Overlapping light heavy-duty material rack

An overlapping, material rack technology, applied in the field of material management warehouses, can solve the problems of large material footprint, large reserves, and unsuitable length and size to produce raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Each shelf position of the overlapping light-duty heavy-duty material rack can include a plurality of independent unit material racks that can be lifted and transferred separately and have the same structure, and all the unit material racks can be combined and overlapped.

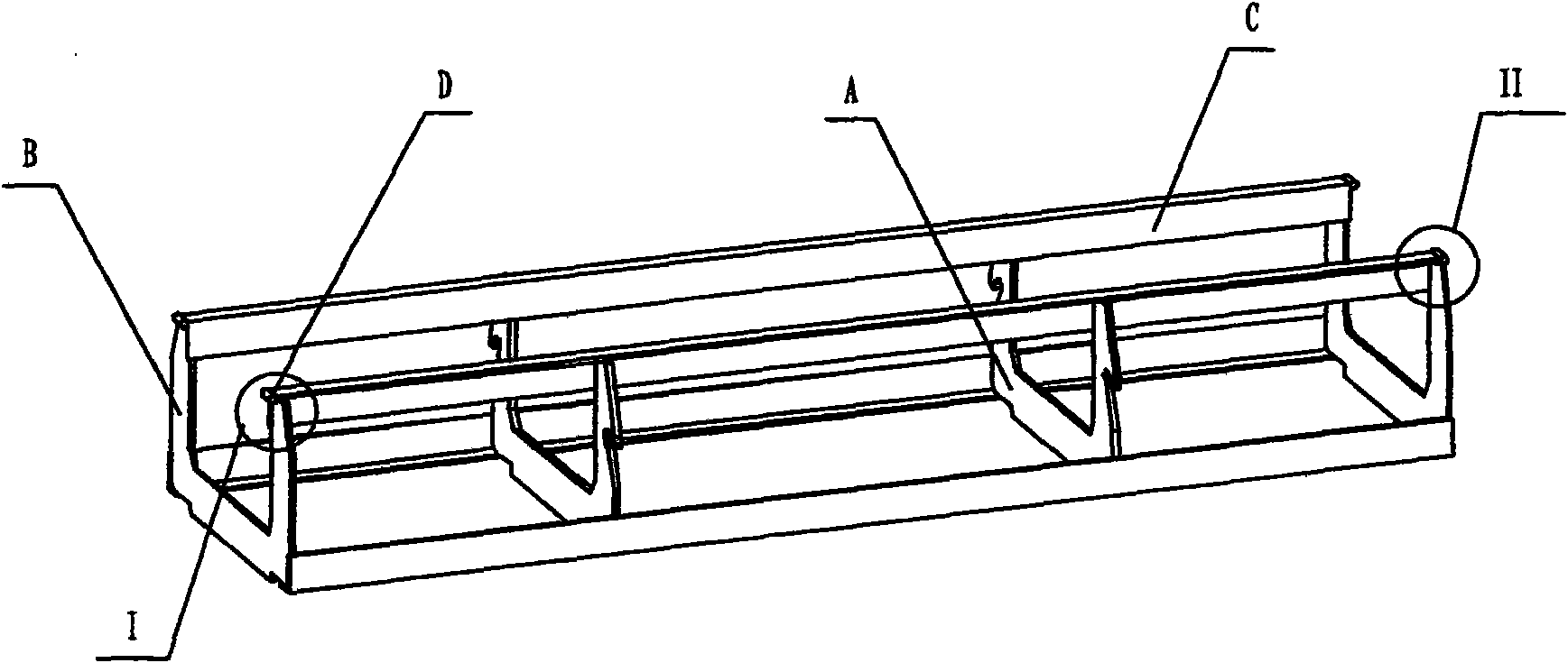

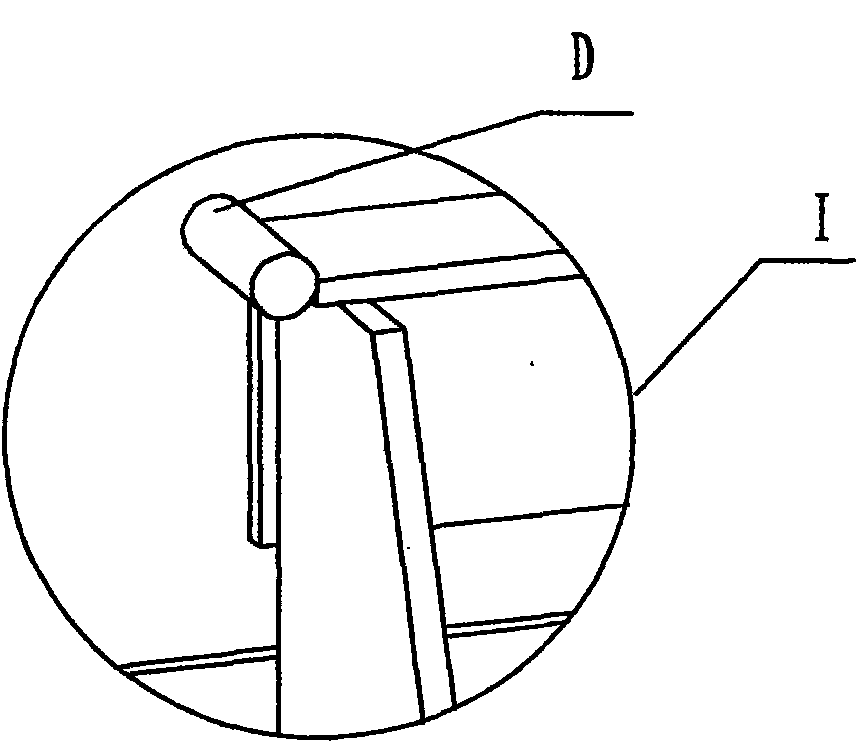

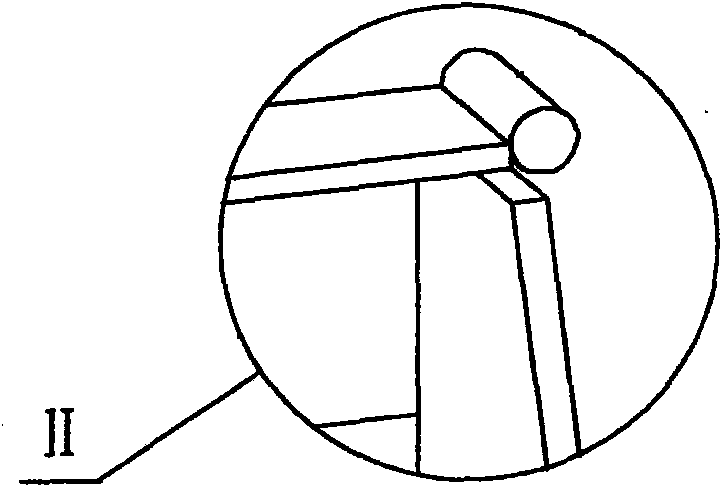

[0025] see figure 1 , Figure 1-a , Figure 1-b , figure 2 and image 3 : Each unit rack is composed of 2 pieces of lug plate A, 2 pieces of reinforcement plate B, 4 pieces of lacing angle steel C and 4 limit cards D. There is a "U" on the lifting lug plate A and reinforcement plate B The two bottom angles β of the material trough of the lug plate A are chamfered at 60°, the two sides of the lug plate A have sling grooves, and the enveloping angle α of the sling groove is greater than 180 °. The 2 lug plates A are symmetrically located in the middle along the length direction of the material rack, all the lug plates A and reinforcement plates B are arranged in parallel and scattered, and the 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com