A buffer zone of a bridge segment prefabrication plant

A technology of buffer zone and prefabrication plant, applied in the field of prefabrication plant, can solve problems such as unfavorable concrete pouring and maintenance, entry, and affecting the quality of concrete bridge segments, and achieve the effect of improving the effect of pouring and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

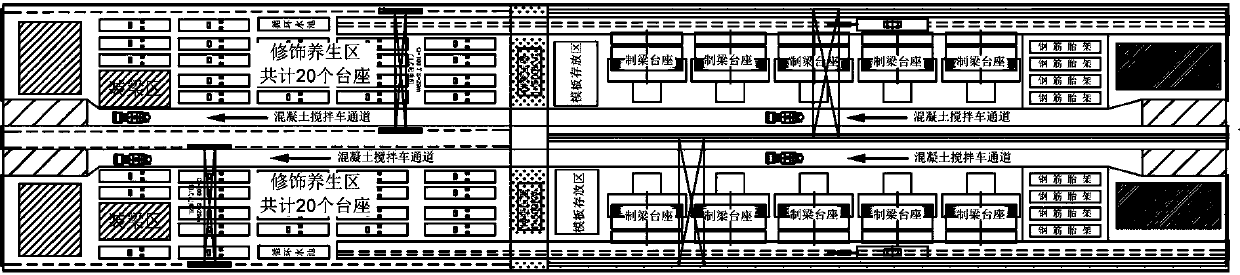

[0025] Reference attached figure 1 , a bridge segment prefabrication plant has two longitudinally arranged concrete mixer aisles. The prefabrication plant is a prefabricated factory building with dual production lines. One side of the area leads to the prefabrication factory, and the other side is connected to the outside.

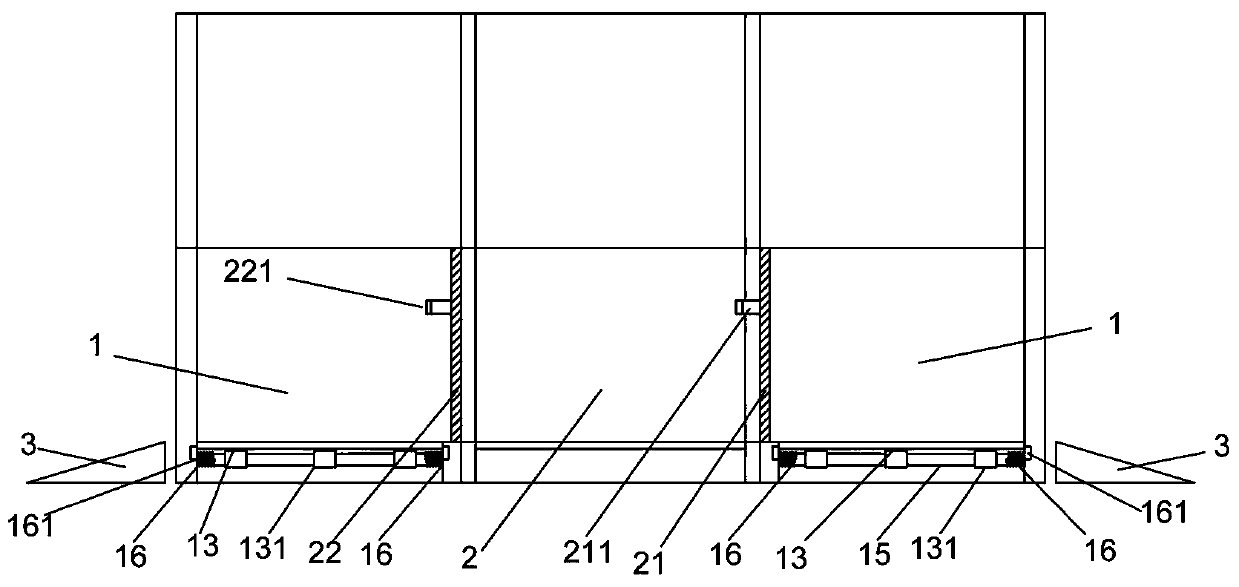

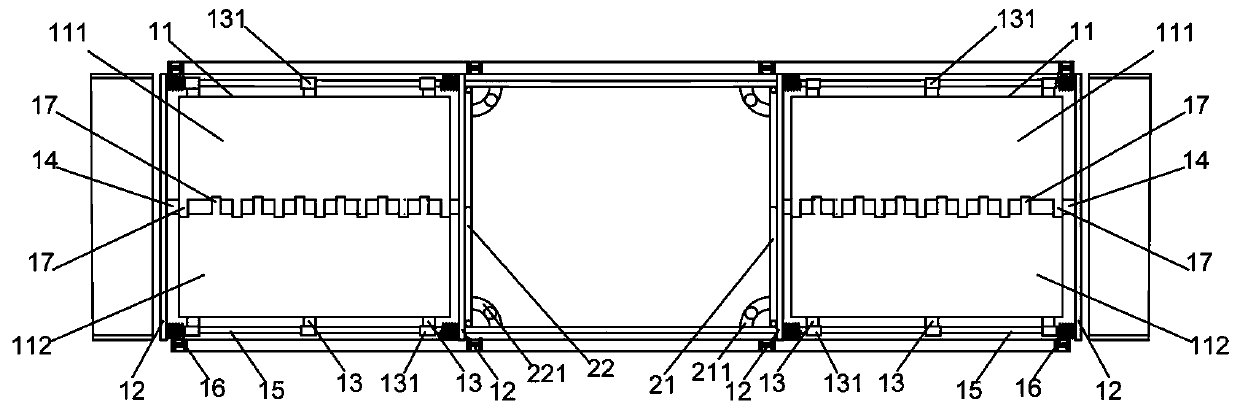

[0026] Reference attached figure 2 and 3 , to further explain the internal structure of the buffer zone, the buffer zone includes the sensing area 1 and the isolation area 2, the induction area 1 is set on both sides of the isolation area 2, and the isolation area 2 includes the first partition 21 and the second partition 22. The first partition 21 is installed on the outside of the isolation area 2, and the second partition 22 is installed on the side of the isolation area 2 close to the prefabrication plant through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com