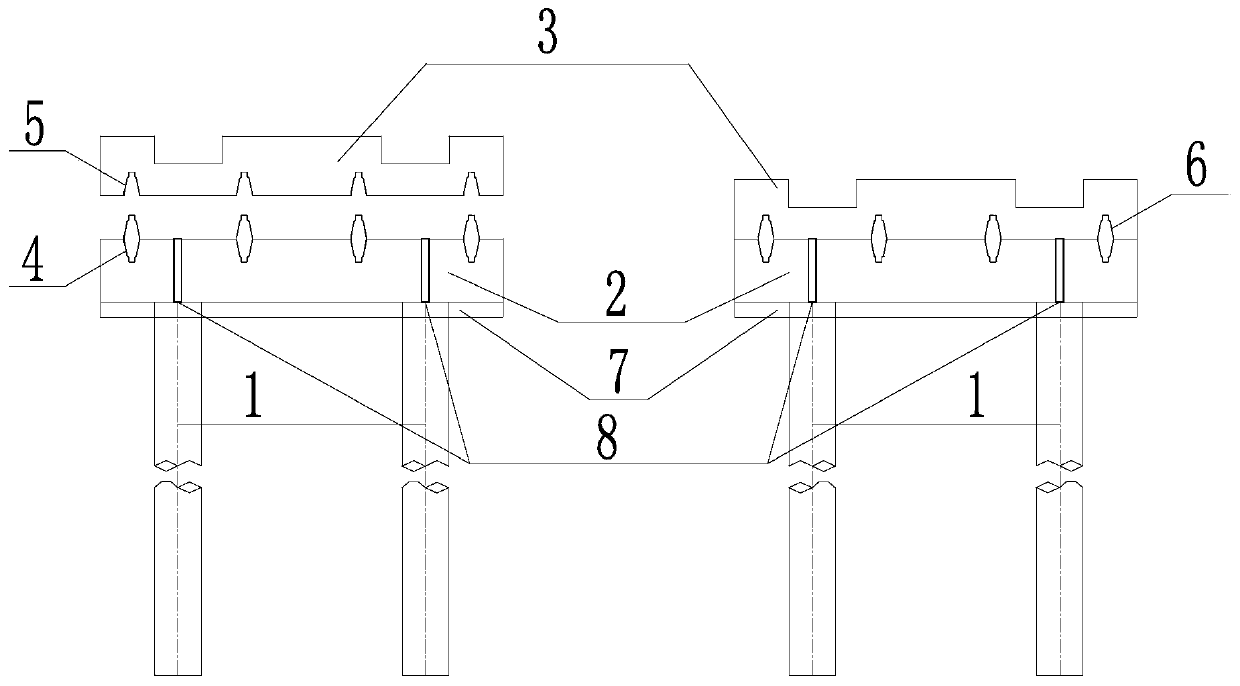

Implementation method of prefabricated under-rail foundation for trams in soft soil areas

ActiveCN108330745BImprove integrityFinish quicklyRailway tracksFoundation engineeringArchitectural engineeringRebar

The invention discloses an implementing method of a fabricated under-rail foundation of a tramcar in a soft soil area. The implementing method comprises the steps that three parts of components of PHCpile foundations, reinforced concrete cross beams and reinforced concrete slab structures are prefabricated in a factory; steel bars are reserved in the position, corresponding to the pile foundations, of prefabricated roadbed beams, after under-beam steel bars and steel plates at the tails of the under-beam steel bars are placed in prefabricated pile hollow parts, shearing pin son-openings are reserved in the prefabricated reinforced concrete cross beams, during fabricating, shearing pin mother-openings in the prefabricated reinforced concrete slab structures and the shearing pin son-openings in the prefabricated reinforced concrete cross beams are subjected to socket welding to form a common beam-slab force-transferring structure; and different slab blocks of prefabricated reinforced concrete slabs are lapped on the cross beams. The implementing method has the beneficial effects that prefabricated components are adopted, the manufacturing precision is high, the quality is ensured, meanwhile, the on-site installation efficiency and installation precision are improved, on-site labor force can be saved, the construction period is shortened, and the integrity of the roadbed structure is improved; and an under-rail foundation structure of the tramcar can be completed quickly, safely, and efficiently in an environmentally friendly mode.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Prefabricated member building and construction process thereof

