Tool type chute and construction method

A construction method and tool-type technology, which is applied in basic structure engineering, construction, building construction, etc., can solve the problems of large impact force of concrete on the wall of the chute, large height of the bent frame, and inflexible pouring position. The effect of saving labor and material consumption, reducing construction noise, and reducing material and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

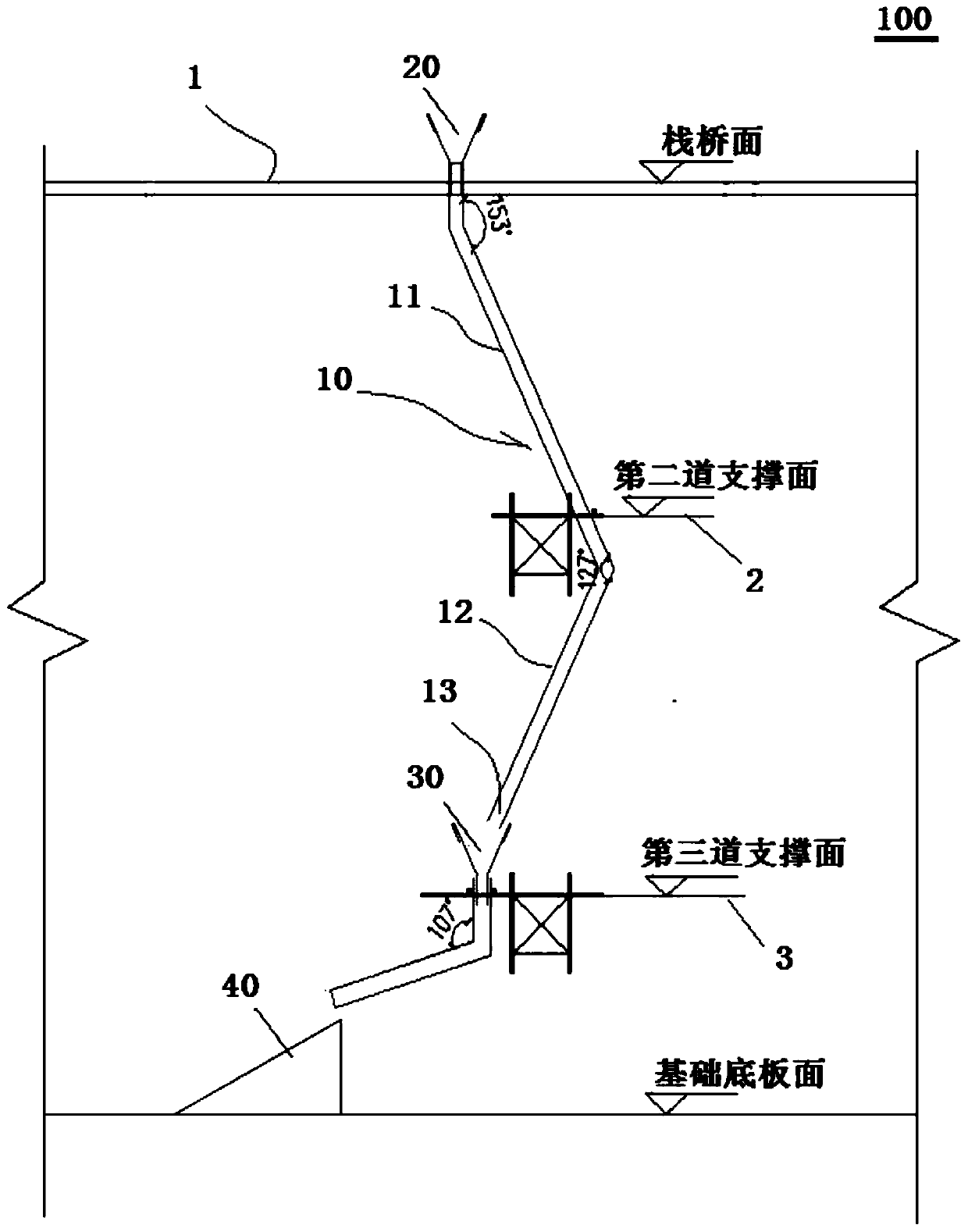

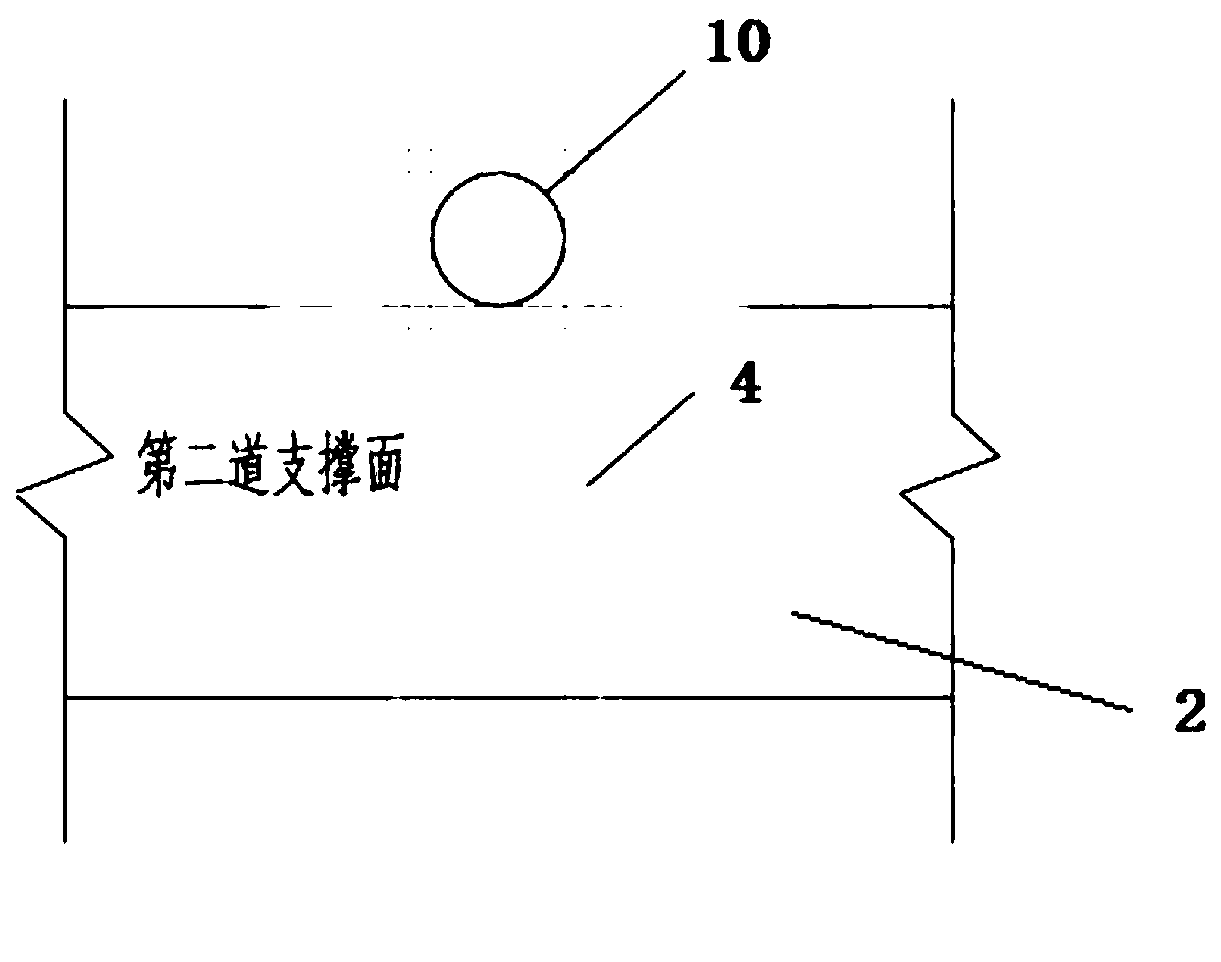

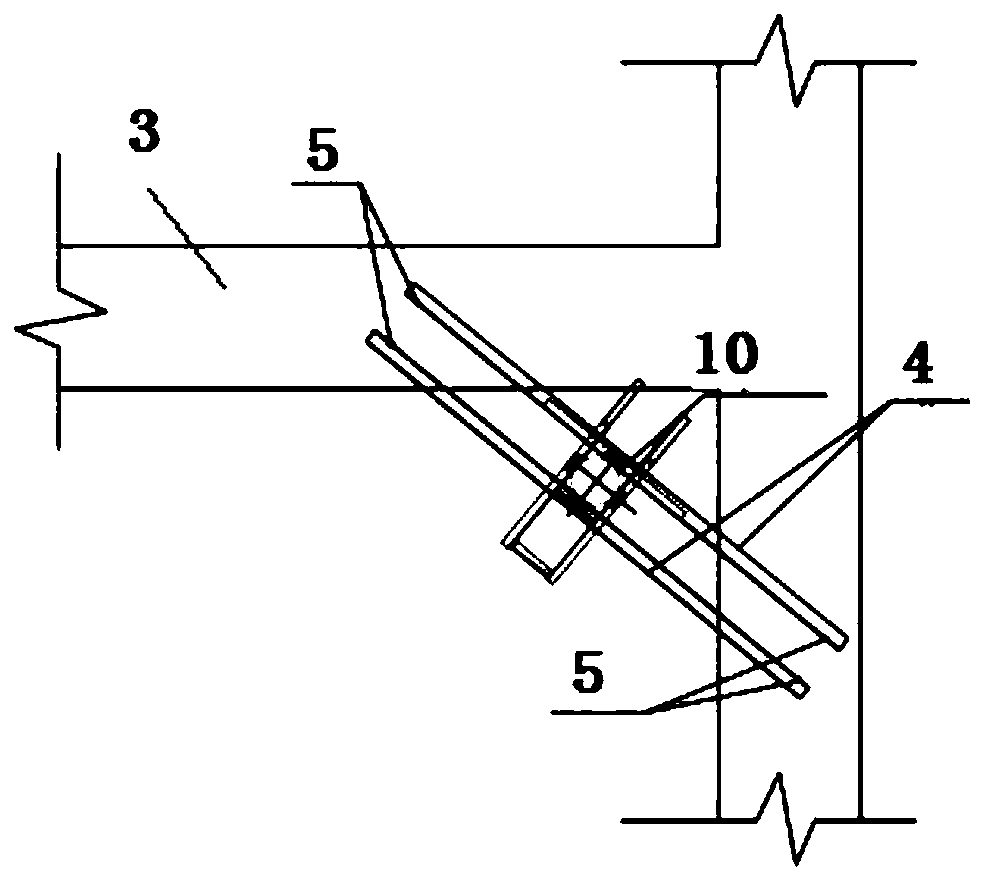

[0041] Such as Figure 1 to Figure 3 As shown, the tool chute 100 provided in this embodiment is used for pouring concrete, and is installed at the enclosure structure of the foundation pit, using the supports and trestles in the enclosure structure of the foundation pit