Integral assembling type building system and installing method

A kind of construction system and assembly technology, applied in the direction of construction, residential construction, building structure, etc., can solve the problems of being unable to keep up with the pace of construction industrialization, high cost of grid structure system, complicated process construction, etc., to achieve convenient Effects of quality control, shortened duration, high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

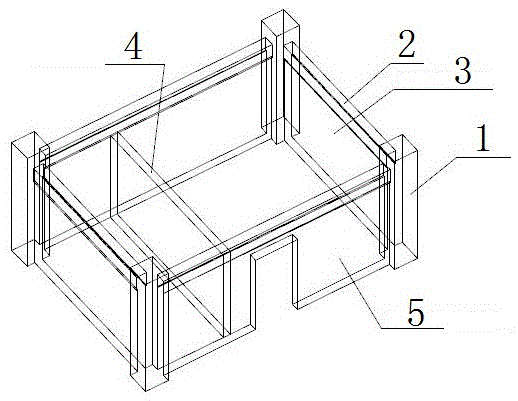

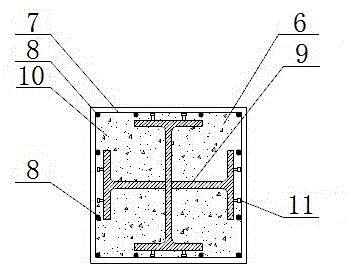

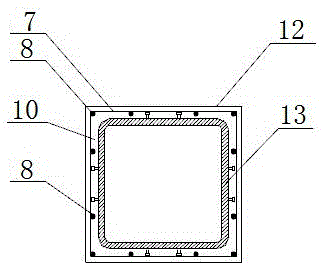

[0046]Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a prefabricated steel-concrete composite column 1 , a prefabricated steel-concrete composite beam 2 , a prefabricated concrete floor 3 , a prefabricated lightweight integrated interior wall 4 and a prefabricated concrete thermal insulation exterior wall 5 assembled together. The prefabricated steel concrete composite column 1 is a cross-shaped steel concrete column 6, and the cross-shaped steel concrete column 6 includes stirrups 7. There are several column bars 8 inside the stirrups 7, and a cross-shaped steel 9 is arranged at the center of the stirrups 7. The stirrups 7, The column reinforcement 8 and the cross-shaped steel 9 are integrated by pouring concrete 10 , and the cross-shaped steel 9 and the stirrup 7 are connected with shear bolts 11 . The prefabricated steel-concrete composite column 1 is a box-shaped steel-concrete column 12, the box-shaped steel-concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com