Hull curved block manufacturing method

A technology of curved surface segmentation and manufacturing methods, which is applied to ship components, ship construction, ships, etc., can solve the problems of heavy trimming workload, large residual stress of outer plates, poor quality of outer plate line shape control, etc., and achieve difficulty in construction Reduce, save time and cost, and achieve high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

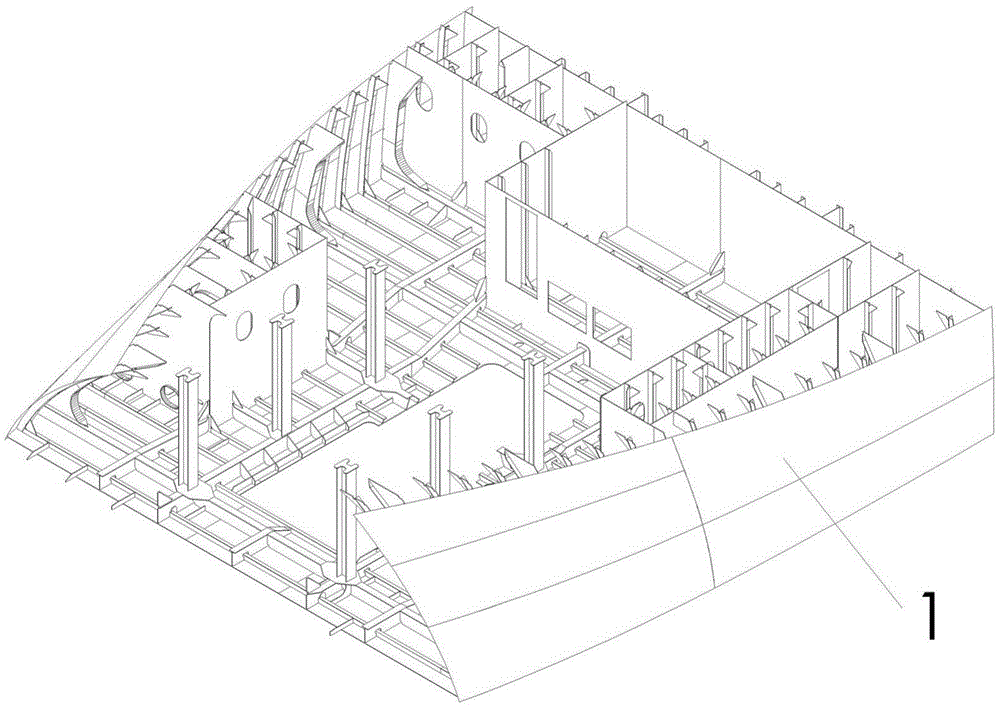

[0040] A method for manufacturing curved surface segments of a hull, wherein the curved surface segments can be L-shaped, F-shaped, P-shaped or door-shaped, and include 1-2 layers of deck frame, and 1 or more curved surface sheets .

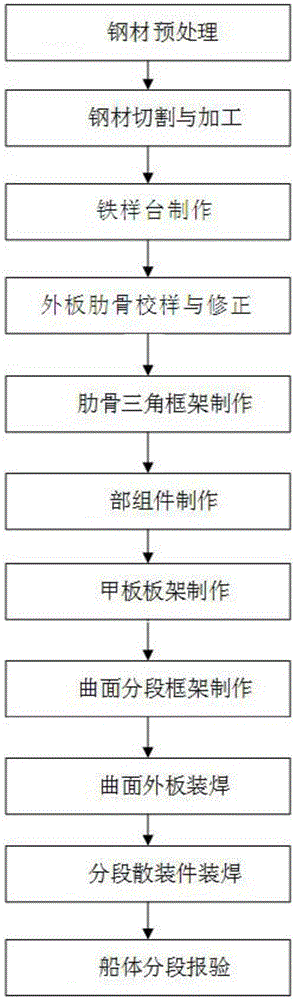

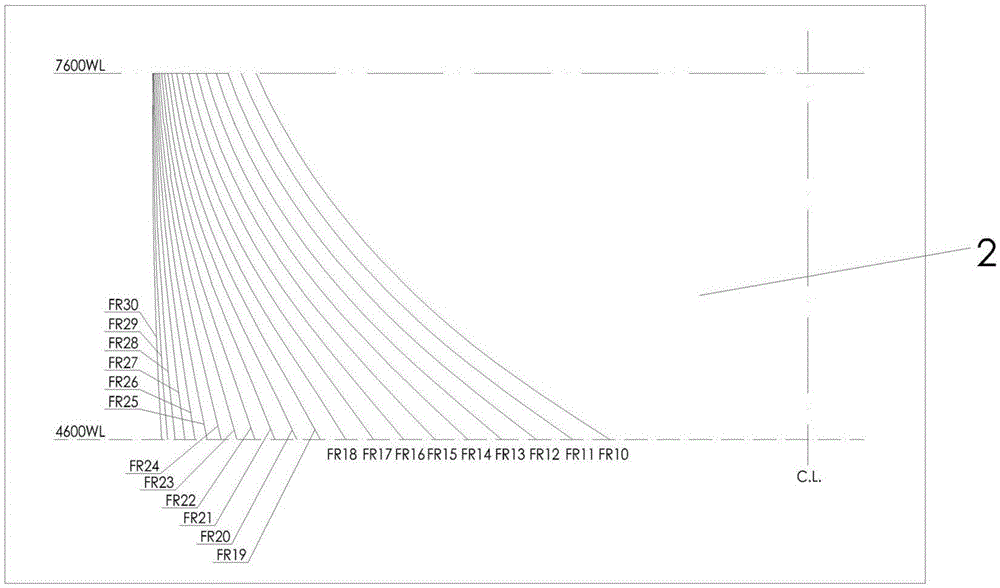

[0041] Below as figure 2 Take the door-shaped aircraft-ship surface segment 1 as an example, and carry out the detailed description of the method for making the hull surface segment in this application, such as figure 1 shown, including the following steps.

[0042] Step 1, steel component cutting blanking and processing

[0043] 1) Pretreatment: Before cutting and cutting steel plates and profiles, pretreatment is required to remove the oxide layer and spray shop primer. After pretreatment, the surface cleanliness of steel plates and profiles must reach the standard of Sa2.5 or above in I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com