Patents

Literature

72results about How to "Easy to weld and install" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

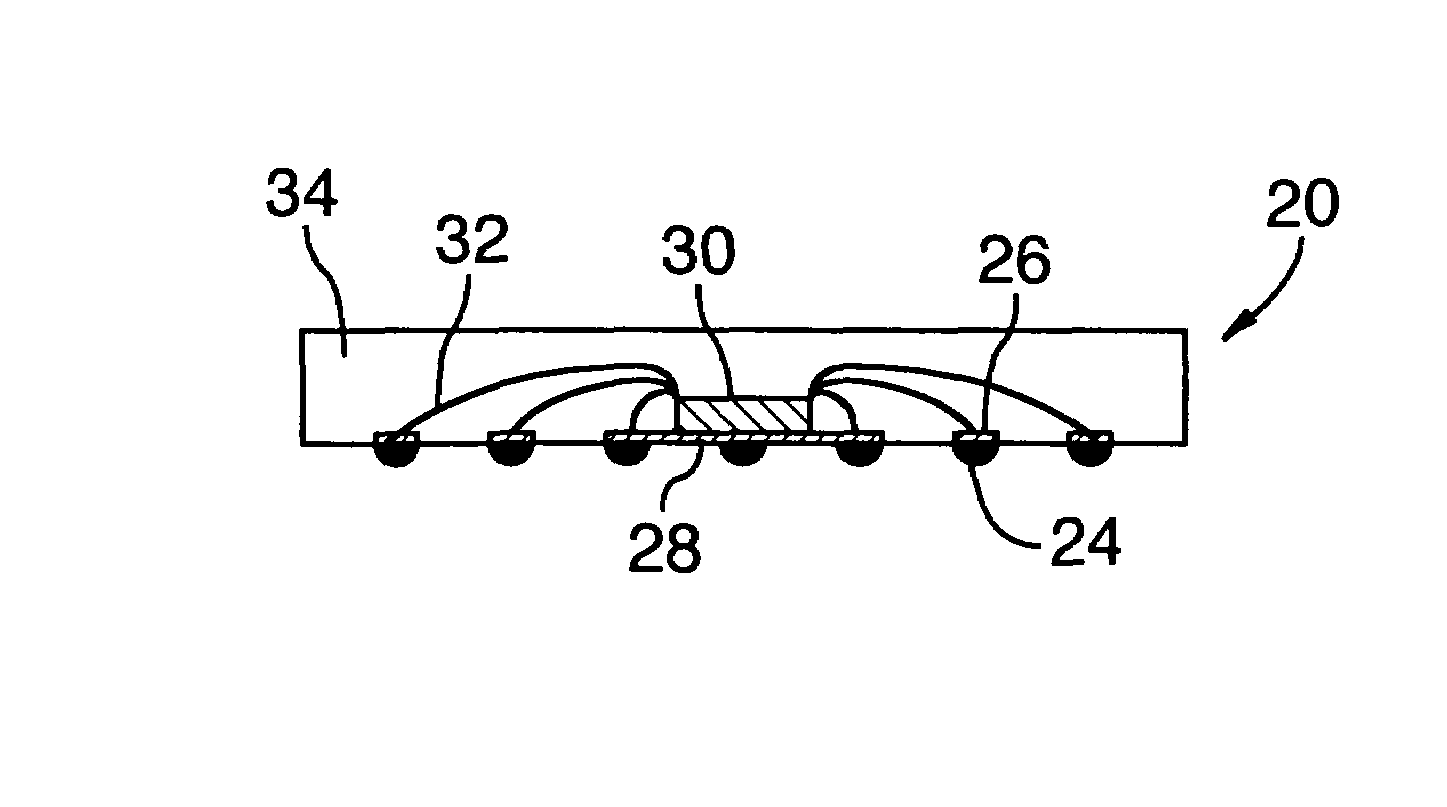

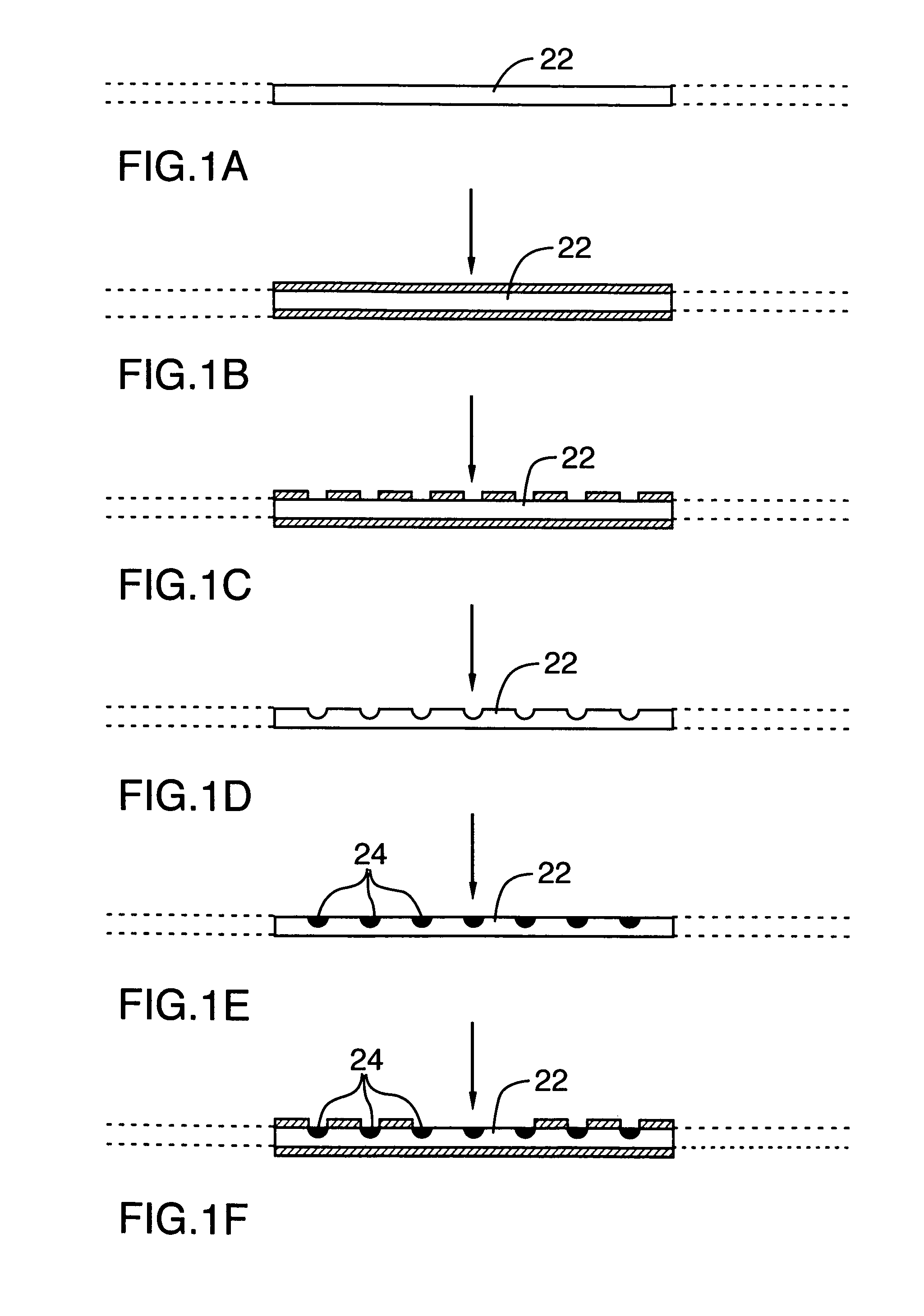

Leadless plastic chip carrier with contact standoff

ActiveUS7595225B1Easy to weld and installEasy to assembleSemiconductor/solid-state device detailsSolid-state devicesContact padElectroplating

Owner:UTAC HEADQUARTERS PTE LTD

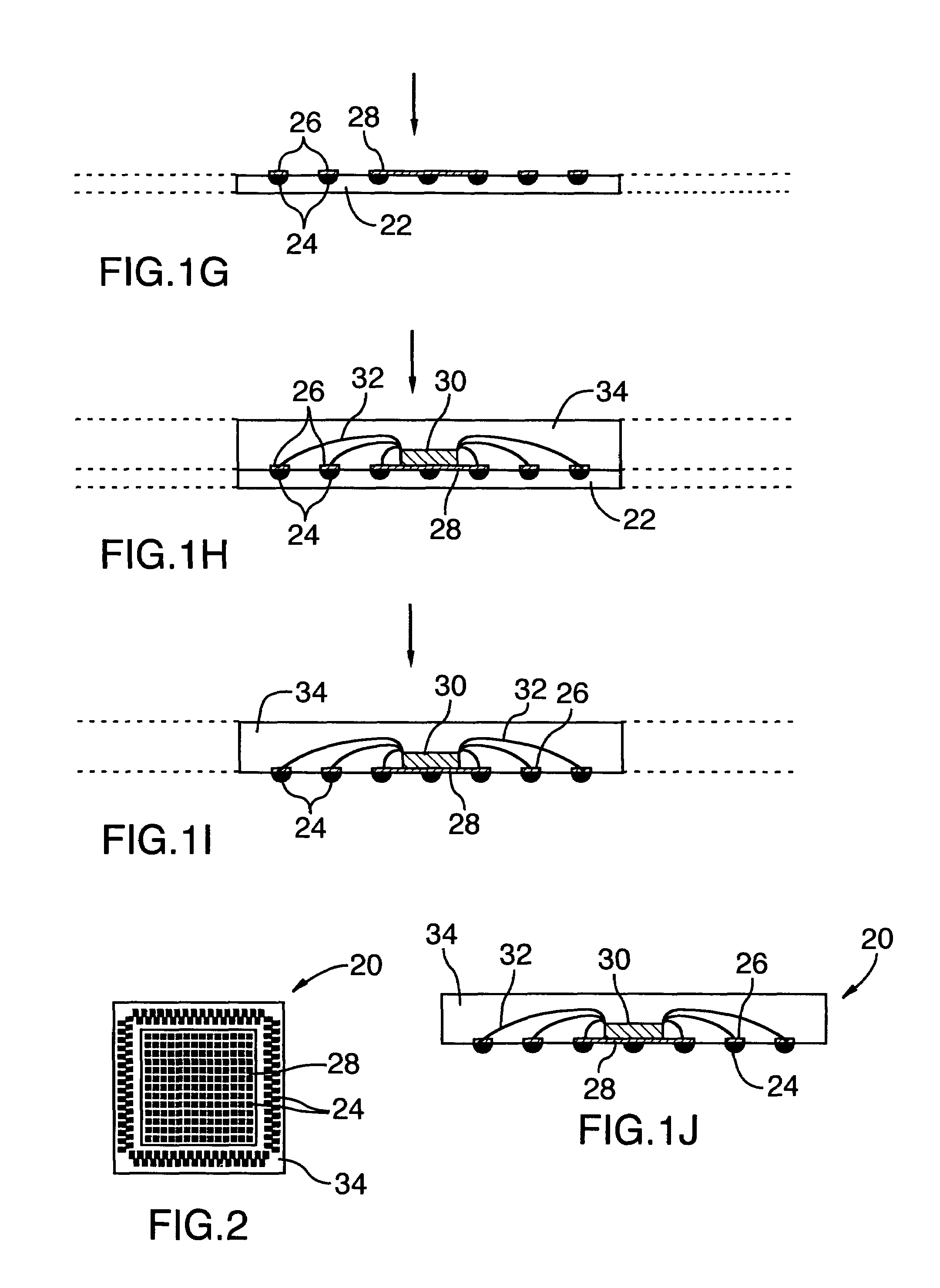

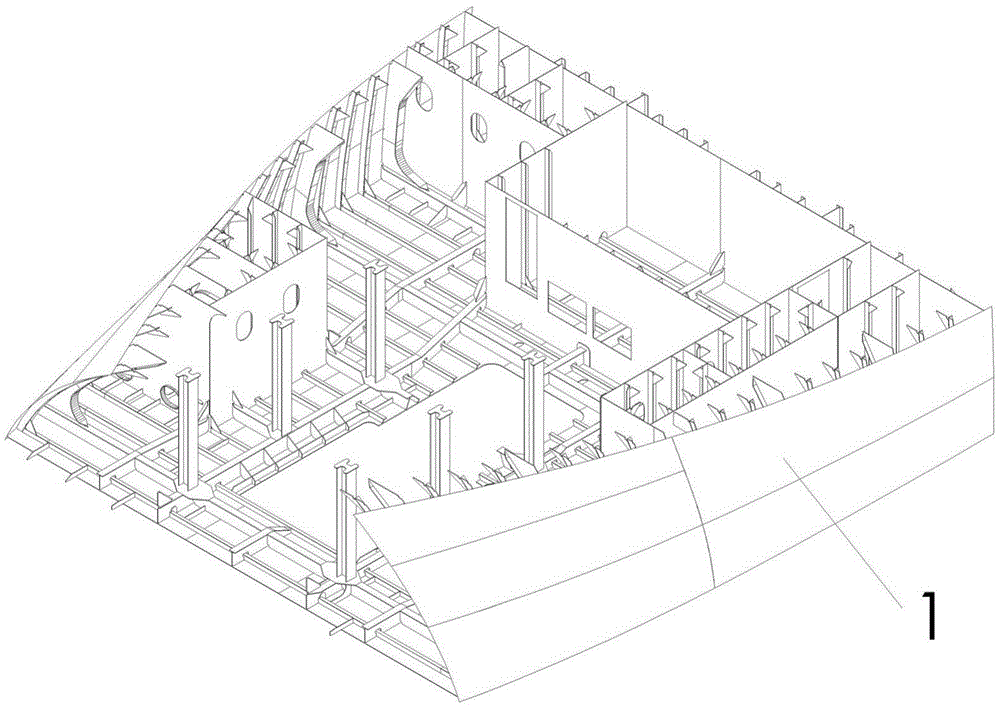

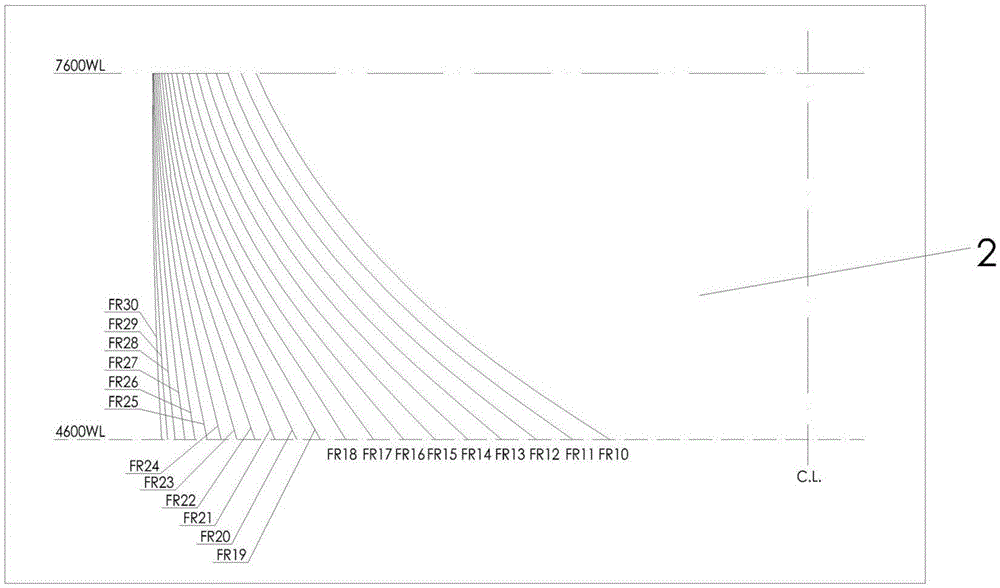

Hull curved block manufacturing method

The invention discloses a hull curved block manufacturing method. The hull curved block manufacturing method includes the steps of carrying out pretreatment on a steel component; carrying out cutting, filling and processing; manufacturing an iron sample table; proofing and modifying an external board rib, specifically, the external board rib is subjected to secondary proofing and firer modification on the iron sample table to make the linetype of the external board rib coincident with the linetype of a corresponding rib on the iron sample table; manufacturing a triangular rib framework, specifically, the triangular rib framework is formed together by the external board rib, a deck cross beam and a temporary inclined strut; manufacturing components, a deck holder and a curved block framework; carrying out assembly welding of a curved external board; and carrying out assembly welding of block parts in bulk and hull block inspection. By adoption of the method, time and cost for manufacturing a curved jig frame are omitted by designing and manufacturing the triangular rib framework; meanwhile, the linetype data of the external board are guaranteed precisely, and the triangular rib framework has sufficient structural stiffness, so that positioning and assembly welding of the external board are convenient, the construction difficulty of the whole curved block is remarkably decreased, and economic benefits are high.

Owner:JIANGSU MODERN SHIPBUILDING TECH

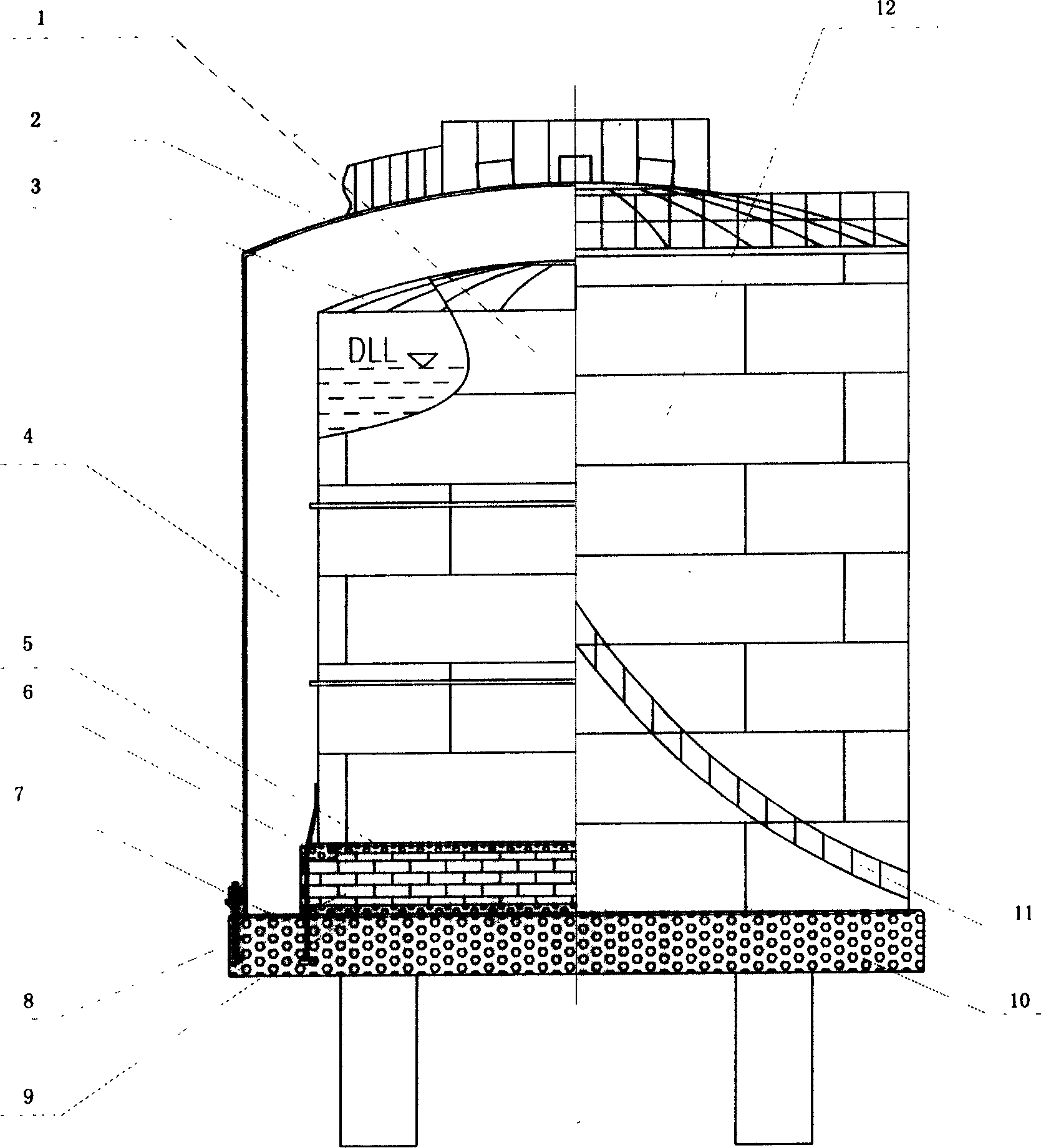

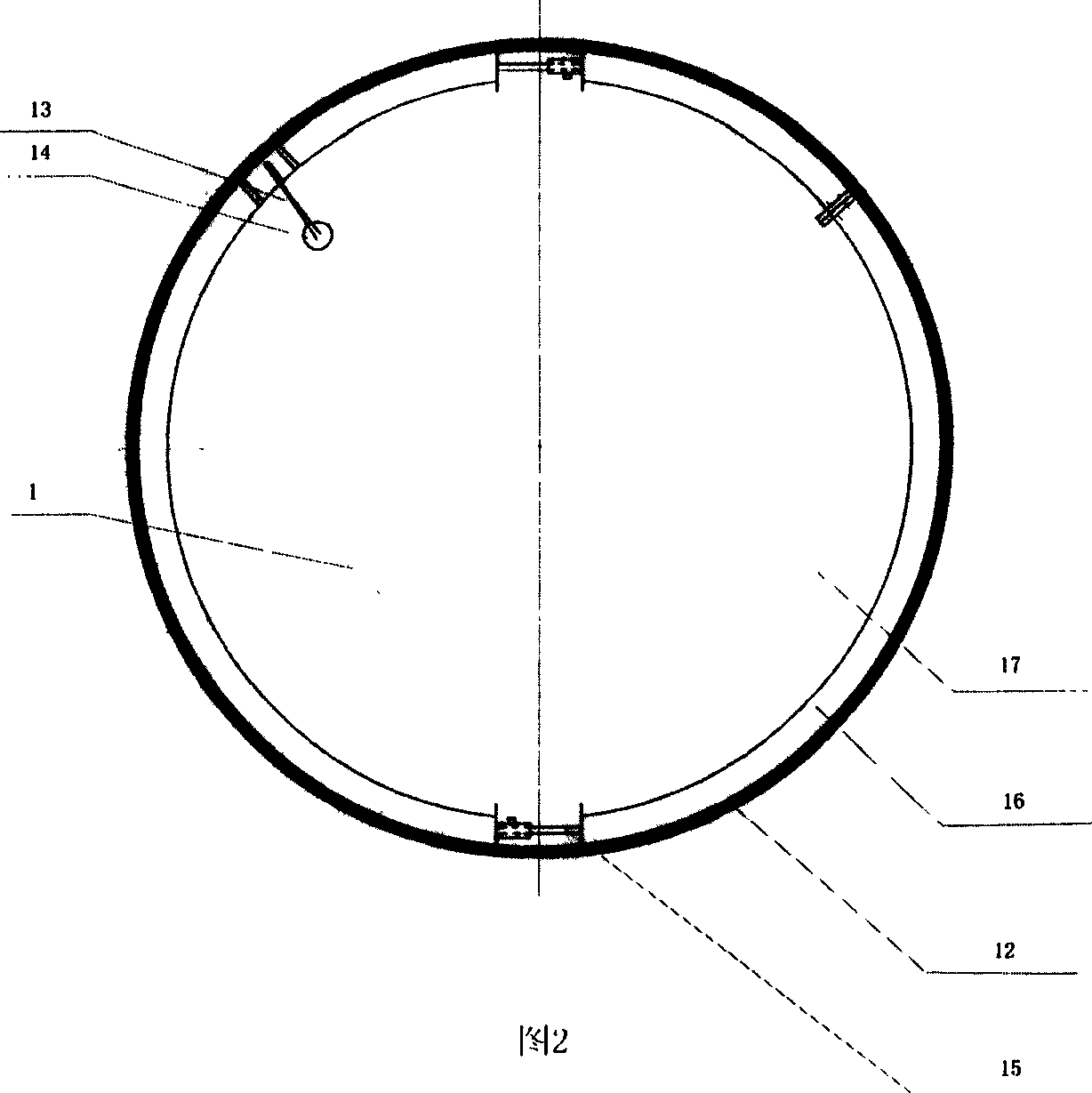

Manufacturing method of low-temperature liquid storage tank

InactiveCN1544843AEasy to weld and installImprove moisture resistanceContainer filling under pressureLiquid storage tankTop cap

The invention discloses a low-temperature liquid storage tank making method, including case installation and inner tube installation. First install the case: weld the first wall plate on the top of the case, install case top cap on the top of the first wall plate, lift the first wall plate, install the second wall plate by the above method, weld the first and second wall plate around seam and lift them. on the analogy of this, from top to bottom, weld the rest wall plate, and finally weld the bottom and the bottom plate. The method of inner tube installation is basically identical with that of the case installation. The case plays a role in screening and shielding wind and rain to benefit inner tube installation, largely heightening welding quality and playing a role in moistureproofing. It eliminates high-altitude work.

