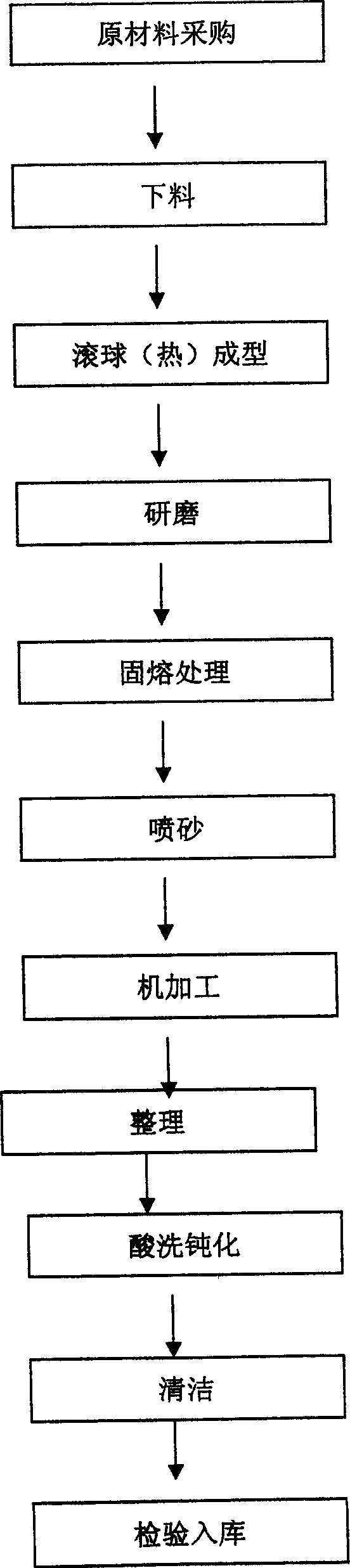

Method for forming pipe fittings by cold extrusion

A cold extrusion and pipe technology, applied in other manufacturing equipment/tools, heat treatment equipment, heat treatment process control and other directions, can solve the problems of unguaranteed quality, non-conformity, difficult shape control, etc., to achieve performance and chemical composition without changing the structure , The effect of high dimensional and geometrical tolerance accuracy, reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

