A prefabricated strip foundation and its construction technology

A strip foundation and prefabricated assembly technology, applied in infrastructure engineering, construction, etc., can solve the problems of inability to achieve building assembly, easy to be affected by weather, low assembly rate, etc., achieve simple and efficient construction technology, reduce construction difficulties, and improve The effect of assembly rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

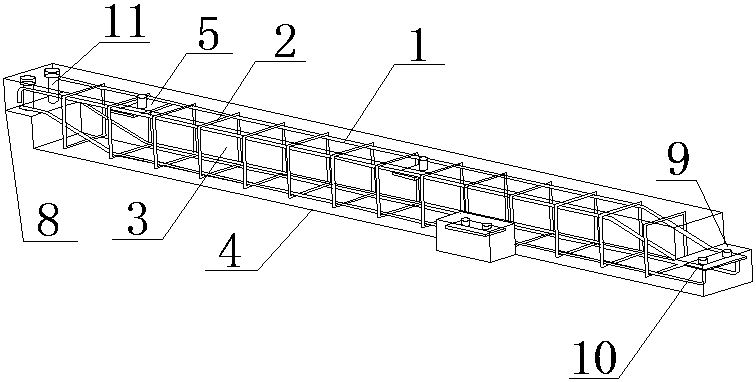

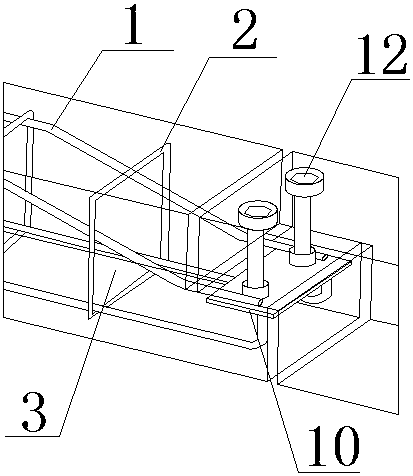

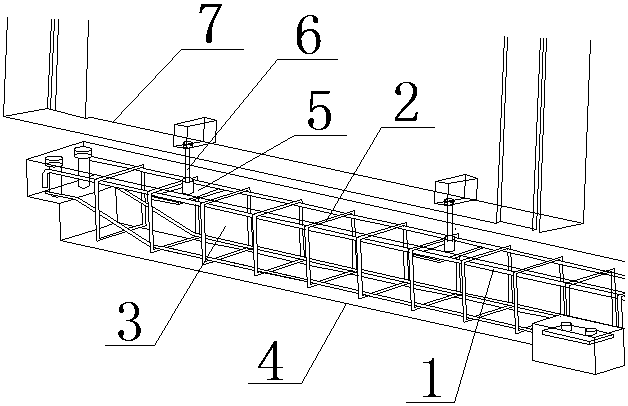

[0031] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a longitudinal steel bar 1 , a number of stirrups 2 are wound and fixed outside the longitudinal steel bar 1 , and the longitudinal steel bars 1 and the stirrups 2 are poured with concrete 3 to form a whole body 4 under force. The upper part of the stressed body 4 is provided with a wall connecting steel plate 5 , and the wall connecting steel plate 5 is fixedly connected with the wall 7 through the wall connecting bolt 6 . The left side of the stressed body 4 is provided with a bump 8, the right side is provided with a groove 9 matching the left side bump 8, the rear side of the stressed body 4 is provided with a bump 8, and the front side is provided with a groove 9 matching with the rear side. Block 8 fits into groove 9 . A connecting steel plate 10 is provided on the groove 9, a connecting sleeve 11 is arranged inside the protrusion 8, and a connecting bolt 12 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com