as the supporting points of the tool chute 100 . That is to say, the present embodiment utilizes supports and trestles as supports for the chute 10, which saves labor and material costs for erecting and dismantling the bent racks, and greatly shortens the construction time of the chute 10, speeds up the construction, and avoids the danger of setting up high bent racks To ensure the safety of construction. Wherein, trestle board 1 place is provided with trestle hole, is used for hoisting chute 10. The utility chute 100 may generally include: a chute 10 , a lower hopper 20 , a movable lower hopper 30 and a small chute 40 . The slide pipe 10 is welded by two iron pipes of equal diameter and equal length, and th...

Embodiment 2

[0049] see Figure 1-Figure 3 , the present invention also provides a construction method using the tool slide pipe 100, which is used for the construction of large-volume concrete pouring in deep foundation pits, and the construction is carried out according to the following steps:

[0050] Step 1, making and processing the chute 10 of the tool type chute 100;

[0051] Step 2, making tool type chute 100 lower hopper 20 and movable lower hopper 30;

[0052] Step 3, using the support and the trestle as the support for the chute 10, installing and fixing the chute 10;

[0053] Step 4, install and debug the lower hopper 20 and the movable lower hopper 30;

[0054] Step 5, the concrete flows into the chute 10 through the lower hopper 20, and the pouring direction is adjusted through the movable lower hopper 30 and the small chute 40 to complete the pouring of the concrete.

[0055] The construction method of the invention is simple and convenient, the construction speed is acce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com