Micro-nano porous material and preparation method thereof

A porous material, micro-nano technology, applied in ceramic products, other household utensils, household utensils, etc., can solve the problems of time-consuming and large consumption, achieve wide adjustable range, suppress the generation of defects and cracks, safe and easy The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, preparation of micro-nano porous material

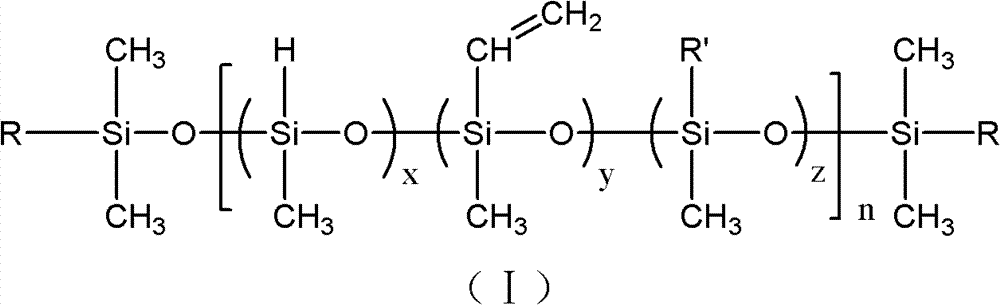

[0038] Polymer (R=-CH=CH) shown in formula (I) 2 , x=0.71, y=0.29, z=0) 4.8g and viscosity are 1.2g of simethicone oil 1000cS (centistokes), and the Karstedt catalyst of 0.3mg, its addition is the polymer shown in formula (I) 0.00625%, mix well, vacuumize to remove air bubbles, pour into a 15mL glass beaker, then heat up to 140°C at a heating rate of 1°C / min, and keep it warm for 3 hours to solidify, and release it after cooling down to room temperature to obtain white Cylinder gel solid sample; then place the sample in a nitrogen-protected tube furnace, raise the temperature to 250°C at a heating rate of 1°C / min and keep it for 2 hours, then raise the temperature to 400°C at a heating rate of 1°C / min ℃, raised the temperature to 550°C at a heating rate of 0.5°C / min and kept it for 2 hours, continued to raise the temperature to 650°C at a heating rate of 0.5°C / min and kept it for 1 hour, and obtained a yellow ha...

Embodiment 2

[0039] Embodiment 2, the preparation of micro-nano porous material

[0040] Polymer (R=-CH=CH) shown in formula (I) 2 , x=0.71, y=0.29 (x / y=2.5), z=0) 3.0g and viscosity are simethicone 3.0g of 1000cS, and the Karstedt catalyst of 0.03mg (for the polymer shown in (I) 0.001% of the mass) were mixed evenly, vacuumed to remove air bubbles, poured into a 15mL glass beaker, and then solidified in an oven at 140°C for 6 hours, and demolded after cooling down to room temperature to obtain a white cylindrical gel solid sample; then Place the sample in a tube furnace protected by a nitrogen atmosphere, raise the temperature to 250°C at a heating rate of 1°C / min and keep it for 2 hours, then raise the temperature to 400°C at a heating rate of 1°C / min, and then increase the temperature at a rate of 0.5°C / min The heating rate was raised to 550°C and kept for 2 hours, and the temperature was continued to be raised to 650°C at a heating rate of 0.5°C / min and kept for 1 hour to obtain a por...

Embodiment 3

[0041] Embodiment 3, the preparation of micro-nano porous material

[0042] Polymer (R=-CH=CH) shown in formula (I) 2 , x=0.71, y=0.29, z=0) 10g and viscosity are 20g of simethicone oil 350cS, and the Karstedt catalyst of 0.09mg (0.0009% of the quality of the polymer shown in (I)), mix uniformly, Vacuumize to remove air bubbles, pour it into a disc with a diameter of 60mm, then raise the temperature to 180°C at a heating rate of 0.5°C / min, and keep it warm for 2 hours for curing. A white disc with a thickness of 10.4mm. Put the cured disc in an atmosphere furnace protected by argon, raise the temperature to 400°C at a heating rate of 2°C / min, raise the temperature to 480°C at a heating rate of 1°C / min, and continue to increase the temperature at a rate of 0.5°C / min Raise the temperature to 550°C and keep it for 2 hours, then continue to raise the temperature to 700°C at a rate of 0.5°C / min and keep it for 1 hour to obtain a yellow hard and tough micro-nano material with a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com