Owner:闻建芳

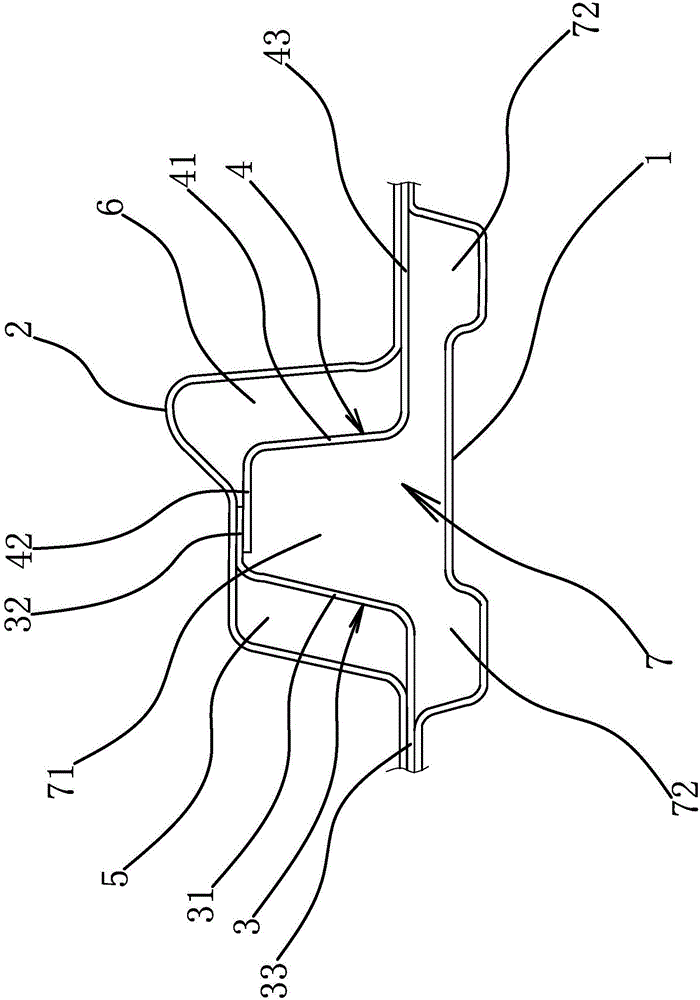

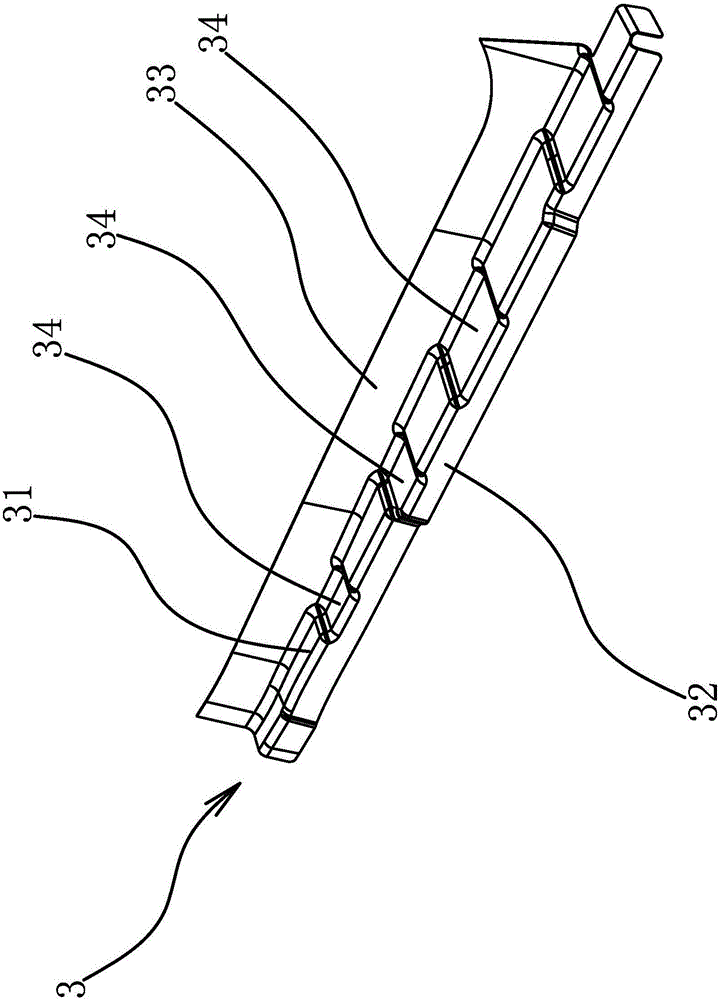

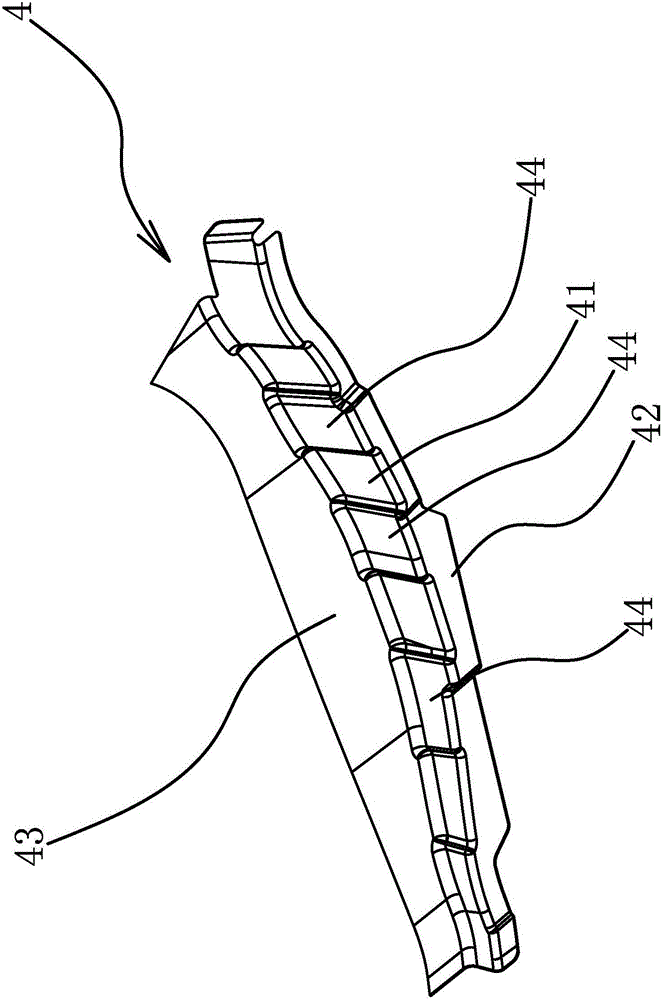

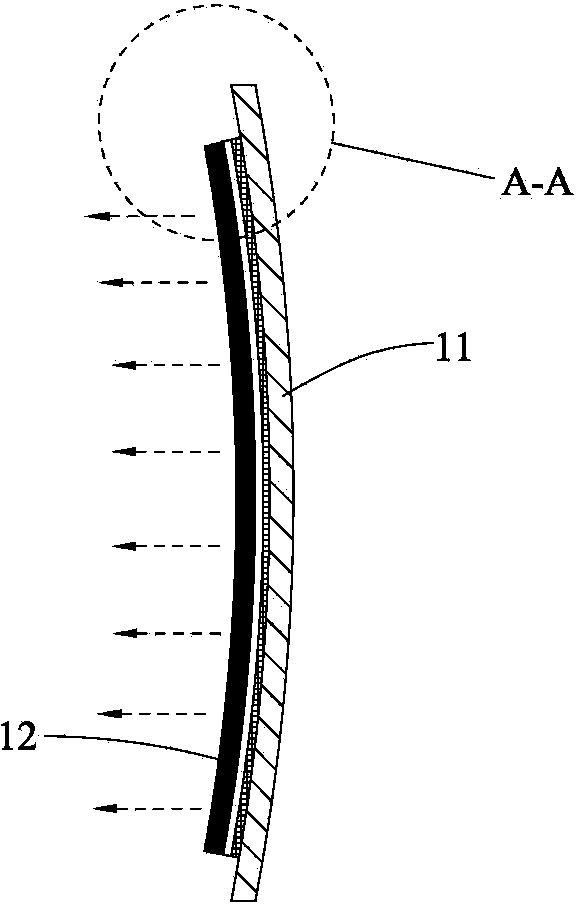

Reinforcing structure of automobile B pillar

ActiveCN105946978AHigh strengthSimple structureSuperstructure subunitsBody weightMechanical engineering

The invention provides a reinforcing structure of an automobile B pillar, and belongs to the technical field of an automobile. The reinforcing structure solves the problem to know how to improve the bending resistance performance of the automobile B pillar while the automobile body weight is reduced. The automobile B pillar comprises a B pillar inner plate and a B pillar outer plate; the reinforcing structure comprises a first reinforcing plate and a second reinforcing plate; the first reinforcing plate and the second reinforcing plate are arranged between the B pillar inner plate and the B pillar outer plate in the longitudinal direction; a first cavity is formed between the first reinforcing plate and the B pillar outer plate; a second cavity is formed between the second reinforcing plate and the B pillar outer plate; the first reinforcing plate and the second reinforcing plate are in mutual lap joint; and a third cavity is formed among the first and second reinforcing plates and the B pillar inner plate. The reinforcing structure has the advantages that only the first reinforcing plate and the second reinforcing plate are used; the automobile body weight is reduced; and meanwhile, the structures and the positions of the first reinforcing plate and the second reinforcing plate are reasonably designed, so that a plurality of cavity structures are formed in the automobile B pillar, and the bending resistance performance of the automobile B pillar is improved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

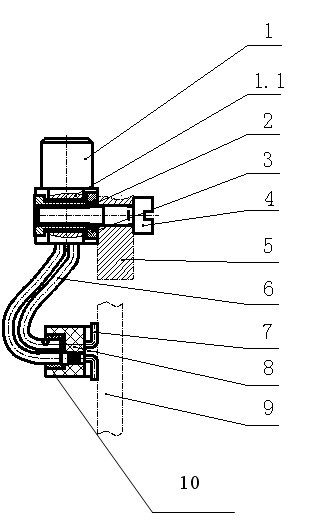

Transition printed circuit board electrical connector

InactiveCN102280738AReduce force transmissionImprove stabilityCoupling device connectionsSurface mountingMating plug

A connection-type printed board electrical connector, including a butt plug connected to a mounting board, a socket fixed on a printed board with a surface sticker, a floating mechanism is provided on the butt plug, the contacts of the butt plug and the printed The pins of the surface mount socket on the board are connected by a flexible cable. The present invention uses a flexible cable to connect the butt plug of the electrical connector and the surface-mounted fixed socket, thereby reducing the force transmission between the two mechanisms. The plug end of the floating installation can float within a certain space range without affecting the socket welded on the printed board, which enhances the stability of the surface mount socket. At the same time, the length of the flexible wire between the two can also be controlled according to requirements, which is convenient for welding and installation.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Shock resistant compound material and preparation thereof

InactiveCN101279522AImprove impact resistanceFull play of impact resistanceLaminationLamination apparatusWear resistantChromium Alloys

The invention relates to the field of anti-wear composite material and discloses a composite material used for resisting impact and wear and a preparation method. The composite material comprises a steel base bottom, a rubber intermediate layer and a high-chromium-alloy wear-resistant layer and the high-chromium-alloy wear-resistant layer is bonded with the steel base bottom through the rubber intermediate layer. The invention has the preparation method that the steel base bottom is cast or welded, then the high-chromium-alloy wear-resistant layer is cast; afterwards the rubber interlayer is vulcanized on the steel base layer and finally the high-chromium-alloy wear-resistant layer is vulcanized and bonded on the rubber intermediate layer. Resisting wear and impact, reducing noise and resisting erosion, the composite material prepared by the invention can be widely applied to the working situations where high impact and wear exists in the industries such as mine, power and machinery.

Owner:XI AN JIAOTONG UNIV

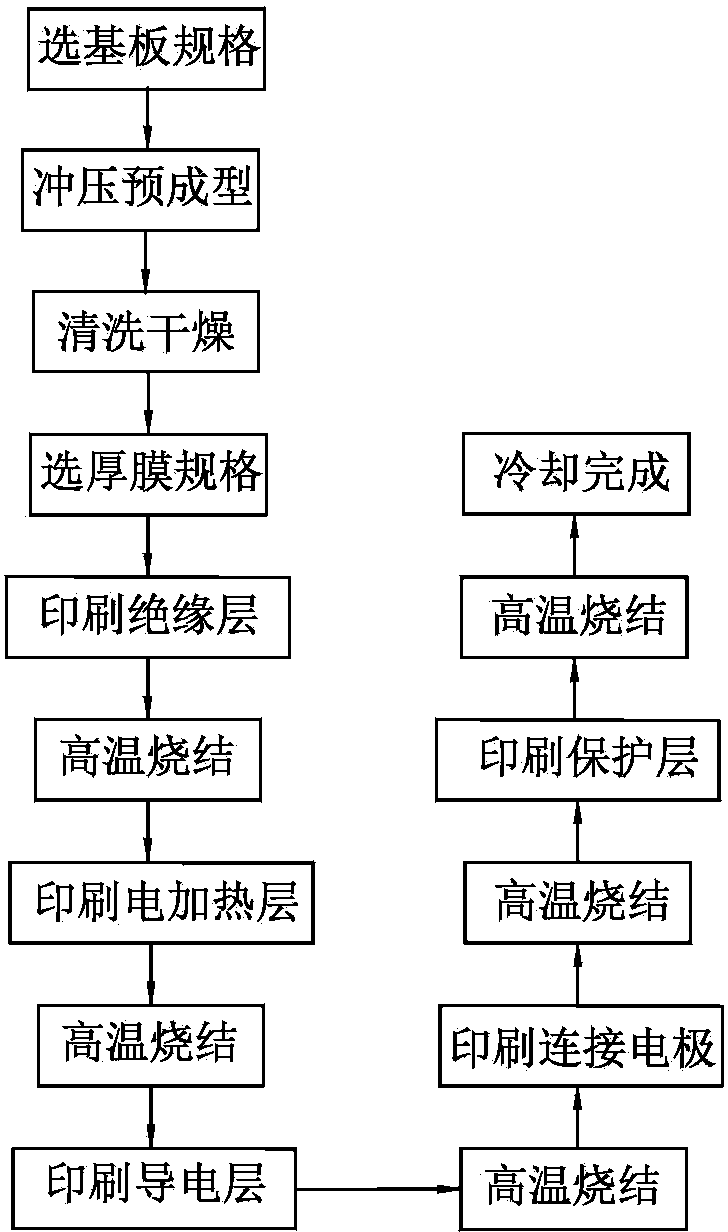

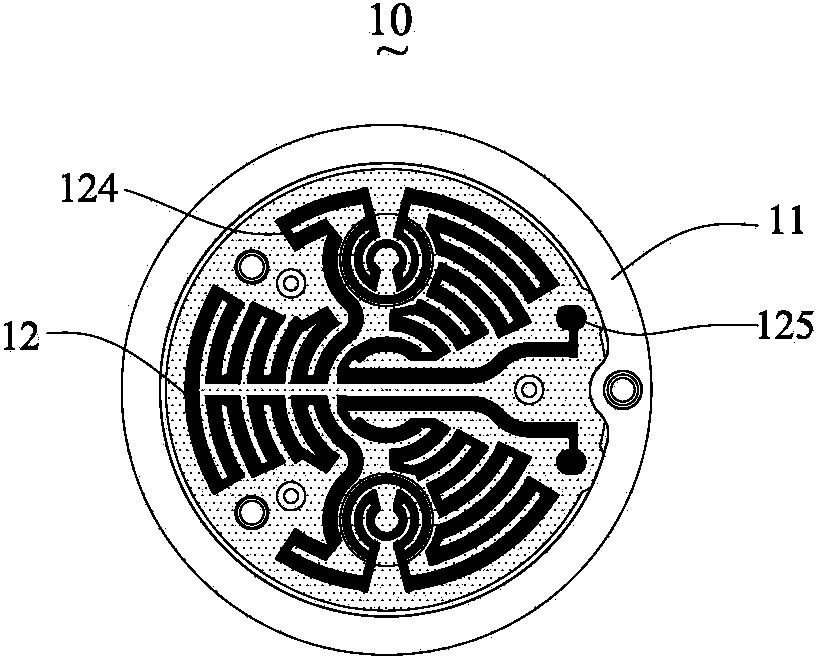

Processing method of thick film heating device, thick film heating container and equipment

ActiveCN103415092APlay the role of dryingAvoid the risk of low yieldBeverage vesselsOhmic-resistance heatingHome applianceComposite material

