Transition printed circuit board electrical connector

A technology for electrical connectors and printed boards, applied in the direction of connections, circuits, electrical components, etc., can solve problems such as poor quality of pin welding, inability to float the docking part of the connector shell, and affect the electrical performance of the connector, etc., to achieve Small footprint, easy welding and installation, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

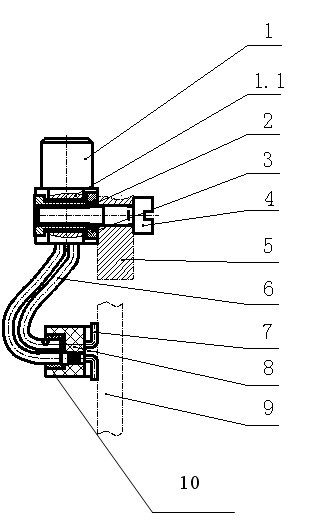

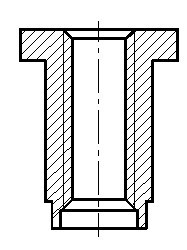

[0016] Such as figure 1 As shown, the transfer type printed board electrical connector of the present invention includes a butt plug 1 connected to the mounting board 5 and a socket 10 fixed on the printed board 9 with a surface mount, and the butt plug 1 is installed on its shell 1.1 A floating mechanism is riveted on the hole to realize its radial and axial floating functions; the floating mechanism is realized by passing the riveting end of the floating riveting tube 2 through the mounting hole of the shell 1.1, and then riveting after assembling the gasket 3; It is convenient for the installation of the butt end, the floating riveting tube 2 can process the internal thread of the corresponding specification according to the installation requirements; when installing, just select the screw 4 that matches the specification of the internal thread of the floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com