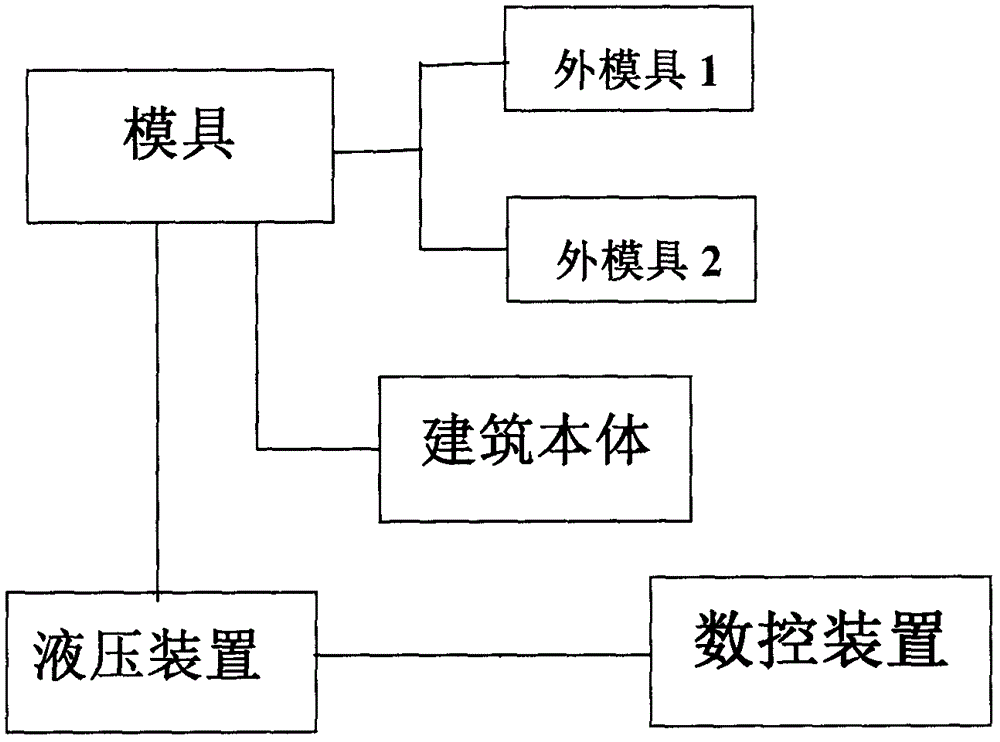

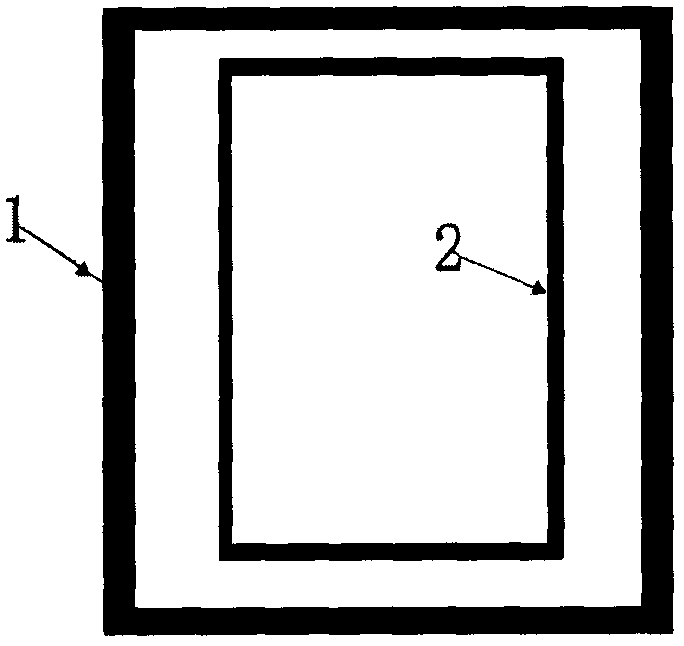

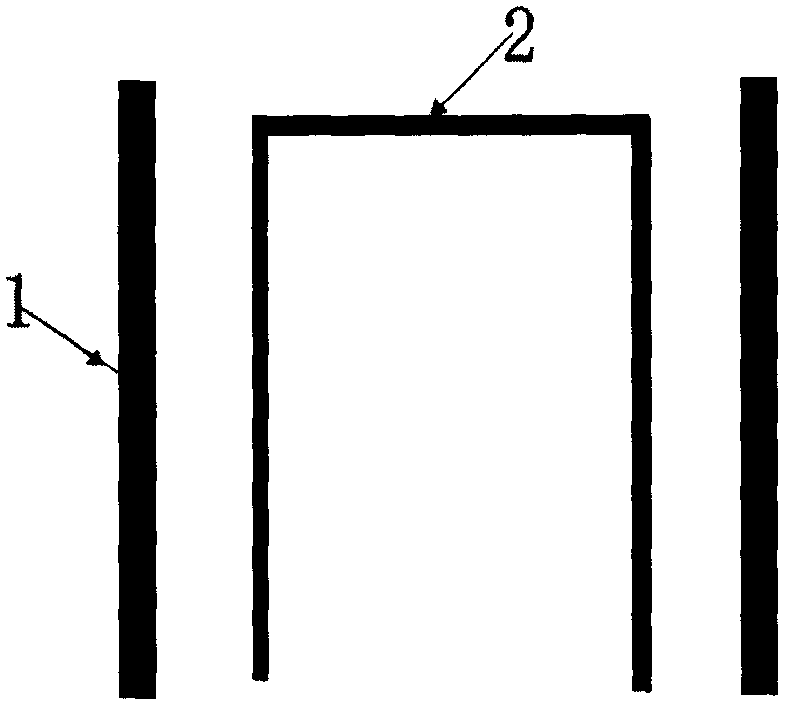

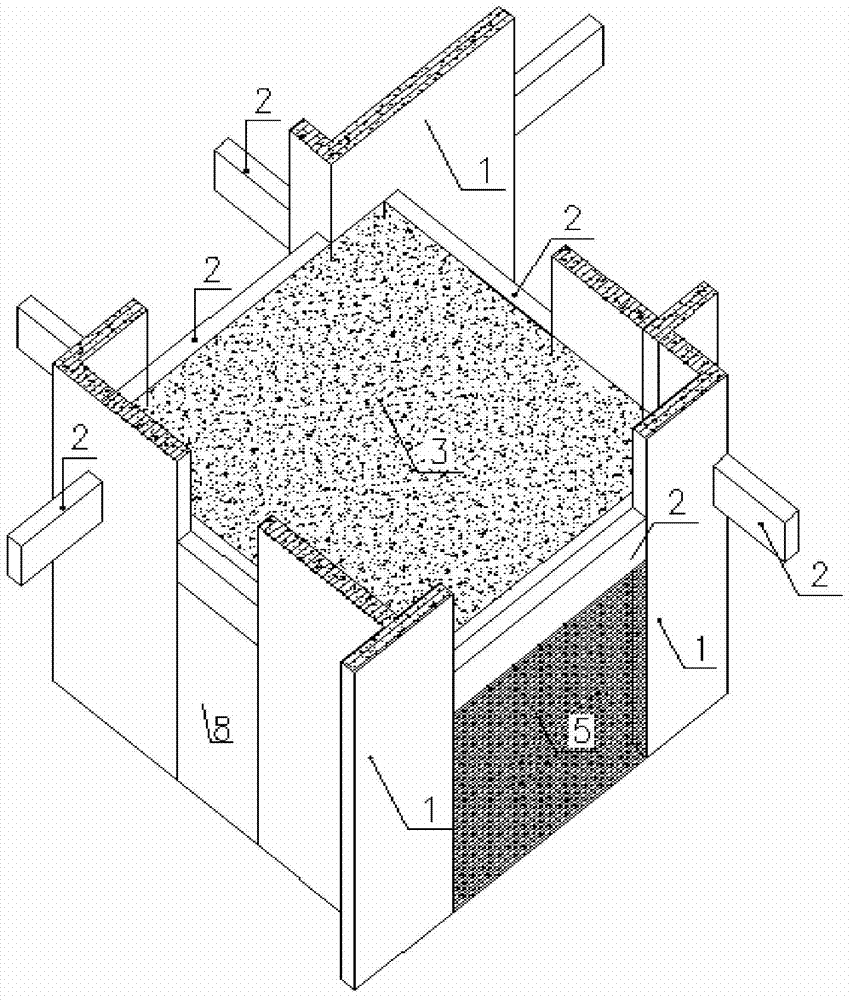

InactiveCN106193272AImprove quality controlEasy to installMoulding surfacesBuilding material handlingNumerical controlEnvironment effect

The invention belongs to the technical field of construction engineering and particularly relates to a prefabricated member building and a construction process thereof. The building comprises a mold body, a lifting device, a hydraulic device, a building body and a numerical control device, wherein the mold body is mounted through the lifting device; the numerical control device is connected with the hydraulic device for constructing the building body. Numerical control is combined with the information technology, and construction waste and cinder are fully used; the building is safe, quick and convenient to mount and has the advantages that the recycling rate of formworks is high, utilization and consumption of the formworks and frame tubes are reduced, the site labor is saved, the construction period is shortened, the site dust is greatly reduced, influence on the environment is small, environmental pollution is reduced, resources are saved and the like.

Owner:刘金泉

A prefabricated steel-concrete shear wall prefabricated building

ActiveCN105089178BImprove quality controlEasy to installWallsBuilding material handlingFoam concreteReinforced concrete

The invention provides a prefabricated steel concrete shear wall prefabricated structure assembly building, the building has a prefabricated structure in the factory, including prefabricated steel concrete shear walls, prefabricated steel concrete beams, reinforced truss concrete floors, prefabricated reinforced concrete stairs, A lightweight masonry partition wall and a prefabricated foam concrete exterior wall; and an installation method for the prefabricated steel concrete shear wall prefabricated structure prefabricated building is also provided. The present invention is characterized in that all components are prefabricated in factories, which is convenient for quality control and can reduce construction difficulties caused by changes in outdoor weather. And assembled on site, the installation is safe, fast and convenient; the reuse rate of the formwork is high, there is no formwork and erection work on site, saving the use and consumption of formwork and erection pipes, saving on-site labor, greatly improving the dust phenomenon on site, and having little impact on the environment ,reduce environmental pollution. The present invention is applicable to various residences and buildings such as high-rise buildings, small high-rise buildings, garden houses, and villas.

Owner:重庆欧冠钢结构有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com