Owner:JOYOUNG CO LTD

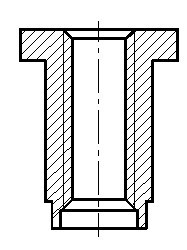

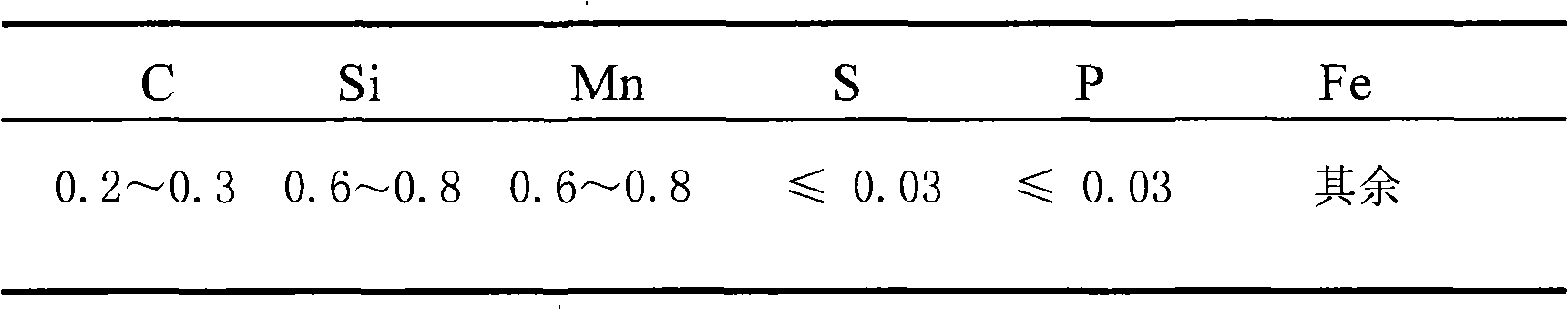

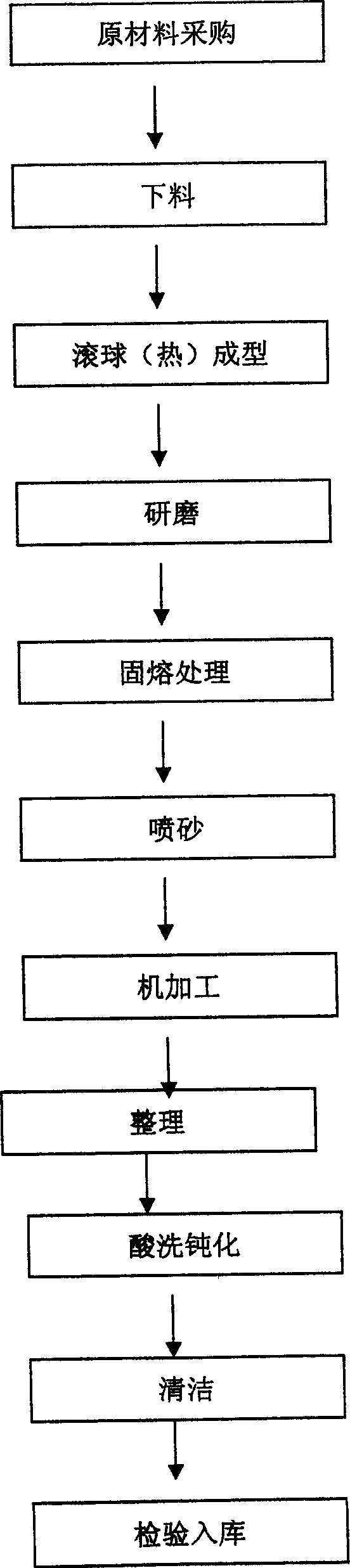

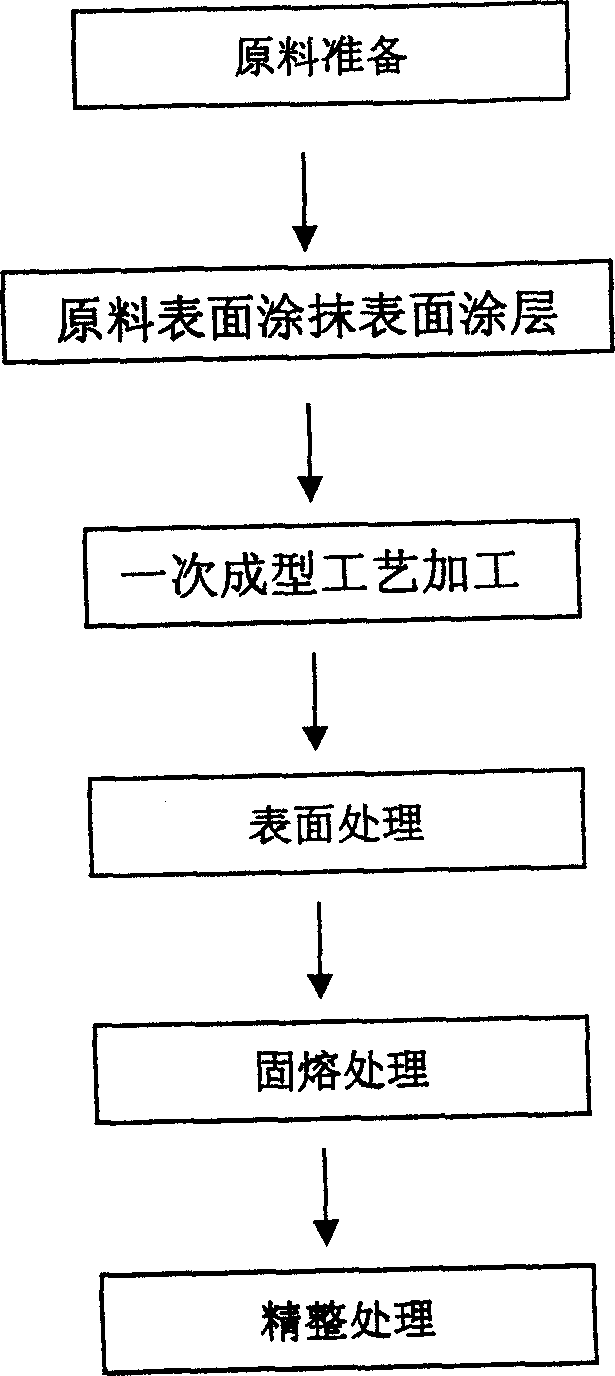

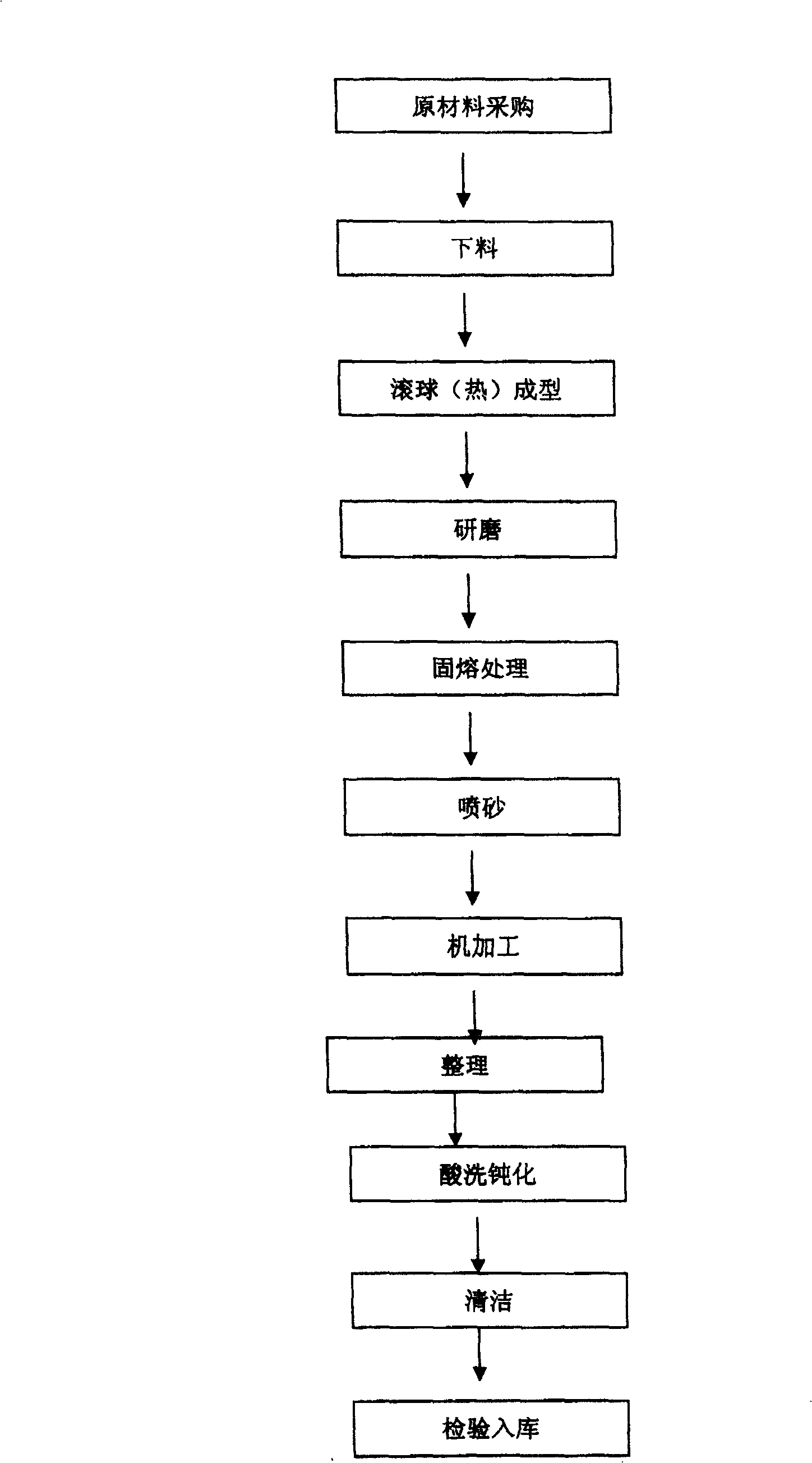

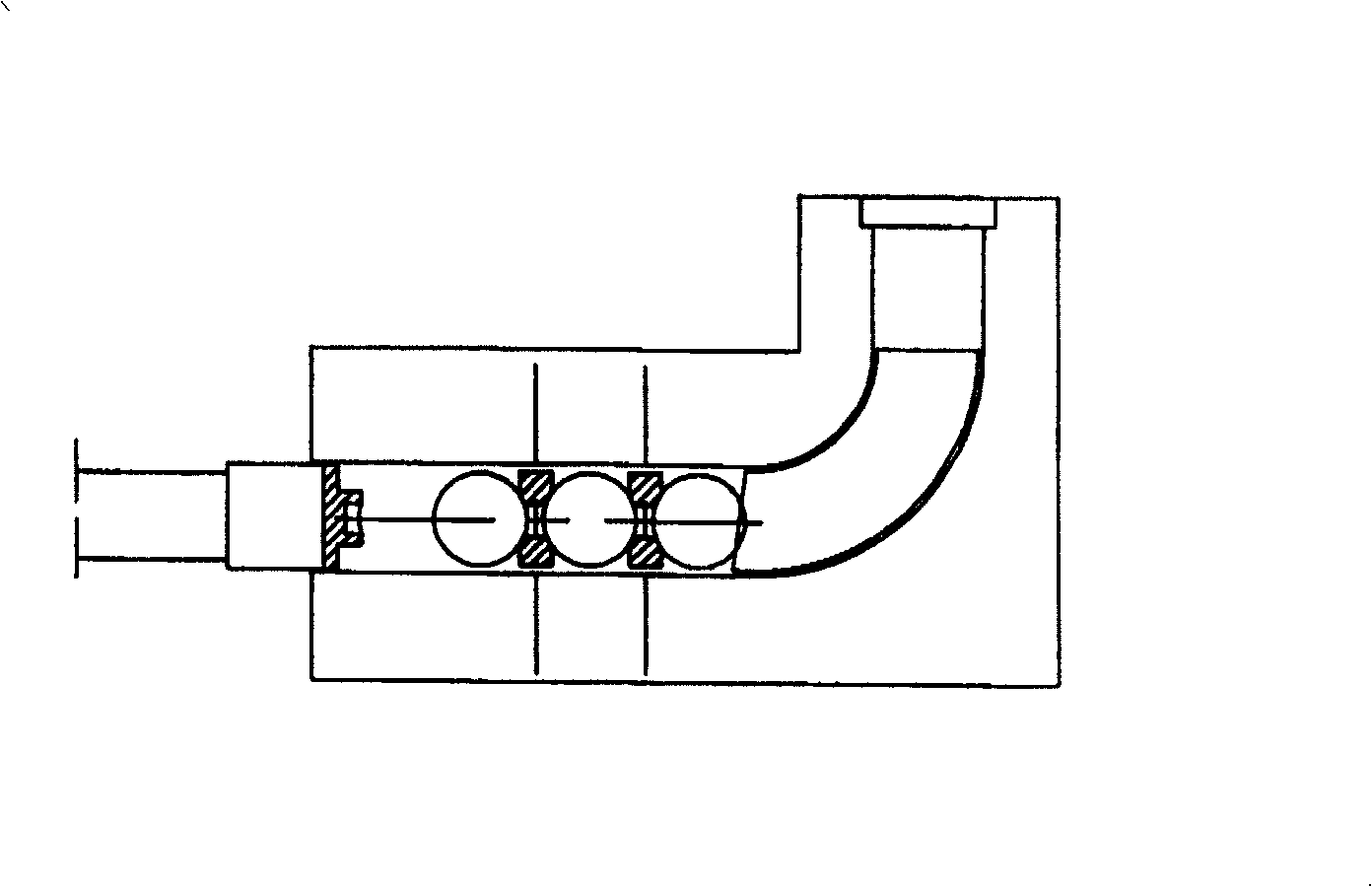

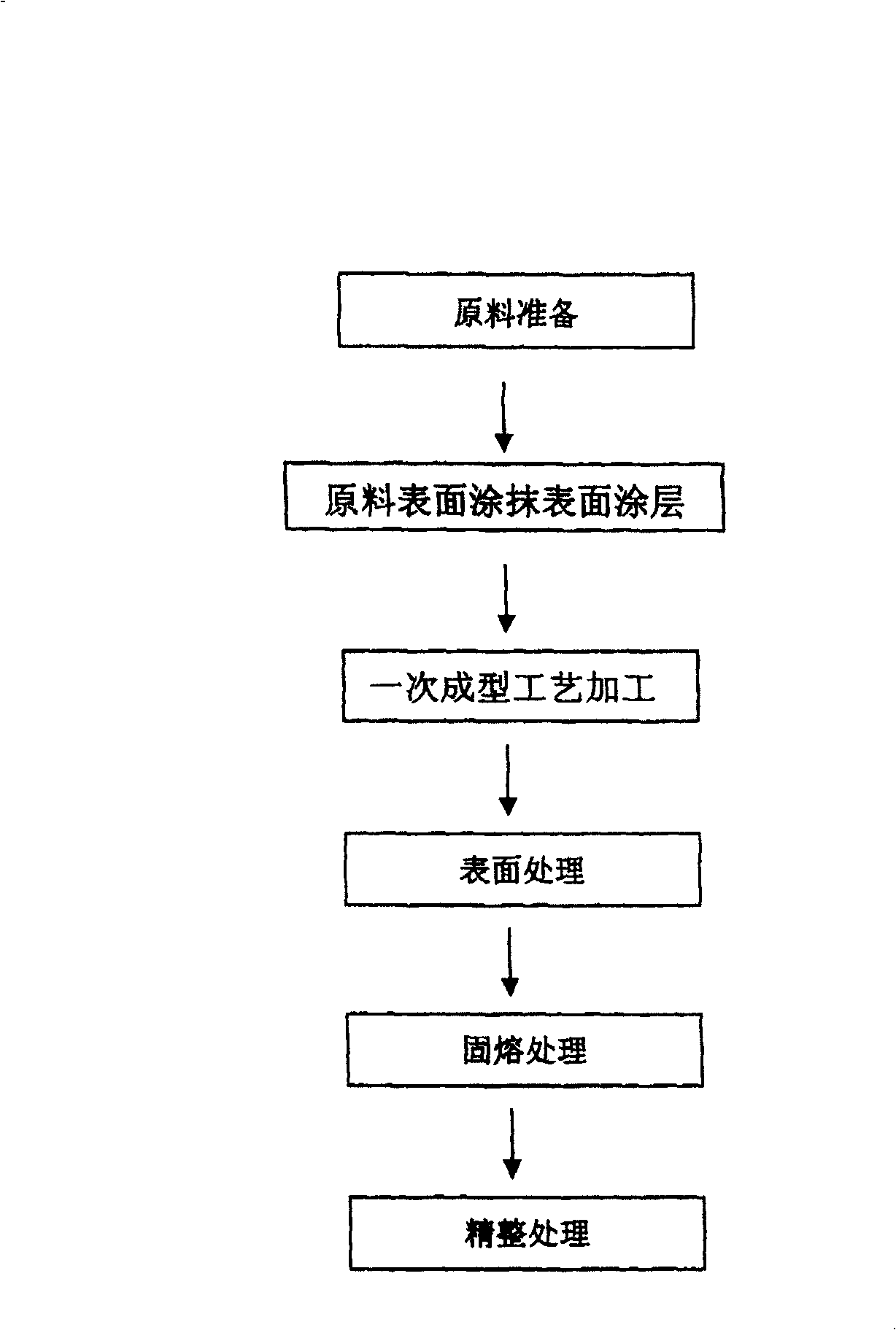

Method for forming pipe fittings by cold extrusion

ActiveCN1843690ALow costEasy to weld and installOther manufacturing equipments/toolsHeat treatment process controlChemical compositionPipe fitting

The invention discloses a method for cold compressing molding tube fittings, which comprises: first, plating surface coats on inner and outer surface of needed tube, to attain a half-finished product whose thickness is uniform and the size meets demand; surface treating the half-finished product; solid solution treating the half-finished product; finishing said half-finished product, to attain the final product. The invention has high efficiency and high quality without changing the property and chemical components of former material. And it can be used in the treatment of variable tube fittings.

Owner:江苏华阳管业股份有限公司

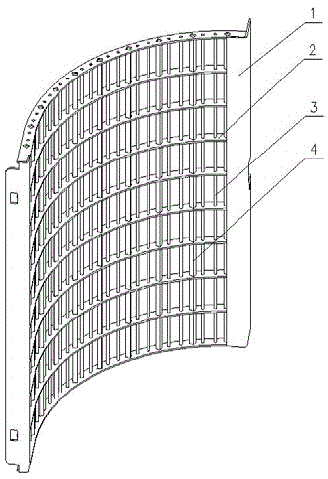

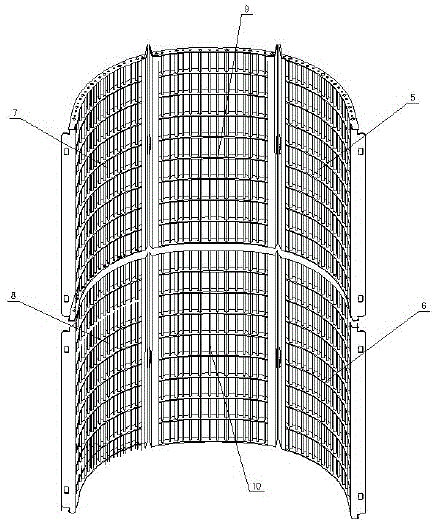

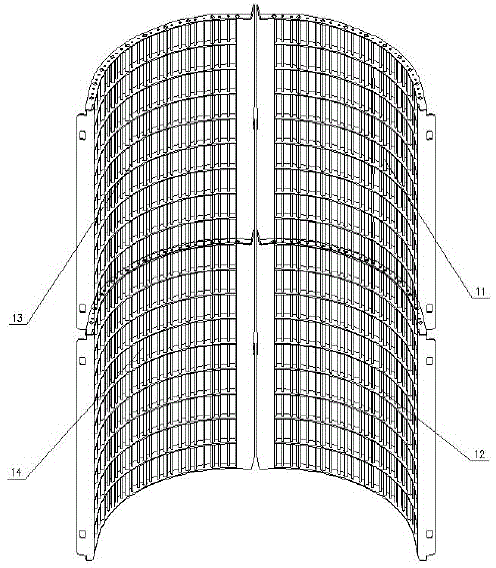

Concave plate screen of combine harvester and concave plate screen device

The invention discloses a concave plate screen of a combine harvester. The concave plate screen comprises frames on the two sides and is characterized in that spaced arc-shaped fixed plates are fixedly connected between the frames on the two frames, the arc-shaped fixed plates are matched with rollers on the harvester, the plate faces of the arc-shaped fixed plates are parallel to one another and are perpendicular to the axes of rotary shafts of the rollers, spaced square steel bars are arranged on the arc-shaped fixed plates in a penetrating mode, at least one round steel bar is arranged between every two adjacent square steel bars, and the square steel bars and the round steel bars are parallel to the axes of the rotary shafts of the rollers. The invention further discloses a concave plate screen device. An arc-shaped screen is formed by assembling the concave plate screens. The concave plate screen and the concave plate screen device are convenient and fast to mount, machining cost is greatly saved, and the threshing and cleaning effect is good. Due to the fact that the concave plate screens can be interchanged, tool manufacturing cost is lowered, and the use and maintenance cost of the harvester is lowered, and the use value of the harvester is improved.

