Ear strap spot welding equipment of mask production machine

A technology of spot welding equipment and production machine, which is applied in the field of mask processing, can solve the problems of weak welding, falling off the welding part of ear straps, affecting the use of masks, etc., and achieves the effects of stable transmission, easy installation and welding, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

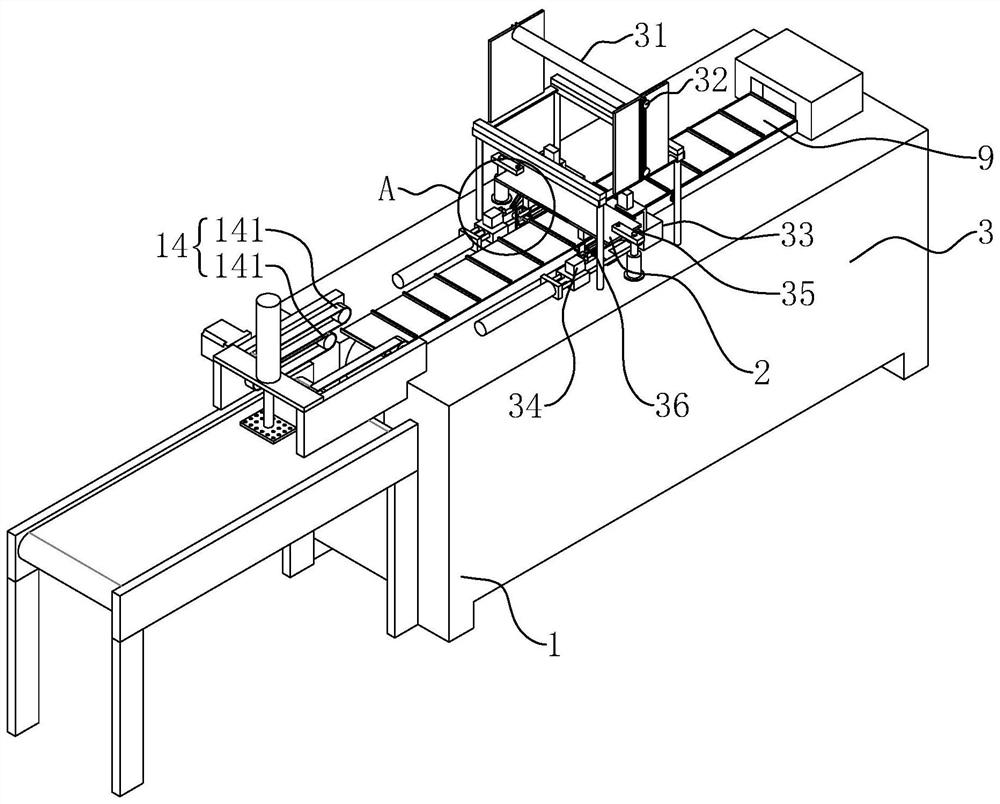

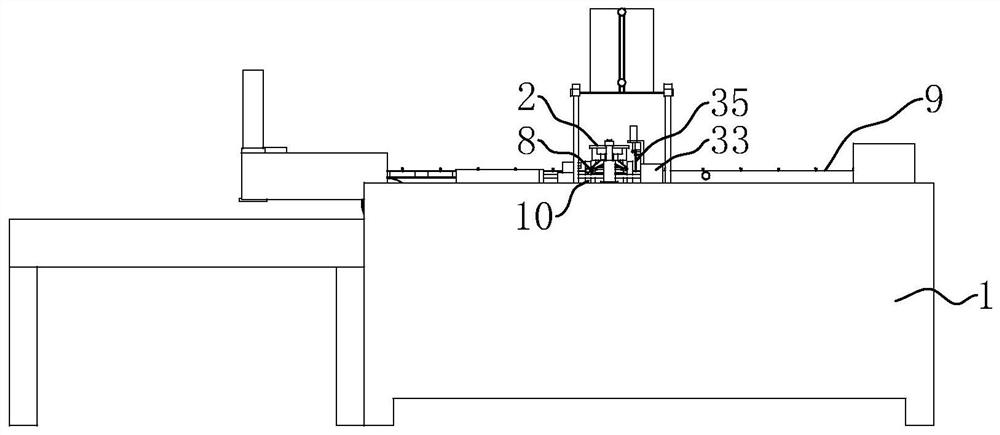

[0044] The embodiment of the present application discloses an earband spot welding device for a mask production machine. refer to figure 1 , the earband spot welding equipment of the mask production machine includes an operation table 1 installed on the ground, on the operation table 1, two mounting platforms 8 are fixedly installed by bolts, and a transmission mechanism 9 is arranged between the two mounting platforms 8, and the transmission mechanism 9 includes a conveyor belt and a placement plate fixed on the transmission belt. The mask is set inside the placement plate during