Implementation method of prefabricated under-rail foundation for trams in soft soil areas

A technology for trams and implementation methods, applied in infrastructure engineering, tracks, roads, etc., can solve the problems of large impact on structural mechanical properties, long construction period, large on-site labor, etc., to shorten the construction period, ensure quality, The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

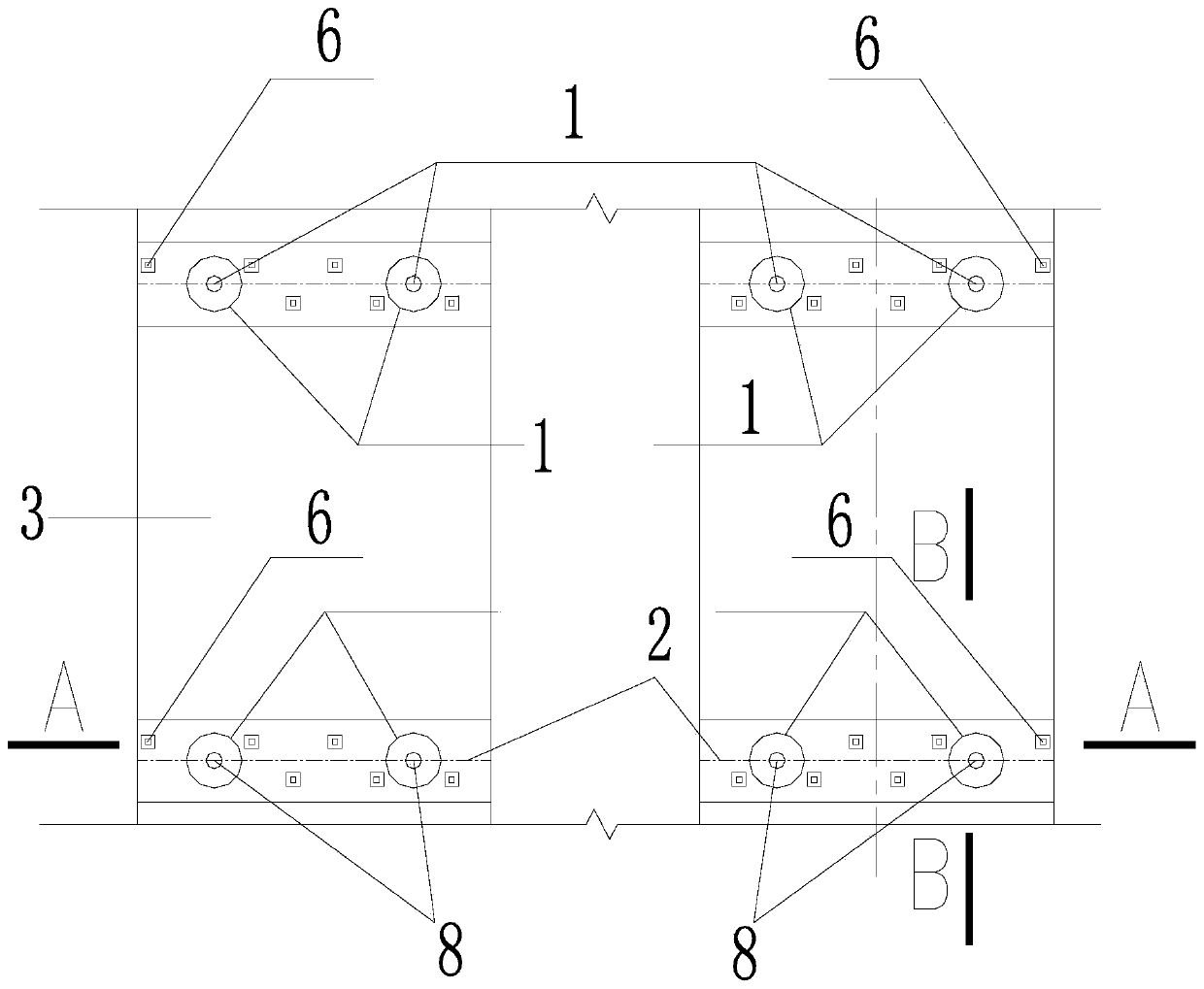

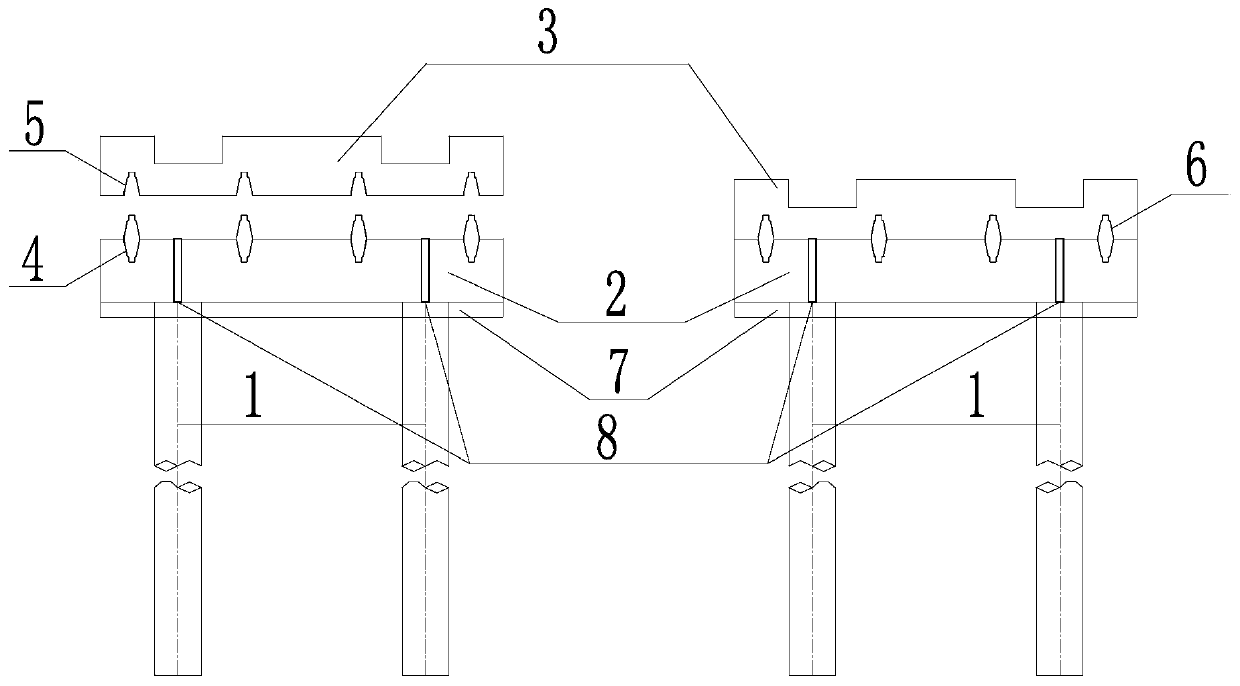

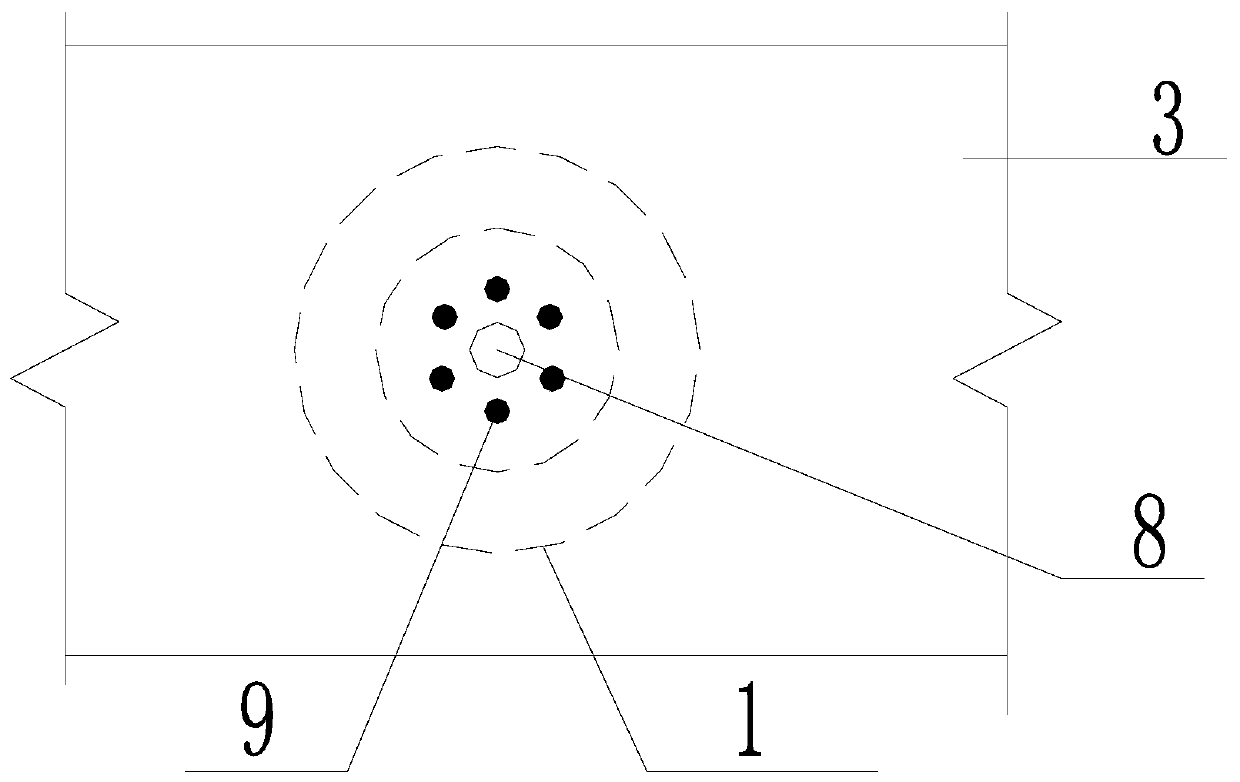

[0032] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

[0033] like Figure 1 to Figure 8 As shown, the implementation method of the prefabricated under-rail foundation of the tram in the soft soil area is as follows:

[0034] Step 1: factory prefabricated PHC pile foundation, prefabricated reinforced concrete beams and prefabricated reinforced concrete slab structure three-part components;

[0035] Step 2: Prefabricated reinforced concrete beams should reserve steel bars corresponding to the pile foundation, and the length of the steel bars should be greater than 1m;

[0036] Step 3: During on-site assembly, reserve the bottom of the steel bar under the beam of the prefabricated reinforced concrete beam to weld the thick steel plate. The welding position of the thick steel plate needs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com