Owner:GUANGDONG KOLEA MODERN AGRI EQUIP

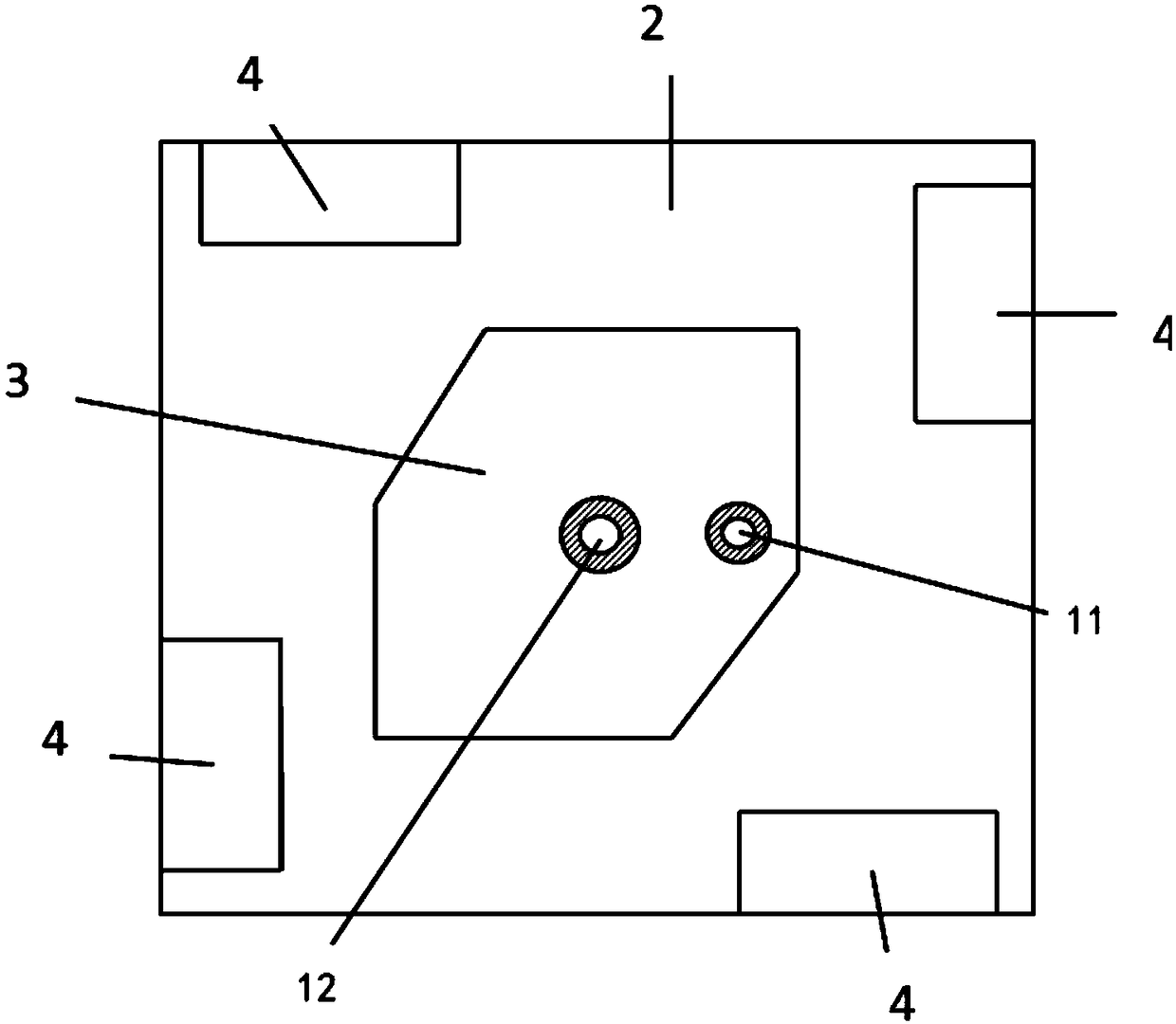

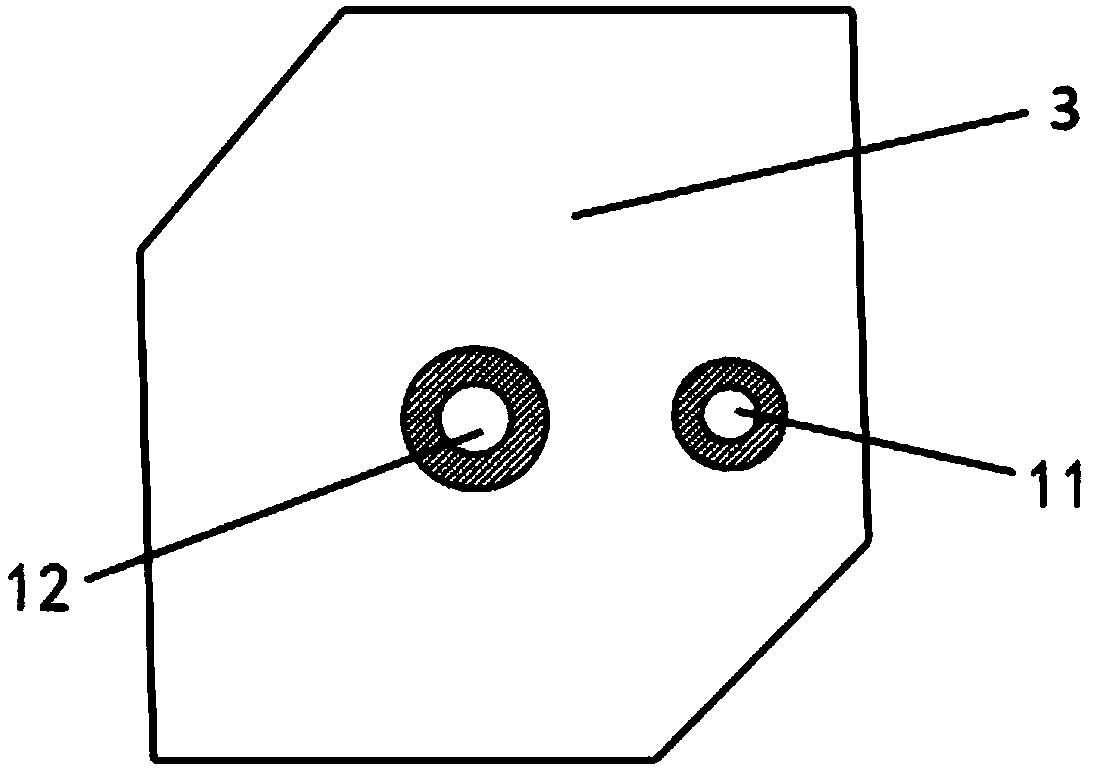

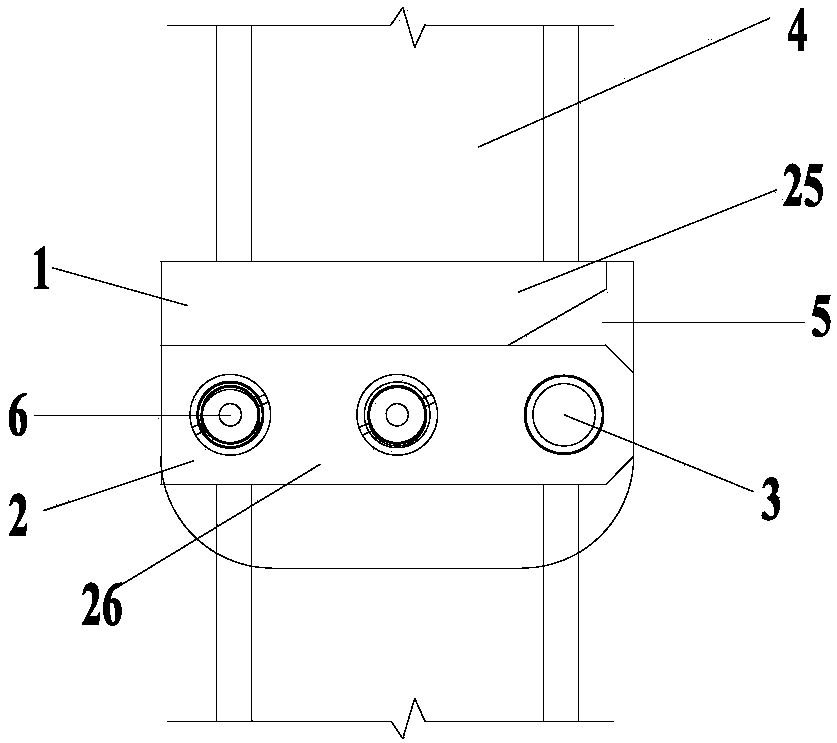

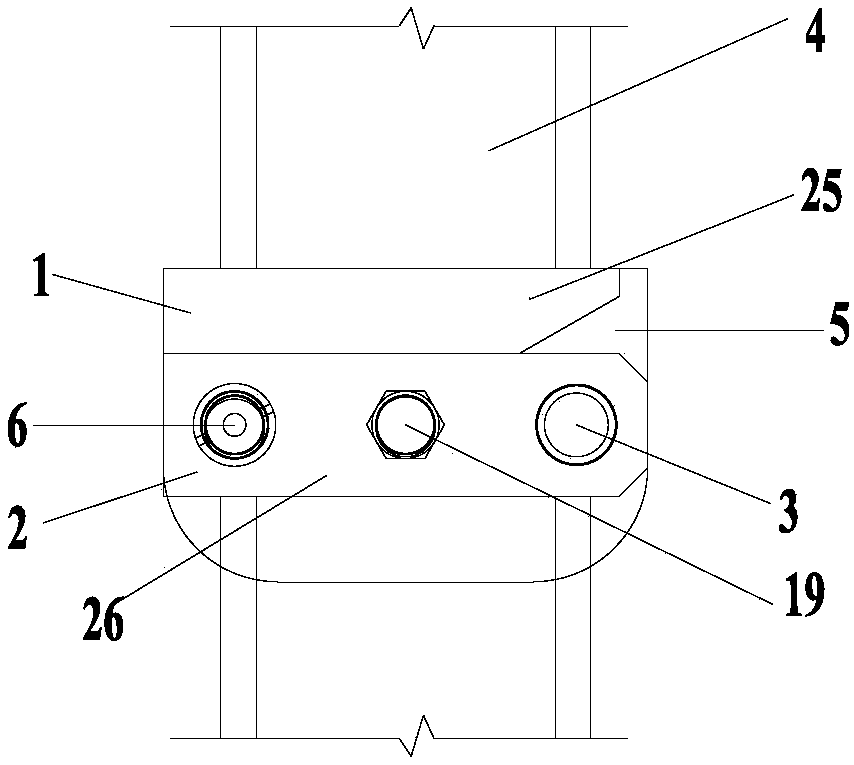

Micro antenna for 5G mobile communication

PendingCN108075226AExcellent impedance characteristicsImprove VSWRRadiating elements structural formsAntennas earthing switches associationStanding wavePhysics

The invention relates to the technical field of an antenna and particularly relates to a micro antenna for 5G mobile communication. The micro antenna comprises a metal reflection plate, a dielectric substrate, a metal square cut angle radiant patch, a metal rectangular radiation patch, a first metallized through hole, a first metal disc, a flanged fixed connector, a second metalized through hole and a short-circuit metal column, wherein the flanged fixed connector is coupled with the first metal disc through the first metallized through hole for feeding, and the short-circuit metal column penetrates through the second metalized through hole. The micro antenna is advantaged in that a coupling feeding mode is employed, the excellent impedance characteristic of the antenna is realized, the antenna standing-wave ratio is improved, work band width of the antenna is enhanced, the structure is simple and compact, the profile is low, and the antenna is easy to process.

Owner:NANJING HOWKING COMM TECH

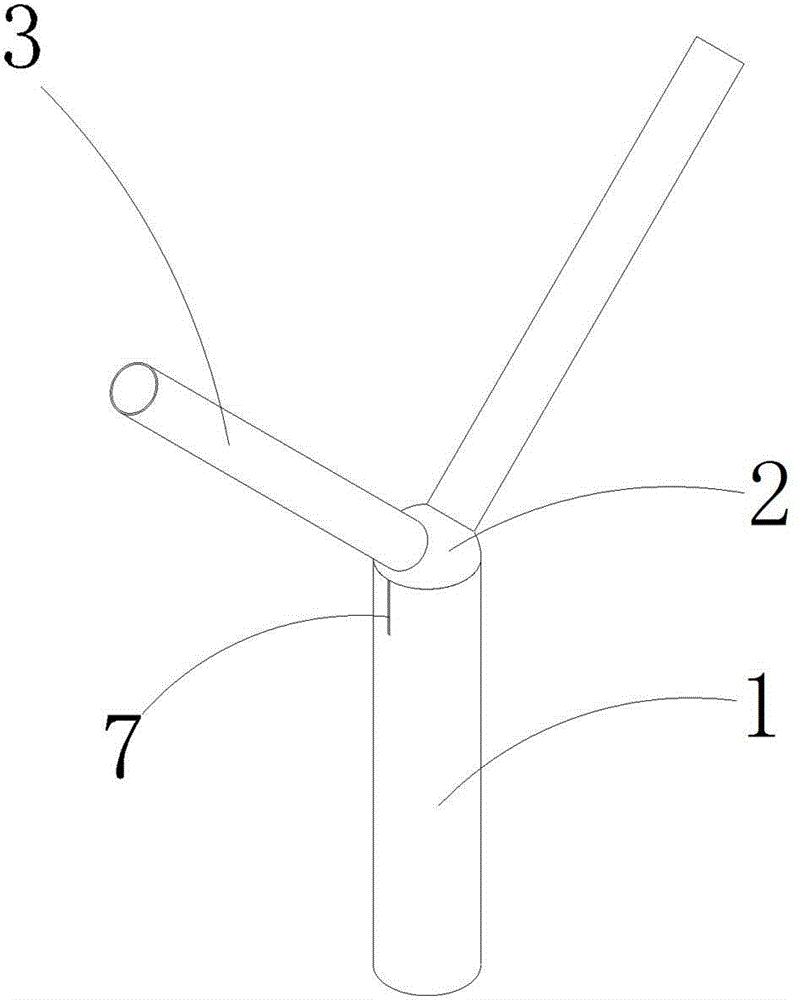

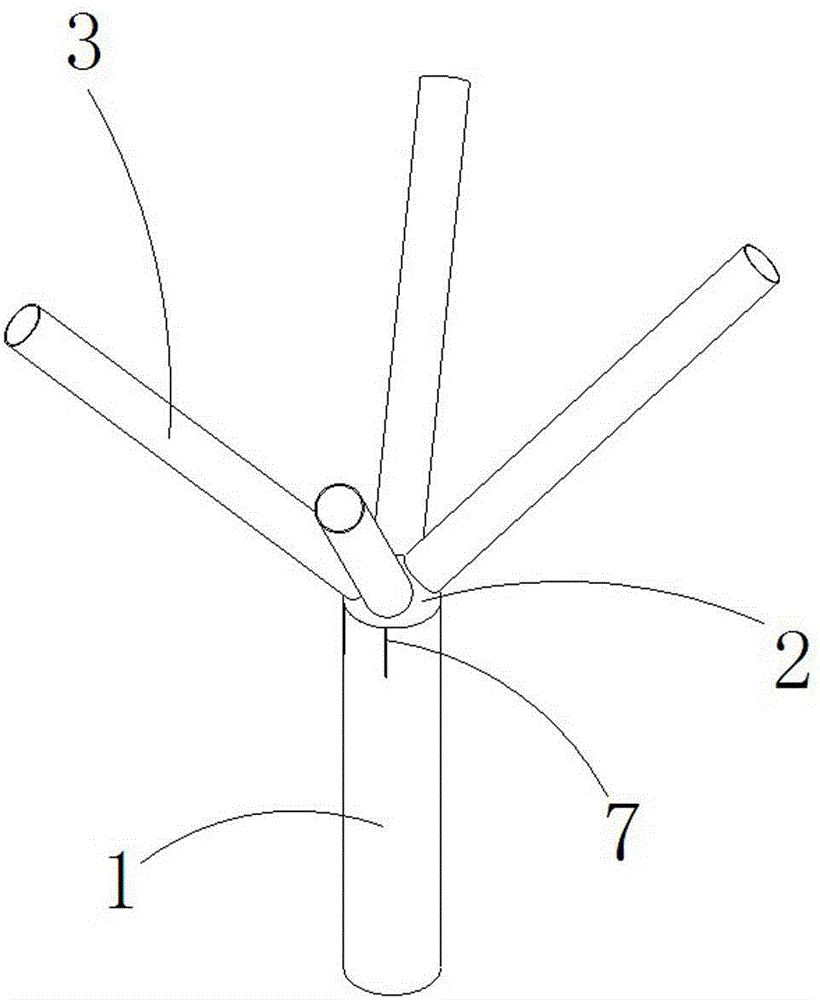

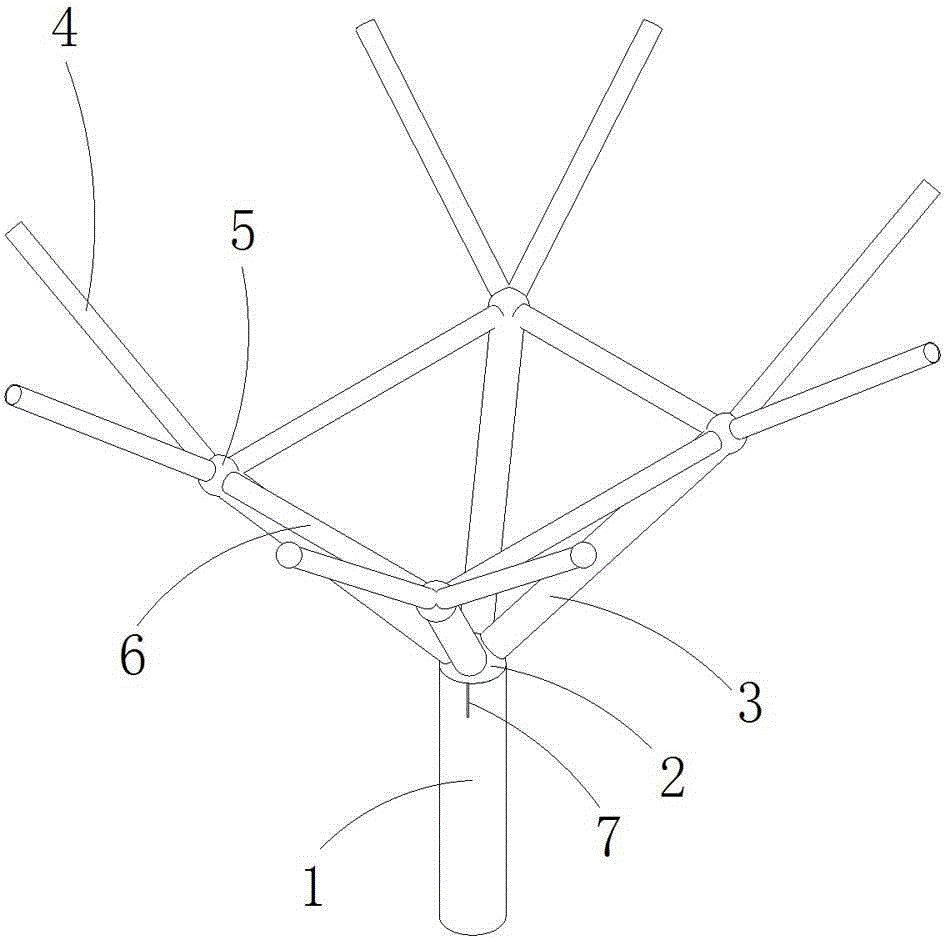

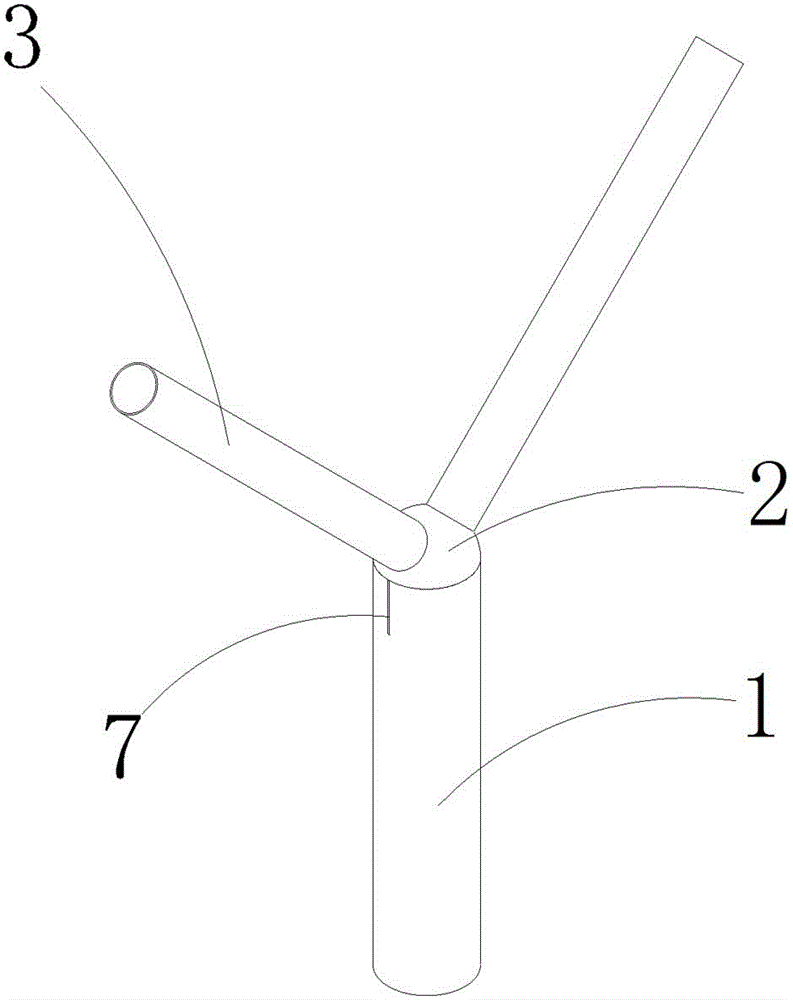

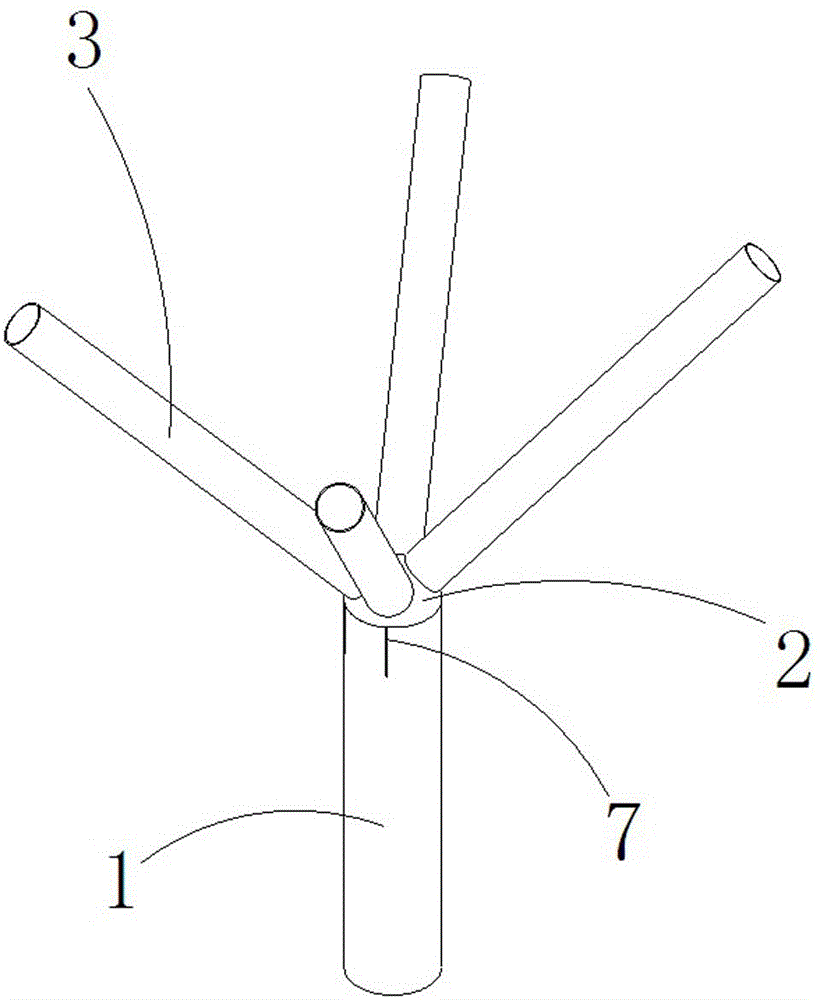

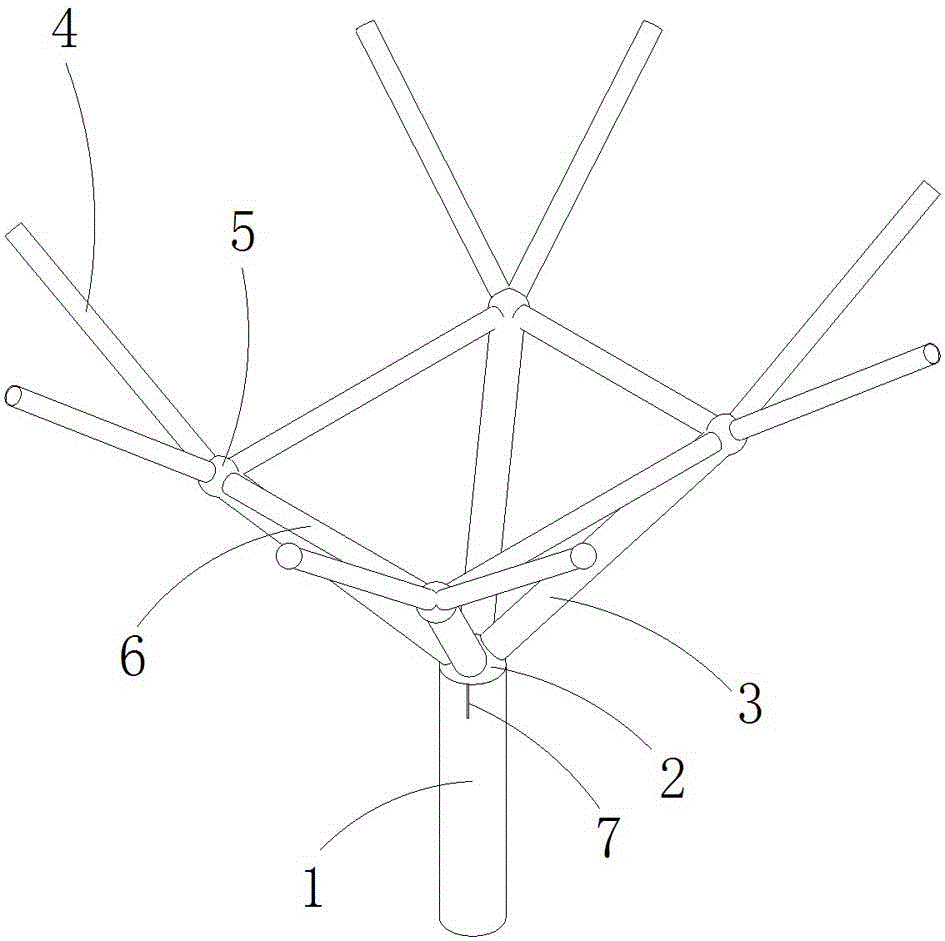

Crotch-shaped element and processing method thereof

ActiveCN104060690AIncrease the use of spaceIncrease spanBuilding material handlingEngineeringUltimate tensile strength

The invention relates to a crotch-shaped element, in particular to the crotch-shaped element and a processing method thereof which are applied to a steel structure. The Y-shaped element comprises a supporting main pipe and top nodes, wherein the top nodes fixed with the supporting main pipe are arranged at the top of the supporting main pipe; at least two bottom branch pipes extending outwards are arranged on each top node; extending mechanisms, which are continuously distributed, are arranged at the upper part of the bottom branch pipes, and comprise branch pipes, upper layer nodes and horizontal pipes; the upper layer nodes are arranged at the upper parts of the bottom branch pipes; the horizontal pipes are arranged between adjacent upper layer nodes; one or more branch pipes are arranged on each upper layer node. The processing method comprises the following steps: cutting, blanking, assembling, welding and detecting strength. The crotch-shaped element and the processing method thereof have the advantages that the structure is compact and reasonable; the modeling is novel; the stress is reliable; resources are saved; the processing is fast and accurate.