transmission, and the transmission belt is driven by a stepping motor to perform intermittent movements. The top of the placement plate and the top of the mounting table 8 are on the same plane, so that The two ends of mouth mask can be in and stay on the set-up platform 8 when moving, which is convenient for punching and welding ear strap lines to mouth mask.

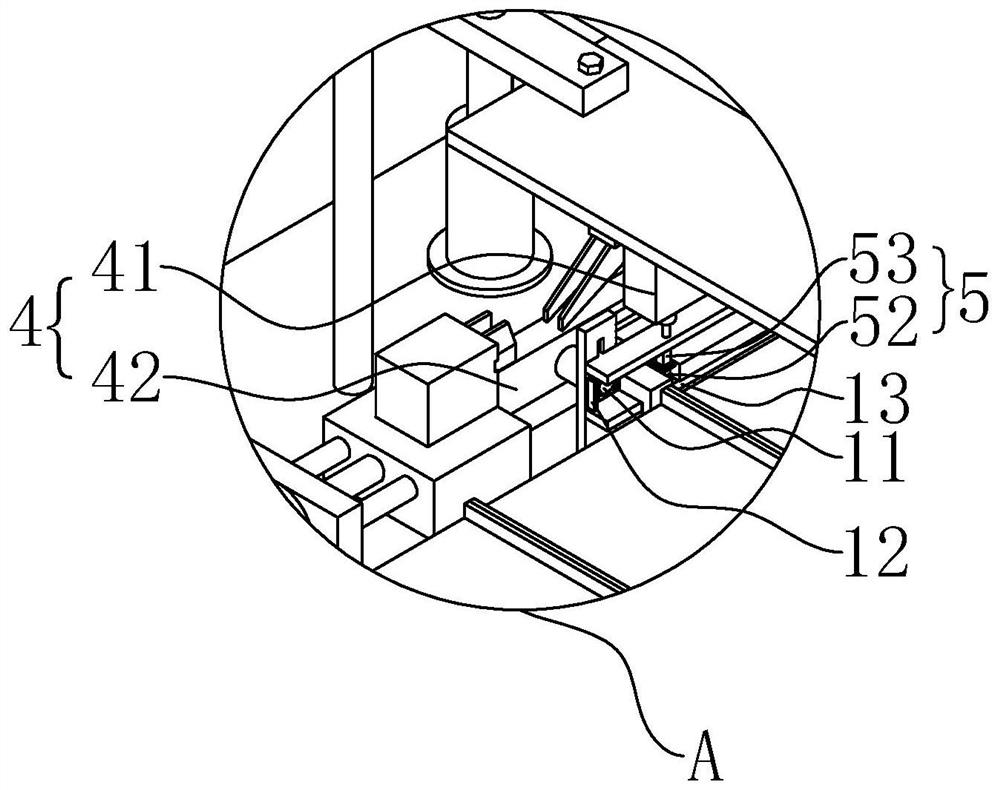

[0045] refer to Figure 1-2 The cons...

Embodiment 2

[0053] In the present embodiment, the earband spot welding equipment of the mask production machine may not include the mask opening mechanism 6, but through holes are opened equidistantly on both sides of the sterile cloth of the mask in advance, so that the mask is cut into shape The through holes on both sides of the back are at the four corners of the mask, so that when the mask passes through the ear strap spot welding equipment, the cut ear strap wire can be directly passed through the through hole, and then the ear strap wire is welded to the mask. Other parts are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com