Compaction forming construction method of concrete poured on the base of structure and device thereof

A technology of pouring concrete and construction methods, which is applied in basic structure engineering, basic structure repair, construction, etc. It can solve the problems of prolonging the construction period, affecting the appearance, increasing the newly poured part, etc., shortening the construction period and simplifying the design scheme , a clear effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0083] Example 1: The extruded slab is 1.0m long and 0.3m high, and the width of the cast beam is 0.5m. The extruded slab on each side is pushed horizontally to the full cylinder a=0.25m, the concrete slump is 16cm, and the twin-screw M12 is selected. Q235 steel, double thread z=2, pitch p=1.75mm, middle diameter d 2 =10.863mm, minor diameter d 1 =10.106mm, standard coarse tooth, friction coefficient f=0.15, force F acting on the wrench max =100N,, the effective radius of the moment arm l=500mm.

example 2

[0084] Example 2: φ150mm circular cross-section cylinder, pushed up to compact 1m, single screw M16, Q345 steel, middle diameter d 2 =14.701mm, minor diameter d 1 =13.835mm, the force F acting on the wrench max =144N, the effective radius of the arm of force l=500mm, and other parameters are the same as Example 1.

[0085] Table calculation, Table 2 shows the design and calculation process of the reinforcing screw for the piston-type compaction push-casting concrete forming and the internal pressure stress of the newly poured concrete.

[0086] Table 2: M12, M16 reinforced screw design and internal compressive stress of concrete

[0087]