Owner:浙江东南网架股份有限公司

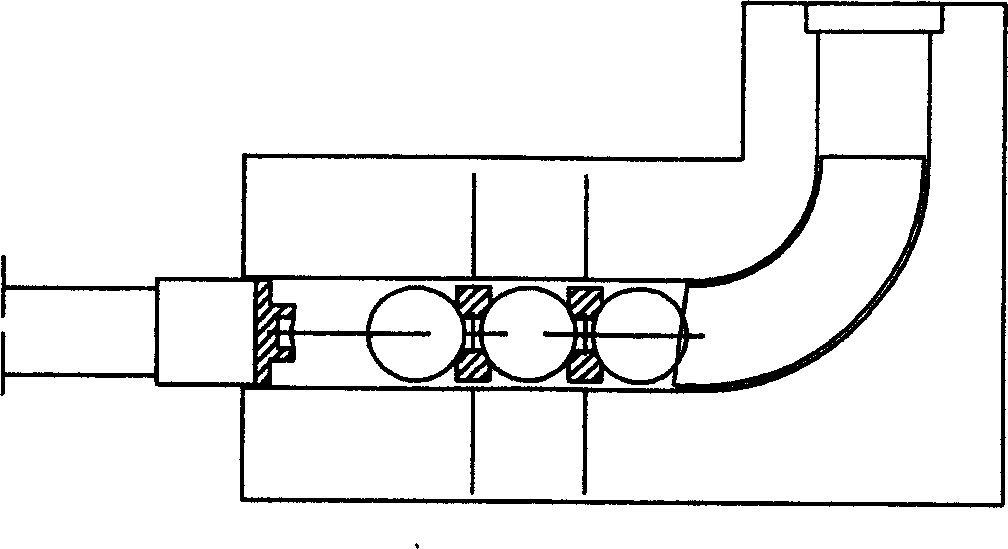

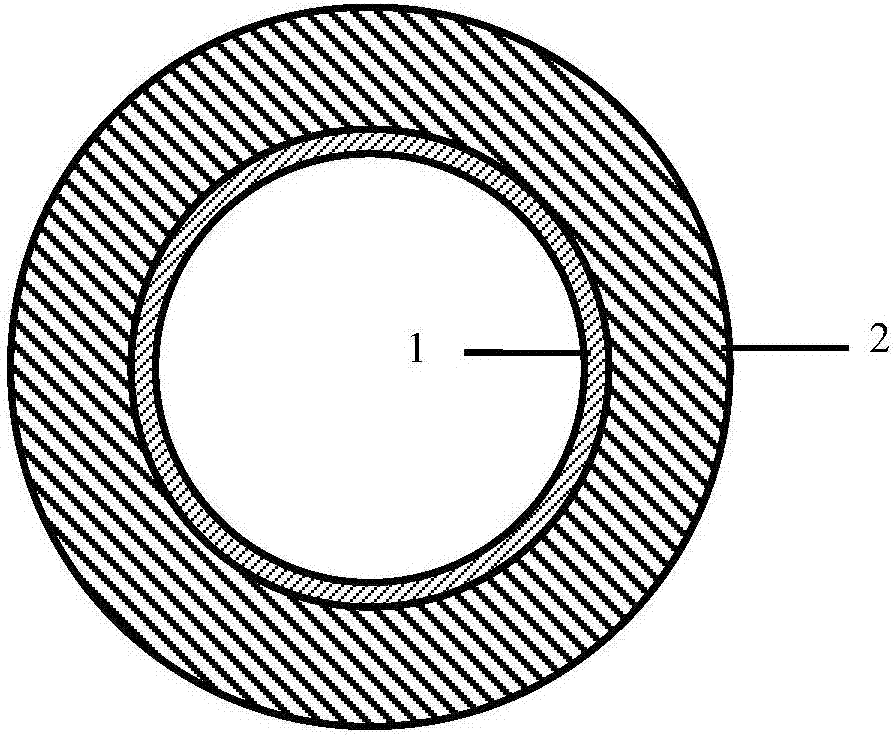

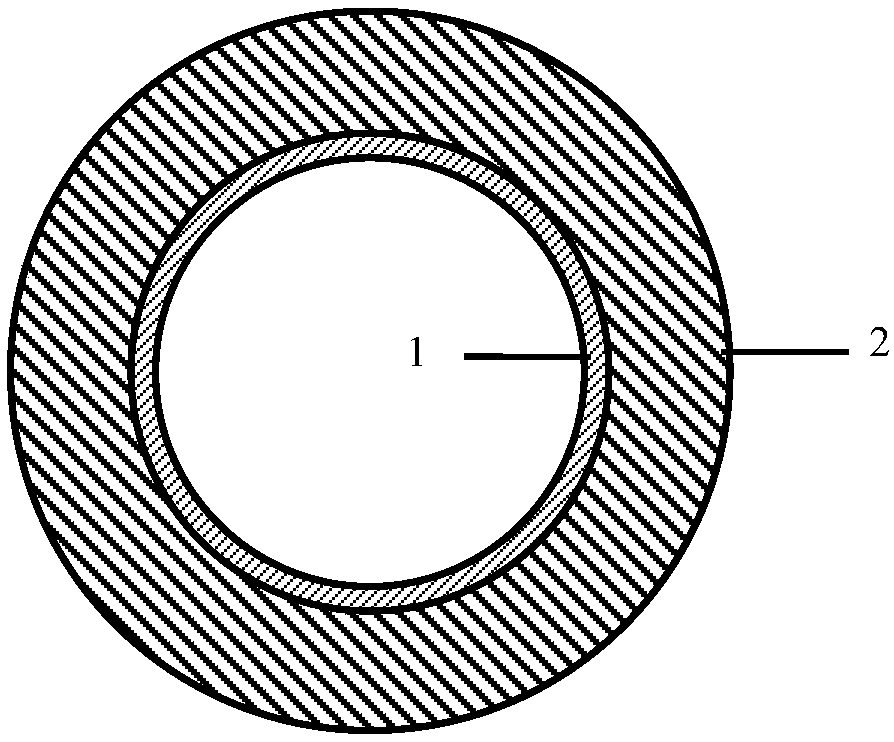

Mechanical composite pipe lined with 825 nickel base alloy and manufacturing method thereof

ActiveCN107143703ABreak the limitsEffective combinationCorrosion preventionPipe protection against corrosion/incrustationAlloyUltimate tensile strength

The invention discloses a mechanical composite pipe lined with 825 nickel base alloy and a manufacturing method thereof. The mechanical composite pipe lined with the 825 nickel base alloy comprises an inner 825 nickel base alloy pipe and an outer low-carbon steel pipe. The manufacturing method comprises the following steps: after the inner 825 nickel base alloy pipe and the outer low-carbon steel pipe are shaft assembled, mechanical diameter expansion equipment is adopted for performing sectional type diameter expansion or continuous diameter expansion on the inner part of the assembled pipe; the diameter expansion quantity is enough to enable the inner 825 nickel base alloy pipe to generate plastic deformation, and the deformation quantity of the outer low-carbon steel pipe is close to the maximum elastic deformation; after the diameter expansion is completed, a reducing and sizing mill is adopted for performing reducing and sizing treatment on the outer part of the assembled pipe; the mechanical composite pipe is inspected after being subjected to diameter expansion at the inner part and reducing and sizing treatment at the outer part; and after the mechanical composite pipe passes the inspection, each of the pipe ends is cut by a certain size for build-up welding and subjected to groove processing treatment. The manufacturing method provided by the invention is not limited by the material strength of the inner and outer pipes, all needed is to change the reducing and sizing quantity of the outer part, and the effective combination of the inner 825 nickel base alloy pipe and the outer low-carbon steel pipe is realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

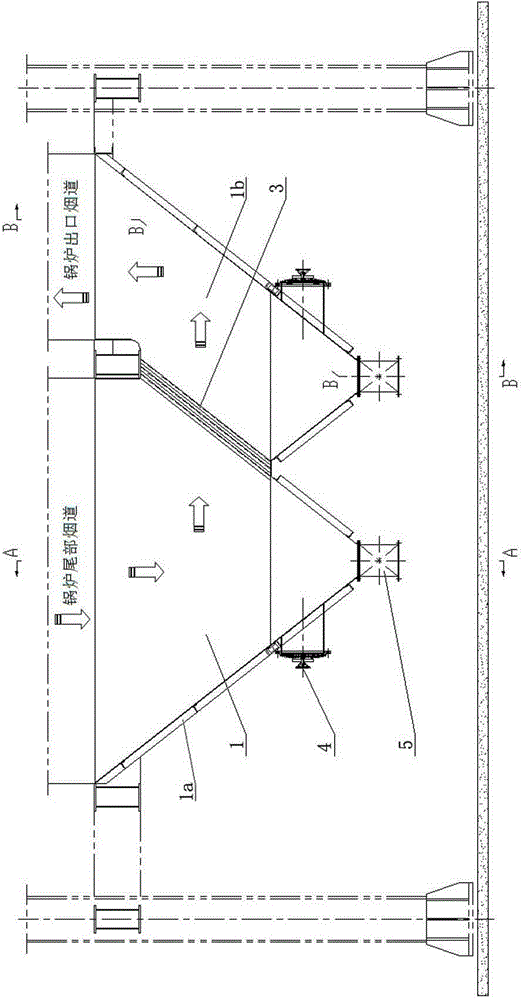

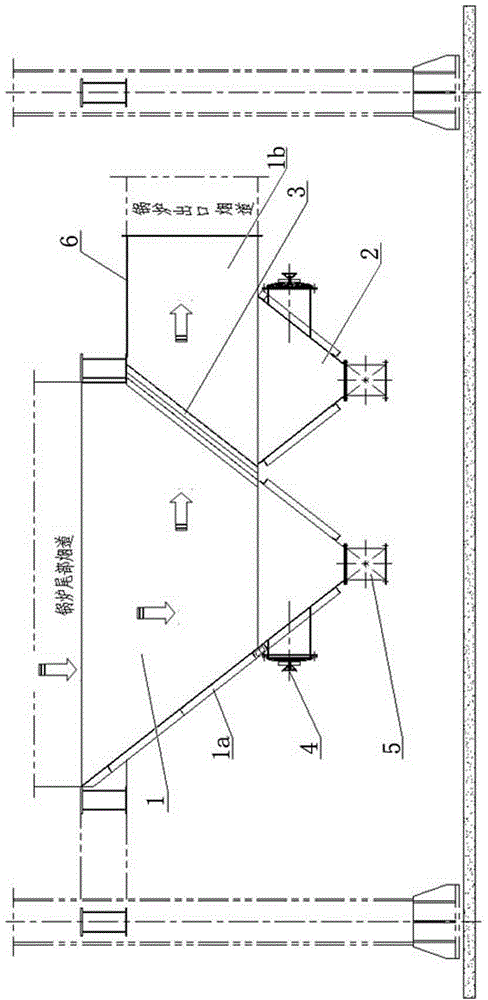

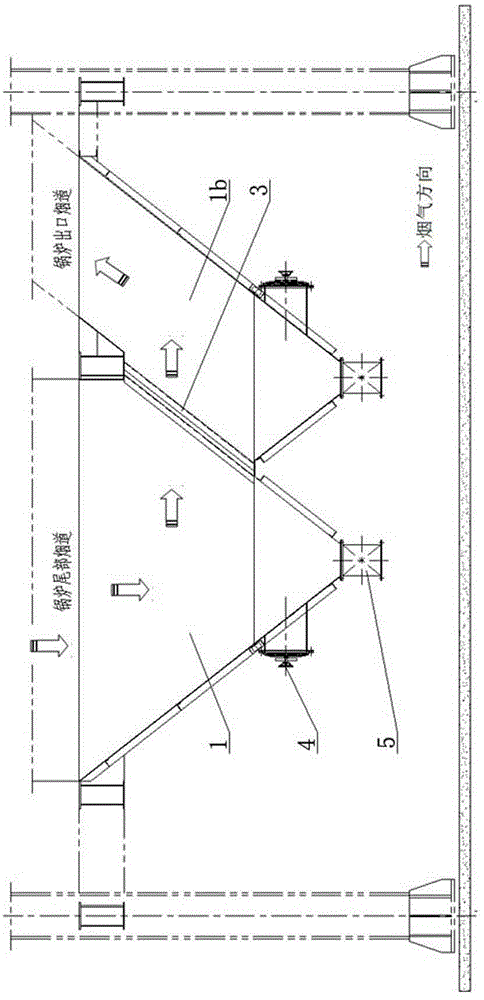

Irregular ash falling device

The invention belongs to the technical field of boiler parts, and specifically relates to an irregular ash falling device. The device comprises a front ash bucket, a rear ash bucket, an access door and a rotary ash discharging valve; the front ash bucket is connected with a smoke channel at the tail part of a boiler; the rear ash bucket which is communicated with the front ash bucket is connected with a smoke channel at an outlet of the boiler; a trough type separator is obliquely arranged at a part in which the front ash bucket is connected with the rear ash bucket. With the adoption of the device, lots of ash in the smoke can be effectively separated, thus the phenomenon of ash-doped smoke returning of the ash buckets can be avoided; the effect of removing ash is obvious, the smoke purifying cost is decreased, and the irregular ash falling device is applicable to the arrangement of ash buckets of boilers of different types.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

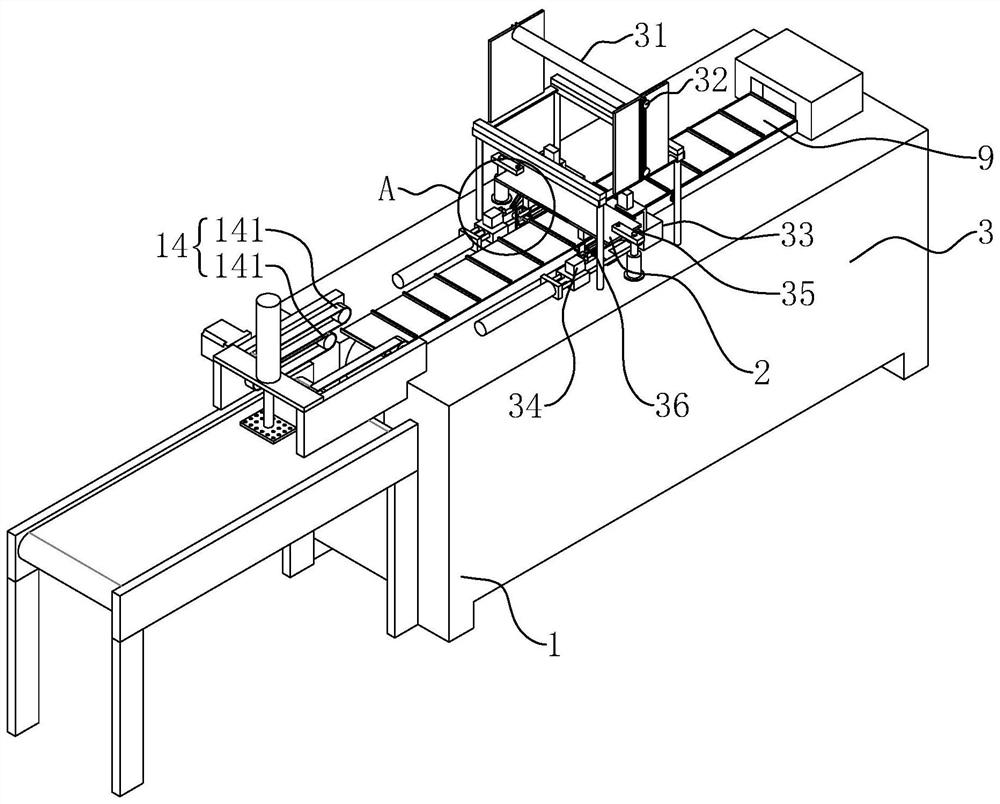

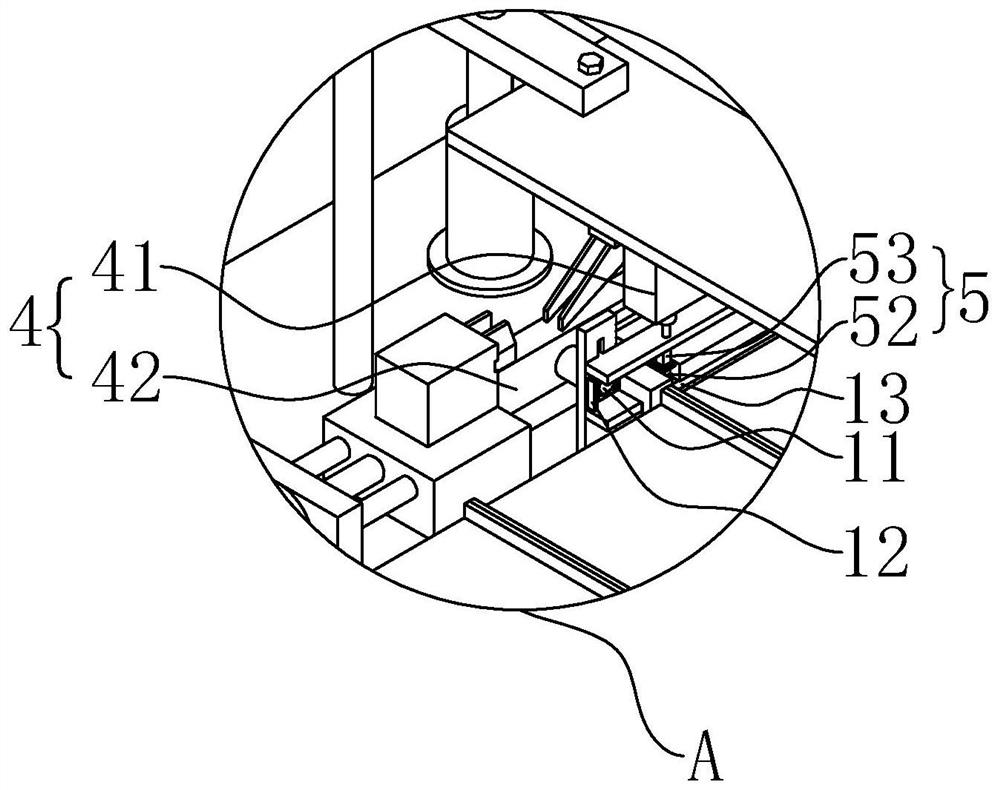

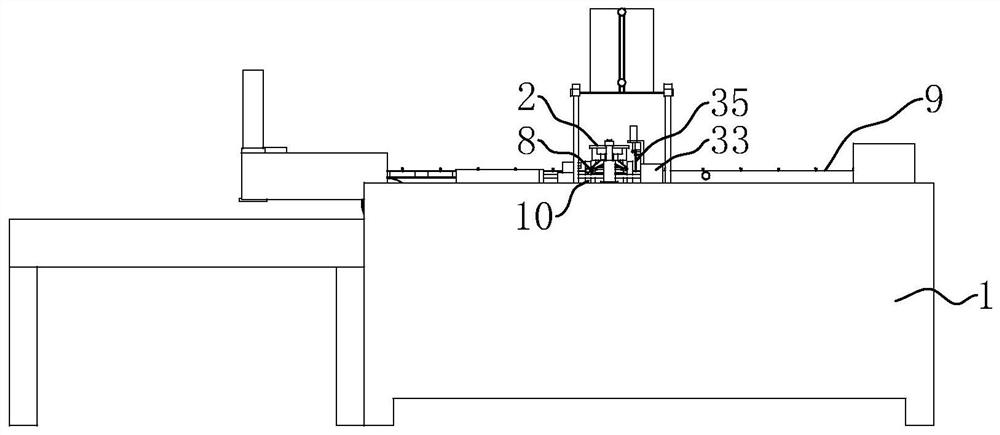

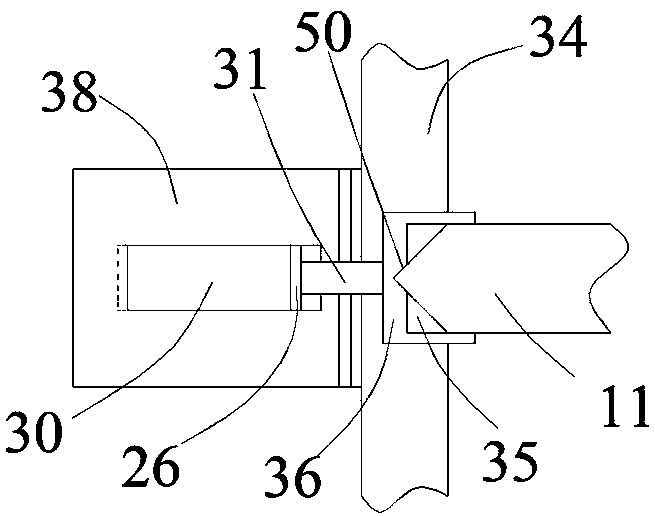

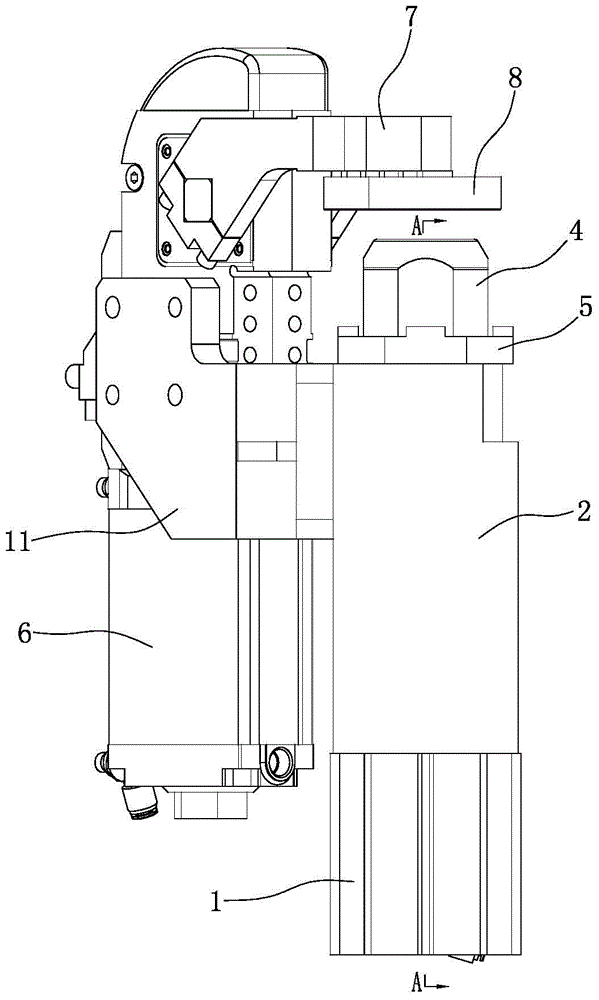

Ear strap spot welding equipment of mask production machine

ActiveCN112917925AHole safetyReduce the temperatureDomestic articlesProtective garmentStructural engineeringSpot welding

The invention relates to ear strap spot welding equipment of a mask production machine, relates to the field of mask machining, and aims to solve the problem that ear straps are only welded to the outer surfaces of masks and are prone to falling off. The ear strap spot welding equipment comprises an operation table and a mounting plate arranged on the operation table. The operation table is provided with a mask trepanning mechanism and two groups of symmetrically arranged ear strap wire feeding mechanisms, a wire pushing mechanism and a welding mechanism; each ear belt feeding mechanism comprises a pay-off rod, a plurality of wire guide wheels, a wire pressing groove, a wire pulling clamp, a wire shearing knife and two wire clamping claws, an ear strap wire released on the pay-off rod is wound outside the wire guide wheels and penetrates through the wire pressing groove, the wire pulling clamp is movably connected along the side vertically arranged on the wire pressing groove, and the wire pulling clamp is used for pulling the ear strap wire to extend; and the wire shearing knife is arranged between one thread clamping claw close to the thread pressing groove and the thread pressing groove. The ear strap spot welding equipment has the effects that the mask can be punched, the ear strap lines penetrate through the mask, and therefore the ear strap lines are welded to the two faces of the mask, welding is more stable, and falling is not likely to happen.

