Trash can cleaning transition position changing structure

A technology for trash cans and garbage transport vehicles, which is applied in the direction of trash cans, garbage cleaning, garbage collection, etc. It can solve problems such as no specific solutions have been proposed, and achieve the effect of saving time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

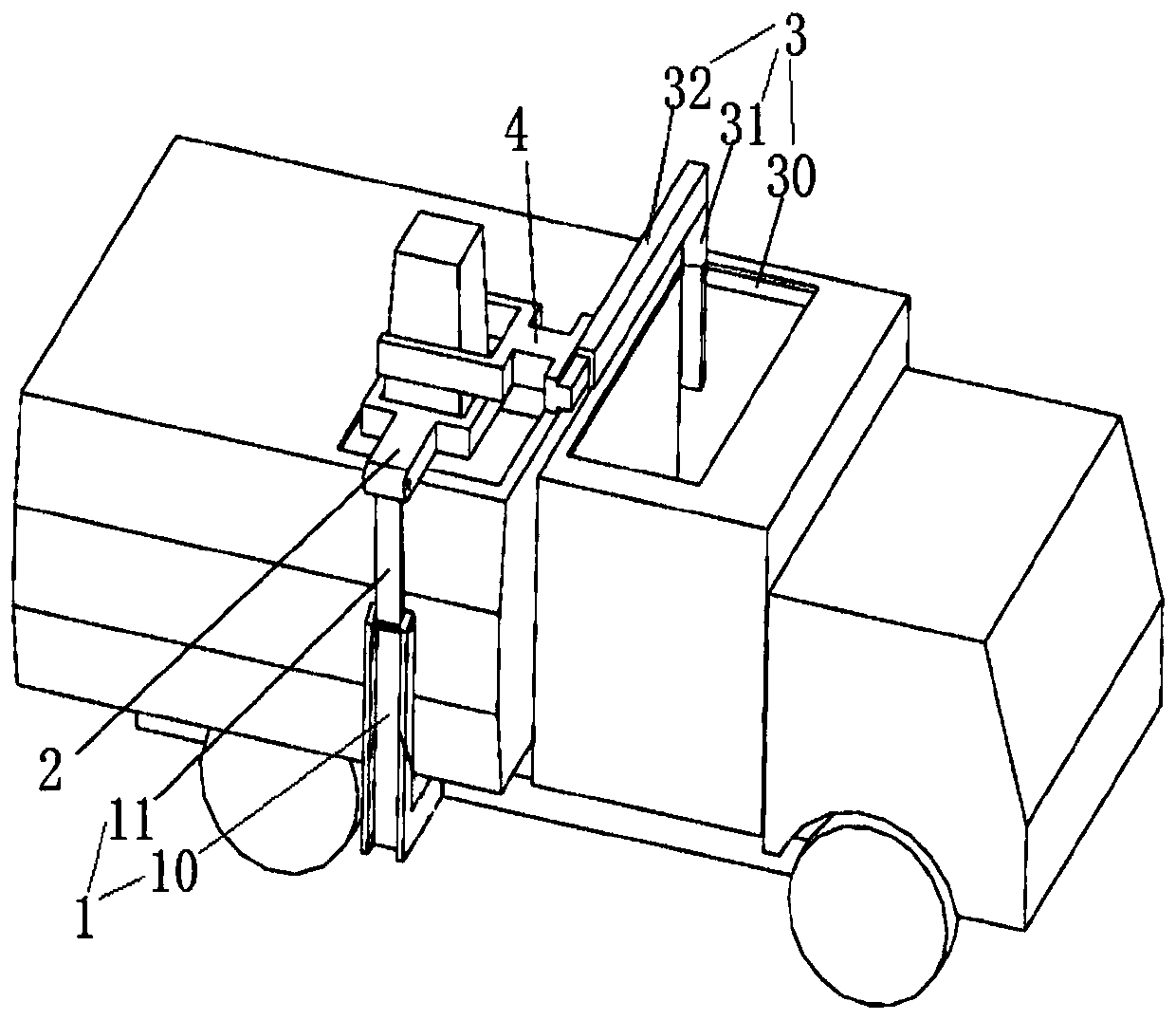

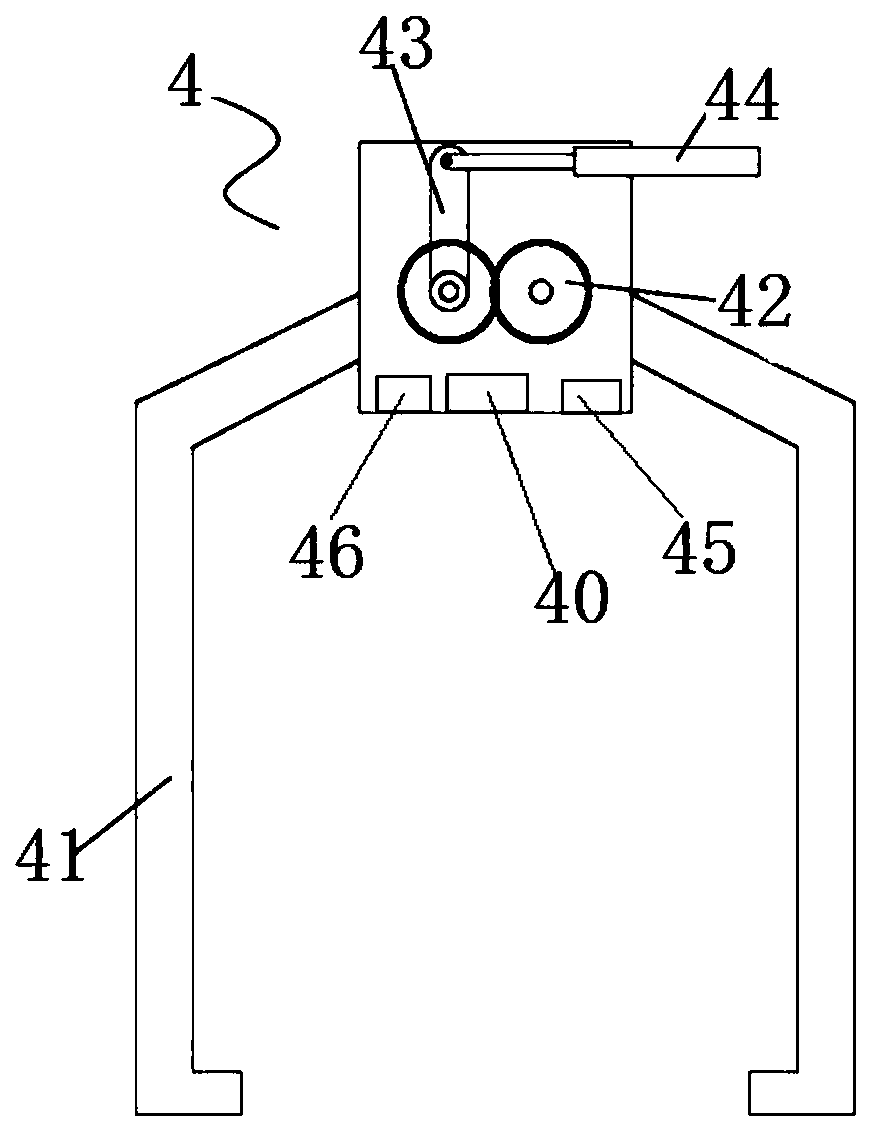

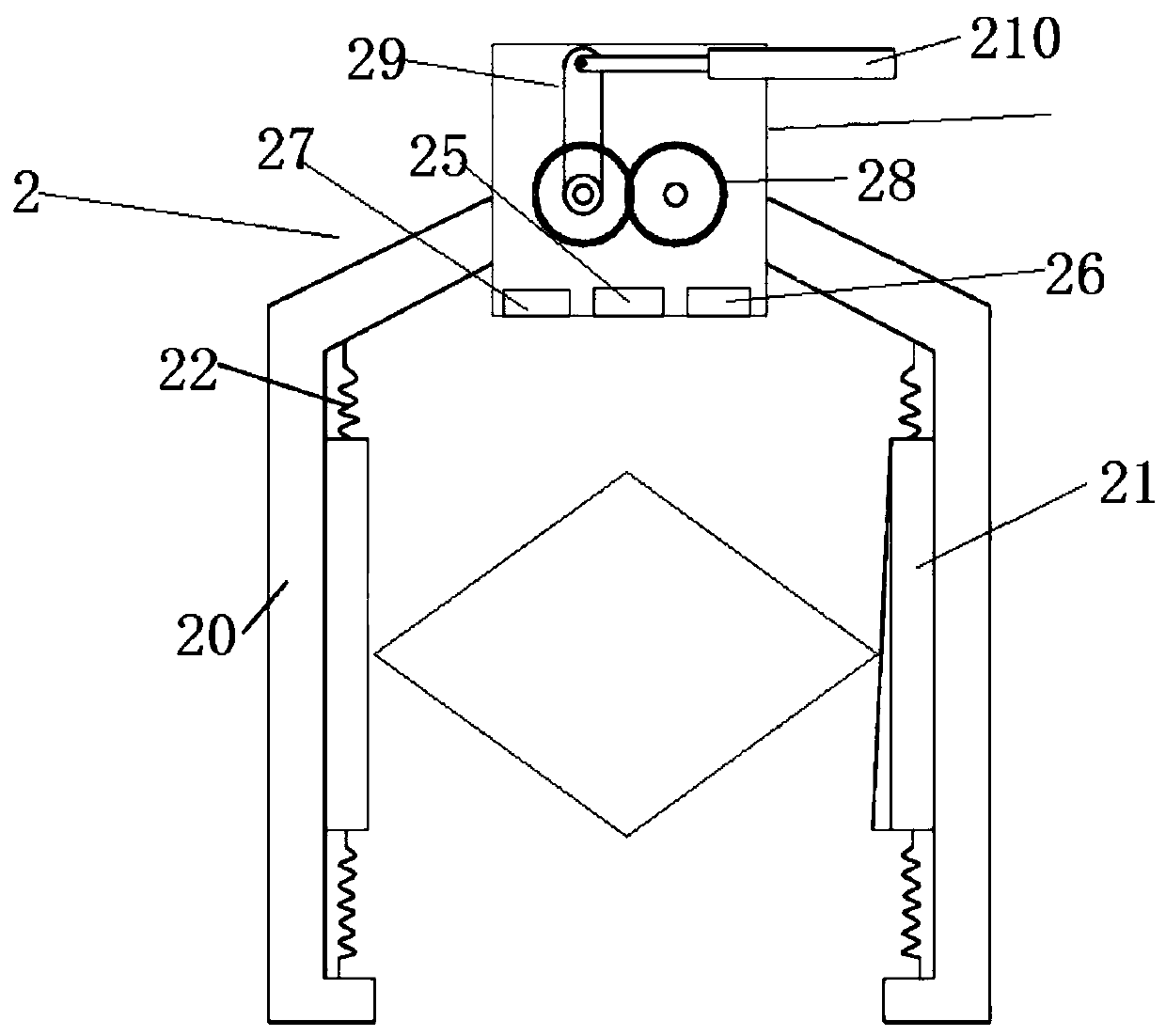

[0036] Such as figure 1 as well as figure 2 As shown, a trash can cleaning handover transposition structure, including the first manipulator 1 installed on the side of the body of the garbage transport vehicle, the first grasping arm 2 installed at the end of the first manipulator 1, installed in the cleaning box of the garbage transport vehicle The second manipulator 3, the second grasping arm 4 installed at the end of the second manipulator 3, the second grasping arm 4 includes the second grasping arm 4 base and the second clips respectively hinged on both sides of the second grasping arm 4 base Holding the rod 41, the base of the second grasping arm 4 is equipped with a second sensing device 40 that can identify the identification label used to mark the height of the trash can body.

