Reinforcing structure of automobile B pillar

A technology for strengthening structures and B-pillars, which is applied to superstructures, subassemblies of superstructures, vehicle components, etc., can solve the problems of increased body weight, complex structures, and low efficiency utilization of reinforced structure sheet metal, so that it is not easy to break Bending, the effect of improving the bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

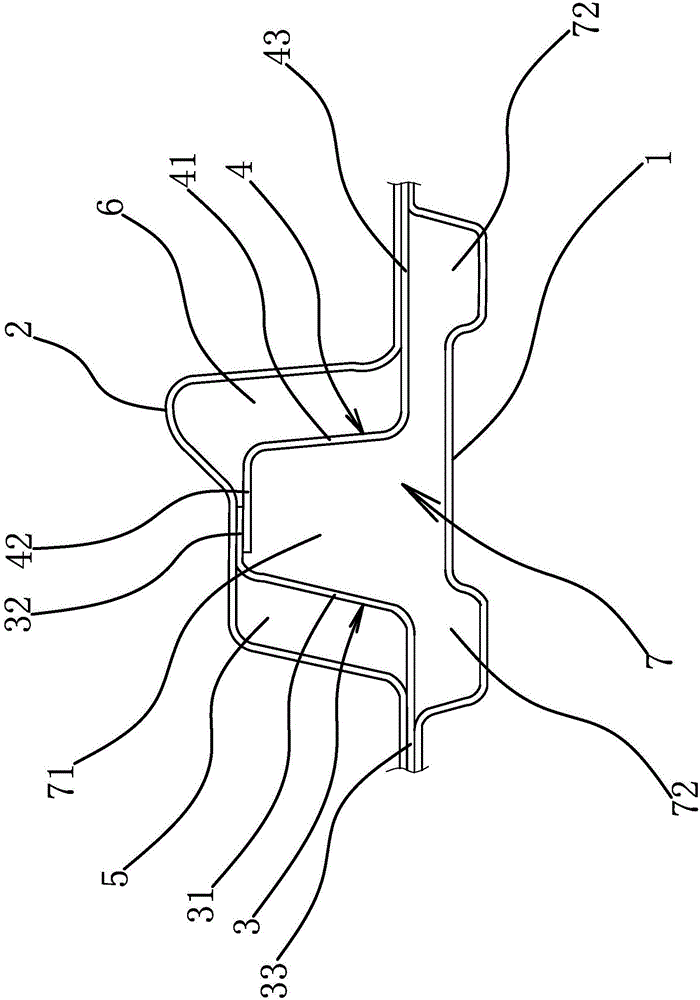

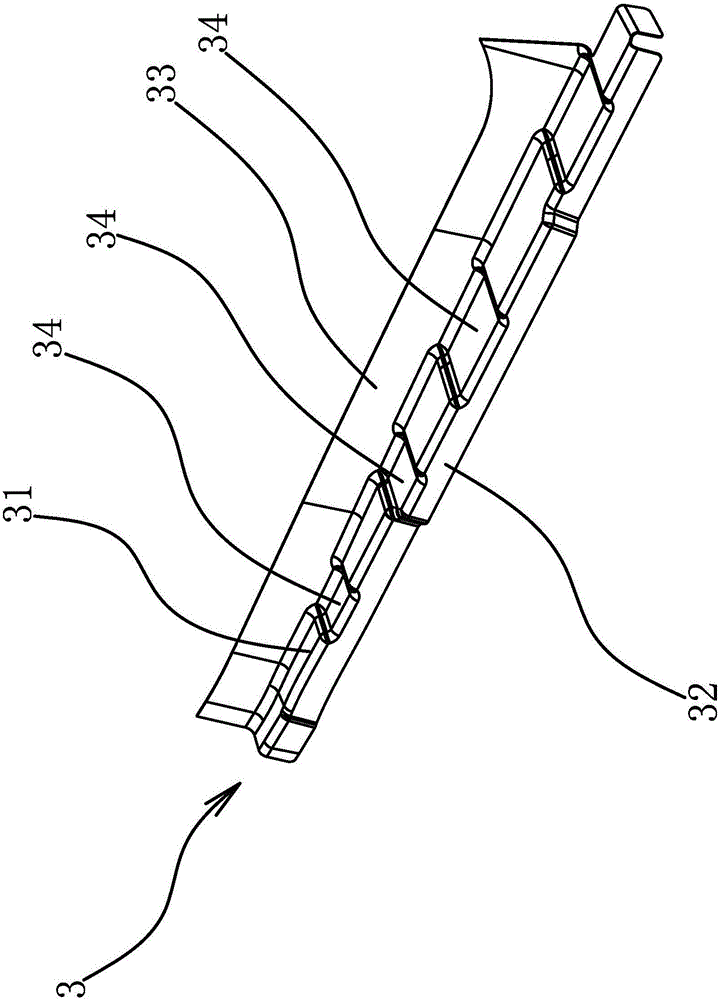

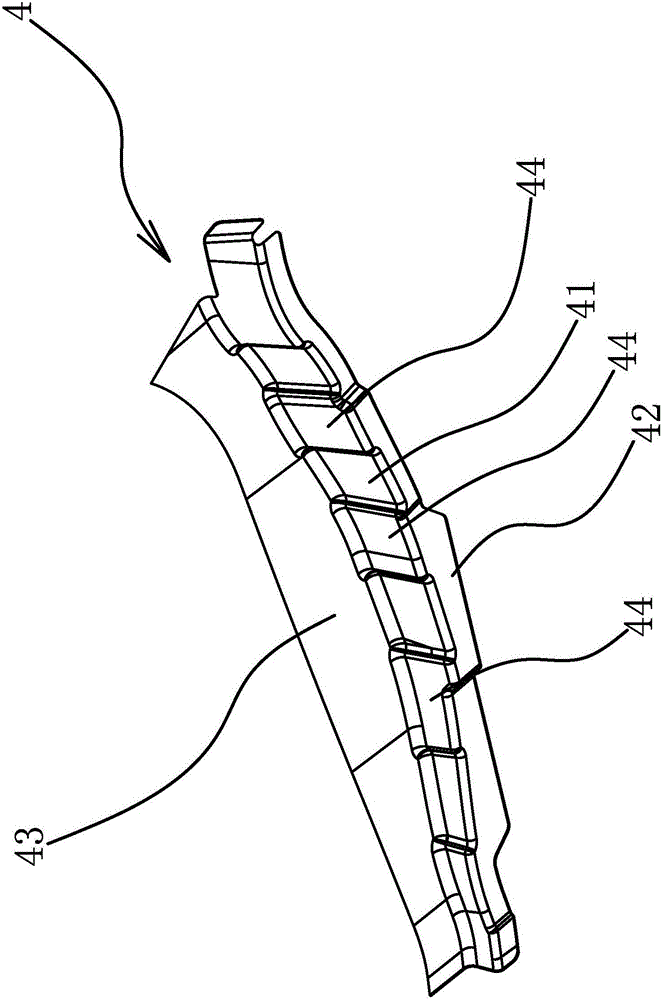

[0024] The reinforcing structure of the B-pillar of the automobile comprises a reinforcing plate 3, a body 1 31, a flange 32, a flange 2 33, an error surface 1 34, a reinforcing plate 2 4, a body 2 41, flange 3 42, and flange 4 43. Error surface two 44, cavity one 5, cavity two 6, cavity three 7, longitudinal chamber 71, and transverse chamber 72.

[0025] Specifically, as figure 1 with Figure 4 As shown, the B-pillar of an automobile includes a B-pillar inner panel 1 , a B-pillar outer panel 2 and a door sill outer panel 8 . The reinforcement structure includes a reinforcement plate 3 and a reinforcement plate 2 4, the reinforcement plate 3 and the reinforcement plate 2 are arranged longitudinally between the B-pillar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com