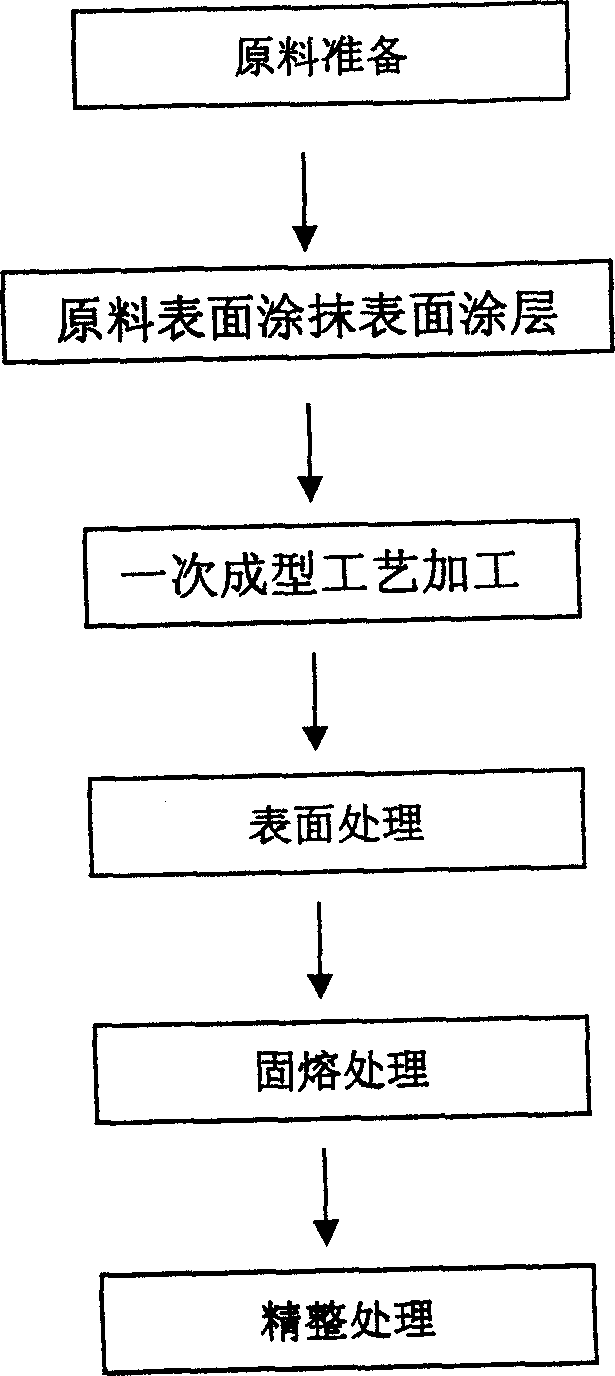

Method used

Image

Examples

Embodiment 1

[0043] A processing method of the ¢219 equal-diameter tee according to the present invention.

[0044] ①Prepare raw material pipes for pipe fittings to be processed; raw materials are seamless steel pipes, blanking: ¢219×510.

[0045] ②Apply the surface coating evenly on the inner and outer surfaces of the raw material pipe, and apply it twice; the surface coating consists of three components: gypsum, machine oil and lubricating grease in a weight ratio of 1: (3-10): (0.1-0.8) mixed. The thickness of the surface coating is 100-250 μm. Here, the mechanical oil is 46# hydraulic oil, and the lubricating grease is lard, specifically: 1 kg of gypsum with a particle size of 500 mesh, 46# hydraulic oil 5 kg, and lard: 0.25 kg. When in use, mix gypsum, 46# hydraulic oil, and lard together, stir evenly, and brush the inside and outside of the tube by hand or mechanically. The thickness of the surface coating is 150 μm.

[0046] ③For the raw material pipe with surface coating, the ex...

Embodiment 2

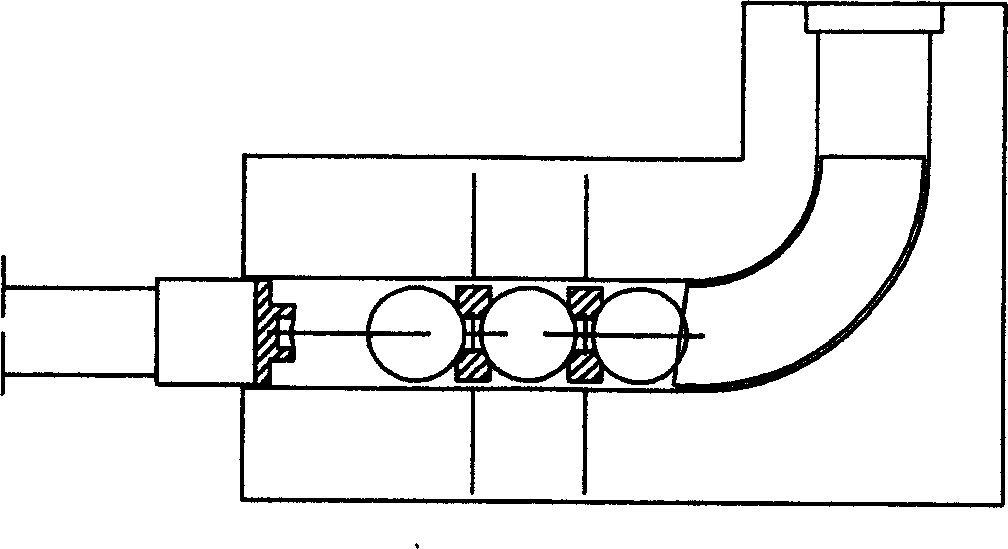

[0061] A processing method of ¢219 elbow according to the present invention.

[0062] ①Prepare raw material tubes for pipe fittings to be processed; raw materials are seamless steel tubes, blanking: ¢219×660.

[0063] ② Evenly smear the surface coating on the inner and outer surfaces of the raw material, and apply it twice; the surface coating is mixed by three components of gypsum, machine oil and grease in a weight ratio of 1: (3-10): (0.1-0.8) made. The thickness of the surface coating is 100-250 μm. Here machine oil selects butter for use, lubricating grease selects lard for use, specifically: 1 kilogram of gypsum, its granularity is 400 orders, 3 kilograms of butter, lard: 0.8 kilogram. When in use, mix gypsum, butter, and lard together, stir well, and brush on the outside of the tube by hand or mechanically, with a coating thickness of 100 μm.

[0064] ③The raw material pipe with surface coating is protected by internal and external molds, and axial pressure is applie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com