[0037] The cleaning, transfer and transposition structure of the trash can also includes a processor. The processor is connected with the first manipulator 1, the first grabbing arm 2, the ...

Embodiment 2

[0043] Such as figure 1 as well as figure 2 As shown, a trash can cleaning handover transposition structure, including the first manipulator 1 installed on the side of the body of the garbage transport vehicle, the first grasping arm 2 installed at the end of the first manipulator 1, installed in the cleaning box of the garbage transport vehicle The second manipulator 3, the second grasping arm 4 installed at the end of the second manipulator 3, the second grasping arm 4 includes the second grasping arm 4 base and the second clips respectively hinged on both sides of the second grasping arm 4 base Holding the rod 41, the base of the second grasping arm 4 is equipped with a second sensing device 40 that can identify the identification label used to mark the height of the trash can body.

[0044] The cleaning, transfer and transposition structure of the trash can also includes a processor. The processor is connected with the first manipulator 1, the first grabbing arm 2, the ...

Embodiment 3

[0059] Such as figure 1 as well as figure 2 As shown, a trash can cleaning handover transposition structure, including the first manipulator 1 installed on the side of the body of the garbage transport vehicle, the first grasping arm 2 installed at the end of the first manipulator 1, installed in the cleaning box of the garbage transport vehicle The second manipulator 3, the second grasping arm 4 installed at the end of the second manipulator 3, the second grasping arm 4 includes the second grasping arm 4 base and the second clips respectively hinged on both sides of the second grasping arm 4 base Holding the rod 41, the base of the second grasping arm 4 is equipped with a second sensing device 40 that can identify the identification label used to mark the height of the trash can body.

[0060] The cleaning, transfer and transposition structure of the trash can also includes a processor. The processor is connected with the first manipulator 1, the first grabbing arm 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com