[0088] (2) Construction part

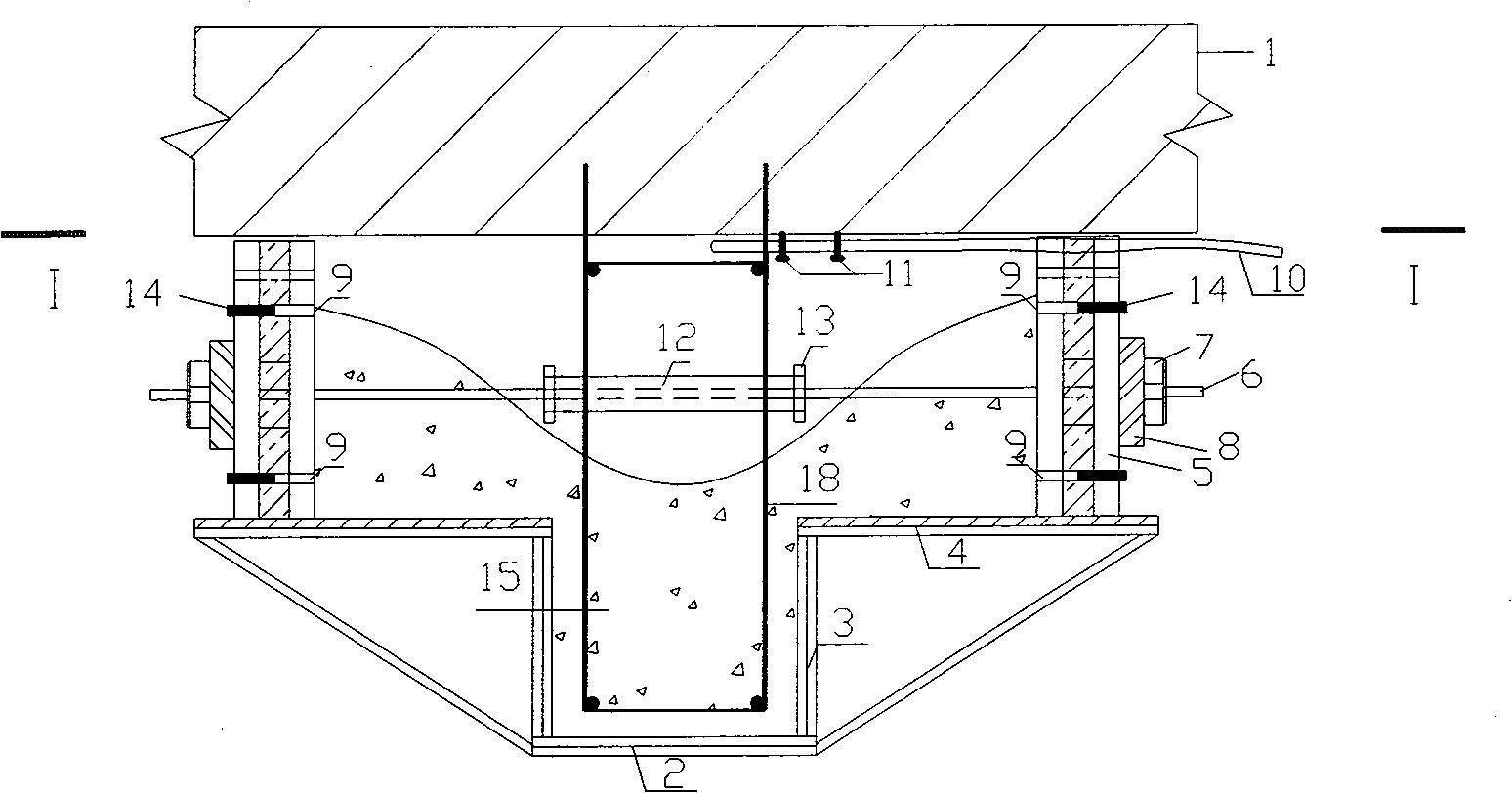

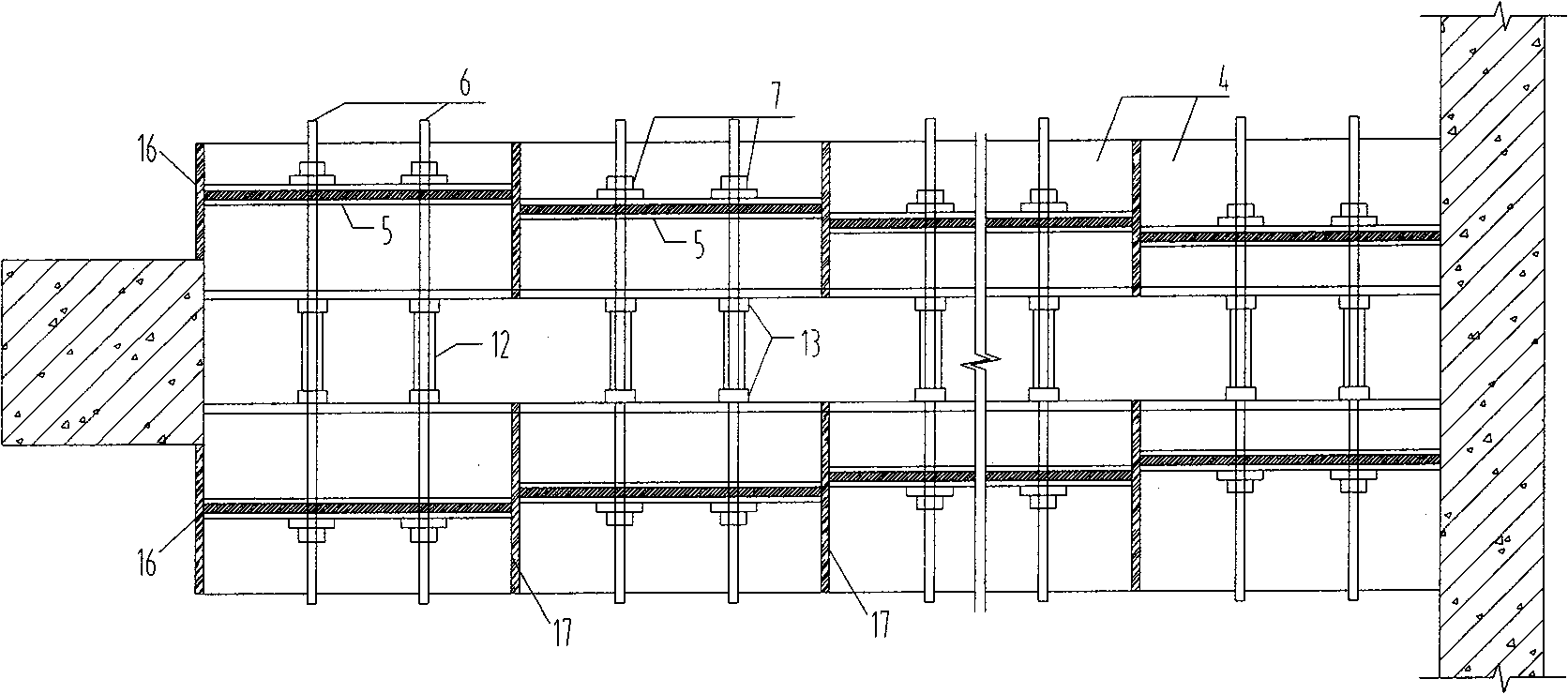

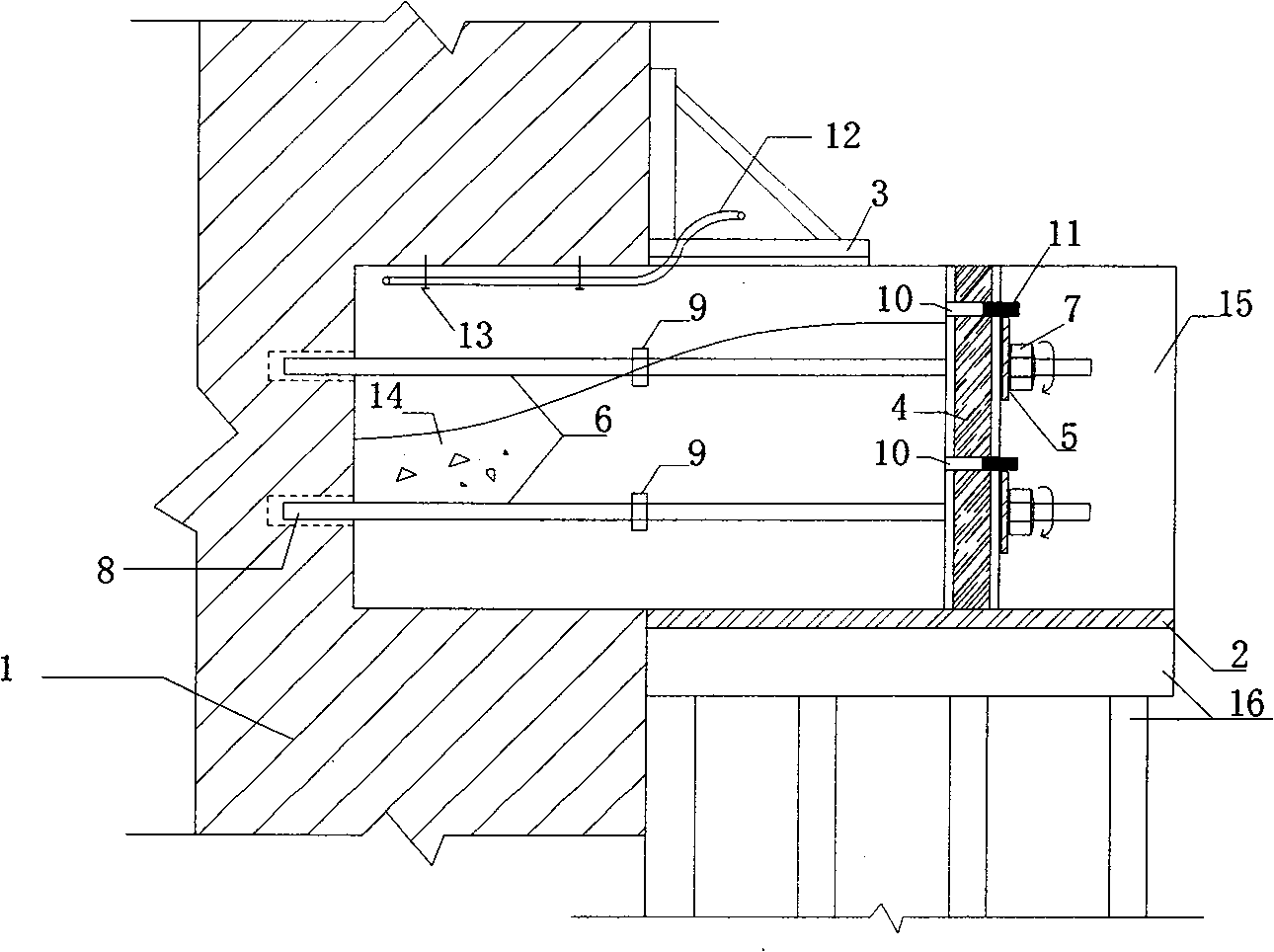

[0089] (1) Method 1, a concrete beam is poured under a closed original concrete slab, and the figure 1 , eject the outer edge of the precast beam side form (the sum of the width of the beam and the thickness of the two extruded slabs) at the bottom of the original slab (1), and draw the scale line of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Middle diameter | aaaaa | aaaaa |

| Trail | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com