Manufacturing method of low-temperature liquid storage tank

A technology for cryogenic liquids and manufacturing methods, applied in the direction of container filling methods, gas/liquid distribution and storage, equipment for loading into pressure vessels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

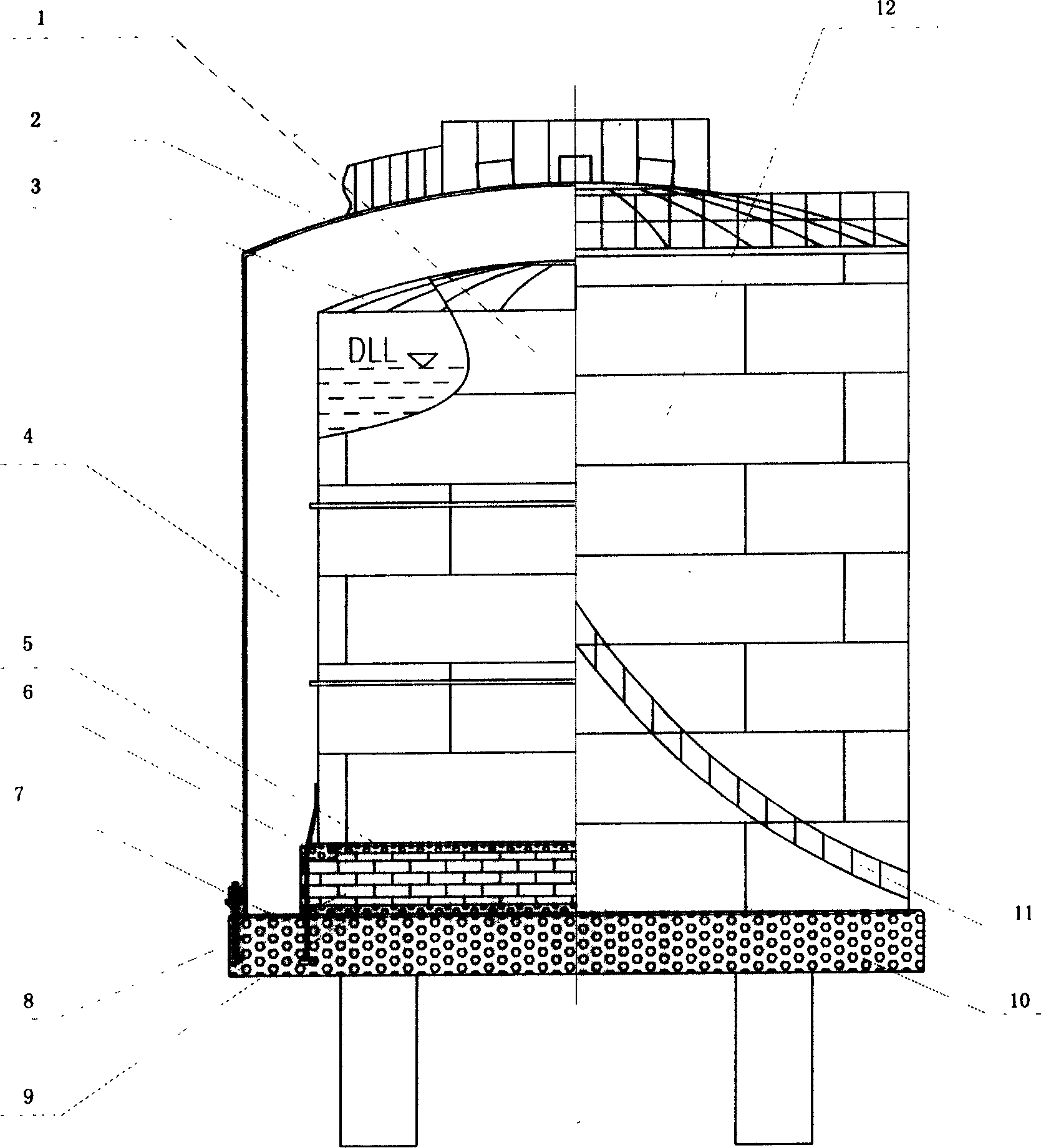

[0017] figure 1 The cryogenic liquid storage tank shown is installed using the following method:

[0018] ① Set 0°, 90°, 180° and 270°, 360° axes and center points on the foundation cap 10, make obvious marks, and use them as benchmarks to guide the laying of the bottom plate in the future, and as the positioning and positioning of the escalator 11 Basis for nozzle orientation.

[0019] ② Lay the bottom plate 7 of the shell, draw the position diagram of each bottom plate on the plane of the foundation cap 10, hoist it in place in sequence, measure the size and position of the anchor belt of the inner cylinder, draw and open holes on each bottom plate. Weld the bottom plate 7 of the shell. After welding, the maximum swelling deformation cannot exceed 2.5cm, and the vacuum leak test of the bottom plate 7 of the shell should be done. The gap under the shell bottom plate 7 is filled with expansive cement by the pressure grouting method. After inspection, there is no void phenome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com