Fabricated double-limb shear wall with an inner arch type coupling beam and assembly method

A shear wall and prefabricated technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of complex assembly process and poor ductility of coupling beams, and achieve the effects of improving seismic performance, convenient welding and improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

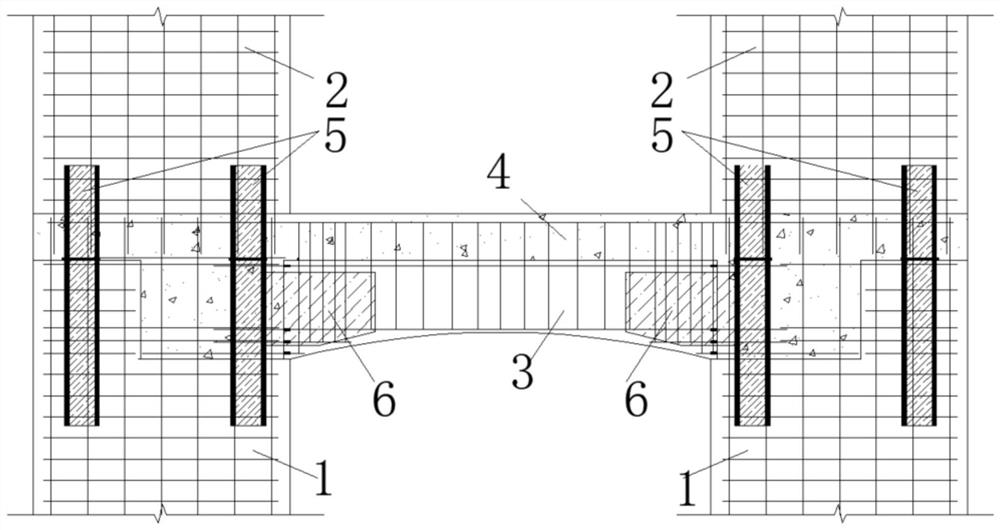

[0028] Such as figure 1 As shown, the present invention provides a prefabricated double-leg shear wall with an inner arched connecting beam, including a first shear wall unit 1, a second shear wall unit 2, an inner arched connecting beam 3, and a laminated layer 4. The vertical connecting member 5 and the horizontal connecting member 6 .

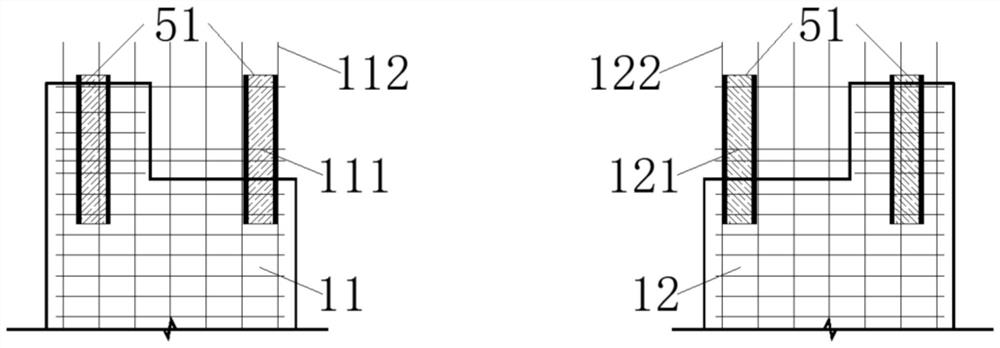

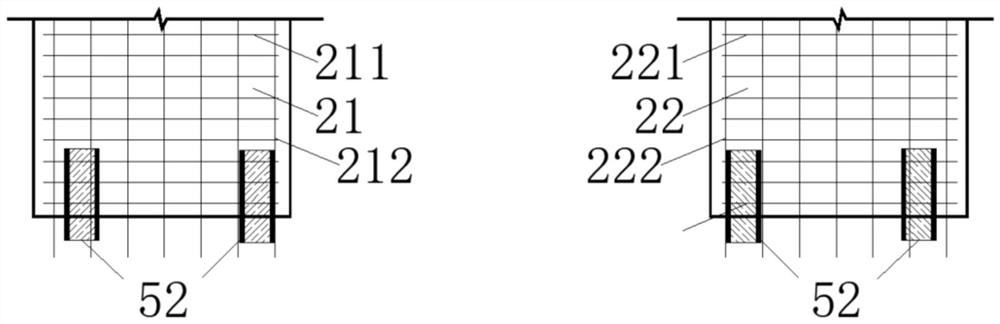

[0029] Such as Figure 1 to Figure 3 As shown, the first shear wall unit 1 is an L-shaped wall pier, which is composed of the left wall pier 11 of the first shear wall unit and the right wall pier 12 of the first shear wall unit. The left wall of the first shear wall unit The limb 11 and the right wall limb 12 of the first shear wall unit are placed at intervals along the horizontal direction, the interval length is less than the span of the inner arch coupling beam 3, and the interior is equipped with horizontal reinforcement bars 111, 121 and vertical reinforcement bars 112, 122; the second The shear wall unit 2 is a rectangular wall pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com