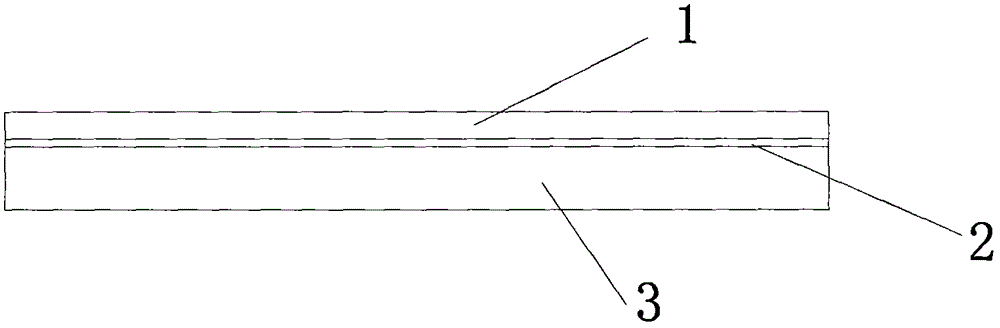

Galvanized composite board

A composite board and galvanized board technology, applied in the field of composite boards, can solve problems such as poor use effect, inconvenient welding and installation, and environmental pollution, and achieve the effects of convenient and reliable installation and welding, reasonable structural design and simple process

Inactive Publication Date: 2017-02-22

马秉芳

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the decorative panels used in the technical field of indoor and outdoor decoration are either all-aluminum or ordinary steel plates. The cost of all-aluminum panels is relatively high, and the strength is low. They are all painted on site, polluting the environment, and welding installation is not convenient. ; while ordinary steel plates are easy to fade, the grade looks relatively low, and the use effect is not good, so the present invention has designed a galvanized composite plate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0017] Example 1: A 0.2mm thick aluminum plate is combined with a 0.8mm thick galvanized steel plate, which is equivalent to a 1.0mm thick aluminum plate after being compounded. The strength is twice that of a full aluminum plate, and it is easy to install and weld.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a galvanized composite board, and relates to the technical field of composite boards. The galvanized composite board is prepared by the following process flows: A, firstly, washing with water and then drying to 100 DEG C; B, bonding an aluminum board and a galvanized board through a high-temperature polymer bonding material; C, high-temperature extrusion: firstly, using an electromagnetic heating tube for rolling to 270 DEG C, and then heating and extruding five times, wherein the heating and extruding temperatures five times are respectively 170 DEG C, 190 DEG C, 210 DEG C, 230 DEG C and 270 DEG C; D, cooling: using processed purified water for cooling to 40 DEG C, and then using a fan for cold-blowing to 20 DEG C; E, finally, flattening. The galvanized composite board provided by the invention is reasonable in structure design, simple in process, durable, low in cost, high in strength, free from baking finish, environment-friendly, and convenient and reliable in mounting and welding.

Description

Technical field [0001] The invention relates to the technical field of composite panels, in particular to a galvanized composite panel. Background technique [0002] At present, the decorative panels used in indoor and outdoor decoration technology are either all-aluminum or ordinary steel plates. All-aluminum plates are relatively high in cost and low in strength. They are all painted on site, which pollutes the environment and is inconvenient for welding and installation. ; And ordinary steel plate is easy to fade, the grade looks relatively low, the use effect is not good, so the present invention designs a galvanized composite plate. Summary of the invention [0003] In view of the deficiencies in the prior art, the purpose of the present invention is to provide a galvanized composite board with low cost, high strength, not easy to fade, no environmental pollution, convenient and reliable installation and welding, and high-grade. [0004] In order to achieve the above objective...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B32B15/01B32B15/18B32B15/20B32B15/04B32B9/02B32B9/04B32B7/12B32B38/16B32B37/06B32B37/12

CPCB32B15/012B32B7/12B32B9/025B32B9/041B32B15/011B32B15/04B32B15/18B32B37/06B32B37/12B32B38/162B32B2307/558B32B2451/00

Inventor 马秉芳

Owner 马秉芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com