Owner:仙桃市银宏防护用品有限公司

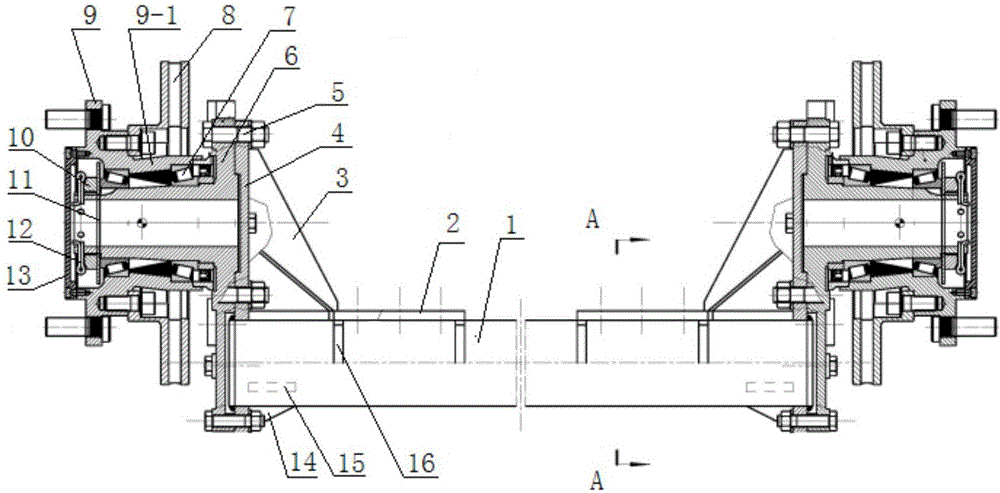

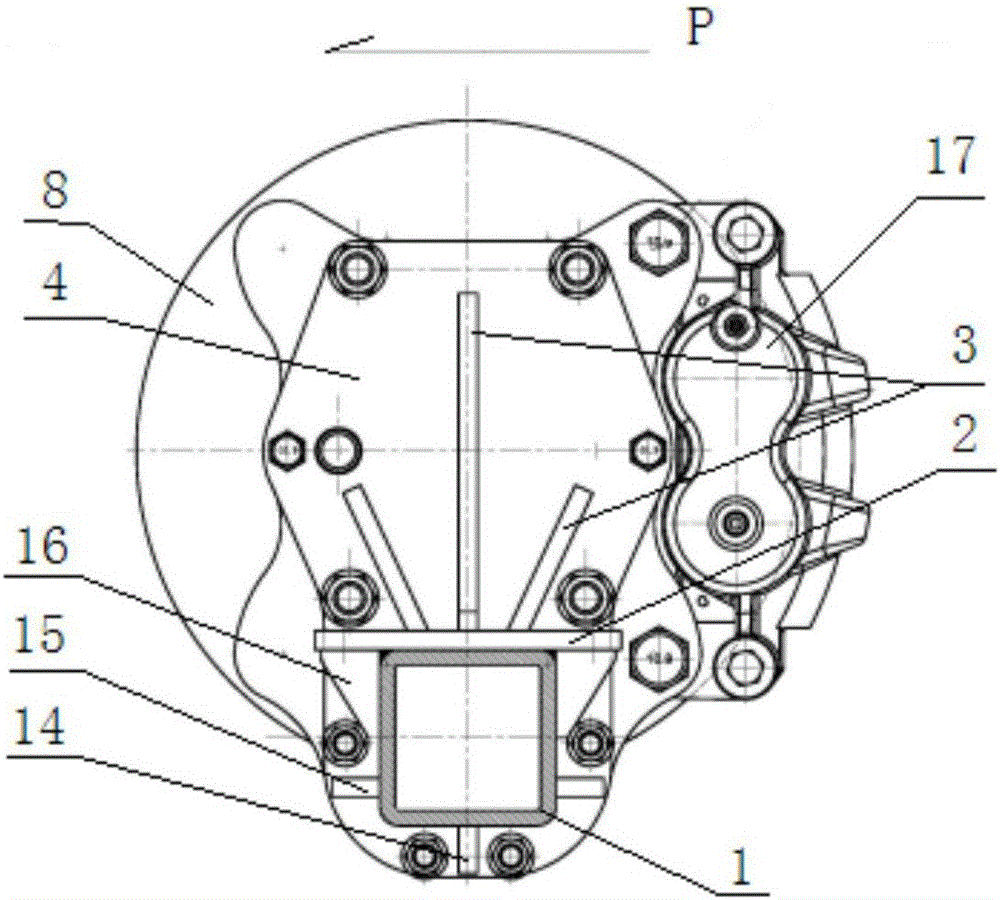

Independent suspension type front drive rear axle assembly

InactiveCN106183632ABig spaceImprove battery lifeBraking element arrangementsAxle unitsGravity centerEngineering

The invention discloses an independent suspension type front drive rear axle assembly. The two ends of a rear axle cross beam are welded and fixed to the lower portions of the inner sides of flange discs respectively. Rear shaft heads are fastened on the outer sides of the upper portions of the flange plates through bolts respectively. The distance between the center of each rear shaft head and the axis of the rear axle cross beam ranges from 130 mm to 160 mm. The rear shaft heads support rear wheel hubs, the rear wheel hubs are provided with shaft sleeves corresponding to the rear shaft heads, and paired single-row tapered roller bearings for bearing positive and reverse axial force are arranged between the shaft sleeves and the rear shaft heads. Locknuts in threaded connection with the rear shaft heads and gaskets of the locknuts are arranged at the ends of the rear shaft heads, the gaskets are jointed with the inner rings of the single-row tapered roller bearings on the outer sides, and stop cotter pins are arranged at the ends of the locknuts and the ends of the rear shaft head. The rear axle cross beam is a square steel pipe, brake discs are fixed to the inner sides of the rear wheel hubs, brake assemblies in friction joint with the brake discs are symmetrically arranged at the transverse front and back positions of the brake discs, and brakes are hydraulic drive brakes. The gravity center of a finished automobile is lowered, and the driving stability can be improved. The independent suspension type front drive rear axle assembly is more beneficial for the arrangement of electrical apparatus elements such as battery packs of purely electric large and medium buses and buses, and therefore the higher speed per hour and the larger endurance mileage can be achieved.

Owner:通天汽车桥(天津)有限公司

Method for forming pipe fittings by cold extrusion

ActiveCN100421873CLow costEasy to weld and installOther manufacturing equipments/toolsHeat treatment process controlChemical compositionPipe fitting

The invention discloses a method for cold compressing molding tube fittings, which comprises: first, plating surface coats on inner and outer surface of needed tube, to attain a half-finished product whose thickness is uniform and the size meets demand; surface treating the half-finished product; solid solution treating the half-finished product; finishing said half-finished product, to attain the final product. The invention has high efficiency and high quality without changing the property and chemical components of former material. And it can be used in the treatment of variable tube fittings.

Owner:江苏华阳管业股份有限公司

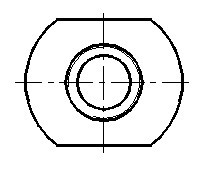

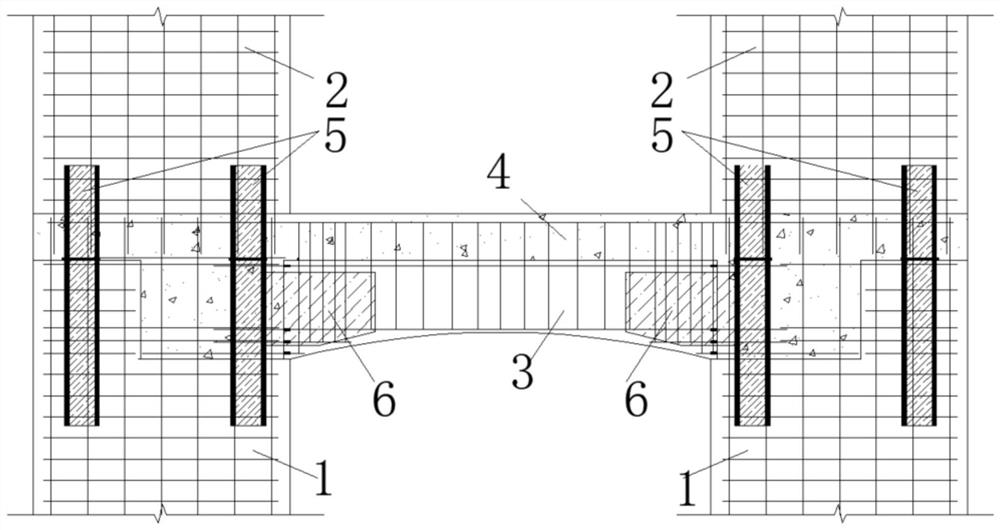

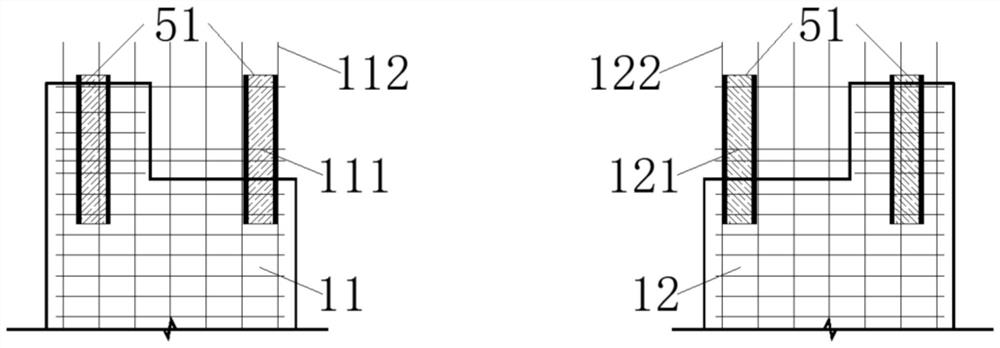

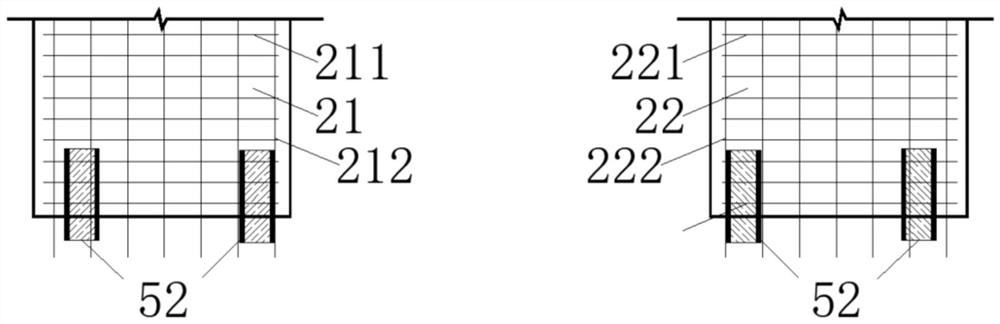

Fabricated double-limb shear wall with an inner arch type coupling beam and assembly method

The invention relates to a fabricated double-limb shear wall with an inner arch type coupling beam. The fabricated double-limb shear wall is characterized by comprising first shear wall units, secondshear wall units, the inner arch type coupling beam, laminated layers, vertical connecting components and horizontal connecting components, and the first shear wall units and the second shear wall units correspond up and down and are connected through the vertical connecting components; and the double-limb first shear wall units are connected to the inner arch type coupling beam through the horizontal connecting components, gaps are reserved between the first shear wall units and the second shear wall units, and concrete is poured into the gaps to form the laminated layers. According to the fabricated double-limb shear wall, the connecting components between the shear wall units can be prefabricated in a component processing factory, and compared with a traditional cast-in-place building structure construction method, on-site welding and mounting are convenient, operation time is saved, on-site labor force is reduced, and assembling efficiency is improved.

Owner:CHANGCHUN INST OF TECH

A mechanical composite pipe lined with 825 nickel-based alloy and its manufacturing method

ActiveCN107143703BBreak the limitsEffective combinationCorrosion preventionPipe protection against corrosion/incrustationAlloyPipe

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

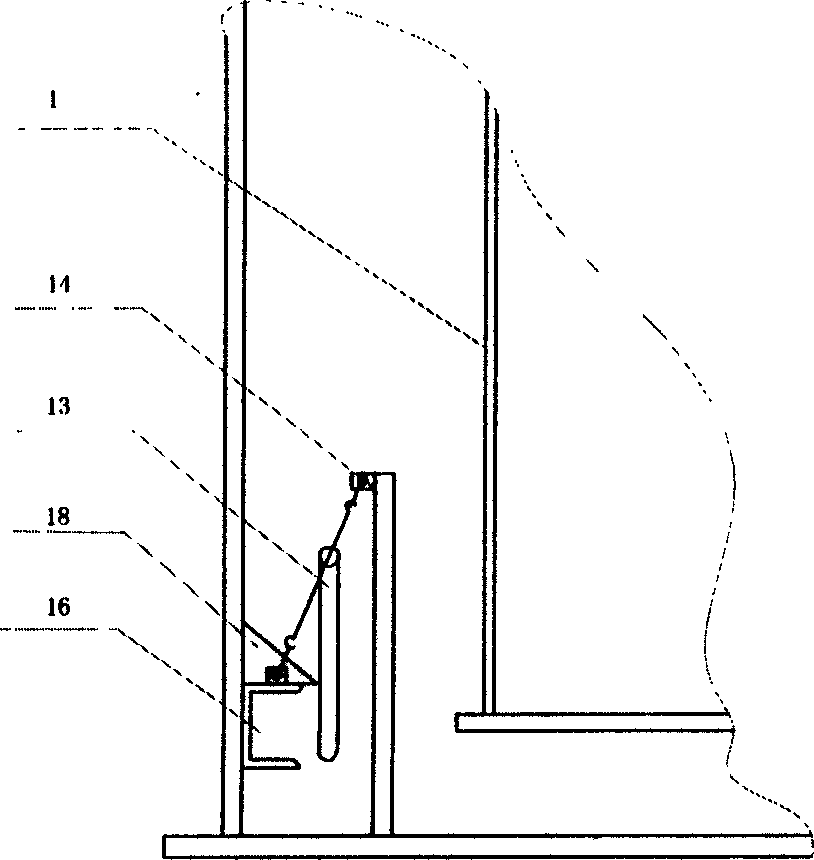

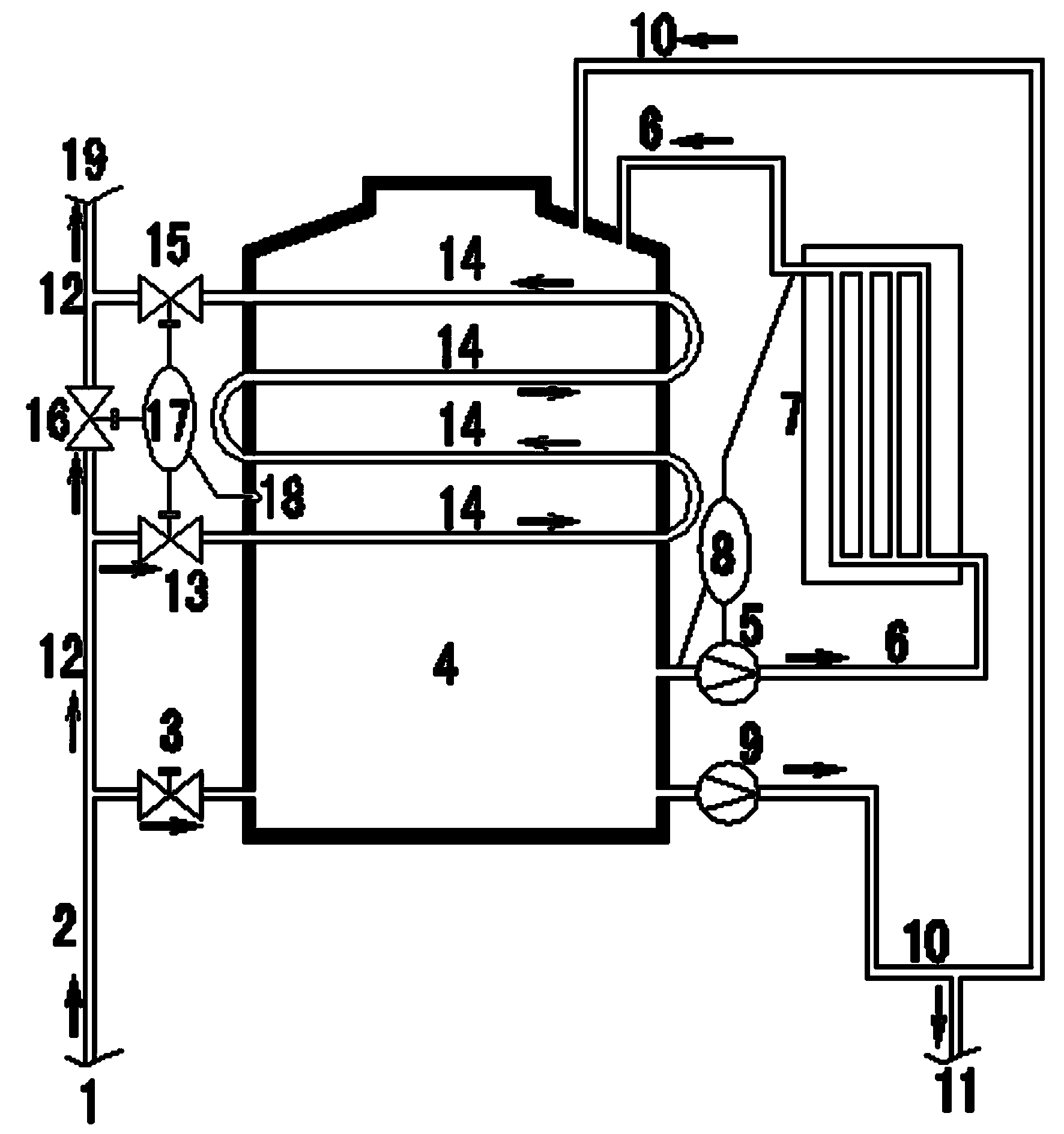

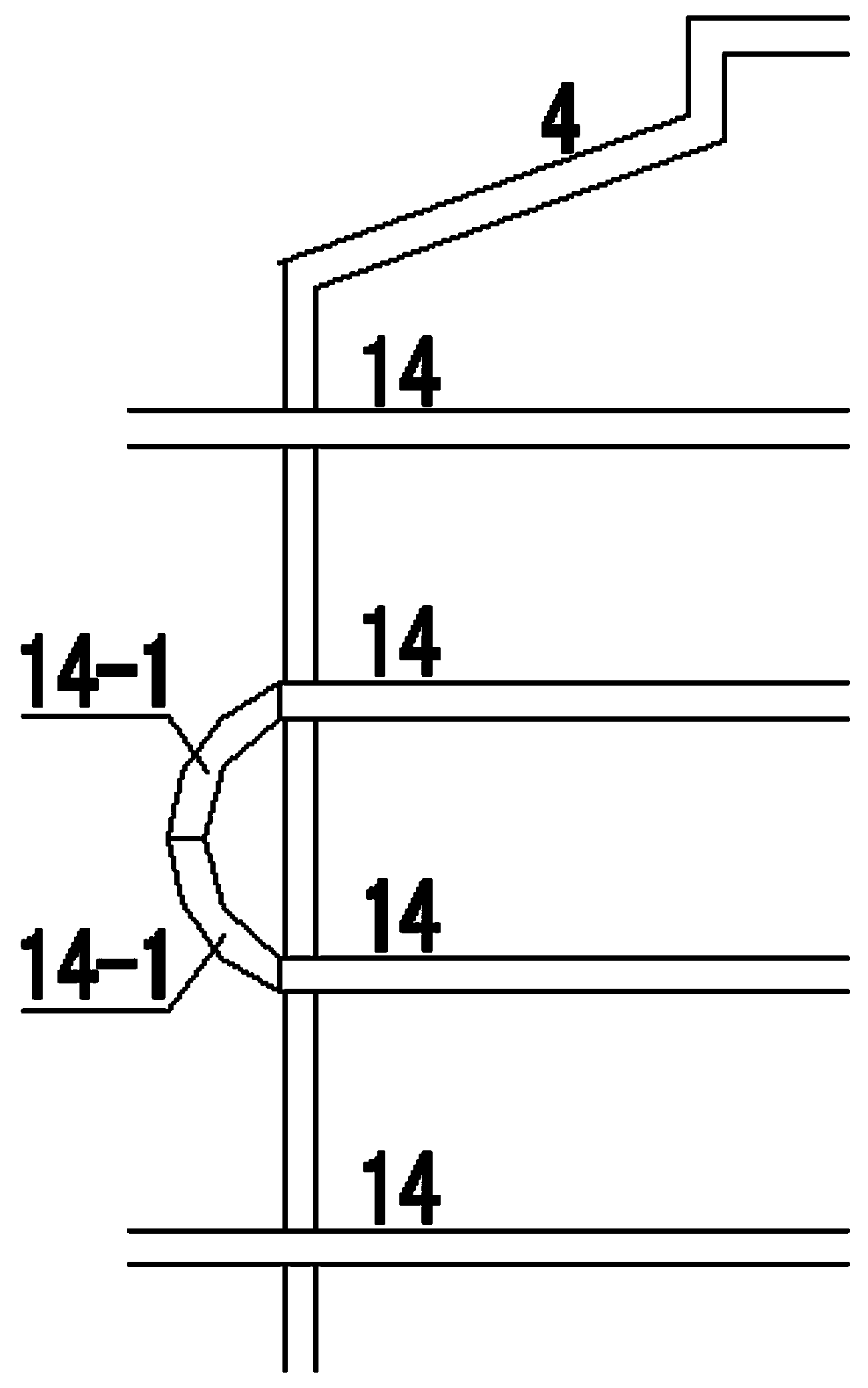

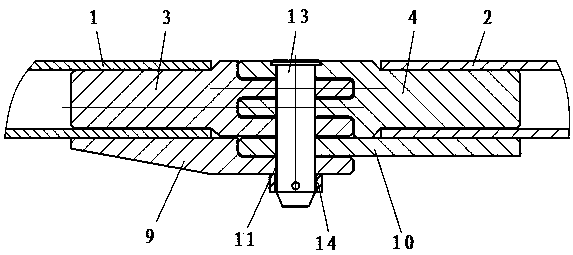

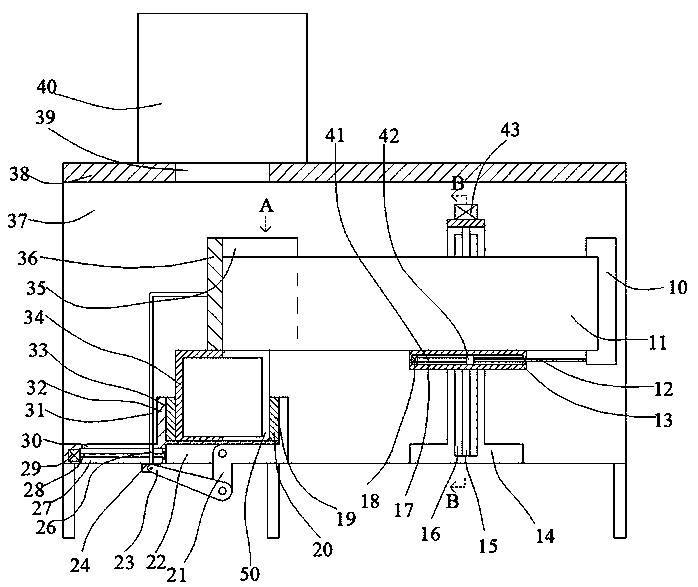

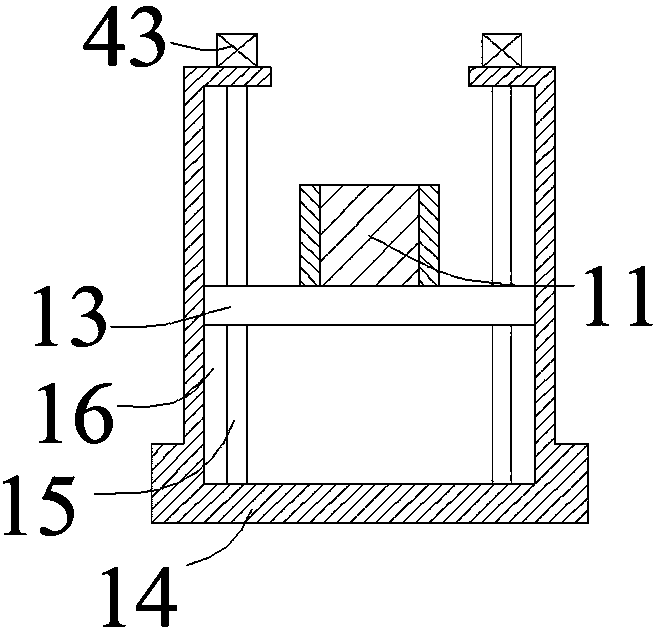

Solar water heating system capable of performing high-temperature protection on heat collector

