Hub template and hub casting process

A technology of wheel hub and body, applied in the field of wheel hub plate and wheel hub casting process, can solve the problems of affecting the qualified rate of castings, increase the manufacturing cost, and have potential safety hazards, and achieve the goal of reducing cleaning labor, increasing additional costs, and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

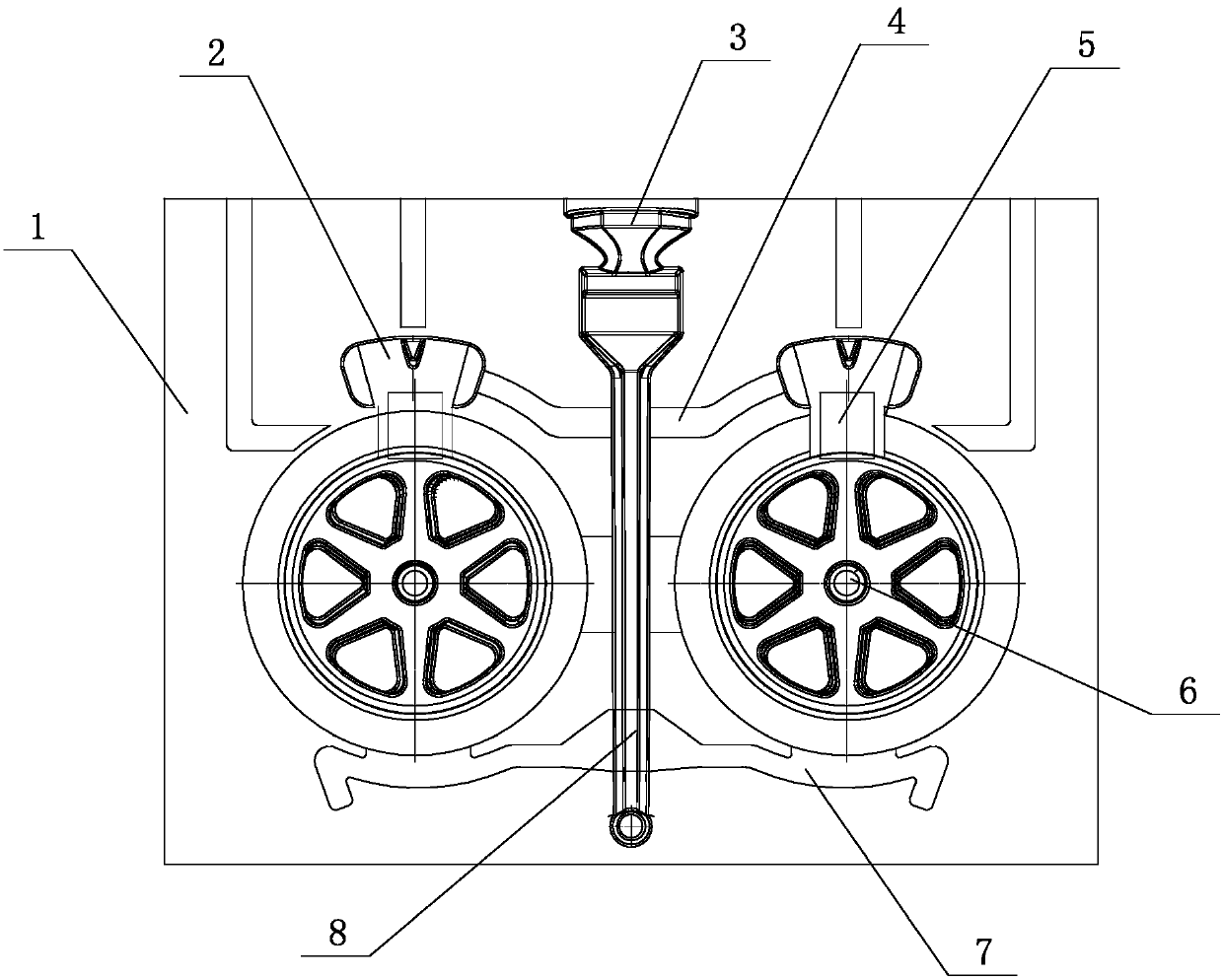

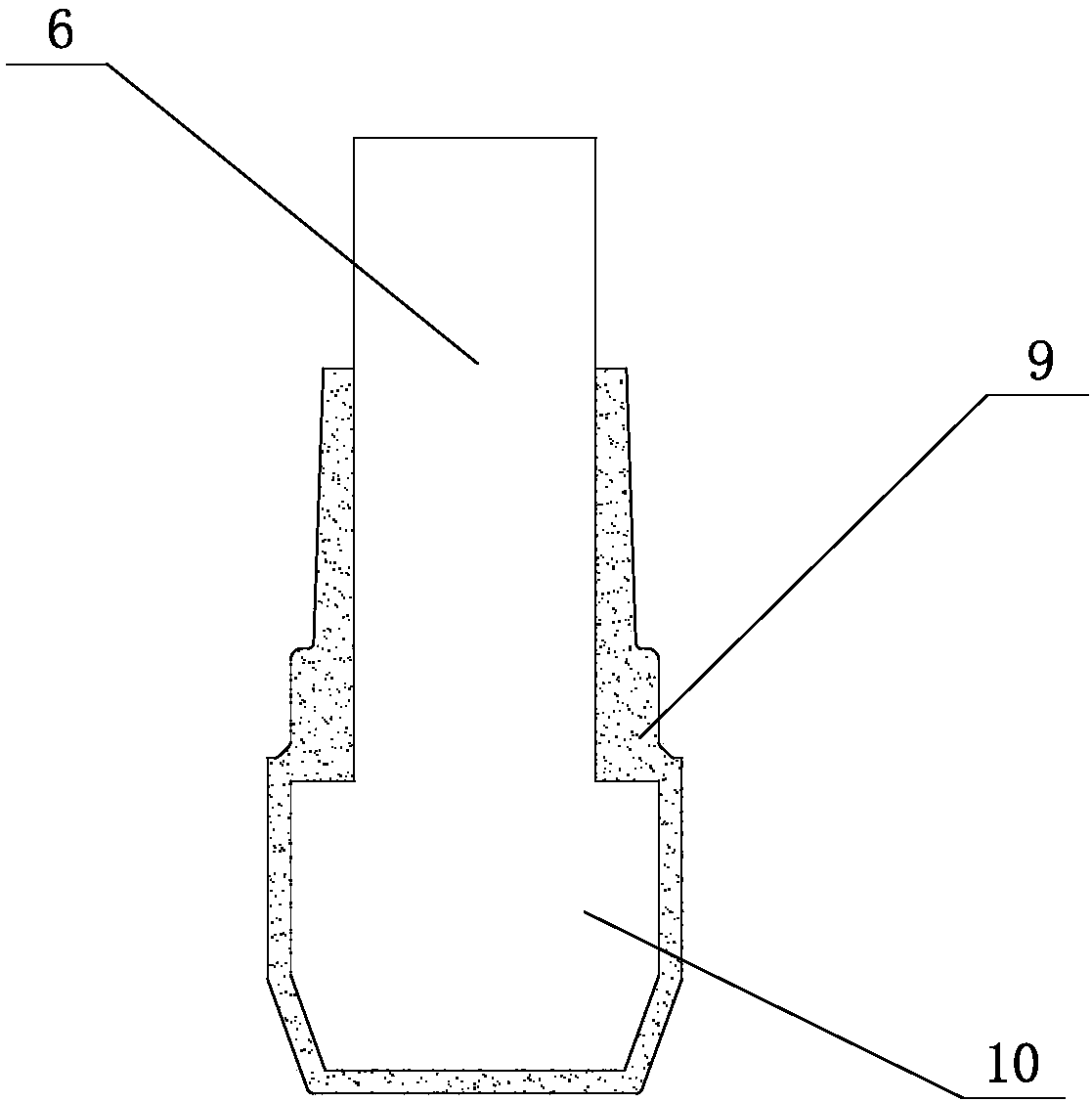

[0021] Such as Figure 1-2 As shown, the hub template of the present invention includes a template body 1, a pair of hub patterns are arranged in the middle of the template body 1, a sprue cup 3 is arranged on the upper end of the template body 1, and the lower end of the sprue cup 3 is connected to the middle Runner 8, the upper runner 4 is arranged on both sides of the upper part of the middle runner 8, the end of the upper runner 4 is connected to the riser 2, and the riser 2 is appropriately enlarged to provide sufficient feeding molten iron for the casting, which can completely improve The problem of subsidence, the riser 2 is connected with the hub shape through the riser neck 5, the lower runner 7 is set on both sides of the lower part of the middle runner 8, the lower runner 7 is connected with the hub shape, and the lower runner 7 speeds up the pouring speed, The feeding effect is improved; the periphery of the center hole of the casting needs to be drilled, and most ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com