Combined long-span ribbed slab structure

A large-span, combined technology, applied in floors, building components, building structures, etc., can solve the problems of complex construction, non-conformity with the industrialized prefabricated assembly production mode of the construction market, and self-heavy types, etc., to reduce the construction period and production. The construction is convenient and fast, and the number of effects is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

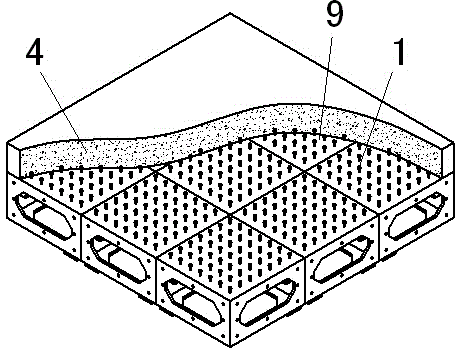

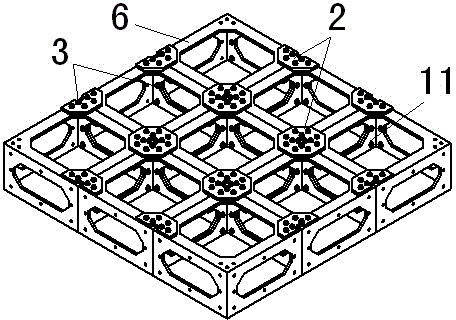

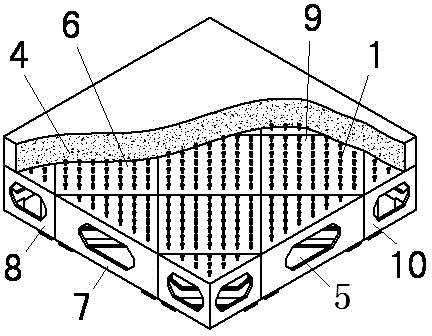

[0032] This example Figure 1-16 As shown, it includes steel box assembly units, steel plate connectors and bolts, and the upper reinforced concrete layer. The steel box assembly unit is composed of an upper top plate, a web and a lower wing plate, and is welded in the factory to form a steel box structure unit with a hole at the bottom. After the assembly is completed, the adjacent unit webs are closely connected as a whole by bolts. The upper roof and lower flange plates are connected to form a multi-ribbed floor structure system, which can bear the construction load of the upper reinforced concrete layer, and then form a whole with the reinforced concrete layer The multi-ribbed composite floor structure bears the combined loads under various working conditions in the use stage. The top plate, web plate and lower wing plate in the steel box assembly unit are welded by steel plate or section steel, and are processed into a whole in the factory, and the connecting bolt holes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com