InactiveCN103423884AEasy to useSimple structureSolar heating energySolar heat devicesSolenoid valveTap water

The invention belongs to the field of solar water heaters, and particularly relates to a heat preservation and protection system used in a solar water heater heat collecting system. A solar water heating system capable of performing high-temperature protection on a heat collector is improved from a common solar water heating system. An overheating protection system is further arranged in the solar water heating system and composed of a water inlet pipe (12), a protective solenoid valve (13), heat exchange U-pipes (14), another protective solenoid valve (15), a protective normally-closed solenoid valve (16) and a cold water use end (19), the water inlet pipe is connected with a tap water pipe, one protective solenoid valve is arranged in the water inlet pipe which is directly connected into a pipeline of the heat exchange U-pipes, an outlet of the heat exchange U-pipes passes the protective solenoid valve (15) to enter the cold water use end (19), and the heat exchange U-pipes are sinuous coils arranged in a hot water tank. The invention can provide a water heating system capable of automatically providing overheating protection when a flat-plate heat collector is subjected to high-temperature sun exposure.

Owner:SHENZHEN PROSUNPRO SOLAR ENERGY

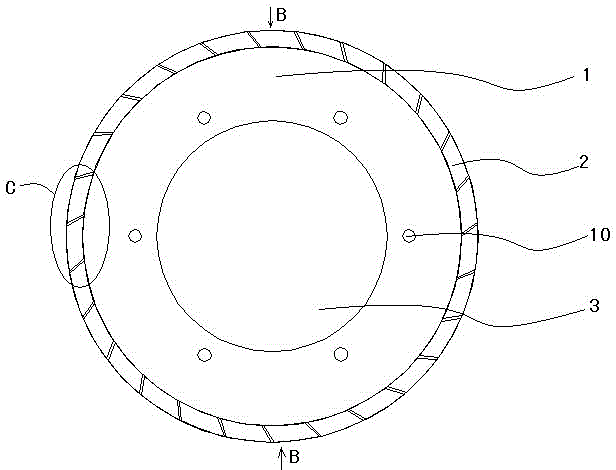

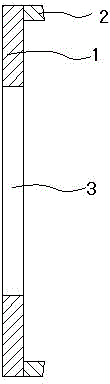

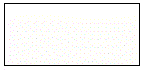

Diamond grinding wheel

The invention relates to a diamond grinding wheel which comprises an annular mounting baseplate and multiple diamond tool bits fixed at the edge of the upper surface of the annular mounting baseplate. The diamond tool bits are arranged in the shape of a circular ring, a gap is formed between each two adjacent diamond tool bits, the diamond tool bits are distributed in a manner of radially inclining along the mounting baseplate, and distances between the diamond tool bits and the center of the mounting baseplate are equal or gradually change; when width gradually changes, the longer distance with the center of the grinding wheel is, the large width is; the outer side of each diamond tool bit is in the shape of an arc, and difference between radium of each arc and that of the mounting baseplate is smaller than or equal to 5mm. Compared with the prior art, the diamond grinding wheel has the advantages of good heat-radiating performance, long service life and convenience for production and machining.

Owner:范新晖

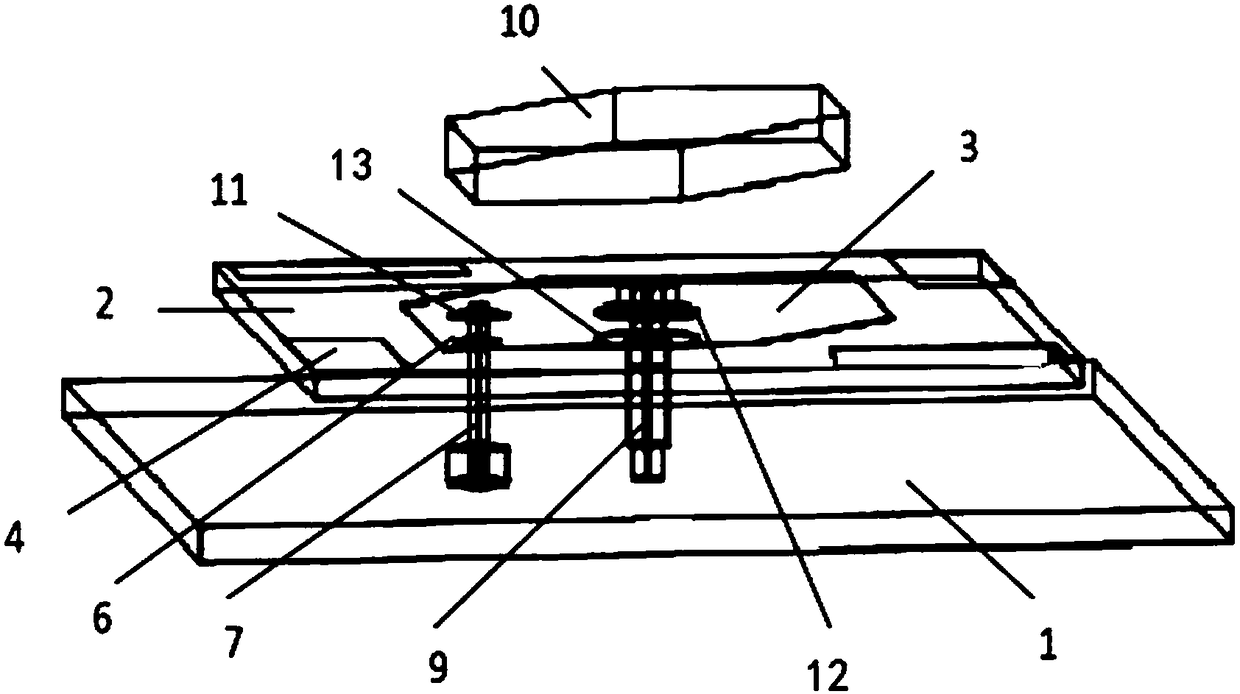

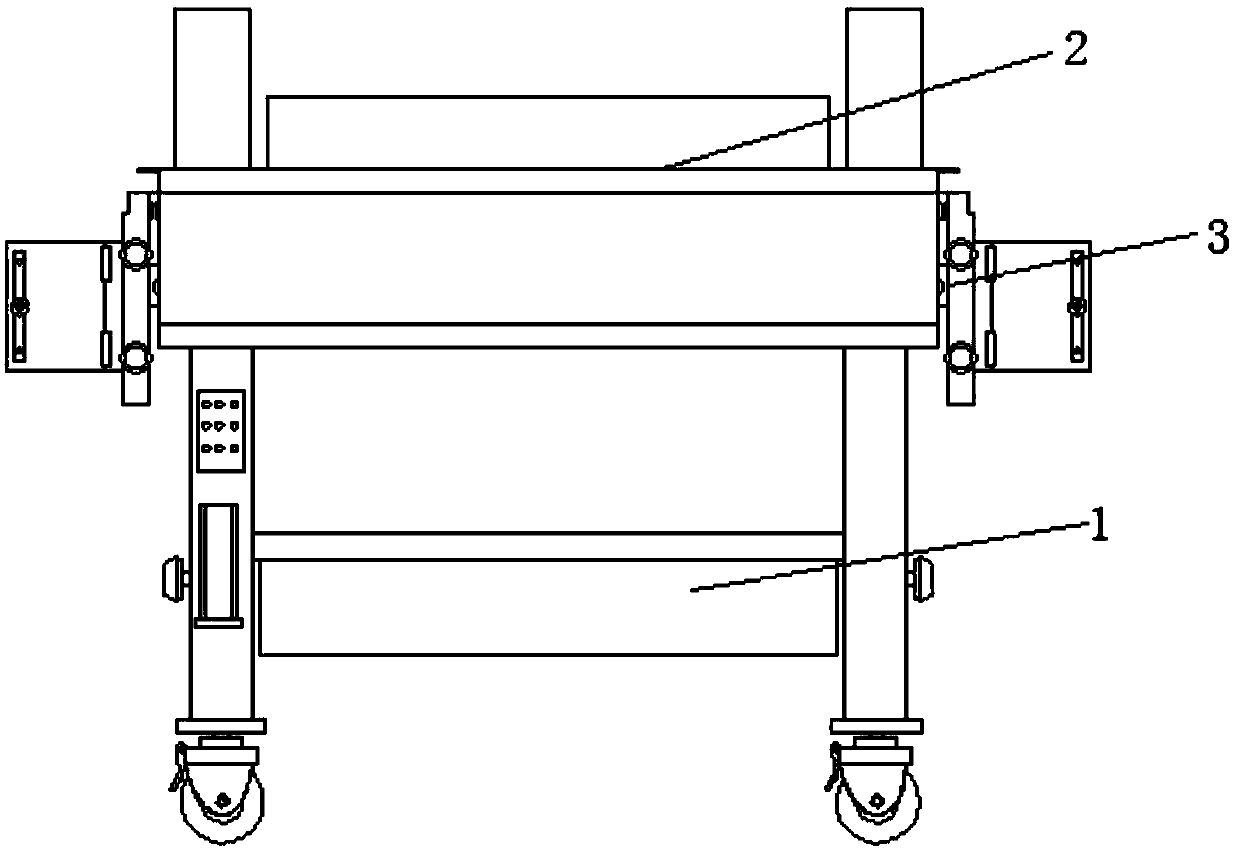

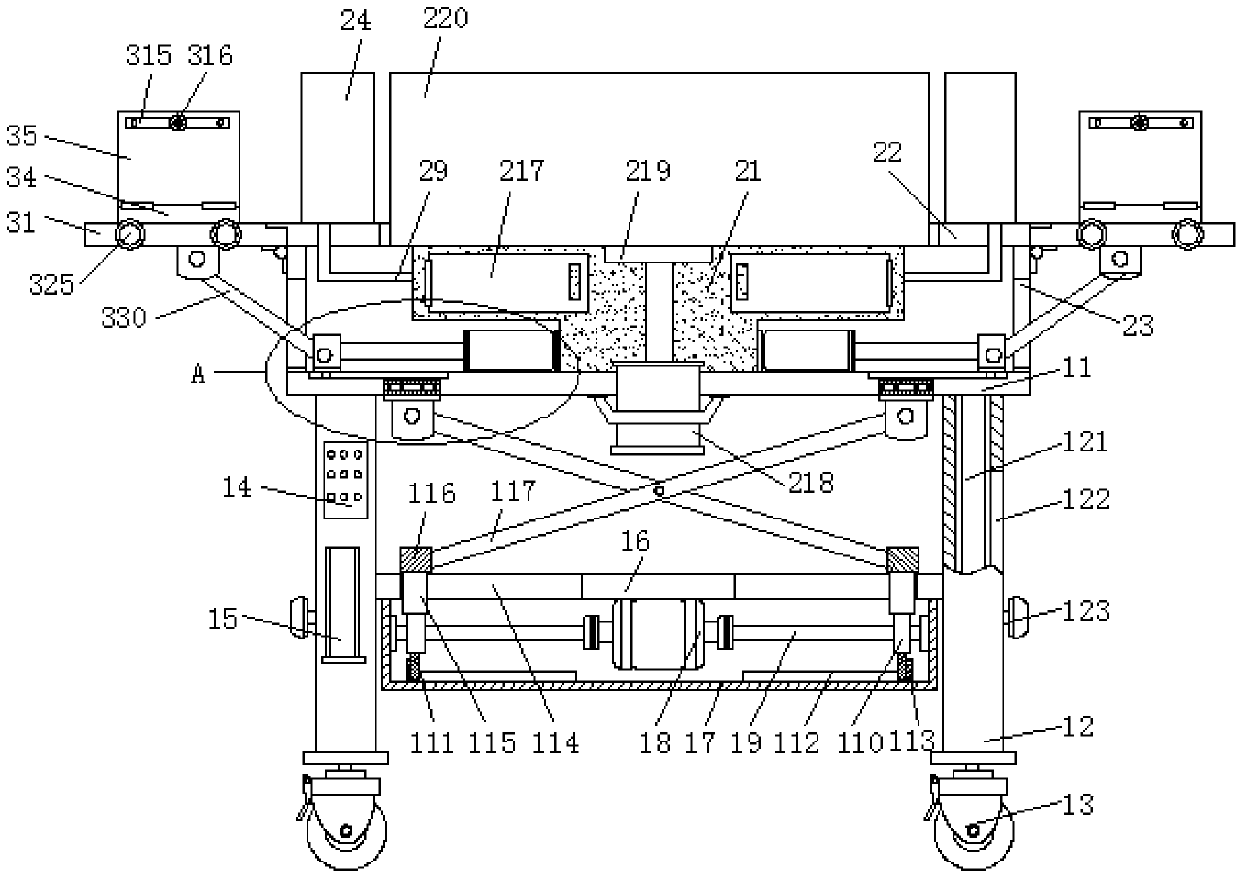

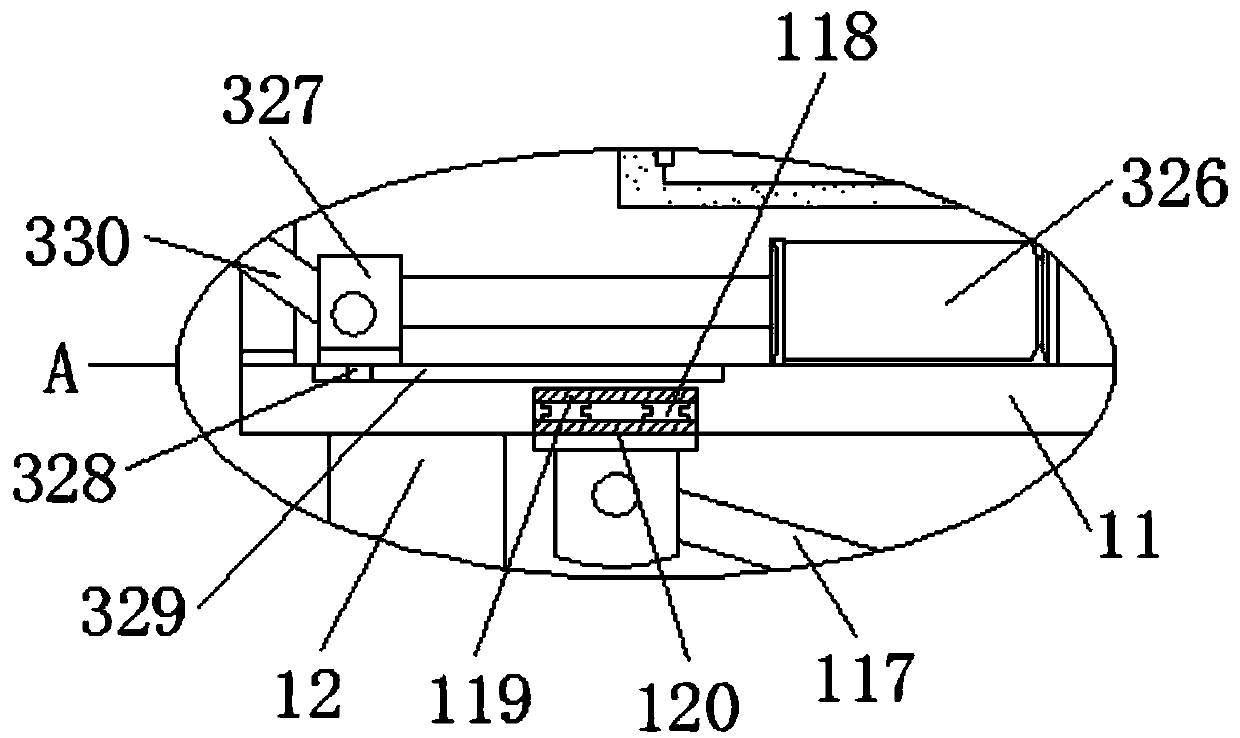

Pipe gallery pipeline section prefabricating platform

PendingCN109604921AImprove fastnessEffective fasteningWelding/cutting auxillary devicesAuxillary welding devicesControl switchIndustrial engineering

The invention relates to the technical field of pipe gallery pipelines, in particular to a pipe gallery pipeline section prefabricating platform. The prefabricating platform comprises a supporting mechanism, an operating mechanism and a clamping mechanism, wherein the supporting mechanism comprises a bottom plate, first supporting columns are arranged on the periphery of the lower end of the bottom plate, the lower end of each first supporting column is provided with a moving wheel, a control switch is arranged on the outer side of one of the first supporting columns, and a welding rod cylinder is arranged on the outer side of one of the first supporting columns; the operating mechanism comprises a supporting seat connected with the bottom plate, the upper end of the supporting seat is connected with an operation table, and the the operation table and one side corresponding to the bottom plate are connected with an outer cover. According to the pipe gallery pipeline section prefabricating platform, the structure design is reasonable, the functionality is high, the height of the prefabricated platform can be effectively and quickly adjusted and fixed, the pipeline can be effectivelyclamped, welding is facilitated, and the welding smoke is effectively treated, so that the body health of workers can be conveniently protected.

Owner:中建五局安装工程有限公司

A tree fork-shaped component and its processing method

ActiveCN104060690BIncrease the use of spaceIncrease spanBuilding material handlingResource savingEngineering

Owner:浙江东南网架股份有限公司

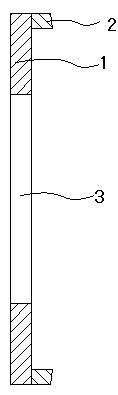

Diamond grinding wheel with inclined teeth

InactiveCN104552036AEasy to install and locateReduce mistakesBonded abrasive wheelsDiamond grindingAcute angle

Disclosed is a diamond grinding wheel with inclined teeth. The diamond grinding wheel comprises an annular mounting baseplate and multiple diamond tool bits fixed at the edge of the upper surface of the annular mounting baseplate, the diamond tool bits are arranged in the shape of a circular ring, a gap is formed between each two adjacent diamond tool bits, the diamond tool bits are distributed in a manner of radially inclining along the mounting baseplate, and each diamond tool bit is provided with acute-angle inclined teeth inclining towards one side on the radial inner side of the mounting baseplate 1 at least. Compared with flat-tooth diamond grinding wheels in the prior art, the diamond grinding wheel has higher grinding efficiency.

Owner:范新晖

Novel connecting structure for lower chord of cargo boom

PendingCN107792794AImprove stabilityImprove securityCranesStructural engineeringMechanical engineering

The invention relates to a novel connecting structure for a lower chord of a cargo boom, and belongs to the field of hoist machinery. The connecting structure comprises a front lower chord, a rear lower chord, a first joint, a second joint, connecting plates and a pin shaft assembly; the first joint is arranged at the right end of the front lower chord, the second joint is arranged at the left endof the rear lower chord, and the first joint is connected with the second joint in a crossed matching mode; the connecting plates are connected with the first joint and the second joint through the pin shaft assembly, and each of the first joint and the second joint comprises an inserting rod, a bottom plate and clamping plates; the inserting rods are correspondingly matched with the front lowerchord and the rear lower chord, the inserting rods are located on one sides of the bottom plates, and at least two clamping plates are evenly arranged on the other side of each bottom plate at intervals. According to the connecting structure, the structural design is simple and reasonable, installation and welding are convenient, the connection is firm and reliable, the structural strength of thelower chord of the cargo boom is effectively improved, the service life of the cargo boom is prolonged, and the safety and the stability of the hoisting machinery operation are improved.

