Concave plate screen of combine harvester and concave plate screen device

A combine harvester and concave screen technology, which is applied in agricultural machinery and tools, threshing equipment, applications, etc., can solve the problems that long straws are easy to fall into the vibrating screen, the concave screen is not interchangeable, and the cleanliness is not high. , to achieve the effect of convenient and fast installation and welding, increase the value of use, and reduce the cost of use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

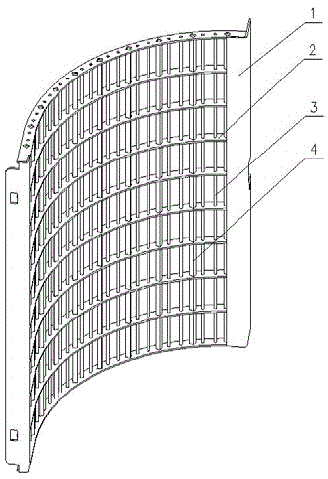

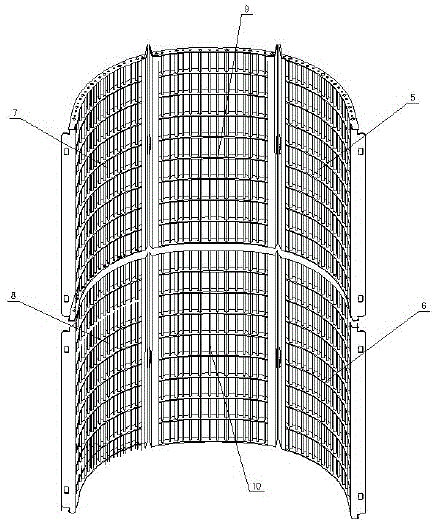

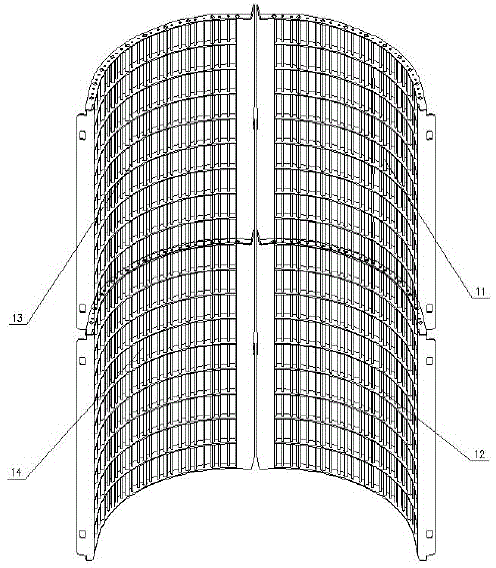

[0019] Below in conjunction with accompanying drawing, the concave plate sieve of combine harvester of the present invention is further described:

[0020] Such as figure 1 As shown, the concave plate sieve of the combine harvester of the present invention comprises frames 1 on both sides, and between the frames on both sides is fixedly connected with spaced arc-shaped fixing plates 2, and each arc-shaped fixing plate is connected to the drum on the harvester. Matching, the plate surfaces of each arc-shaped fixing plate are parallel to each other and perpendicular to the axis of the rotating shaft of the drum, and each arc-shaped fixing plate is pierced with spaced apart square steel bars 4, and there are also spaced apart square steel bars 4 between the adjacent two steel bars. At least one round steel bar 3 is provided, and the square steel bar 4 and the round steel bar 3 are all parallel to the rotating shaft axis of the drum. That is to say, the square steel bar 4 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com