Full-automatic deodorization equipment for garbage classification throwing point deodorization

A technology for sorting and disposing of garbage, which is applied in garbage bins, garbage cleaning, garbage collection, etc. It can solve problems such as the spread of infectious diseases, the growth of bacteria, and the generation of large odors in garbage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

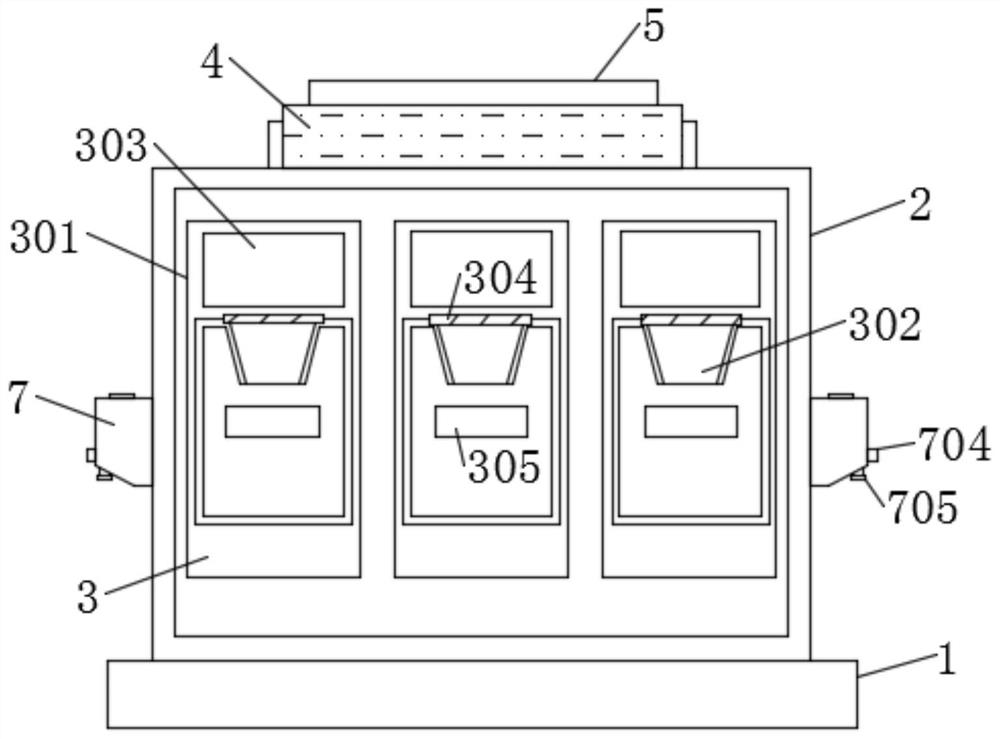

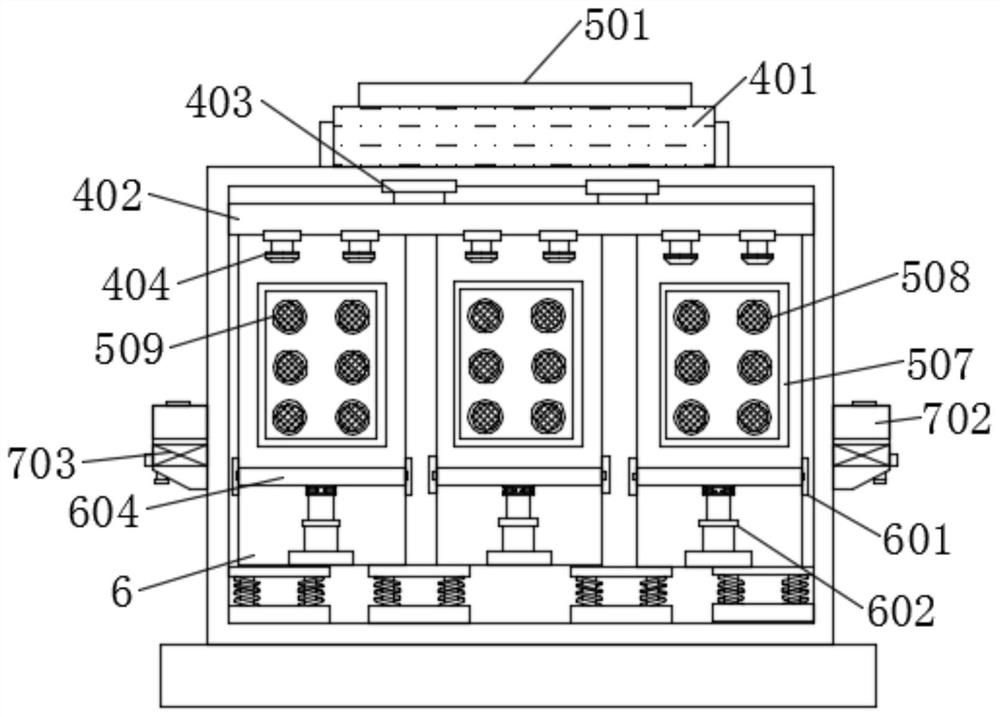

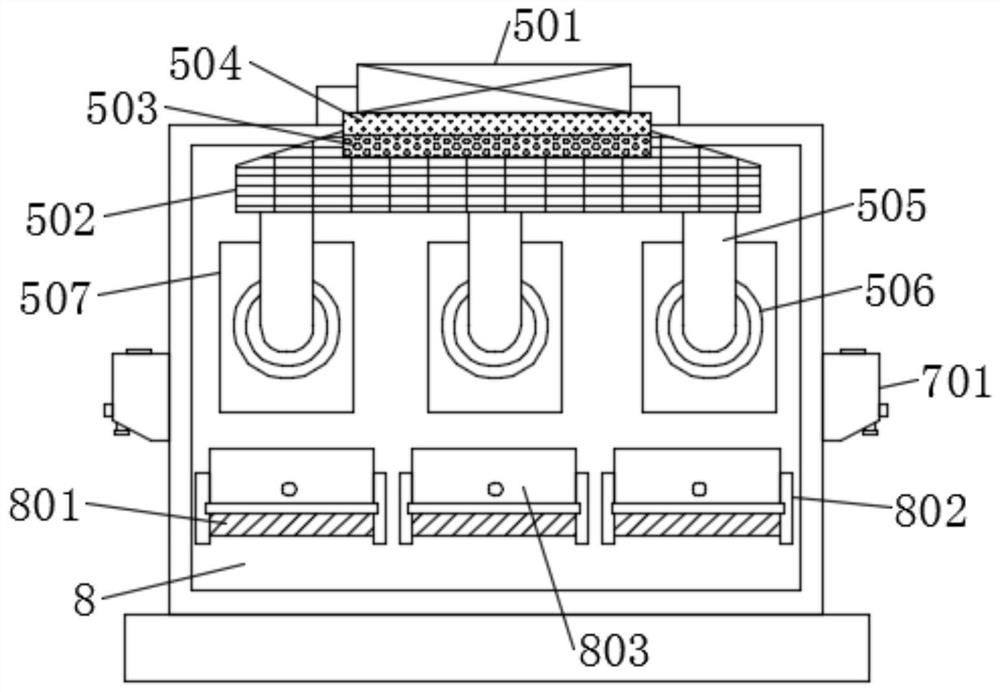

[0023] see Figure 1~4 , in an embodiment of the present invention, a fully automatic deodorizing device for deodorizing garbage sorting points, including a base 1, a housing 2 is installed above the base 1, and equidistantly installed inside the housing 2 There are three garbage disposal bins 3, the left garbage disposal bin 3 is used to collect recyclable garbage, the middle garbage disposal bin 3 is used to collect non-recyclable garbage, and the right garbage disposal bin 3 is used to collect dangerous goods garbage. 2. An atomization disinfection device 4 connected to the three garbage disposal bins 3 is installed on the upper side. The atomization disinfection device 4 can carry out regular atomization disinfection on the interior of the garbage disposal bin 3, and can also carry out long-term disinfection after the garbage is exported. Spray disinfection to prevent bacterial growth. A deodorizing device 5 connected to the three garbage disposal bins 3 is installed on th...

Embodiment 2

[0025] In this embodiment, a drop-in area 301 is provided outside the front end of the garbage disposal bin 3, and a feeding port 302 communicating with the garbage disposal bin 3 is arranged in the middle of the drop-in area 301. A display screen 303 is electrically installed on the top, and the display screen 303 can display garbage sorting publicity information, which is conducive to people's garbage learning of garbage sorting knowledge. An ultraviolet disinfection lamp 304 is installed horizontally above the feed port 302, and the ultraviolet disinfection lamp 304 can The feed port 302 is subjected to ultraviolet disinfection treatment to prevent the residual garbage at the feed port 302 from causing bacteria to grow. A sign column 305 is installed horizontally at the bottom of the charge port 302, through which the types of garbage can be placed in each garbage disposal bin 3. Marking to prevent wrong delivery; the atomization disinfection device 4 includes a liquid stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com