Low-position electric box body

A technology for electric boxes and boxes, which is applied to electrical components, substation/distribution device shells, substation/switch layout details, etc. It can solve the problems of wasting mortar and cement, wasting manpower and materials, and there are many lines and pipes, so as to save resources. , reduce waste, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

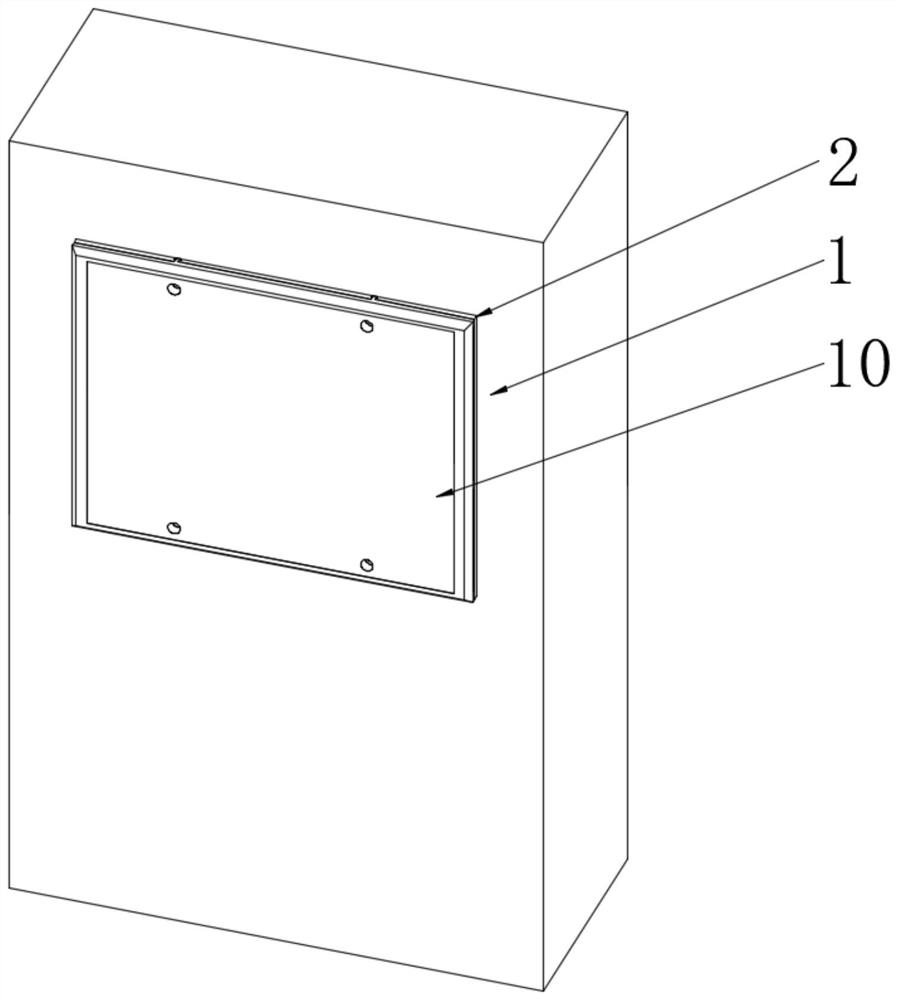

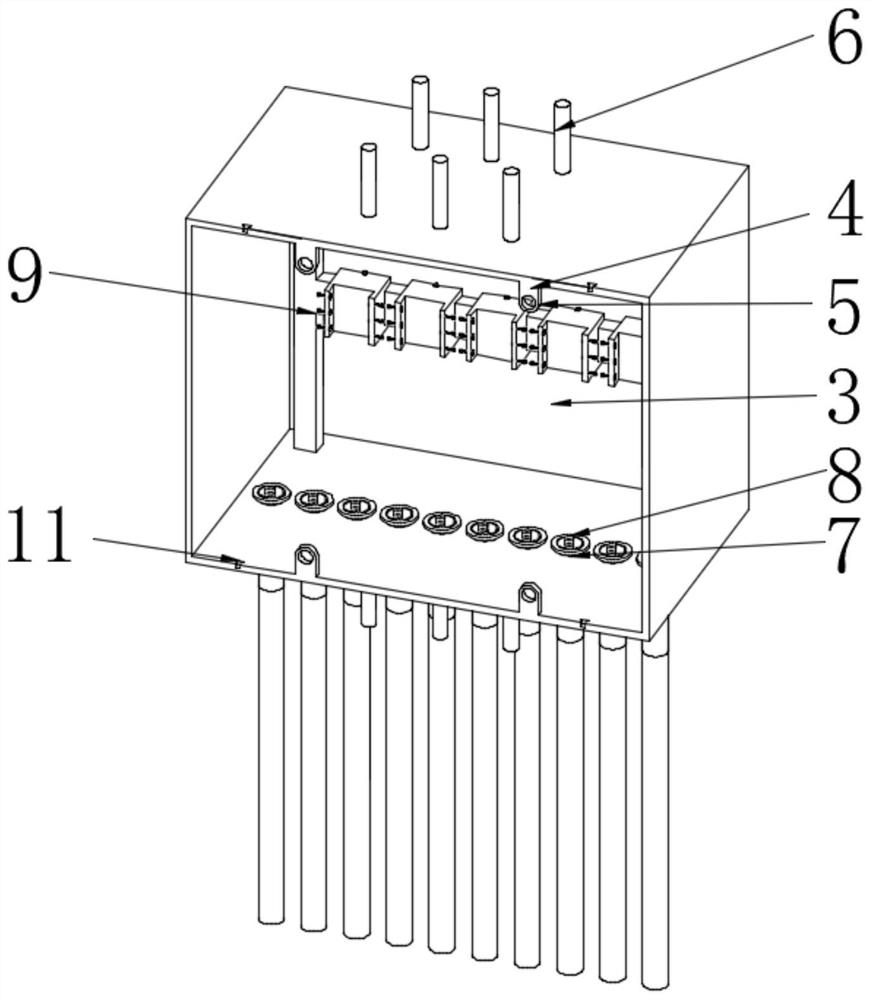

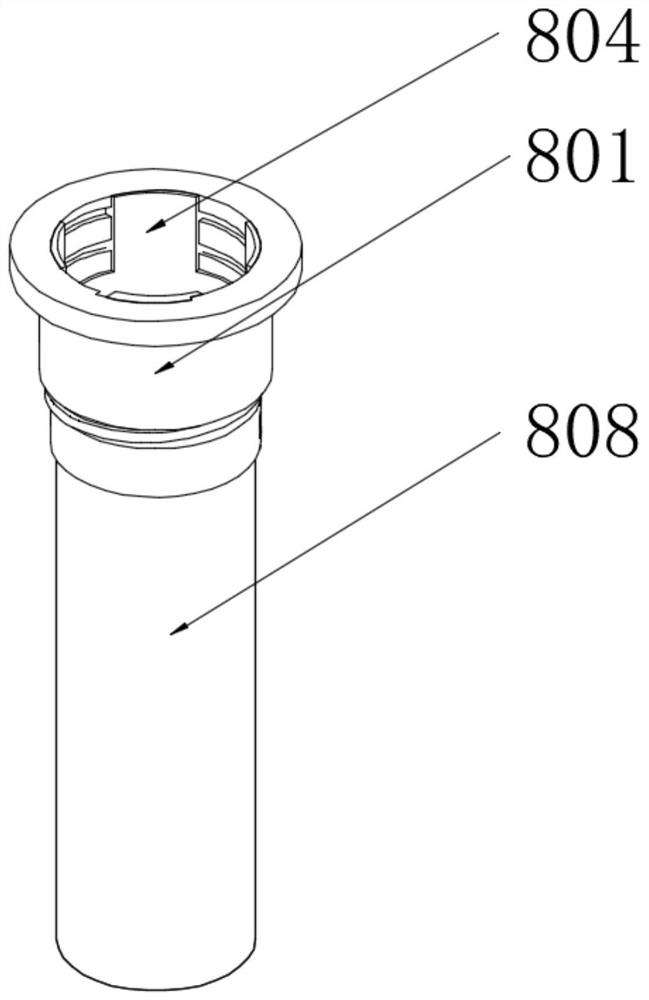

[0036] like figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, and 11, the embodiment of the present invention provides a low-level electric box body, including an electric box main body 2, and the electric box main body 2 is fixedly installed by pouring Inside the concrete block 1, a number of positioning pins 6 are fixedly installed on the upper surface and the lower surface of the main body 2 of the electric box. A plurality of through holes 7 are provided through the surface, and each of the through holes 7 is connected with a cable pipe fixing mechanism 8. A plurality of fixing plates 4 are fixedly installed on the outer sides of the upper and lower sides of the inner wall 3 of the electric box. The first fixing threaded holes 5 are provided on the fixing plates 4 , a positioning mechanism 9 is installed inside the main body 2 of the electric box, and a box cover 10 is installed on one side of the main body 2 of the electric box.

[0037]Through the above-mentioned technical schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com