Owner:浙江省建设工程机械集团有限公司

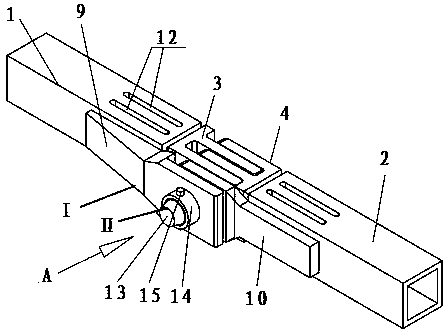

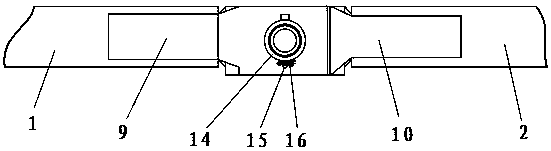

Square tube welding equipment

ActiveCN111151878ASimple structureGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser soldering

The invention discloses square tube welding equipment. The square tube welding equipment comprises a supporting box body which is internally provided with an inner installation cavity through from left to right; a through inner cavity is formed in the upper end wall of the inner installation cavity in a communication mode; the inner installation cavity is internally provided with a bottom tube anda top tube perpendicular to the bottom tube; the bottom tube is internally provided with a clamping matched surface having an opening, the clamping matched surface is a triangular opening, the bottomtube abuts against the top tube, and the outer side of the bottom tube is provided with a linkage placement device used for conducting clamping linkage placement on the bottom tube; the equipment needs to driven an inner structure, the top tube is placed into the clamping matched surface, moreover, the top tube is completely flush with the bottom tube, and after a laser welding head works, the clamping matched surface is subjected to laser welding.

Owner:WENLING SHUANGSEN STAINLESS STEEL

Underground project assembly type lagging jack automatic connection joint and mechanized construction method

PendingCN107905255ASimple structureReduce processing costsArtificial islandsUnderwater structuresConstruction engineeringMachining process

The invention discloses an underground project assembly type lagging jack automatic connection joint and a mechanized construction method. An assembly type connecting device and a guide pressure bearing connecting device which are welded to two adjacent lagging jacks are included, and the assembly type connecting device and the guide pressure bearing connecting device are connected through a pin shaft rotating mechanism. Three rows of through holes are formed inside a connecting plate, guide stretchable devices are allocated in the holes, and the front ends of force transmission pins extend out of the holes through internal return springs. When the guide pressure bearing connecting device rotates around the pin shaft mechanism, the force transmission pins are extruded by a guide plate, thereturn springs are compressed, after a fixing connecting plate and the connecting plate are attached, the force transmission pins pop up to be combined with guide plate pin shaft holes in a clamped manner, joints are locked and connected together, and finally the joint strength and stability are improved through a bolt connecting mechanism. The joint is simple in structure, low in machining cost,simple in machining process, convenient and quick in welding and installing and wide in application scope.

Owner:SHANDONG UNIV +2

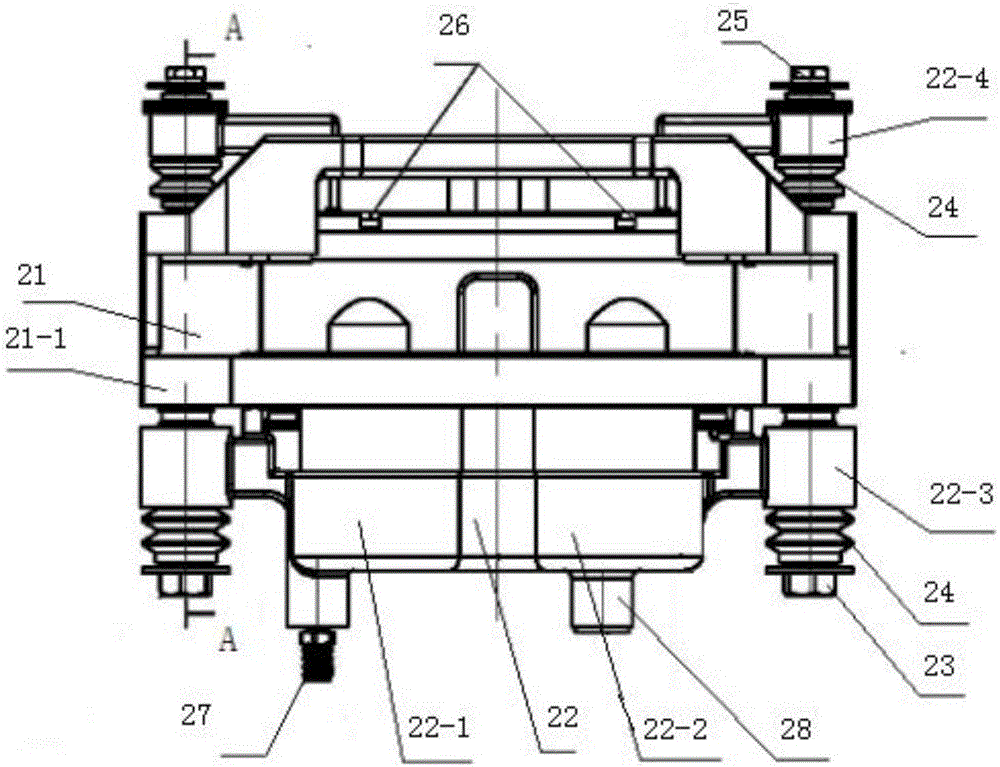

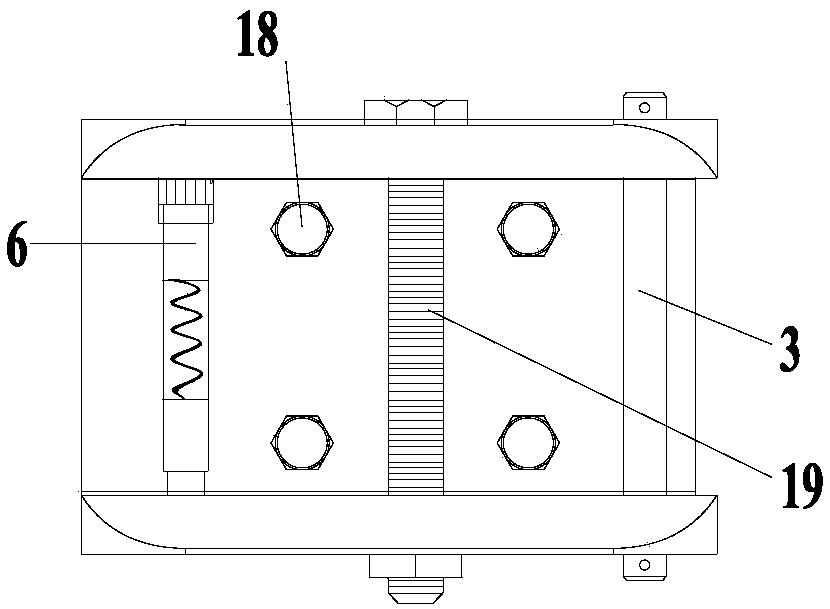

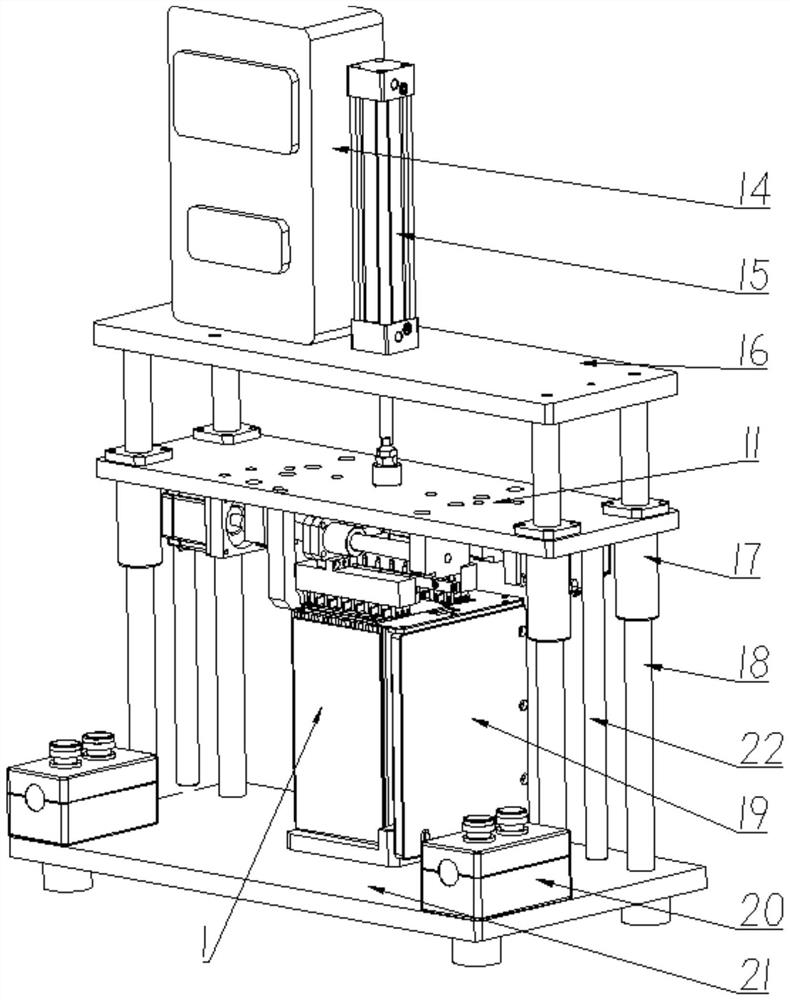

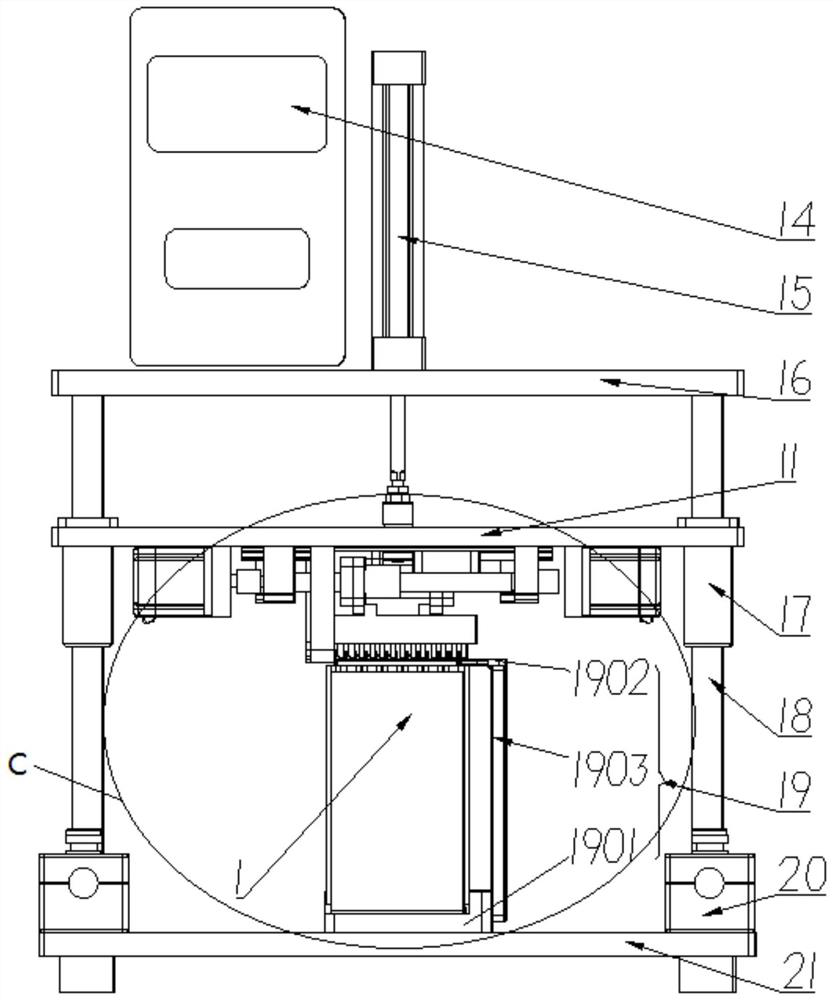

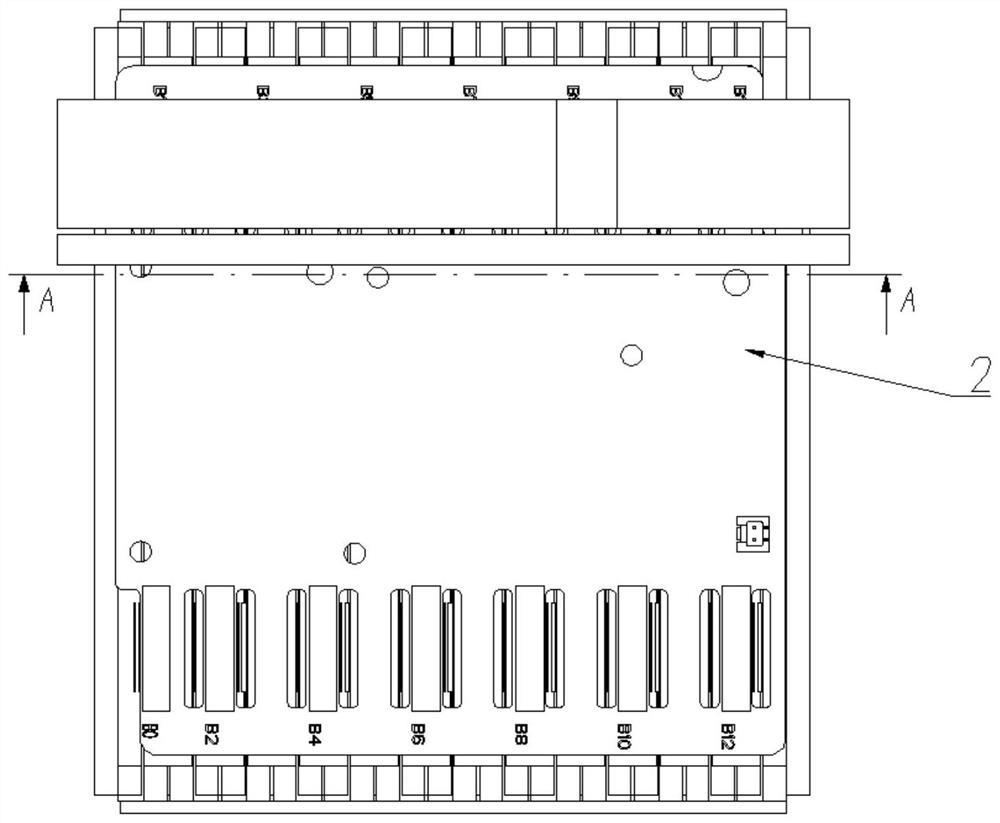

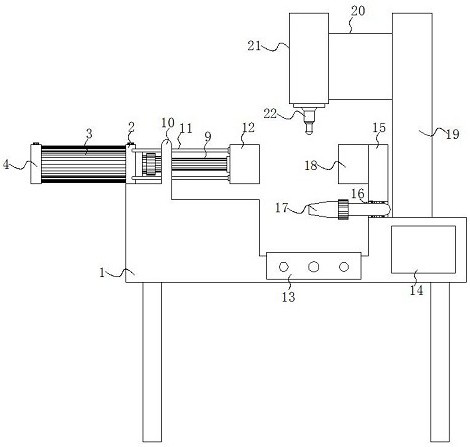

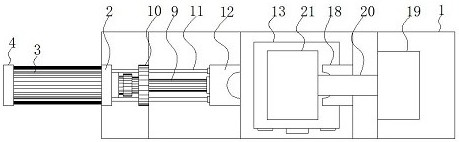

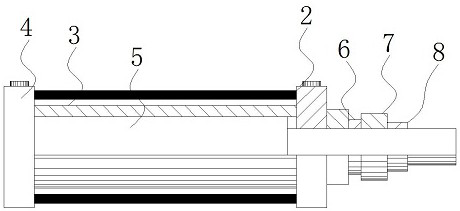

Soft package lithium battery protection plate mounting equipment

PendingCN113506956AEasy to weldEasy to weld and installFinal product manufactureCells structural combinationStructural engineeringMechanical engineering

The invention discloses soft package lithium battery protection plate mounting equipment which comprises a rolling block assembly arranged corresponding to a single row of battery cell tabs on a protection plate, and a driving assembly connected with the rolling block assembly and used for driving the rolling block assembly to roll the battery cell tabs; and the rolling block assembly comprises a plurality of ball modules for bending the battery cell tabs through rolling. According to the soft package lithium battery protection plate mounting equipment, battery cell tabs are bent to a bonding pad through two-time opposite-direction actions of the driving assembly and in a rolling mode of a plurality of ball modules on the rolling block assembly, follow-up welding installation is facilitated, labor can be saved through the arrangement mode, the production procedures are reduced, and therefore, the production efficiency is improved and the production cost is reduced.

Owner:山东爱德邦智能科技有限公司

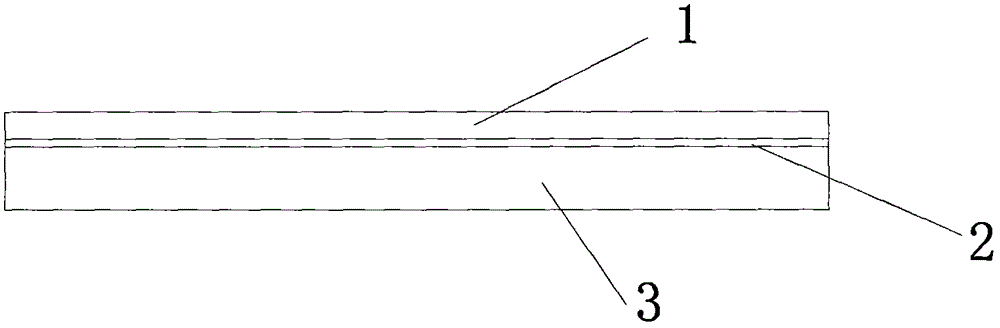

Galvanized composite board

InactiveCN106427128AReasonable structural designSimple processLamination ancillary operationsLaminationPolymer bondingComposite plate

The invention discloses a galvanized composite board, and relates to the technical field of composite boards. The galvanized composite board is prepared by the following process flows: A, firstly, washing with water and then drying to 100 DEG C; B, bonding an aluminum board and a galvanized board through a high-temperature polymer bonding material; C, high-temperature extrusion: firstly, using an electromagnetic heating tube for rolling to 270 DEG C, and then heating and extruding five times, wherein the heating and extruding temperatures five times are respectively 170 DEG C, 190 DEG C, 210 DEG C, 230 DEG C and 270 DEG C; D, cooling: using processed purified water for cooling to 40 DEG C, and then using a fan for cold-blowing to 20 DEG C; E, finally, flattening. The galvanized composite board provided by the invention is reasonable in structure design, simple in process, durable, low in cost, high in strength, free from baking finish, environment-friendly, and convenient and reliable in mounting and welding.

Owner:马秉芳

Continuous ultrasonic welding equipment

The invention discloses continuous ultrasonic welding equipment. The continuous ultrasonic welding equipment comprises an operation table, a plunger type telescopic cylinder is arranged on the left side of the upper surface of the operation table, a workbench is installed in a middle groove of the operation table, a circuit controller is arranged on the right side surface of the operation table, amachine box is arranged on the upper surface of the circuit controller and the right side of a vertical plate, a connecting box is connected to the upper surface of the left side of the machine box,a welding machine is arranged on the surface of the left side of the connecting box, and a mold is arranged in the middle of the lower surface of the welding machine. Through arrangement of a movableclamp and a static clamp above a rotating clamping jaw and a movable mold and a static mold, a workpiece can be conveniently fixed, through arrangement of the movable clamp and a first piston rod, theeffect of automatically clamping the workpiece is achieved conveniently, and therefore the effect of protecting workers is achieved.

Owner:重庆信易源智能科技有限公司

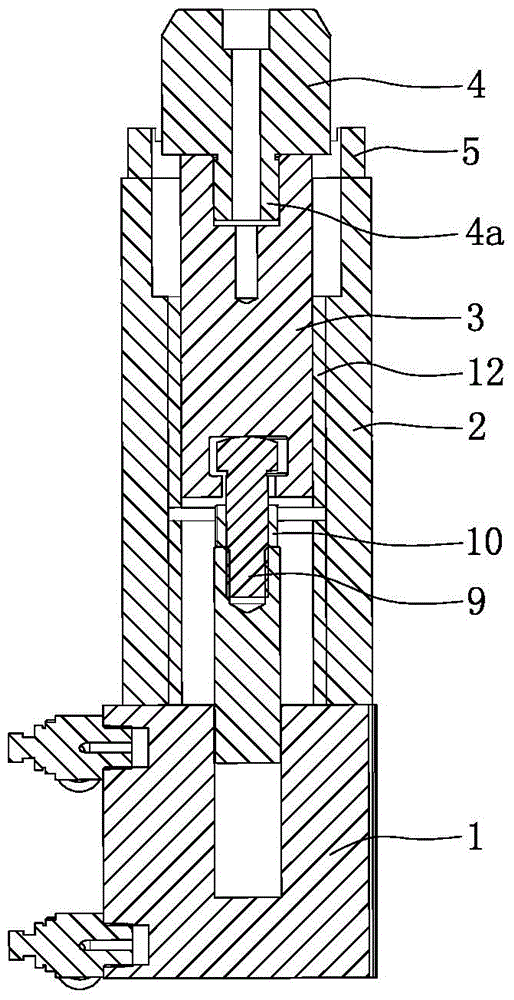

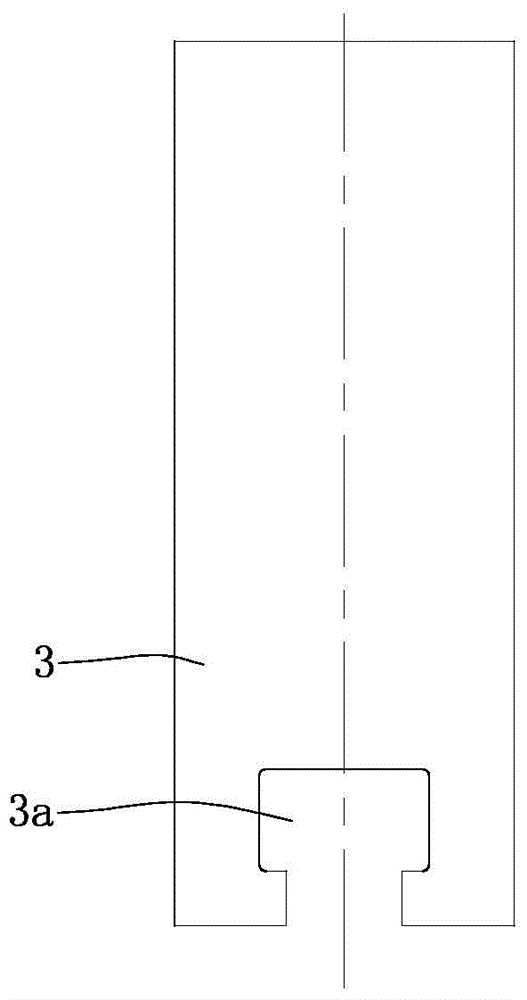

Pneumatic double-cylinder liner positioning mechanism for automobile welding fixture

ActiveCN105269235BNo shakingGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesSheet steelEngineering

Owner:JIANGSU YOUFU AUTO PARTS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com