Fabricated construction method of air-conditioning plant room

A construction method and prefabricated technology, applied in the processing of building materials, special buildings, small buildings, etc., can solve the problems of complex pipeline construction, difficult to install in place at one time, poor construction accuracy, low construction efficiency, etc., to prevent damage Pipeline paint, reduce on-site labor, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

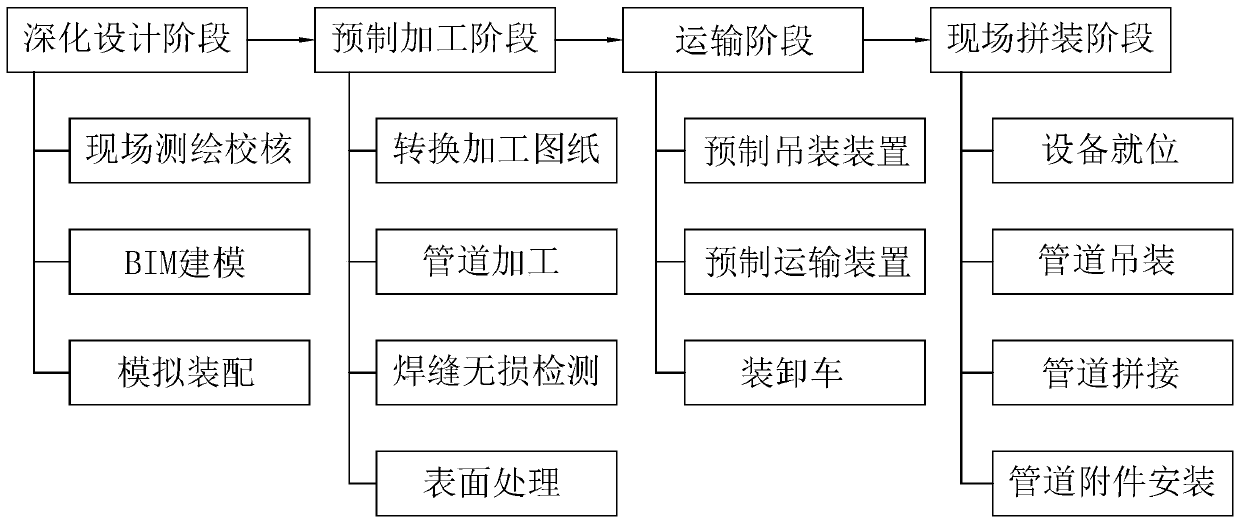

[0033] Example: Combine figure 1 , a prefabricated construction method for an air-conditioning machine room, including four stages, respectively, the detailed design stage, the prefabrication processing stage, the transportation stage and the on-site assembly stage, wherein the steps of the detailed design stage are as follows:

[0034] 1. On-site surveying and mapping, check the drawings of the machine room; the main content of the check includes beams, columns, walls, and foundations; there will be some errors in the civil construction process, and the civil structure of the machine room is the carrier of the equipment in the machine room, so it is necessary to ensure that the walls and panels , the beam is consistent with the modeling situation, so that the mechanical and electrical pipelines can be installed after prefabrication in the factory.

[0035] 2. Carry out BIM modeling based on the drawings of the machine room; surround the equipment in the machine room, includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com